Log in

Search

Latest topics

» Purchased the last of any bult engines from Ken Enyaby sosam117 Today at 10:25 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» My N-1R build log

by rdw777 Today at 9:17 am

» Funny what you find when you go looking

by rsv1cox Yesterday at 3:21 pm

» Landing-gear tips

by 1975 control line guy Yesterday at 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

» My current avatar photo

by roddie Mon Nov 18, 2024 9:05 pm

» My latest doodle...

by TD ABUSER Mon Nov 18, 2024 11:30 am

» Brushless motors?

by rsv1cox Sun Nov 17, 2024 6:40 pm

» Tribute Shoestring build

by amurphy6812 Sun Nov 17, 2024 5:43 pm

Cox Engine of The Month

min. flow required at optimal RPM?

Page 1 of 1

min. flow required at optimal RPM?

min. flow required at optimal RPM?

Curious to know what the most aggressively-ported Cox .049/.051 engines (naturally aspirated) require for "fuel-flow". Will the venturi pull fuel through a short length of tubing with a 1/32" (.031") inside diameter without becoming fuel-starved?

Last edited by roddie on Sat Nov 04, 2023 1:18 pm; edited 1 time in total (Reason for editing : specified inside diameter)

Re: min. flow required at optimal RPM?

Re: min. flow required at optimal RPM?

I'm pretty sure it would work but fuel viscosity and outside temperature would be a huge factor in that equation.

Ken Cook- Top Poster

- Posts : 5635

Join date : 2012-03-27

Location : pennsylvania

Re: min. flow required at optimal RPM?

Re: min. flow required at optimal RPM?

I use a bit larger diameter fuel tube between the tank and the carb and add a short, smaller dia section just at the carb fuel nipple, to minimize pressure drop of fuel in the feed line. The only fuel starvation I sometimes experienced was caused by the commonly known air seeping into the carb along the needle valve stem, that we all cure by pulling that short silicone tube over the NV and the threaded end of the spraybar..with some care these COX critters will never let you down..

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: min. flow required at optimal RPM?

Re: min. flow required at optimal RPM?

Thanks for the replies gents.. I found a source for .031" ID X .062" OD silicone tubing.. which reduces overall weight when compared to garden-variety sm. size silicone line.. and could possibly be used in a micro clunk-tank/fuel pick-up application. Trying these things out is all part of the fun!

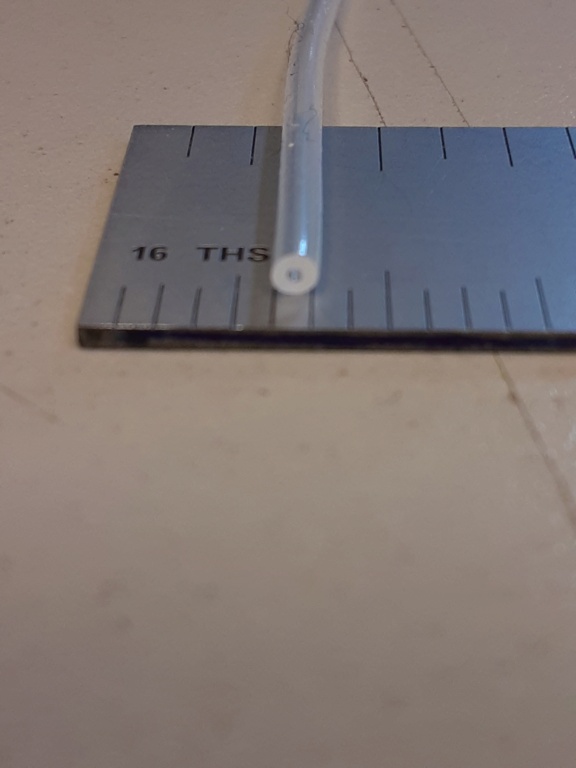

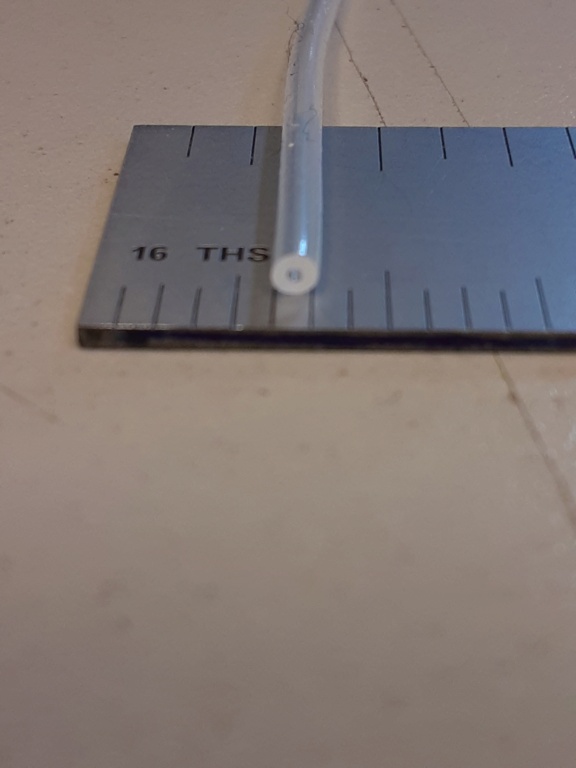

sub-micro silicone tubing

sub-micro silicone tubing

Hi friends. I received the aforementioned sub-micro silicone tubing a few days ago (a few days ahead of Amazon's delivery forecast)

This tubing is small........ but it does have a substantial wall-thickness.

I love small stuff.. probably why I love the Cox 1/2A engines... and anything else that might contribute to their longevity.

I did pose the question of whether a higher-performance Cox 1/2A engine would be able to draw enough fuel through this lines' small ID... naturally aspirated.. to sustain combustion while running at full-bore.

This tubing may well be a better suited for .010/.020 displacement glow engines. I'll note my findings here.

This tubing is small........ but it does have a substantial wall-thickness.

I love small stuff.. probably why I love the Cox 1/2A engines... and anything else that might contribute to their longevity.

I did pose the question of whether a higher-performance Cox 1/2A engine would be able to draw enough fuel through this lines' small ID... naturally aspirated.. to sustain combustion while running at full-bore.

This tubing may well be a better suited for .010/.020 displacement glow engines. I'll note my findings here.

Re: min. flow required at optimal RPM?

Re: min. flow required at optimal RPM?

As Ken Cook pointed out; the fuels' viscosity and ambient air-temperature will surely affect the flow-characteristics of the tubing.

Here's a photo comparing "this" tubing with the Dubro #221 (sm.) tubing.

Might this tubing work for a balloon-tank set-up.. as a perforated pick-up tube? It would make the most use of the available space inside the balloon.

Here's a photo comparing "this" tubing with the Dubro #221 (sm.) tubing.

Might this tubing work for a balloon-tank set-up.. as a perforated pick-up tube? It would make the most use of the available space inside the balloon.

Similar topics

Similar topics» Flow control

» Having trouble with fuel flow!!

» Can it be done? A fixture for testing fuel tank flow under a G-load

» Having trouble with fuel flow!!

» Can it be done? A fixture for testing fuel tank flow under a G-load

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules