Log in

Search

Latest topics

» Purchased the last of any bult engines from Ken Enyaby getback Today at 12:05 pm

» My N-1R build log

by getback Today at 11:53 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» Funny what you find when you go looking

by rsv1cox Yesterday at 3:21 pm

» Landing-gear tips

by 1975 control line guy Yesterday at 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

» My current avatar photo

by roddie Mon Nov 18, 2024 9:05 pm

» My latest doodle...

by TD ABUSER Mon Nov 18, 2024 11:30 am

» Brushless motors?

by rsv1cox Sun Nov 17, 2024 6:40 pm

» Tribute Shoestring build

by amurphy6812 Sun Nov 17, 2024 5:43 pm

Cox Engine of The Month

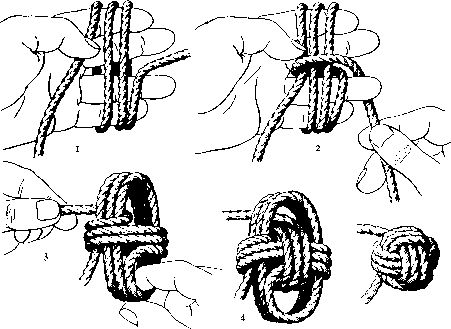

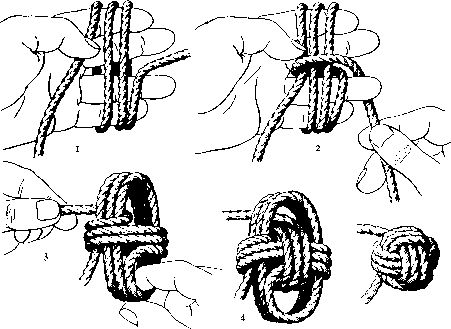

rope-weave

Page 1 of 1

rope-weave

rope-weave

One of many handy things my Grandfather knew how to do. He made this hitch. I wish I'd asked him to teach me.

Gramps had a boat similar to this one (same Science & Mechanics series-1950's/60's vintage) that he had someone build from the plans for him.

It was a little smaller and didn't have the walk-through bulkhead, dash-panel or windshield. It's hull was painted white with red accents toward the stern. The insides were natural wood, sealed with gloss spar-varnish. Power was a tiller-controlled Kiekhaefer-Mercury 10hp 2-stroke. This was probably the bow-line for that boat.

Gramps had a boat similar to this one (same Science & Mechanics series-1950's/60's vintage) that he had someone build from the plans for him.

It was a little smaller and didn't have the walk-through bulkhead, dash-panel or windshield. It's hull was painted white with red accents toward the stern. The insides were natural wood, sealed with gloss spar-varnish. Power was a tiller-controlled Kiekhaefer-Mercury 10hp 2-stroke. This was probably the bow-line for that boat.

Re: rope-weave

Re: rope-weave

Here's your Granddad's eye loop. I've done it before, but can't recall the details. This guy does it without a fid. I think the one I remember was a multi-core rope that required the use of a fid to guide the weaving.

https://youtu.be/pLox_ajDGLo

https://youtu.be/pLox_ajDGLo

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: rope-weave

Re: rope-weave

Very cool Rusty! I'm not sure how my Gramps did it.. but the rope I have is natural fiber (jute?).. so I have to wonder how the end of the weave stays secured?? I guess it just tightens when tensioned.. and stays locked together.

Re: rope-weave

Re: rope-weave

Tape it while you're weaving it, then just cut off the tip ends. Jute isn't going to allow any slippage.roddie wrote:Very cool Rusty! I'm not sure how my Gramps did it.. but the rope I have is natural fiber (jute?).. so I have to wonder how the end of the weave stays secured?? I guess it just tightens when tensioned.. and stays locked together.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: rope-weave

Re: rope-weave

Short splicing twist 3 strand is easy. As long as the rope is not actually damaged used 3-strand rope will splice almost as easy new rope. (unlike braid on braid)

The first row is the hardest row. The video is very clear on that, except it doesn't show very clearly that he untwisted (loosened) the portion of rope contained in the eye about 1/2 twist when forming it so it doesn't try to figure-8 for the rest of its life. He untwists by how he holds the rope before forming the eye. Figure-8 tendencies are more a nuisance than anything else.

If the ends are not heat fused (and quite possibly if they are heat fused) wrap about an inch of the end of each strand in electrical tape, and then make the tape slightly pointed off the end of the strand. Don't spare the tape, and don't plan to save it either.

If the rope is particularly hard then use a tool to open the lay. (The rope in the video is rather soft nylon) A large diameter Phillips screwdriver (#3) is a fair choice that most people have. A tapered wooden pin is a better choice that most people can easily make out of any strong, dense, tight grained wood (figure about 6 inches long tapering from 3/4 inch to 1/8 inch, then ball ended or blunt pointed, the exact size is not very important as long as it is similar to the size of the strand in the rope)

Another tool that may be useful is a loop of stout wire or rod that is shaped like a large needle threader (diamond shaped) with a handle on it (I don't have one of these, but I have used one) A wire rope loop on a skinny handle is the same type of tool, as is having a piece of small rope/heavy cord handy.

In nylon rope, as shown in the video, 3-5 tucks is normal, I prefer 5 tucks before tapering in nylon. (Do not do less than 3 tucks on any material, natural fibers can use 3). Terminating the splice on separate layers is a tapering method that is both easy and clean. In practice tapering like that makes the splice much easier to handle vs ending the splice all at the same tuck.

The other tapering method is, after performing the splice, unlay the remainder of the strand and cut a taper into the strand, wax and relay the strand. Continue tucking until the taper is taken in. This is only necessary for rope that has to pass through certain machines like anchor winches, or block and tackle. Tapering the strand to finish the splice is preferred for natural fibers.

Binding the splice with waxed cord is always an option, if you want.

The first row is the hardest row. The video is very clear on that, except it doesn't show very clearly that he untwisted (loosened) the portion of rope contained in the eye about 1/2 twist when forming it so it doesn't try to figure-8 for the rest of its life. He untwists by how he holds the rope before forming the eye. Figure-8 tendencies are more a nuisance than anything else.

If the ends are not heat fused (and quite possibly if they are heat fused) wrap about an inch of the end of each strand in electrical tape, and then make the tape slightly pointed off the end of the strand. Don't spare the tape, and don't plan to save it either.

If the rope is particularly hard then use a tool to open the lay. (The rope in the video is rather soft nylon) A large diameter Phillips screwdriver (#3) is a fair choice that most people have. A tapered wooden pin is a better choice that most people can easily make out of any strong, dense, tight grained wood (figure about 6 inches long tapering from 3/4 inch to 1/8 inch, then ball ended or blunt pointed, the exact size is not very important as long as it is similar to the size of the strand in the rope)

Another tool that may be useful is a loop of stout wire or rod that is shaped like a large needle threader (diamond shaped) with a handle on it (I don't have one of these, but I have used one) A wire rope loop on a skinny handle is the same type of tool, as is having a piece of small rope/heavy cord handy.

In nylon rope, as shown in the video, 3-5 tucks is normal, I prefer 5 tucks before tapering in nylon. (Do not do less than 3 tucks on any material, natural fibers can use 3). Terminating the splice on separate layers is a tapering method that is both easy and clean. In practice tapering like that makes the splice much easier to handle vs ending the splice all at the same tuck.

The other tapering method is, after performing the splice, unlay the remainder of the strand and cut a taper into the strand, wax and relay the strand. Continue tucking until the taper is taken in. This is only necessary for rope that has to pass through certain machines like anchor winches, or block and tackle. Tapering the strand to finish the splice is preferred for natural fibers.

Binding the splice with waxed cord is always an option, if you want.

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: rope-weave

Re: rope-weave

I used to know how to make those eyes and things when I was sailing, although I didn't needed it in the engine room. I've seen sailors making eyes like that on steel cables using a spike.

A few times, I managed to make a rope ball used as a weight for a heaving line. Before closing the ball, you insert a piece of rag to have a bit of volume. Some people put nuts in the centre, so the heaving line would fly further but this was sometimes unpleasant for the one who had to catch the line!!

A few times, I managed to make a rope ball used as a weight for a heaving line. Before closing the ball, you insert a piece of rag to have a bit of volume. Some people put nuts in the centre, so the heaving line would fly further but this was sometimes unpleasant for the one who had to catch the line!!

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

Re: rope-weave

Re: rope-weave

I have my Dad's old Bluejacket manual from WWII. It can show you how to do about anything nautical. Great little book.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: rope-weave

Re: rope-weave

OVERLORD wrote:A few times, I managed to make a rope ball used as a weight for a heaving line. Before closing the ball, you insert a piece of rag to have a bit of volume. Some people put nuts in the centre, so the heaving line would fly further but this was sometimes unpleasant for the one who had to catch the line!!

Wow! It's been a long time since I made a monkey fist! A heaving line is usually used to pass a larger line that is too large and heavy to throw.

Nice illustrations.

George

gcb- Platinum Member

- Posts : 908

Join date : 2011-08-11

Location : Port Ewen, NY

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules