Log in

Search

Latest topics

» Roger Harris revisitedby rsv1cox Today at 3:38 pm

» My N-1R build log

by GallopingGhostler Today at 3:04 pm

» Tee Dee .020 combat model

by 1/2A Nut Today at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» My latest doodle...

by batjac Yesterday at 9:47 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

Cox Engine of The Month

Question for Bernie

Page 1 of 1

Question for Bernie

Question for Bernie

You said you had a set of special engine tools made up, really nice ones.

Any chance you have a picture of them someplace? I'm very curious to see them.

I always used to wonder how cox assembled the engines, especially the cylinders without leaving a scratch in the oxide coating. And, those old cylinders that had no flats, how the hell did they torque those down??

I used to hate it when no matter how careful I was, I couldn't tighten a cylinder without leaving at least a small mark in the oxide.

Any chance you have a picture of them someplace? I'm very curious to see them.

I always used to wonder how cox assembled the engines, especially the cylinders without leaving a scratch in the oxide coating. And, those old cylinders that had no flats, how the hell did they torque those down??

I used to hate it when no matter how careful I was, I couldn't tighten a cylinder without leaving at least a small mark in the oxide.

MeerschaumSteve- Gold Member

- Posts : 121

Join date : 2012-10-21

Location : Oklahoma

Re: Question for Bernie

Re: Question for Bernie

I too want to know this!

Bump! back to the top of the latest topics panel with yee

Bump! back to the top of the latest topics panel with yee

shell shock- Gold Member

- Posts : 401

Join date : 2011-10-05

Age : 32

Location : Mississauga Ontario, Canada

Re: Question for Bernie

Re: Question for Bernie

I don't really know but I would assume that they tightened the cylinder and head together by the head slots.

Motra- Gold Member

- Posts : 111

Join date : 2010-08-20

Location : SLC, UT

Re: Question for Bernie

Re: Question for Bernie

Wrenches fit in the exhaust ports typically, then they went to the double slit exhausts and relieved the top fin of the cylinder to put a wrench on.

Phil

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: Question for Bernie

Re: Question for Bernie

how would they prevent burring of the exhaust slots? I damaged a babe bee cylinder like that

shell shock- Gold Member

- Posts : 401

Join date : 2011-10-05

Age : 32

Location : Mississauga Ontario, Canada

Re: Question for Bernie

Re: Question for Bernie

Bernie may correct me, but I am going to take a shot at this anyway.

Due to the design of the engine I doubt the factory assembly tools were much different than what we use currently. They were most likely a little more easy to grip on to.

If you are marring parts when assembling then either the tool fit is too sloppy or you are using too much force. Since we don't have a torque specification for these things, the best bet would be to snug parts as opposed to torquing them down. Go through your wrenches and find the ones with really good fits and use them exclusively.

Sometimes I make tool marks during dissassembly. Once the castor goo takes hold the parts like to fuse together. This can be lessened if you use heat and soaking methods. Most times I can do it without leaving a mark.

Ron

Due to the design of the engine I doubt the factory assembly tools were much different than what we use currently. They were most likely a little more easy to grip on to.

If you are marring parts when assembling then either the tool fit is too sloppy or you are using too much force. Since we don't have a torque specification for these things, the best bet would be to snug parts as opposed to torquing them down. Go through your wrenches and find the ones with really good fits and use them exclusively.

Sometimes I make tool marks during dissassembly. Once the castor goo takes hold the parts like to fuse together. This can be lessened if you use heat and soaking methods. Most times I can do it without leaving a mark.

Ron

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Question for Bernie

Re: Question for Bernie

Poor wrench fit can be temporarily helped with a piece of paper or card between the wrench and the part. Cut the paper into a strip and fold the part in it, then slide the wrench over the paper. You may use several layers if it helps, but there is a limit to this. The limit usually is 2 or 3 pieces max before the paper is too thick to allow the wrench to work properly.

Soaking in fuel or denatured alcohol overnight followed by heat from a hair dryer or heat gun can really help with freeing used parts that are gummed with castor.

I would expect the factory tools were more fitted and hardened steel, like a wrench instead of a universal tool.

The screwdrivers were properly fitted to the screws, they would also be flat-sided and fill the slot entirely. This would prevent the screw from being damaged by the tool.

Finding a screwdriver that fits in this manner is not very difficult. Take a clean engine to the store and expect to pay $5 or more for a single screwdriver. If it is not a perfect fit don't buy the screwdriver. If you cannot test the fit, don't buy the screwdriver. Lowe's Kobalt brand fit pretty good.

I also recall when I was young taking apart my older brother's NIB Cox engine on his birthday with my bare hands, so they may not have even used wrenches to assemble the cylinder and glow head, expecting the customer to do this with the included wrenches. This would be the late 1980's.

Phil

Soaking in fuel or denatured alcohol overnight followed by heat from a hair dryer or heat gun can really help with freeing used parts that are gummed with castor.

I would expect the factory tools were more fitted and hardened steel, like a wrench instead of a universal tool.

The screwdrivers were properly fitted to the screws, they would also be flat-sided and fill the slot entirely. This would prevent the screw from being damaged by the tool.

Finding a screwdriver that fits in this manner is not very difficult. Take a clean engine to the store and expect to pay $5 or more for a single screwdriver. If it is not a perfect fit don't buy the screwdriver. If you cannot test the fit, don't buy the screwdriver. Lowe's Kobalt brand fit pretty good.

I also recall when I was young taking apart my older brother's NIB Cox engine on his birthday with my bare hands, so they may not have even used wrenches to assemble the cylinder and glow head, expecting the customer to do this with the included wrenches. This would be the late 1980's.

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: Question for Bernie

Re: Question for Bernie

I use a Craftsman 5/8" open end wrench on the cylinders with flats. It's not a perfect fit, but the closest I've found. I've been meaning to grind a smaller wrench to the right size, but haven't marred a cylinder yet, so haven't gotten around to it.

The old standard Cox wrench theoretically works perfectly for the exhaust ports. When brand new, the forks do not touch any of the inner facing. But they are weak metal and immediately spread and gall the inner face causing the burr. To prevent this, even with an old wrench, you can trap the wrench in the jaws of your vice so that the forks cannot spread(not too tight or they will bend and close). Then holding the engine upside down, slide the cylinder ports into the jaws and turn the crankcase to loosen the cylinder. With the forks trapped, they cannot spread and come in contact with the inner face of the ports to gall them.

The old standard Cox wrench theoretically works perfectly for the exhaust ports. When brand new, the forks do not touch any of the inner facing. But they are weak metal and immediately spread and gall the inner face causing the burr. To prevent this, even with an old wrench, you can trap the wrench in the jaws of your vice so that the forks cannot spread(not too tight or they will bend and close). Then holding the engine upside down, slide the cylinder ports into the jaws and turn the crankcase to loosen the cylinder. With the forks trapped, they cannot spread and come in contact with the inner face of the ports to gall them.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Question for Bernie

Re: Question for Bernie

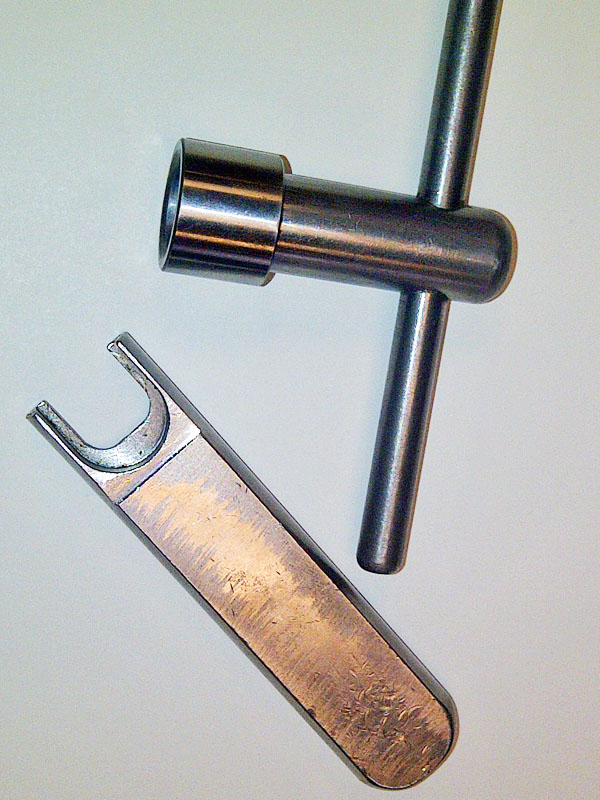

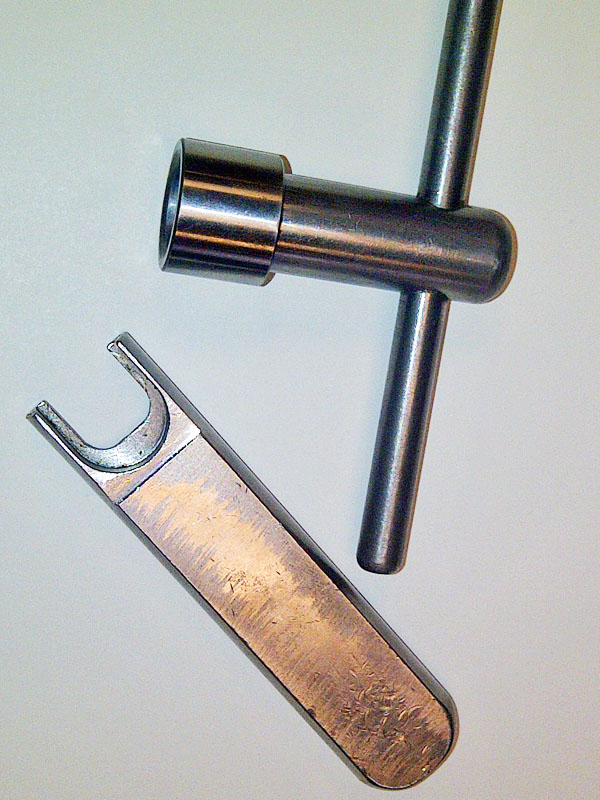

That's a genUine Cox service dept tool.

John Goddard- Diamond Member

- Posts : 2447

Join date : 2011-11-24

Age : 60

Location : Leyton North East London

Re: Question for Bernie

Re: Question for Bernie

Any part reluctant to come free from an engine should first be soaked for a period of time then mildly heated before force is applied.

Being in a rush is the biggest source of engine damage. Once you develop PATIENCE and EXPERIENCE this all becomes standard practice.

SD

Being in a rush is the biggest source of engine damage. Once you develop PATIENCE and EXPERIENCE this all becomes standard practice.

SD

SuperDave- Rest In Peace

- Posts : 3552

Join date : 2011-08-13

Location : Washington (state)

Re: Question for Bernie

Re: Question for Bernie

Here are some pics of the tools we had made. Don't have my SLR camera in the office today and Blackberrys only have so much pic quality lol.

Re: Question for Bernie

Re: Question for Bernie

Daaayyuummm...

You ever consider offering a set like that for your greatest fans?

You ever consider offering a set like that for your greatest fans?

MeerschaumSteve- Gold Member

- Posts : 121

Join date : 2012-10-21

Location : Oklahoma

Re: Question for Bernie

Re: Question for Bernie

MeerschaumSteve wrote:Daaayyuummm...

You ever consider offering a set like that for your greatest fans?

EXACTLY!

Bernie, You should have had those mass produced! I would buy a set and I'm sure many others around here would too!

Re: Question for Bernie

Re: Question for Bernie

Hand-made by a local machine shop. Cost $250 / retail $495. Ain't gonna happen

Re: Question for Bernie

Re: Question for Bernie

Now that's a Cox tool, fits perfectly and never flexes at the wrong moment!

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Question for Bernie

Re: Question for Bernie

At near $500 a pop, I'll stick with Cox wrenches in used tandem.

Haven't damaged a Cox part in a long while either.

Haven't damaged a Cox part in a long while either.

SuperDave- Rest In Peace

- Posts : 3552

Join date : 2011-08-13

Location : Washington (state)

Re: Question for Bernie

Re: Question for Bernie

For a run of 100 I am sure retail price could drop to $100 but still. If we have $5,000 to spend on product it will be on less expensive items that are expected to sell in large numbers at higher margins.

Re: Question for Bernie

Re: Question for Bernie

I imagine anyone could take their standard tools to a machine shop and have them made as Bernie did. I also imagine you could shop around and have it done on the cheap.

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Question for Bernie

Re: Question for Bernie

We went to a local welding / machining outfit and asked for commercial grade tools. They charge $85/hr and 3 hours later we have tools that have now taken apart in excess of 20,000 engines and still going strong.

Re: Question for Bernie

Re: Question for Bernie

If one is in the Cox business the expense is justified long-run.

For the hobbyist however that's not the case and I believe that's evident from the money involved. Over the years I've freed up lots of parts using solvent, Cox wrenches. mild heat and PATIENCE.

So who's in a hurry anyway? Certainly no me.

SD

For the hobbyist however that's not the case and I believe that's evident from the money involved. Over the years I've freed up lots of parts using solvent, Cox wrenches. mild heat and PATIENCE.

So who's in a hurry anyway? Certainly no me.

SD

SuperDave- Rest In Peace

- Posts : 3552

Join date : 2011-08-13

Location : Washington (state)

Mudhen- Gold Member

- Posts : 489

Join date : 2011-09-19

Re: Question for Bernie

Re: Question for Bernie

All great advice but it seems like the original question hasn't really been answered, and I'm interested to learn this. On the new engines assembled at the factory, is a tool used to tighten the cylinder or is the cylinder and head tightened together by the head? It seems like there would be some kind of tool marks on the black oxide, especially on the early thin walled cylinders that have no wrench flats other than the exhaust ports.

Motra- Gold Member

- Posts : 111

Join date : 2010-08-20

Location : SLC, UT

Similar topics

Similar topics» Cox International wish list

» The history of the Cox .049 Die Cast crankcases

» Name our new engine!

» HUGE lot of Cox items for sale!

» Great news!

» The history of the Cox .049 Die Cast crankcases

» Name our new engine!

» HUGE lot of Cox items for sale!

» Great news!

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules