Log in

Search

Latest topics

» Roger Harris revisitedby rsv1cox Today at 3:38 pm

» My N-1R build log

by GallopingGhostler Today at 3:04 pm

» Tee Dee .020 combat model

by 1/2A Nut Today at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» My latest doodle...

by batjac Yesterday at 9:47 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

Cox Engine of The Month

rod/piston connecting

Page 1 of 1

rod/piston connecting

rod/piston connecting

Hi, i'm frenche, sorry fbut i speak very poor english. It s possible to disassemble the piston rod in a 049 cox ? I want machining twins and I do not know how the rod is fixed in the piston.

My new engine is a .122 CI same the g mark engine (the cylinder of he cox is very too small for machining with my lathe and my milling machine)

If you are pics it's better for me.

Very thanks

My new engine is a .122 CI same the g mark engine (the cylinder of he cox is very too small for machining with my lathe and my milling machine)

If you are pics it's better for me.

Very thanks

chris74100- Silver Member

- Posts : 66

Join date : 2012-08-17

Age : 55

Location : ANNEMASSE (FRANCE)

Re: rod/piston connecting

Re: rod/piston connecting

Chris,

The piston has the rod installed by stamping them together at the factory. It is a ball and socket arrangement with the socket on the bottom side of the piston stamped around the ball that is on the upper end of the connecting rod.

George

The piston has the rod installed by stamping them together at the factory. It is a ball and socket arrangement with the socket on the bottom side of the piston stamped around the ball that is on the upper end of the connecting rod.

George

gcb- Platinum Member

- Posts : 908

Join date : 2011-08-11

Location : Port Ewen, NY

tooling

tooling

Im a fitter turner as well operating cnc and nothing is too small!grind a b/bar out of a piece of hss and hold it in a collet if you dont have a b/bar small enough or a 'u'drill (ie a tap if you have no round hss). and g40/g41/g42 becomes your friend when writing in iso!Cheers Troy.

frog349- New Member

- Posts : 3

Join date : 2012-08-16

Age : 43

Location : australia

Re: rod/piston connecting

Re: rod/piston connecting

This picture gives a pretty good view of the piston, rod and ball socket.chris74100 wrote:If you are pics it's better for me.

Very thanks

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: rod/piston connecting

Re: rod/piston connecting

thank you for your answers but it will be difficult to make oneself

chris74100- Silver Member

- Posts : 66

Join date : 2012-08-17

Age : 55

Location : ANNEMASSE (FRANCE)

Re: rod/piston connecting

Re: rod/piston connecting

Yes, it will be difficult, but it is the difficult things that are worth doing.

Like putting Monokote on a STOL wingtip.

Please post pictures as your project progresses.

Like putting Monokote on a STOL wingtip.

Please post pictures as your project progresses.

ahrma_581- Gold Member

- Posts : 290

Join date : 2012-03-21

Location : Sonoran desert

Re: rod/piston connecting

Re: rod/piston connecting

no problems, but the next engine will be a little bigger, same a OS 10,or the cox 0.9 it will be a little easier to machining.

It's a similar in the 0.9 cox engine ?

It's a similar in the 0.9 cox engine ?

chris74100- Silver Member

- Posts : 66

Join date : 2012-08-17

Age : 55

Location : ANNEMASSE (FRANCE)

Re: rod/piston connecting

Re: rod/piston connecting

frog349 wrote:Im a fitter turner as well operating cnc and nothing is too small!grind a b/bar out of a piece of hss and hold it in a collet if you dont have a b/bar small enough or a 'u'drill (ie a tap if you have no round hss). and g40/g41/g42 becomes your friend when writing in iso!Cheers Troy.

Yes but my cnc is very small it's a X2 it's not a industrial cnc ,I made it myself, but the next one will be bigger and more accurate.And im not a turner it is just my hobbie

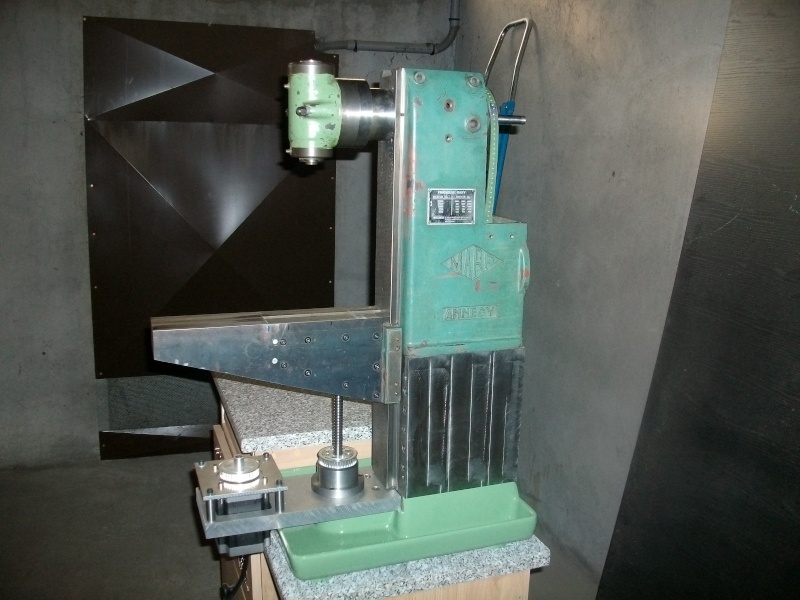

THE CURRENT MILL

the lathe

the next mill under construction

my workshop

chris74100- Silver Member

- Posts : 66

Join date : 2012-08-17

Age : 55

Location : ANNEMASSE (FRANCE)

re: cox twin

re: cox twin

chris74100: is your plan to machine the entire engine? why not start with the pistons and machine the other parts for the first prototype? or pistons and cylinders and machine whatever parts you will need to complete the rest. the pistons, cylinders, crankshafts, and crankcases are readily available in the U.S., England and Germany. and if you need any help finding or getting parts feel free to ask. most of the vendors who advertise here ship worldwide.chris74100 wrote:Hi, i'm frenche, sorry fbut i speak very poor english. It s possible to disassemble the piston rod in a 049 cox ? I want machining twins and I do not know how the rod is fixed in the piston.

My new engine is a .122 CI same the g mark engine (the cylinder of he cox is very too small for machining with my lathe and my milling machine)

If you are pics it's better for me.

Very thanks

also there is an older 3 - part piston from the early 1960's discussed and shown in other discussions here. i think it has a circular clip holding a plate holding the connecting rod into a cup in the piston head. not too many were made.

happydad

happydad- Rest In Peace

- Posts : 1592

Join date : 2012-05-28

Age : 79

Location : Escondido, CA

Re: rod/piston connecting

Re: rod/piston connecting

That is a very nice shop.

lousyflyer- Gold Member

- Posts : 342

Join date : 2012-06-25

Age : 64

Location : Garden City Ga

Re: rod/piston connecting

Re: rod/piston connecting

Chris,

You have a very nice shop. Of the tools you display, I know how to use the vise. :-)

Don't worry about your poor English, you write much better English than I do French. We can understand what you are saying.

If you do an online search, there are groups of machinists who build small engines and could probably give you more ideas and information.

The G-Mark was an excellent engine.

Good luck with your project. Keep us posted.

George

You have a very nice shop. Of the tools you display, I know how to use the vise. :-)

Don't worry about your poor English, you write much better English than I do French. We can understand what you are saying.

If you do an online search, there are groups of machinists who build small engines and could probably give you more ideas and information.

The G-Mark was an excellent engine.

Good luck with your project. Keep us posted.

George

gcb- Platinum Member

- Posts : 908

Join date : 2011-08-11

Location : Port Ewen, NY

Re: rod/piston connecting

Re: rod/piston connecting

happydad wrote:

chris74100: is your plan to machine the entire engine? why not start with the pistons and machine the other parts for the first prototype? or pistons and cylinders and machine whatever parts you will need to complete the rest. the pistons, cylinders, crankshafts, and crankcases are readily available in the U.S., England and Germany. and if you need any help finding or getting parts feel free to ask. most of the vendors who advertise here ship worldwide.

also there is an older 3 - part piston from the early 1960's discussed and shown in other discussions here. i think it has a circular clip holding a plate holding the connecting rod into a cup in the piston head. not too many were made.

happydad

the piston and cylinder parts are the most difficult to machine and therefore the most interesting.

Buy these items get a lot of interest in the manufacture of motor

chris74100- Silver Member

- Posts : 66

Join date : 2012-08-17

Age : 55

Location : ANNEMASSE (FRANCE)

re: 3 part piston

re: 3 part piston

chris74100 wrote:happydad wrote:

chris74100: is your plan to machine the entire engine? why not start with the pistons and machine the other parts for the first prototype? or pistons and cylinders and machine whatever parts you will need to complete the rest. the pistons, cylinders, crankshafts, and crankcases are readily available in the U.S., England and Germany. and if you need any help finding or getting parts feel free to ask. most of the vendors who advertise here ship worldwide.

also there is an older 3 - part piston from the early 1960's discussed and shown in other discussions here. i think it has a circular clip holding a plate holding the connecting rod into a cup in the piston head. not too many were made.

happydad

the piston and cylinder parts are the most difficult to machine and therefore the most interesting.

Buy these items get a lot of interest in the manufacture of motor

search for "3 part piston" and see this pic. there is also an explanation.

hope this helps.

happydad

happydad- Rest In Peace

- Posts : 1592

Join date : 2012-05-28

Age : 79

Location : Escondido, CA

Re: rod/piston connecting

Re: rod/piston connecting

happydad wrote:

why not start with the pistons and machine the other parts for the first prototype? or pistons and cylinders and machine whatever parts you will need to complete the rest. the pistons, cylinders, crankshafts, and crankcases are readily available in the U.S., England and Germany. and if you need any help finding or getting parts feel free to ask. most of the vendors who advertise here ship worldwide.

also there is an older 3 - part piston from the early 1960's discussed and shown in other discussions here. i think it has a circular clip holding a plate holding the connecting rod into a cup in the piston head. not too many were made.

happydad

I reflected well and you are right, I am buy 2 piston and 2 cylinders and I am make a twin. I machining the crankshaft and the "body"(crankcase ?) of the motor. the fuel tank is same at the babe bee with the reed valve. know you the screw thread of the cylinder ?

chris74100- Silver Member

- Posts : 66

Join date : 2012-08-17

Age : 55

Location : ANNEMASSE (FRANCE)

Re: rod/piston connecting

Re: rod/piston connecting

17/32-40 is for the .049 head and cylinder.

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: rod/piston connecting

Re: rod/piston connecting

Jason_WI wrote:17/32-40 is for the .049 head and cylinder.

Thanks, it's a very fine thread, i supposed no tap exist ?

I think make the crakshaft as gmark, I find that's a very good idea and it's no dificult to machining

chris74100- Silver Member

- Posts : 66

Join date : 2012-08-17

Age : 55

Location : ANNEMASSE (FRANCE)

Similar topics

Similar topics» loose connecting rod to piston fit

» Cox .049 Connecting Rod Irregularity?

» Loose Connecting Rod .049

» What causes a piston head to mushroom when you reset the piston rod?

» Wanted: Cox .15 piston, or piston/cylinder - FOUND!

» Cox .049 Connecting Rod Irregularity?

» Loose Connecting Rod .049

» What causes a piston head to mushroom when you reset the piston rod?

» Wanted: Cox .15 piston, or piston/cylinder - FOUND!

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules