Log in

Search

Latest topics

» Roger Harris revisitedby rsv1cox Today at 3:38 pm

» My N-1R build log

by GallopingGhostler Today at 3:04 pm

» Tee Dee .020 combat model

by 1/2A Nut Today at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» My latest doodle...

by batjac Yesterday at 9:47 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

Cox Engine of The Month

my "twin bee"

Page 3 of 4

Page 3 of 4 •  1, 2, 3, 4

1, 2, 3, 4

Re: my "twin bee"

Re: my "twin bee"

No, it is the only one whom I built.The fuel is standard with 5% nitromethane, and this engine use a stock "reed".

Now I builds one 4 cylinders boxer of 16 cm3, 2 stroke

Now I builds one 4 cylinders boxer of 16 cm3, 2 stroke

chris74100- Silver Member

- Posts : 66

Join date : 2012-08-17

Age : 55

Location : ANNEMASSE (FRANCE)

Re: my "twin bee"

Re: my "twin bee"

I am assuming a 4 cyl. will have a proportionately sized "rotary-valve" induction?chris74100 wrote:No, it is the only one whom I built.The fuel is standard with 5% nitromethane, and this engine use a stock "reed".

Now I builds one 4 cylinders boxer of 16 cm3, 2 stroke

Did you increase the fuel/air-flow in the 1st 2 cylinder engine? (asked in my previous post) I am aware of the fuel restrictions/availability in your region... but your Cox engine components were designed to run on fuel with a nitro content of 3-times (minimum) of what your stated test-fuel has.

I would "personally" pay the shipping... "to and from" the U.S. to have one of our "engine people" here; run your 2 cylinder model, on "cox" fuel. You already have several people interested in your engine... and there's quite a large Cox community here in the U.S. You "may" be able to profit from a production-run, if the engine's performance is adequate.

We are all very envious of your skills!

Roddie

Re: my "twin bee"

Re: my "twin bee"

Hi, Roddie, the fuel/air-flow is similar at the standard babee be. I'm not modified.

Maybe would be it better to put a carburetor

Maybe would be it better to put a carburetor

chris74100- Silver Member

- Posts : 66

Join date : 2012-08-17

Age : 55

Location : ANNEMASSE (FRANCE)

Re: my "twin bee"

Re: my "twin bee"

Chris, in my opinion... a 4 cylinder should have a venturi size of a .15 to .20 engine (if using the Cox .049 cylinders) and large enough to bore-out, if there's still not enough air-flow.chris74100 wrote:Hi, Roddie, the fuel/air-flow is similar at the standard babee be. I'm not modified.

Maybe would be it better to put a carburetor

Maybe design a crankcase with the venturi in the "center"; equally feeding the 2 front and rear cylinders with a rotary-valve crankshaft supported with bearings?

There's always the consideration of the "mounting" provisions too. A "radial" mount would probably be better than "beam mounts". I've seen multi's with a "rear" intake... and this makes it difficult to mount the engine to a firewall.

I am sure that if "anyone" can build it... "you" can!

Roddie

Re: my "twin bee"

Re: my "twin bee"

Lol, the 4 cylinders is 4x .20ci, (16cm3 in metric).

chris74100- Silver Member

- Posts : 66

Join date : 2012-08-17

Age : 55

Location : ANNEMASSE (FRANCE)

Re: my "twin bee"

Re: my "twin bee"

Sorry Chris... I should have caught that in your previous post...chris74100 wrote:Lol, the 4 cylinders is 4x .20ci, (16cm3 in metric).

Re: my "twin bee"

Re: my "twin bee"

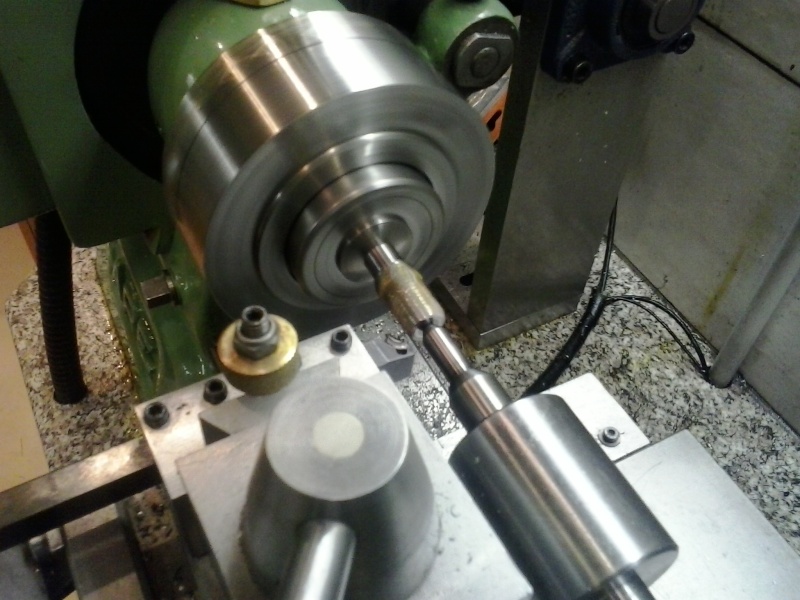

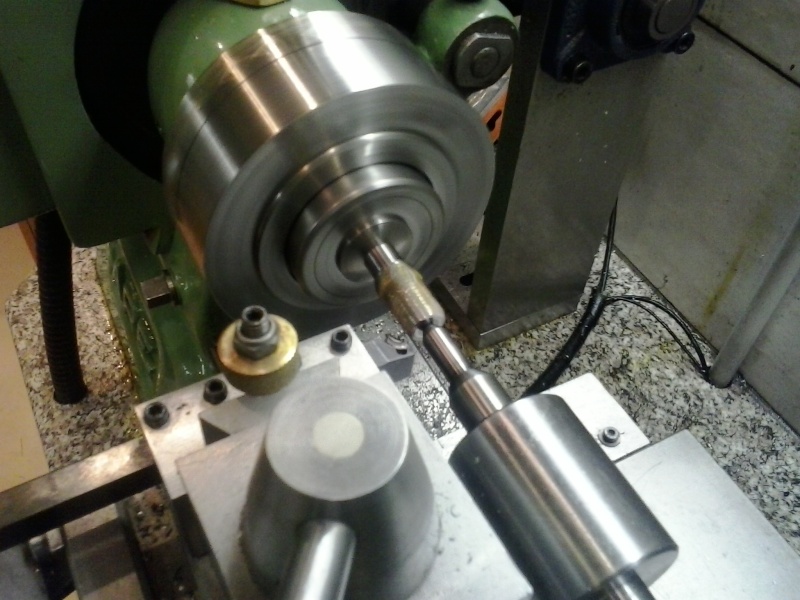

This morning, I made a tap to fix cylinders

chris74100- Silver Member

- Posts : 66

Join date : 2012-08-17

Age : 55

Location : ANNEMASSE (FRANCE)

chris74100- Silver Member

- Posts : 66

Join date : 2012-08-17

Age : 55

Location : ANNEMASSE (FRANCE)

Re: my "twin bee"

Re: my "twin bee"

I've never seen somebody make a tap himself - And of such a fine thread. Very nice job!

lieven

lieven

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

Re: my "twin bee"

Re: my "twin bee"

Nice shop you have there! I ran a "Blake" grinder years ago, for a small local tap company. The machine was for grinding the "flutes" in the tap. The abrasive wheel was "diamond-dressed" down each side, to the proper thickness, and then a "radius" was dressed on; which was frequently "re-dressed" as needed. There was a "rhythm/technique" that had to be mastered while "feeding" into the wheel and then "retracting"... that produced a finish; free of chatter/burn. When completing a piece, the "lands" had to measure within .003" of each other in thickness. It could be a bear to set up... especially with small stuff such as 000-120 pitch. You could almost "see through" the wheel, after dressing it into thickness for these.

Keep us posted on the 4 cylinder's development!

Roddie

Keep us posted on the 4 cylinder's development!

Roddie

Last edited by roddie on Sat Oct 26, 2013 11:06 am; edited 1 time in total

Re: my "twin bee"

Re: my "twin bee"

Thanks, but this tap can only aluminium tapping.

chris74100- Silver Member

- Posts : 66

Join date : 2012-08-17

Age : 55

Location : ANNEMASSE (FRANCE)

Re: my "twin bee"

Re: my "twin bee"

Here is the beginning of the construction of my second " twin bee ".I wait for the parts of Canada to continue.

chris74100- Silver Member

- Posts : 66

Join date : 2012-08-17

Age : 55

Location : ANNEMASSE (FRANCE)

chris74100- Silver Member

- Posts : 66

Join date : 2012-08-17

Age : 55

Location : ANNEMASSE (FRANCE)

Re: my "twin bee"

Re: my "twin bee"

Watching with fascination.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: my "twin bee"

Re: my "twin bee"

yes. same here.RknRusty wrote:Watching with fascination.

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: my "twin bee"

Re: my "twin bee"

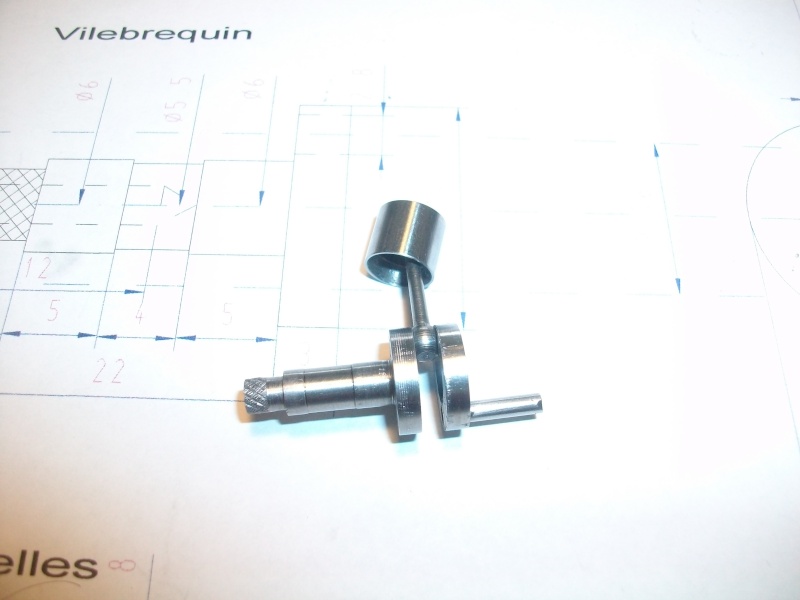

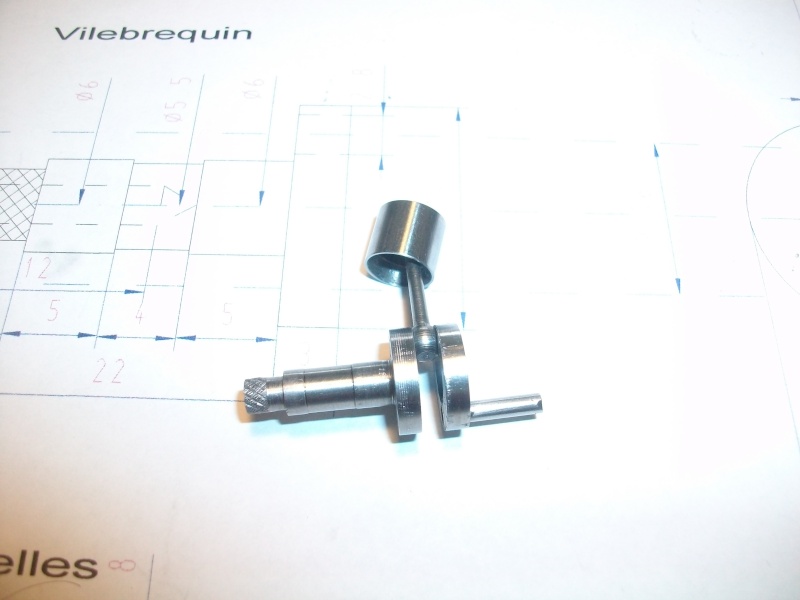

The Crankshaft is almost ended.

chris74100- Silver Member

- Posts : 66

Join date : 2012-08-17

Age : 55

Location : ANNEMASSE (FRANCE)

Re: my "twin bee"

Re: my "twin bee"

That's my new stand of the new "twin bee"

And with the engine

And with the engine

chris74100- Silver Member

- Posts : 66

Join date : 2012-08-17

Age : 55

Location : ANNEMASSE (FRANCE)

Re: my "twin bee"

Re: my "twin bee"

With "paint" and name, N° 0000 for the prototype, CBY.98 for the name and "capacity", and my name (Christian BaillY), the commercial engine will have n°0001

chris74100- Silver Member

- Posts : 66

Join date : 2012-08-17

Age : 55

Location : ANNEMASSE (FRANCE)

Re: my "twin bee"

Re: my "twin bee"

Very clean, indeed. You've got talent.

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

Re: my "twin bee"

Re: my "twin bee"

Very thanks

chris74100- Silver Member

- Posts : 66

Join date : 2012-08-17

Age : 55

Location : ANNEMASSE (FRANCE)

Re: my "twin bee"

Re: my "twin bee"

The new engine is finished. It remains to start it and I would sell it

chris74100- Silver Member

- Posts : 66

Join date : 2012-08-17

Age : 55

Location : ANNEMASSE (FRANCE)

Page 3 of 4 •  1, 2, 3, 4

1, 2, 3, 4

Similar topics

Similar topics» rod/piston connecting

» .020 V-Twin

» Yet another twin.

» Schroeder Opposed .020 Twin EBAY

» Cox Simple .020 Twin By Roger J Schroeder on RCG

» .020 V-Twin

» Yet another twin.

» Schroeder Opposed .020 Twin EBAY

» Cox Simple .020 Twin By Roger J Schroeder on RCG

Page 3 of 4

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules