Log in

Search

Latest topics

» My N-1R build logby KariFS Today at 1:56 pm

» New Model Build

by bsadonkill Today at 11:31 am

» Project Cox .049 r/c & Citabrian Champion

by MauricioB Today at 10:49 am

» Octura engines?

by UncleLumpy Today at 8:16 am

» Tatone EM-7

by sosam117 Today at 7:50 am

» Honoring All Who Served

by roddie Yesterday at 8:59 pm

» Cox NaBOO - Just in time for Halloween

by rsv1cox Yesterday at 3:30 pm

» Free Flight Radio Assist

by TD ABUSER Yesterday at 1:41 pm

» Cox 020 PeeWee rebuild questions

by balogh Yesterday at 1:36 pm

» K&B .09 Torpedo Engine

by LooseSpinner99 Yesterday at 12:01 pm

» 3D printing of parts?

by UncleLumpy Yesterday at 9:08 am

» L4 Grasshopper

by bottomgun Yesterday at 7:58 am

Cox Engine of The Month

Ball - Socket Joints

Page 2 of 3

Page 2 of 3 •  1, 2, 3

1, 2, 3

Re: Ball - Socket Joints

Re: Ball - Socket Joints

I have to admit, Robert's Workmate makes mine look pretty good. But the pastal shades give it a character that mine does not have. But, I have used it like Robert running engines.......a lot of engines over the years. Instead of paint it's castor coated.

It is handy and flexible roddie. Pegs and holes make it useful for many tasks. If you can find one.

It is handy and flexible roddie. Pegs and holes make it useful for many tasks. If you can find one.

rsv1cox- Top Poster

Posts : 11214

Join date : 2014-08-18

Location : West Virginia

Re: Ball - Socket Joints

Re: Ball - Socket Joints

I wonder if deforming the cup could also deform the piston the piston seems to be hard so maybe it would be ok but I don't know if I would be willing to take that risk...

A high temperature glue like the stuf using with brake pads or other components like the magnets of a magneto??! I tink this glue would work and u should be able to find it somewhere I would start with that I think I like this model of small engine I would like to build a plane dedicated to testing different engines I would like to use mine once repaired A big thank you To rdw 777 Who generously offered the part I was missing, thank you very much

A high temperature glue like the stuf using with brake pads or other components like the magnets of a magneto??! I tink this glue would work and u should be able to find it somewhere I would start with that I think I like this model of small engine I would like to build a plane dedicated to testing different engines I would like to use mine once repaired A big thank you To rdw 777 Who generously offered the part I was missing, thank you very much

davidll1984- Diamond Member

- Posts : 2327

Join date : 2020-02-12

Age : 39

Location : shawinigan

Re: Ball - Socket Joints

Re: Ball - Socket Joints

Wow Not a bad run Robert good to hear the baby singing / what prop are you using / Looks big from here . Well I was just looking to see if i could find the prop size and seen a clean/has comp. with prop (couldn't see the size ) for sale 5.27 US , what ok ck out 12$ shipping  OK it has the needle too so now the other one will wait .... I have not tried to fit the cap back on yet i had cleaned it up and was thinking more on the needle at the time and yes Mecoa has it !!

OK it has the needle too so now the other one will wait .... I have not tried to fit the cap back on yet i had cleaned it up and was thinking more on the needle at the time and yes Mecoa has it !!  I had forgot we did a trade or something ? on the engine ,, I am pleased it runs for you and hope you can get some service out of the Wasp , Robert

I had forgot we did a trade or something ? on the engine ,, I am pleased it runs for you and hope you can get some service out of the Wasp , Robert

getback- Top Poster

Posts : 10428

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Ball - Socket Joints

Re: Ball - Socket Joints

OH David i will see if i can get the measurements on the cap for you if you want have to wait a bit too early right now lol

getback- Top Poster

Posts : 10428

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Ball - Socket Joints

Re: Ball - Socket Joints

Eric, The prop was a Cox 6-3…. It may look large on the engine because the Wasp is very compact for an .049 due to its short stroke….. Photo below to compare to Bee….. They are light too….

32.2 grams compared to the the Bee’s 50g…. It would spin up some more if I used a

5-1/2 - 3 per the test in sceptreflight but I was just letting it loaf in order to not break something….. We traded the engine for a Combat Kittens kit two pack….I’m tickled with the little motor, Thanks

https://sceptreflight.com/Model%20Engine%20Tests/Atwood%20Wasp.html

32.2 grams compared to the the Bee’s 50g…. It would spin up some more if I used a

5-1/2 - 3 per the test in sceptreflight but I was just letting it loaf in order to not break something….. We traded the engine for a Combat Kittens kit two pack….I’m tickled with the little motor, Thanks

https://sceptreflight.com/Model%20Engine%20Tests/Atwood%20Wasp.html

rdw777- Diamond Member

Posts : 1688

Join date : 2021-03-11

Location : West Texas

rsv1cox- Top Poster

Posts : 11214

Join date : 2014-08-18

Location : West Virginia

Re: Ball - Socket Joints

Re: Ball - Socket Joints

Thanks Bob, It was a truly satisfying project….. I think your rehabbing old broken or crusty stuff is rubbing off on me

Robert

Robert

rdw777- Diamond Member

Posts : 1688

Join date : 2021-03-11

Location : West Texas

Re: Ball - Socket Joints

Re: Ball - Socket Joints

Combat Kittens kit two pack !! OH Man I had to go look and its put right where I left it // I am glad you are happy with the engine and I understand the first runs with that old an engine and prop pick Thanks ! ( I have got to find ,more building /fling time in my life before it runs out

getback- Top Poster

Posts : 10428

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Ball - Socket Joints

Re: Ball - Socket Joints

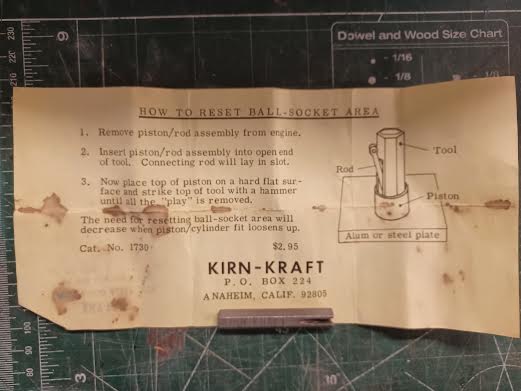

Hi lla, I think we collectively determined the Wasp’s piston/rod joint was not malleable like a Cox and could possibly shatter if a reset was attempted …. I guess those that are a little loose will have to be ran gently…. Thanks for pointing out the tool though, Appreciated,

Robert

Robert

rdw777- Diamond Member

Posts : 1688

Join date : 2021-03-11

Location : West Texas

Re: Ball - Socket Joints

Re: Ball - Socket Joints

Agreed 100%, if it was possible the tool doesn't fit the socket of the Wasp properly anyhow. I would also think its possible to do in a heat controlled environment. The iron would become malleable enough with a lot of heat and allowed to cool.

Ken Cook- Top Poster

- Posts : 5633

Join date : 2012-03-27

Location : pennsylvania

Re: Ball - Socket Joints

Re: Ball - Socket Joints

Hi All,

At 14yrs old we could reset Cox .049 piston/conrods...

With well aimed 1/16 nail punches...

Just saying,

Love this Cox Forum...

Thanks,

Take care,

Have fun,

Dave

At 14yrs old we could reset Cox .049 piston/conrods...

With well aimed 1/16 nail punches...

Just saying,

Love this Cox Forum...

Thanks,

Take care,

Have fun,

Dave

HalfaDave- Platinum Member

- Posts : 615

Join date : 2022-12-06

Location : Oakville, Ontario

Re: Ball - Socket Joints

Re: Ball - Socket Joints

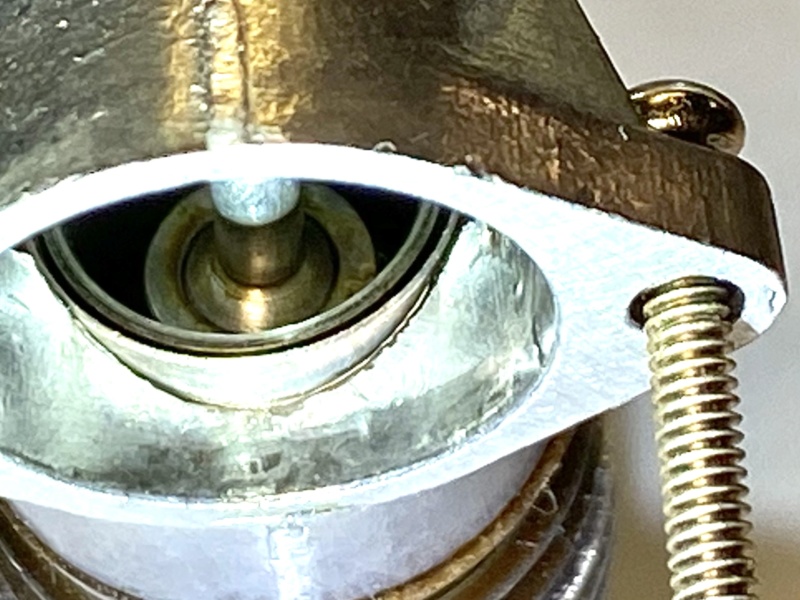

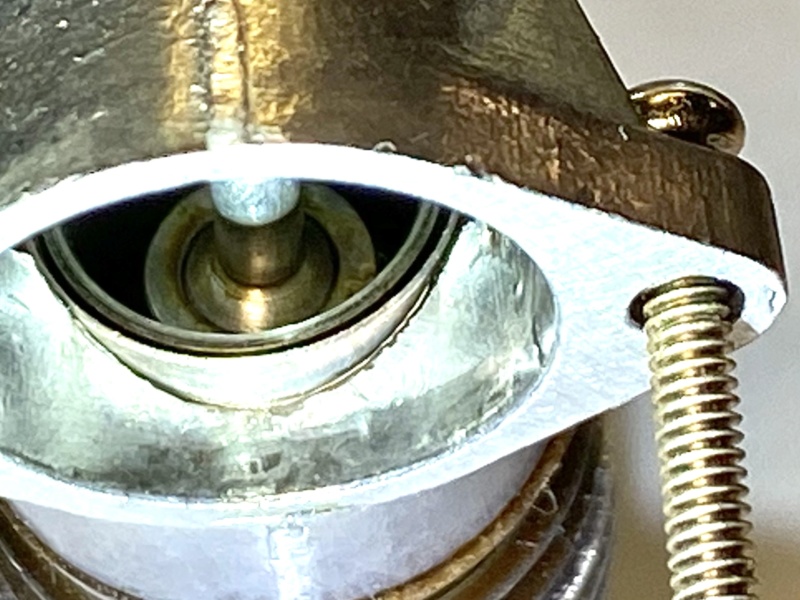

I know enough about Wasp engines to utilize them for my freeflight stuff. I have a few running and new in the box examples. I can't bring myself to run the NIB version. I figure it this way, they've been in the box for over 60 years they might as well stay there. I have a Shriek which I just took this piston out of. I don't know if this is any different piston wise vs a standard Wasp. I believe the Cadet was another model and I have no idea other than the versions that use a glow head vs a glow plug. I couldn't get this engine to run and the compression feels great and the glow head is in working order. The spraybar was the culprit and even though I put a wire through it, I never fully checked to see if it was totally clear. I had it apart on my bench when I was looking at the ball socket.

There's a circlip that holds the ball end in the socket. I'm not certain if this pic is detailed enough to see it but it's in there Look directly at 12 oclock and you can see the opening where the two legs of the circlip is open. Are all Wasps like this? I can't say for certain but I do see this one has it.

There's a circlip that holds the ball end in the socket. I'm not certain if this pic is detailed enough to see it but it's in there Look directly at 12 oclock and you can see the opening where the two legs of the circlip is open. Are all Wasps like this? I can't say for certain but I do see this one has it.

There's a circlip that holds the ball end in the socket. I'm not certain if this pic is detailed enough to see it but it's in there Look directly at 12 oclock and you can see the opening where the two legs of the circlip is open. Are all Wasps like this? I can't say for certain but I do see this one has it.

There's a circlip that holds the ball end in the socket. I'm not certain if this pic is detailed enough to see it but it's in there Look directly at 12 oclock and you can see the opening where the two legs of the circlip is open. Are all Wasps like this? I can't say for certain but I do see this one has it.

Ken Cook- Top Poster

- Posts : 5633

Join date : 2012-03-27

Location : pennsylvania

Re: Ball - Socket Joints

Re: Ball - Socket Joints

Ken, The first photo is the ball/socket that is on the engine in this thread…. I think first version, Atwood Wasp….No gaps visible in the ring in the photo…. Just speculation but when I had it apart and could see it better I was thinking maybe a cup within a cup sort of thing…. Maybe a smaller cup slid over the connecting rod and pressed into a mating cup in the piston….

Next photo is of the “H” - Holland Wasp that was on the Firebaby I recently purchased…. Looks more like it was crimped over the ball similar to Cox…. Again speculation but maybe done with the piston very hot?…. Fortunately it’s in good shape with no need for re-set…. This particular engine is a sweet starter and runner…. Anemic as you say but fun to play with for what they are….

Yes, I see the circlip in your photo….. Ball/socket play good?…. Glad you got your Shriek going…. Fun little engines….

Next photo is of the “H” - Holland Wasp that was on the Firebaby I recently purchased…. Looks more like it was crimped over the ball similar to Cox…. Again speculation but maybe done with the piston very hot?…. Fortunately it’s in good shape with no need for re-set…. This particular engine is a sweet starter and runner…. Anemic as you say but fun to play with for what they are….

Yes, I see the circlip in your photo….. Ball/socket play good?…. Glad you got your Shriek going…. Fun little engines….

rdw777- Diamond Member

Posts : 1688

Join date : 2021-03-11

Location : West Texas

Re: Ball - Socket Joints

Re: Ball - Socket Joints

I just never studied these enough but seeing these examples makes it quite interesting. My example is good. I have a K&B Stallion .049 that uses this archaic type of plate which is essentially crushed over the ball socket and then a circlip retains it. It works so I guess it's good enough. It hasn't self destructed yet. I've had a few Cox pistons where the rod popped through the top. Funny thing is the engines would still run.

Ken Cook- Top Poster

- Posts : 5633

Join date : 2012-03-27

Location : pennsylvania

Re: Ball - Socket Joints

Re: Ball - Socket Joints

Was Cox the only maker of pistons having rod-sockets that can be successfully re-swaged cold?

Re: Ball - Socket Joints

Re: Ball - Socket Joints

I think if I have some JB Weld for metal/alum would work , would clean with carb' cleaner and go inside the piston and put a bead around the outside diameter of the boss where the cap will set /press back in . this is the only way I see to keep from getting JB on the ball it self . What do you guys think?

getback- Top Poster

Posts : 10428

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Ball - Socket Joints

Re: Ball - Socket Joints

I have two different engine models and I can say with certainty that the piston bal joint is different. In diameter and also the way they are fixed in place I realized this after receiving the connecting rod

davidll1984- Diamond Member

- Posts : 2327

Join date : 2020-02-12

Age : 39

Location : shawinigan

Re: Ball - Socket Joints

Re: Ball - Socket Joints

getback wrote:My wasp. See it has a cap that holds the rod on to the piston

Eric, Is the cap on the rod tight or loose when you try to start it back on the piston?….. Did it fail like this when running?…. If it’s tight you might have a chance to press it back in….

If it’s too loose I don’t think an adhesive would hold due to the heat….On the other hand maybe the solids in JB Weld (or other?) might help shim/jamb the fit tighter….Maybe oil or grease the ball to keep it from sticking….. You’d have to rig up a way to press instead of tapping with a hammer to reduce the chance of breaking it….. If you go for it, Put the piston in the freezer for awhile to shrink it a bit right before you attempt it…

Last edited by rdw777 on Mon May 06, 2024 8:49 am; edited 1 time in total

rdw777- Diamond Member

Posts : 1688

Join date : 2021-03-11

Location : West Texas

Re: Ball - Socket Joints

Re: Ball - Socket Joints

I had to go get it and its still pretty tight ,used a small straight hd. to push the cap on and don't think it was all the way ? ( It will only go so far has a lip inside) But was fairly hard to pull off .. So humm maybe just put the piston in the freezer and tap ! it back on w/out anything else >It has to go further than that there was a lot of slop <> the engine came to me this way so I don't know and the piston has a dome at the top and don't look like its been hammering .

getback- Top Poster

Posts : 10428

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Ball - Socket Joints

Re: Ball - Socket Joints

The engine I have has the piston with the domme and doesn't seem to have a groove for a snap ring but it's possible that I missed this detaill I don't have time to work on the engine at the moment but I intend to get started on the work one day or another when I have time After some measurement I quickly noticed that several differences between the different models of wasp the crank pin je larger and the bal joint smaler the model that I have has a different connecting rod from the one that rdw777 bob sent me But with the part it will be possible to measure and possibly modify it to be able to use it anyway or make a custom one. I think it's the model with the retaining cup not the clips  Making the retainer cup will be easy I think

Making the retainer cup will be easy I think

Making the retainer cup will be easy I think

Making the retainer cup will be easy I think

davidll1984- Diamond Member

- Posts : 2327

Join date : 2020-02-12

Age : 39

Location : shawinigan

Re: Ball - Socket Joints

Re: Ball - Socket Joints

Sounds like you may have a chance at it Eric…. If you have a Cox reset tool and it will sit squarely on the cap maybe it could be used to press it back in?….. Maybe with a drill press or vise ….. The thing is you would have to know that just right stopping point ….Lube it up good when you try…… Let us know how it works out

rdw777- Diamond Member

Posts : 1688

Join date : 2021-03-11

Location : West Texas

Re: Ball - Socket Joints

Re: Ball - Socket Joints

The piston that I have here really resembles the one you have in the piston seems to have only half of a round the other half of the round had to be made in the retaining cup so using a reset tool on one of this model seems useless I suggest modifying the cup so that it sits deeper in the piston and thus the ball will become tightergetback wrote:I think if I have some JB Weld for metal/alum would work , would clean with carb' cleaner and go inside the piston and put a bead around the outside diameter of the boss where the cap will set /press back in . this is the only way I see to keep from getting JB on the ball it self . What do you guys think?

davidll1984- Diamond Member

- Posts : 2327

Join date : 2020-02-12

Age : 39

Location : shawinigan

Re: Ball - Socket Joints

Re: Ball - Socket Joints

davidll1984 wrote:Making the retainer cup will be easy I think

I hope you are able to make the part David…… Challenging but should be possible if you have a small lathe…..You may just come up with a procedure that saves a lot of old Wasps… Good luck and please let us know how it works out

rdw777- Diamond Member

Posts : 1688

Join date : 2021-03-11

Location : West Texas

Re: Ball - Socket Joints

Re: Ball - Socket Joints

Roddie wrote:Was Cox the only maker of pistons having rod-sockets that can be successfully re-swaged cold?

I don’t know the answer for sure Roddie but I think mostly yes…. Maybe post Cox hay day years some others had similar but I think most went with a pin…. We really have to credit Cox with that design to produce a piston with two grades of hardness…. Piston side hard to reduce wear and socket softer to remain malleable to set the rod…. Quite a feat in metallurgy on something that small…. We read often that for engines that run a lot may need a reset after awhile but the need for more resets becomes less as run time accrues on them…Intended by design?…. Cox had some top notch engineers….

rdw777- Diamond Member

Posts : 1688

Join date : 2021-03-11

Location : West Texas

Page 2 of 3 •  1, 2, 3

1, 2, 3

Similar topics

Similar topics» seized Medallion .049

» Cox Piston/Rod Ball Socket Resetting

» old glue joints

» 5-40 x 1" socket head bolts

» Need help selecting socket screws

» Cox Piston/Rod Ball Socket Resetting

» old glue joints

» 5-40 x 1" socket head bolts

» Need help selecting socket screws

Page 2 of 3

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules