Log in

Search

Latest topics

» My latest doodle...by batjac Yesterday at 9:47 pm

» My N-1R build log

by roddie Yesterday at 8:50 pm

» Tee Dee .020 combat model

by rdw777 Yesterday at 5:07 pm

» Free Flight Radio Assist

by rdw777 Yesterday at 4:51 pm

» Purchased the last of any bult engines from Ken Enya

by getback Yesterday at 12:05 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

» My current avatar photo

by roddie Mon Nov 18, 2024 9:05 pm

» Brushless motors?

by rsv1cox Sun Nov 17, 2024 6:40 pm

Cox Engine of The Month

Making aluminum engine bearers

Page 1 of 1

Making aluminum engine bearers

Making aluminum engine bearers

For my profile planes I always make aluminum engine bearers, plates that go between the engine and the wooden beam. Until I started using brass threaded inserts I would put them on both sides to help keep the bolts from compressing the wood. For the Shoestring and the yak I cut up some old broken Dural landing gear. It worked pretty well. Now I'm running out of it and need to buy some stock to cut them from, but I don't know how to choose the right stuff or the best place to get it. Hardness would be of most importance and weight less so. I know metals are categorized in certain numeric ways and hoped someone could give me a quickie primer on what I need to know to intelligently search or ask for it. Where to buy and what to ask for. Or where to scavenge it from.

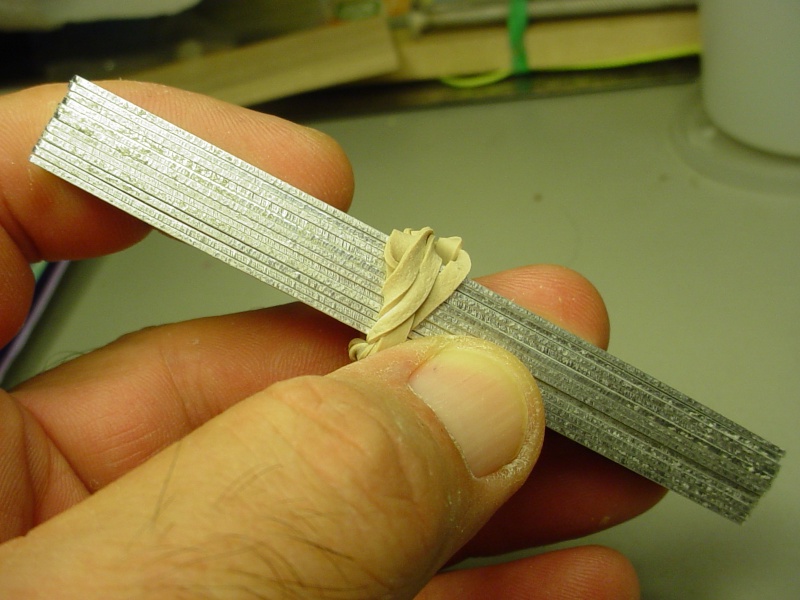

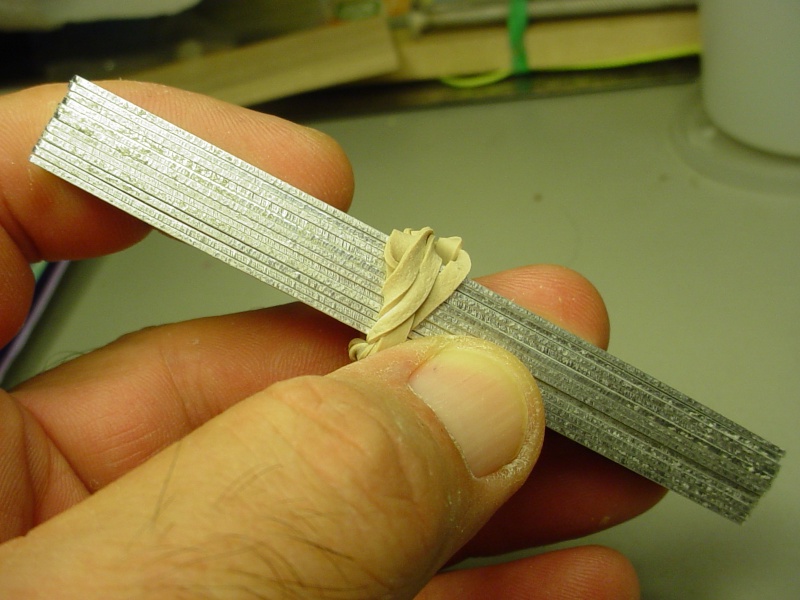

I collect things that might be useful some day, and for this job I have some old computer hard drive cases that appear to be some rigid aluminum alloy. I may try hacking some of that up. Here's a picture of how I use it.

Thanks,

Rusty

I collect things that might be useful some day, and for this job I have some old computer hard drive cases that appear to be some rigid aluminum alloy. I may try hacking some of that up. Here's a picture of how I use it.

Thanks,

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Making aluminum engine bearers

Re: Making aluminum engine bearers

Bump.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Making aluminum engine bearers

Re: Making aluminum engine bearers

Rusty,

I come across gold anodized aluminum quite frequently inside electronic equipment cages. It's pretty tough stuff.

It may possibly be aircraft grade. Anyway it's pretty plentiful and easy to find. I thought hard drive cases were made of thin sheet steel.

I come across gold anodized aluminum quite frequently inside electronic equipment cages. It's pretty tough stuff.

It may possibly be aircraft grade. Anyway it's pretty plentiful and easy to find. I thought hard drive cases were made of thin sheet steel.

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Making aluminum engine bearers

Re: Making aluminum engine bearers

I thought aluminum since it's non ferrous and won't conduct magnetism. I'll investigate.Cribbs74 wrote:Rusty,

I come across gold anodized aluminum quite frequently inside electronic equipment cages. It's pretty tough stuff.

It may possibly be aircraft grade. Anyway it's pretty plentiful and easy to find. I thought hard drive cases were made of thin sheet steel.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Making aluminum engine bearers

Re: Making aluminum engine bearers

Look at at the Windy 799 video posted by CLGUY. He states a grade of aluminium.

There is aluminium and aluminium. I use free turning aluminium - this is not suitable for engine bearer blocks.

I collect metals from all sources of "scrap recovery" - disk drives, casings.........

For aluminium - get a few different samples and see how difficult they are to scratch with a blunt cutting blade. You will soon get a feel for hardness.

Ding it, bend it - the harder the better for this application.

There is aluminium and aluminium. I use free turning aluminium - this is not suitable for engine bearer blocks.

I collect metals from all sources of "scrap recovery" - disk drives, casings.........

For aluminium - get a few different samples and see how difficult they are to scratch with a blunt cutting blade. You will soon get a feel for hardness.

Ding it, bend it - the harder the better for this application.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Making aluminum engine bearers

Re: Making aluminum engine bearers

May sound ridiculous but I quite often use empty aluminum beercans cutting and folding them in multiple layers as shim plates or even exhaust pipe extensions...strong enough when folded in multiple, easy to cut and form, and light as well, which especially in the COX 049 category of our business is also worth considering...plus I have to produce sufficient number of EMPTY beercans which gives me the real stimulus.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Making aluminum engine bearers

Re: Making aluminum engine bearers

And by the way, following Rusty's weekly song recommendation, this is the song of the week in this part of the world today:

https://www.youtube.com/watch?v=yVj8Sh4phzM

https://www.youtube.com/watch?v=yVj8Sh4phzM

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Making aluminum engine bearers

Re: Making aluminum engine bearers

Yessir!balogh wrote:And by the way, following Rusty's weekly song recommendation, this is the song of the week in this part of the world today:

https://www.youtube.com/watch?v=yVj8Sh4phzM

And thanks for the tips András

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Making aluminum engine bearers

Re: Making aluminum engine bearers

Rusty, I can hook you up. I just need to know the size(s) you need. We commonly use .040", .060" and .080" aluminum sheet at work.. and I can cut plates for you with elongated slots.. or a precise hole spacing. Give me your screw sizes and I'll cut plates for you. I'm thinking that slightly elongated slots might be a better way to go for being able to use the plates "universally" between engines. I am unsure of the hardness of the stock.. but I can't see it being too much of an issue. Look through your kits and note the sizes of your hardwood engine bearers.. (3/8", 7/16", 1/2" etc.) and we'll design the plates you need together.

If you need thicker material than what I've listed as "on hand".. I can get some. It will more than likely be 6061-T6 grade.

Here's a link for what a 12" x 12" square sheet of .125" thick 7075-T6 aircraft grade aluminum (hard) sheet would cost from this supplier. It's almost twice the cost of 6061-T6.

http://www.onlinemetals.com/merchant.cfm?pid=12663&step=4&showunits=inches&id=916&top_cat=0

If you need thicker material than what I've listed as "on hand".. I can get some. It will more than likely be 6061-T6 grade.

Here's a link for what a 12" x 12" square sheet of .125" thick 7075-T6 aircraft grade aluminum (hard) sheet would cost from this supplier. It's almost twice the cost of 6061-T6.

http://www.onlinemetals.com/merchant.cfm?pid=12663&step=4&showunits=inches&id=916&top_cat=0

Re: Making aluminum engine bearers

Re: Making aluminum engine bearers

Roddie, you da man! Thanks a bunch. That smallest sheet in the link you posted is expensive and I would be hacking it up with a hacksaw too. I'll go back out tonight and get the measurements for the Skyray. It will use #4 bolts with whatever the hole pattern is on an OS .25FP, and I'll see how wide the hardwood beams are. Soon I'll be needing some for the Oriental's OS .40FP unless it throws some unforeseen measurement off, so I'll try to figure that out. I don't want you to get in trouble at work for doing this though, so make sure it's really 100% okay.

Thanks again,

Rusty

Thanks again,

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Making aluminum engine bearers

Re: Making aluminum engine bearers

Here's some samples that I ran yesterday out of .040" sheet. They measure 1/2" wide by 4" long. Too thin for .25+ two-strokes.. but tomorrow I have a job set up for .080"... and I will run some strips along side of the work stuff. We also have some very interesting material that is 1/8" thick.. which has .020" aluminum facers, and a core of .085" dense plastic. I'll see if I can get the exact specs on it.. but it might be "trick" for plates.

Re: Making aluminum engine bearers

Re: Making aluminum engine bearers

Hey Roddie. The maple beam on the Skyray is 3/8" on the mounting face. I thought the bolt pattern would be in my spec sheets, but I'll have to go back and look at the engine to estimate it. The holes would accommodate #4 screws.

Rusty

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Making aluminum engine bearers

Re: Making aluminum engine bearers

RknRusty wrote:Hey Roddie. The maple beam on the Skyray is 3/8" on the mounting face. I thought the bolt pattern would be in my spec sheets, but I'll have to go back and look at the engine to estimate it. The holes would accommodate #4 screws.

Rusty

Rusty's OS .25FP-S was determined to have a .550" hole-spacing (on center) for drilling-out hardwood mount-beams and bearer-plates. An OS .40FP-S is .690". This also applies to the same size "LA" engines. I need to double-check the case clearance.

Here's a set of .080" aluminum plates I made today for my Fox .29/.35 Stunt engines. Their hole-spacing is .625" (5/8") with .093" (3/32") case-clearance. The hole diameter in my plates is .125" (1/8"). I "think" that's OEM spec.. but both my .29 and .35 have some enlarged holes in the mounts.

(I didn't do it..)

(I didn't do it..)This is my Fox .29 Stunt. Virtually the same as the .35... only slightly heavier, due to the smaller bore in the cylinder sleeve.

These plates measure; 1.25" long by .311" wide. The width was determined by .093" clearance either side of the .125" hole diameter.

I have some 1/2" thickness cast acrylic sheet that might make interesting plates for the Foxes on profile airplanes.. because of that protruding "lobe" on the bottom of the case. If you're installing threaded-inserts in your hardwood beams for a tidier appearance.. you could face the inboard side of them "flush" with sheeting.. without worry about that case protrusion. Anybody know what I mean?

Re: Making aluminum engine bearers

Re: Making aluminum engine bearers

Roddie,

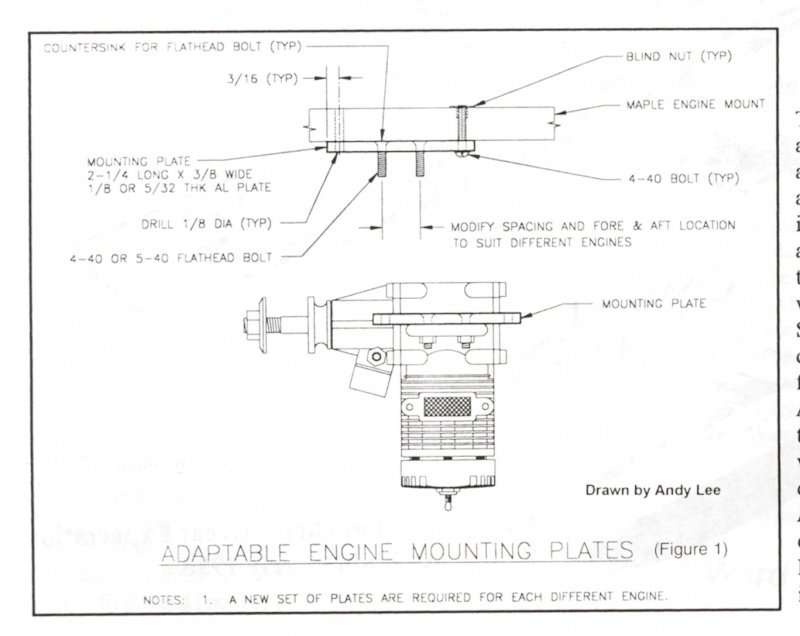

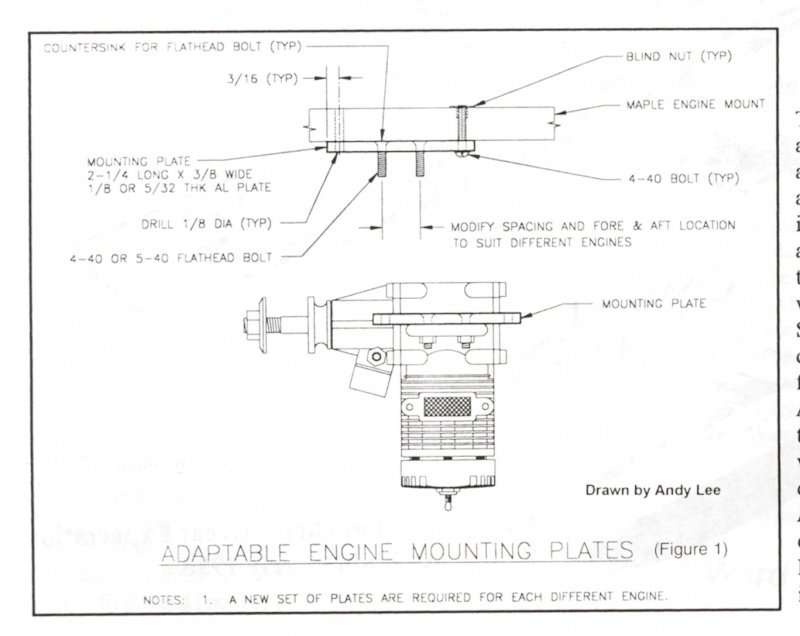

I found this drawing in Stuntnews of Jan/Feb 1996. It shows similar engine plates with the purpose of fitting different engines on 1 plane. Each engine you use has its own pair of plates with holes proper to the engine and with another pair of holes, for all plates the same, used for screwing into the engine bearers. I will send you a pdf file with the complete article.

Lieven

I found this drawing in Stuntnews of Jan/Feb 1996. It shows similar engine plates with the purpose of fitting different engines on 1 plane. Each engine you use has its own pair of plates with holes proper to the engine and with another pair of holes, for all plates the same, used for screwing into the engine bearers. I will send you a pdf file with the complete article.

Lieven

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

Re: Making aluminum engine bearers

Re: Making aluminum engine bearers

Brodak sells universal metal mounting plates, but they cost too much for my taste, about $35 bucks. I just looked and couldn't find it in a search.

Rusty

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Making aluminum engine bearers

Re: Making aluminum engine bearers

A "universal" anything, is usually not as good as a purpose-designed article. For engines with the same case-width and side to side hole spacing.. to fit between the hardwood beams in a particular model.. I suppose they would work. Different plates (like those shown in Lieven's photo) could also be made with alternate fore/aft spacing for a given engine, to help adjust the center of gravity slightly.. without having to drill different holes in your beams (and weakening them). I just have to wonder if that type of "universal" plate would be prone to inducing vibration, because the engine is not rigidly mounted directly below it's cylinder; where it's "case" mounts are generally located. I guess it would depend on the thickness of the plate and it's spacing-spread where it mounts to the beams. I'm curious about the $35 Brodak plates.

Re: Making aluminum engine bearers

Re: Making aluminum engine bearers

Here's some experimental beam-mount plates. This is an exterior sign panel product that we have at work. It is 3mil thickness (approx. .117") and has a core (I believe) of rigid plastic PVC or ABS.. faced both sides with .010" sheet aluminum. This particular sample is high gloss red on both sides.. but we have white too.

I'm holding a plate sized for a Fox .35 Stunt's mount. The holes are drilled .125" diameter, .625" on center with .093" side-clearance for the crankcase. Overall width is .311" and length is 1.250". The "blank" plates are .375" wide x 1.5" long and .500" wide x 1.5" long. The other 4 "pairs" of sets are for Rusty to try; which are sized for his OS .25FP-S and OS .40 FP-S engines, with .55" and .69" hole-spacing (respectively).. and are both 1.375" in length.

I am also making .060" and .080" thickness "solid" aluminum plates. A pair of the .080" Fox .35 size plates weighs 2 grams. The "same" 3mil composite pair won't yield a scale reading.. so they're quite lightweight.

EDIT: I can't seem to upload photos tonight.. and no "smileys" either.... ?

I'm holding a plate sized for a Fox .35 Stunt's mount. The holes are drilled .125" diameter, .625" on center with .093" side-clearance for the crankcase. Overall width is .311" and length is 1.250". The "blank" plates are .375" wide x 1.5" long and .500" wide x 1.5" long. The other 4 "pairs" of sets are for Rusty to try; which are sized for his OS .25FP-S and OS .40 FP-S engines, with .55" and .69" hole-spacing (respectively).. and are both 1.375" in length.

I am also making .060" and .080" thickness "solid" aluminum plates. A pair of the .080" Fox .35 size plates weighs 2 grams. The "same" 3mil composite pair won't yield a scale reading.. so they're quite lightweight.

EDIT: I can't seem to upload photos tonight.. and no "smileys" either.... ?

Re: Making aluminum engine bearers

Re: Making aluminum engine bearers

Thanks Roddie, I thought it was my old laptop acting up.roddie wrote: I can't seem to upload photos tonight.. and no "smileys" either.... ?

I'll drop Jacob a note.

Bob

dckrsn- Diamond Member

- Posts : 2750

Join date : 2010-10-21

Age : 71

Location : Long Island, New York

Re: Making aluminum engine bearers

Re: Making aluminum engine bearers

Those look great Roddie. That will keep us from crushing our beams by spreading out the load and providing a solid boss for any thrust wedges or washers. It's nice when you preflight your plane and don't find you need to tighten the engine bolts. For those that use bolts all the way through the fuselage it keeps the nuts from sinking into the back side too. I like the polymer sandwich idea.

Thanks for taking the time to make them.

Rusty

Thanks for taking the time to make them.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Making aluminum engine bearers

Re: Making aluminum engine bearers

They look superb Roddie!

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Making aluminum engine bearers

Re: Making aluminum engine bearers

RknRusty wrote:Those look great Roddie. That will keep us from crushing our beams by spreading out the load and providing a solid boss for any thrust wedges or washers. It's nice when you preflight your plane and don't find you need to tighten the engine bolts. For those that use bolts all the way through the fuselage it keeps the nuts from sinking into the back side too. I like the polymer sandwich idea.

Thanks for taking the time to make them.

Rusty

I really enjoy this side of the hobby (if nothing else, it' educational..) Rusty mentioned the "back-side" (or under-side) of the beams.. where conventionally; there would be nuts/washers. An .040" thick plate would work well there.. and would be very lightweight.

The "composite" plates shown in my last post.. I'm not sure how the alum. skins are bonded to the core. They'd be "purely" experimental. The .010" alum "skins" are pretty thin.. and I'm not sure how much tightening torque the core would take, before it starts to crush. I can't bend those plates with my fingers... which is somewhat of an indicator as to their rigidity. The "red" coating should "sand-off" to bare aluminum; if there's a cosmetic concern. If they work-out.. they're a very lightweight option; rather than using "solid" aluminum plates for this application.

Similar topics

Similar topics» Extending engine bearers?

» Narrowing engine bearers

» 1/2A Aluminum Speed Pan for Cox Engine

» building a Guillows kit P 40

» Making Glowplug Igniter Adapter For Cox Engine?

» Narrowing engine bearers

» 1/2A Aluminum Speed Pan for Cox Engine

» building a Guillows kit P 40

» Making Glowplug Igniter Adapter For Cox Engine?

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules