Log in

Search

Latest topics

» My N-1R build logby KariFS Today at 1:56 pm

» New Model Build

by bsadonkill Today at 11:31 am

» Project Cox .049 r/c & Citabrian Champion

by MauricioB Today at 10:49 am

» Octura engines?

by UncleLumpy Today at 8:16 am

» Tatone EM-7

by sosam117 Today at 7:50 am

» Honoring All Who Served

by roddie Yesterday at 8:59 pm

» Cox NaBOO - Just in time for Halloween

by rsv1cox Yesterday at 3:30 pm

» Free Flight Radio Assist

by TD ABUSER Yesterday at 1:41 pm

» Cox 020 PeeWee rebuild questions

by balogh Yesterday at 1:36 pm

» K&B .09 Torpedo Engine

by LooseSpinner99 Yesterday at 12:01 pm

» 3D printing of parts?

by UncleLumpy Yesterday at 9:08 am

» L4 Grasshopper

by bottomgun Yesterday at 7:58 am

Cox Engine of The Month

OS/Graupner Wankel - It had to happen

Page 2 of 6

Page 2 of 6 •  1, 2, 3, 4, 5, 6

1, 2, 3, 4, 5, 6

Re: OS/Graupner Wankel - It had to happen

Re: OS/Graupner Wankel - It had to happen

No, but I wouldn't put it past them. They went overboard packing and shipping the thing. Even built up the foam and connected it with clear packing tape.

I ain't throwin' it away.

But, it's actually a battery depleted thermometer with a stong magnet that keeps my razor blade from getting lost in my junk drawer.

But, while we are at it. Anyone have an idea how I can remove the drive washer. Fellow in the video had a nifty little puller. I could make one, bar stock, three machine screws and a couple of taps. But that's like work.

My standard last resort "when all else fails" won't work unless I grind the jaws to fit in the groove, vice it up then heat and tap the shaft with a hammer. China sells something that might work, but China is a long way away.

rsv1cox- Top Poster

Posts : 11214

Join date : 2014-08-18

Location : West Virginia

Re: OS/Graupner Wankel - It had to happen

Re: OS/Graupner Wankel - It had to happen

I never dismantled a Wankel but I've had some taper-loc drive washers that were very difficult to remove. I put the assembly in my small arbor press and keep pressure on it and I hit the assembly with my beater hammer. The hammer I believe is a rawhide hammer.

Ken Cook- Top Poster

- Posts : 5633

Join date : 2012-03-27

Location : pennsylvania

Re: OS/Graupner Wankel - It had to happen

Re: OS/Graupner Wankel - It had to happen

I messed up an Enya engine's bearing when I tried to hammer the crankshaft out.

The key buggered up the bearing, but I did get the crankshaft out. And I didn't lose the key.

The plus side was the bearing needed to be replaced because it was rusted and didn't move.

You could go to David McIntire's video and click on the area where he has a kitty cat and email him as to what the name of the puller he has?

Just an idea?

Dave is fairly good at replying within a week.

I looked thru my sent emails and found David McIntire's email address.

I'm not too sure that it is current as he moved from Florida to Wisconsin the end of August.

Anyway, here is his personal email address: dmrcflyr@gmail.com

The key buggered up the bearing, but I did get the crankshaft out. And I didn't lose the key.

The plus side was the bearing needed to be replaced because it was rusted and didn't move.

You could go to David McIntire's video and click on the area where he has a kitty cat and email him as to what the name of the puller he has?

Just an idea?

Dave is fairly good at replying within a week.

I looked thru my sent emails and found David McIntire's email address.

I'm not too sure that it is current as he moved from Florida to Wisconsin the end of August.

Anyway, here is his personal email address: dmrcflyr@gmail.com

Last edited by sosam117 on Sun Dec 11, 2022 2:54 pm; edited 1 time in total (Reason for editing : David McIntire email)

sosam117- Diamond Member

- Posts : 1345

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Re: OS/Graupner Wankel - It had to happen

Re: OS/Graupner Wankel - It had to happen

Battery terminal or wiper arm pullers are popular for pulling drive hubs. I have an old Armstrong similar to this one, https://www.ebay.com/itm/115620040333 Mine has slightly longer arms and is bolted together.

gkamysz- Gold Member

- Posts : 414

Join date : 2018-02-22

Location : Chicagoland

Re: OS/Graupner Wankel - It had to happen

Re: OS/Graupner Wankel - It had to happen

gkamysz wrote:Battery terminal or wiper arm pullers are popular for pulling drive hubs. I have an old Armstrong similar to this one, https://www.ebay.com/itm/115620040333 Mine has slightly longer arms and is bolted together.

Thanks, that may do it. I might have to grind a bit off the ears to fit the groove but I'm sure it would do it.

rsv1cox- Top Poster

Posts : 11214

Join date : 2014-08-18

Location : West Virginia

Re: OS/Graupner Wankel - It had to happen

Re: OS/Graupner Wankel - It had to happen

rsv1cox wrote:gkamysz wrote:Battery terminal or wiper arm pullers are popular for pulling drive hubs. I have an old Armstrong similar to this one, https://www.ebay.com/itm/115620040333 Mine has slightly longer arms and is bolted together.

Thanks, that may do it. I might have to grind a bit off the ears to fit the groove but I'm sure it would do it.

Not that you couldn't buy a new one, But you could checkout a local AutoZone, Advance Auto or O'Reilley Auto Parts store ( if ya have one nearby) and check one out of their tool lending library. I just used a Tap and Die thread chaser set from O'reily $105 deposit on CC, full credit upon return of tool kit. Thread chased and cleaned. I Didn't wanna spend $30 for a one-time use tap.

Marleysky- Top Poster

Posts : 3618

Join date : 2014-09-28

Age : 72

Location : Grand Rapids, MI

Re: OS/Graupner Wankel - It had to happen

Re: OS/Graupner Wankel - It had to happen

Marleysky wrote:rsv1cox wrote:gkamysz wrote:Battery terminal or wiper arm pullers are popular for pulling drive hubs. I have an old Armstrong similar to this one, https://www.ebay.com/itm/115620040333 Mine has slightly longer arms and is bolted together.

Thanks, that may do it. I might have to grind a bit off the ears to fit the groove but I'm sure it would do it.

Not that you couldn't buy a new one, But you could checkout a local AutoZone, Advance Auto or O'Reilley Auto Parts store ( if ya have one nearby) and check one out of their tool lending library. I just used a Tap and Die thread chaser set from O'reily $105 deposit on CC, full credit upon return of tool kit. Thread chased and cleaned. I Didn't wanna spend $30 for a one-time use tap.

That's a thought too. Another one is my son, if I don't have it, he usually does.

rsv1cox- Top Poster

Posts : 11214

Join date : 2014-08-18

Location : West Virginia

Re: OS/Graupner Wankel - It had to happen

Re: OS/Graupner Wankel - It had to happen

Hi rsv1cox,

I am enjoying this post. Thanks.

Any chance putting hardwood wedges between the case/drive washer ?

Pressure over time and heat/cold cycles has worked for me before. Takes time, but has popped the most stubborn things.

(just don't douse in DW-40, and use a propane torch ! Got that t-shirt !)

I am interested in the inner workings of that engine.

No piston? It will never work was the opinion of when it was new.

The one I saw ran great.

Equal to a 'modern' OSFX.25 in my estimation.

A 'Wankelized' Ford Tri-Moter would be pretty big.

I am sure Henry Ford would approve...

I'll sit back now,

And watch a Master at work...

Thanks,

Dave

I am enjoying this post. Thanks.

Any chance putting hardwood wedges between the case/drive washer ?

Pressure over time and heat/cold cycles has worked for me before. Takes time, but has popped the most stubborn things.

(just don't douse in DW-40, and use a propane torch ! Got that t-shirt !)

I am interested in the inner workings of that engine.

No piston? It will never work was the opinion of when it was new.

The one I saw ran great.

Equal to a 'modern' OSFX.25 in my estimation.

A 'Wankelized' Ford Tri-Moter would be pretty big.

I am sure Henry Ford would approve...

I'll sit back now,

And watch a Master at work...

Thanks,

Dave

HalfaDave- Platinum Member

- Posts : 615

Join date : 2022-12-06

Location : Oakville, Ontario

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

Re: OS/Graupner Wankel - It had to happen

Re: OS/Graupner Wankel - It had to happen

Hi OVERLORD,

With those plans, you made this way more interesting !

Thanks,

Dave

With those plans, you made this way more interesting !

Thanks,

Dave

HalfaDave- Platinum Member

- Posts : 615

Join date : 2022-12-06

Location : Oakville, Ontario

Levent Suberk- Diamond Member

- Posts : 2258

Join date : 2017-12-24

Location : Türkiye

Re: OS/Graupner Wankel - It had to happen

Re: OS/Graupner Wankel - It had to happen

Thanks Dave, Lieven, and Levent.

59" WS on the Ford Tri Dave. I think about right for the three .30's Wankels.

I tried the wedge thing, but I can't even get a razor blade in there. My go-to heat anymore is a butane torch. Pin-point heat right where you need it. Invaluable in loosening the brake line fittings on the RX-7.

I'm learning about these Wankels, both big and little right along with everyone else.

Bob

59" WS on the Ford Tri Dave. I think about right for the three .30's Wankels.

I tried the wedge thing, but I can't even get a razor blade in there. My go-to heat anymore is a butane torch. Pin-point heat right where you need it. Invaluable in loosening the brake line fittings on the RX-7.

I'm learning about these Wankels, both big and little right along with everyone else.

Bob

rsv1cox- Top Poster

Posts : 11214

Join date : 2014-08-18

Location : West Virginia

Levent Suberk- Diamond Member

- Posts : 2258

Join date : 2017-12-24

Location : Türkiye

Re: OS/Graupner Wankel - It had to happen

Re: OS/Graupner Wankel - It had to happen

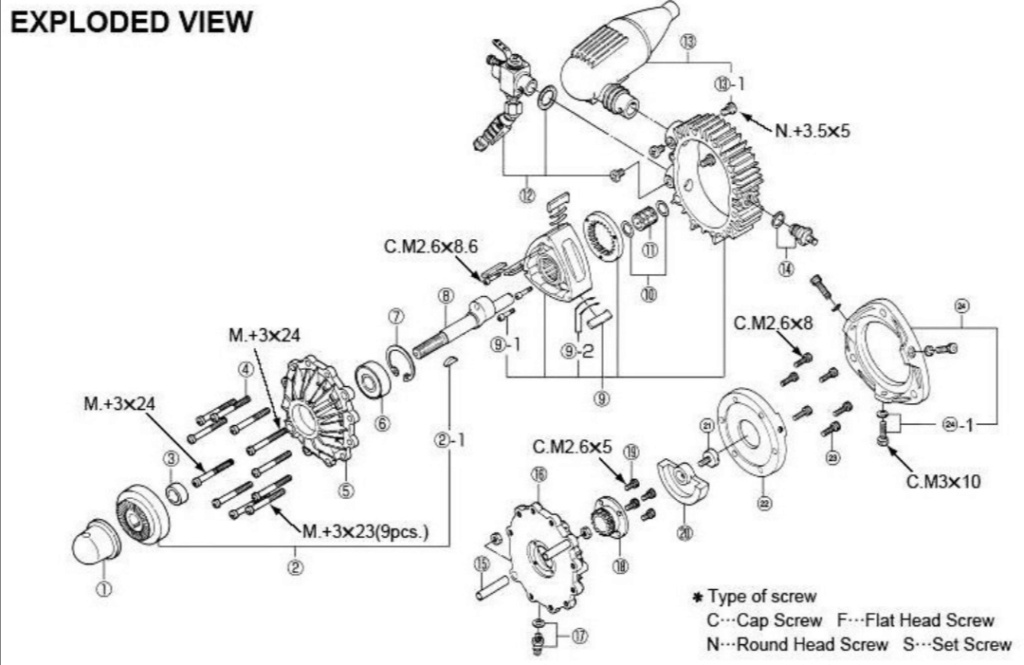

Bob, this tool is out of stock but you can fabricate this tool as one-off for Wankel engine measurements

Levent Suberk- Diamond Member

- Posts : 2258

Join date : 2017-12-24

Location : Türkiye

Re: OS/Graupner Wankel - It had to happen

Re: OS/Graupner Wankel - It had to happen

Be careful referencing the PI version of the OS Wankel. While much of it is the same, a few parts are not. Obviously, there is the peripheral induction. Other than that, the counterweight screw in the PI is a left hand thread with a large slotted head. I do believe the rotor/seals/springs are the same. I don't have the first version so don't know any other specific differences.

The hub has a key and no taper, so it really should just come off with enough heat to soften the castor goo, or a little help from a puller.

The hub has a key and no taper, so it really should just come off with enough heat to soften the castor goo, or a little help from a puller.

gkamysz- Gold Member

- Posts : 414

Join date : 2018-02-22

Location : Chicagoland

Re: OS/Graupner Wankel - It had to happen

Re: OS/Graupner Wankel - It had to happen

Bob, I have an idea of my own that I apply to my MVVS 58 cc engine, give me a few minutes and I'll show you right away.

MauricioB- Top Poster

- Posts : 3709

Join date : 2016-02-16

Age : 53

Location : ARG

Re: OS/Graupner Wankel - It had to happen

Re: OS/Graupner Wankel - It had to happen

"The hub has a key and no taper, so it really should just come off with enough heat to soften the castor goo, or a little help from a puller."

So true.

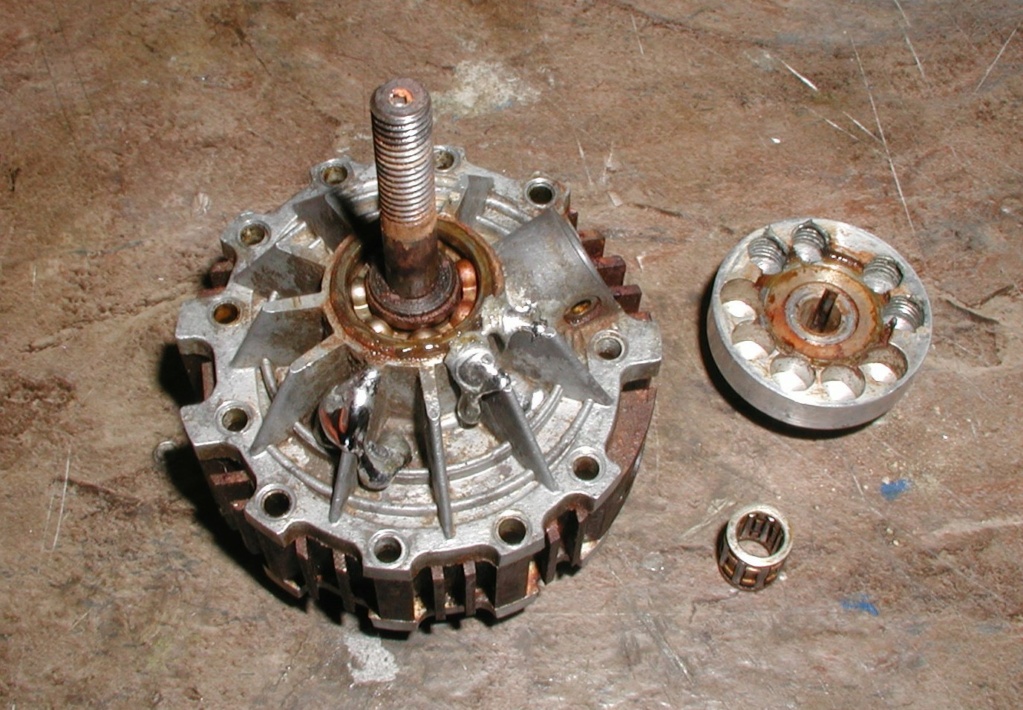

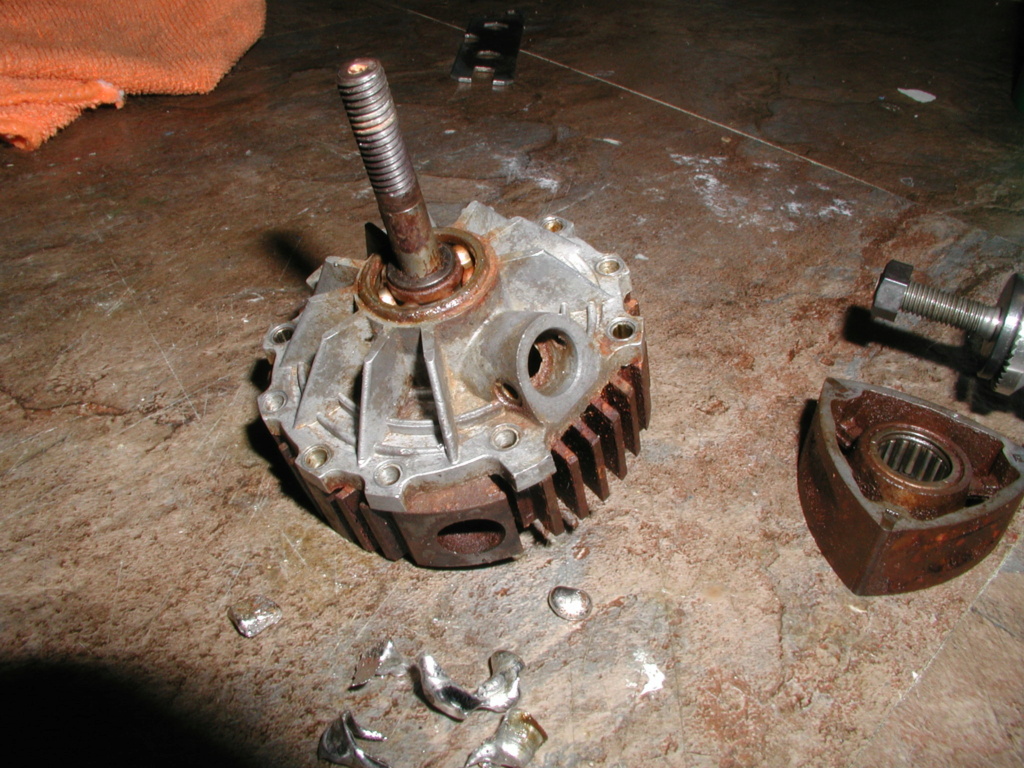

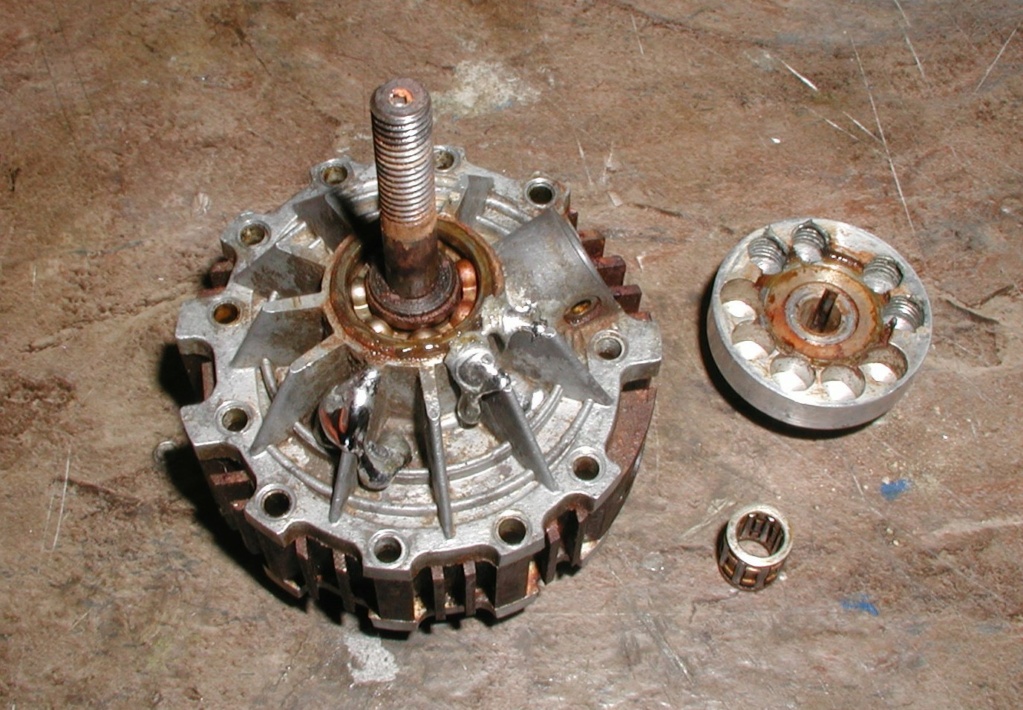

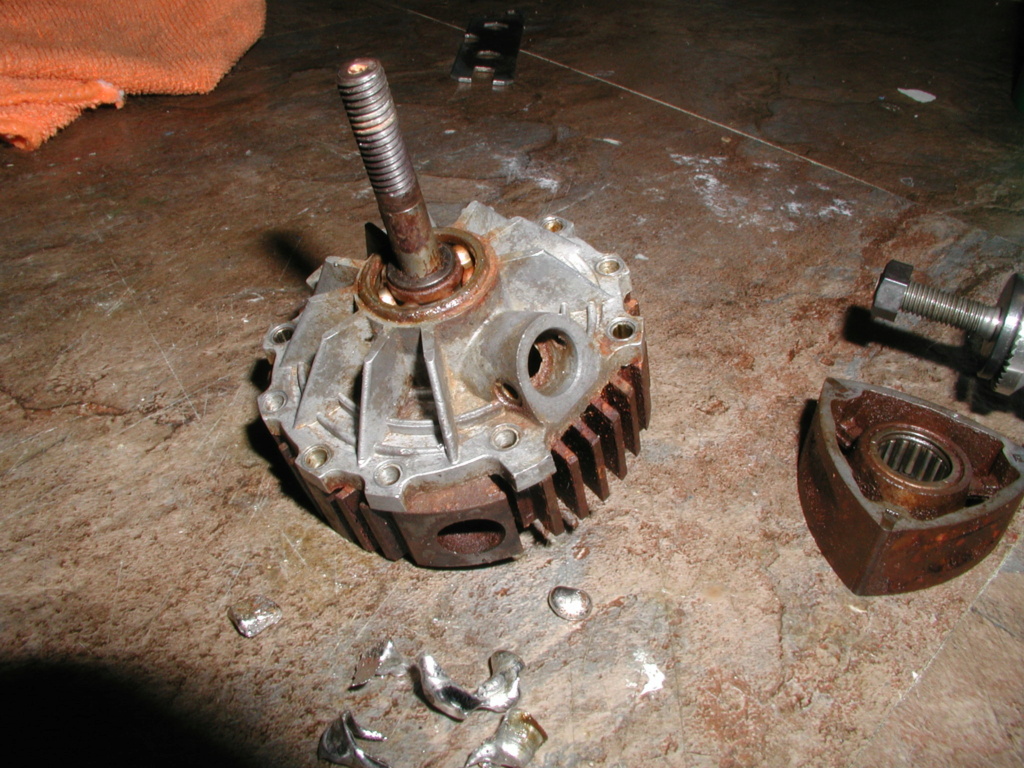

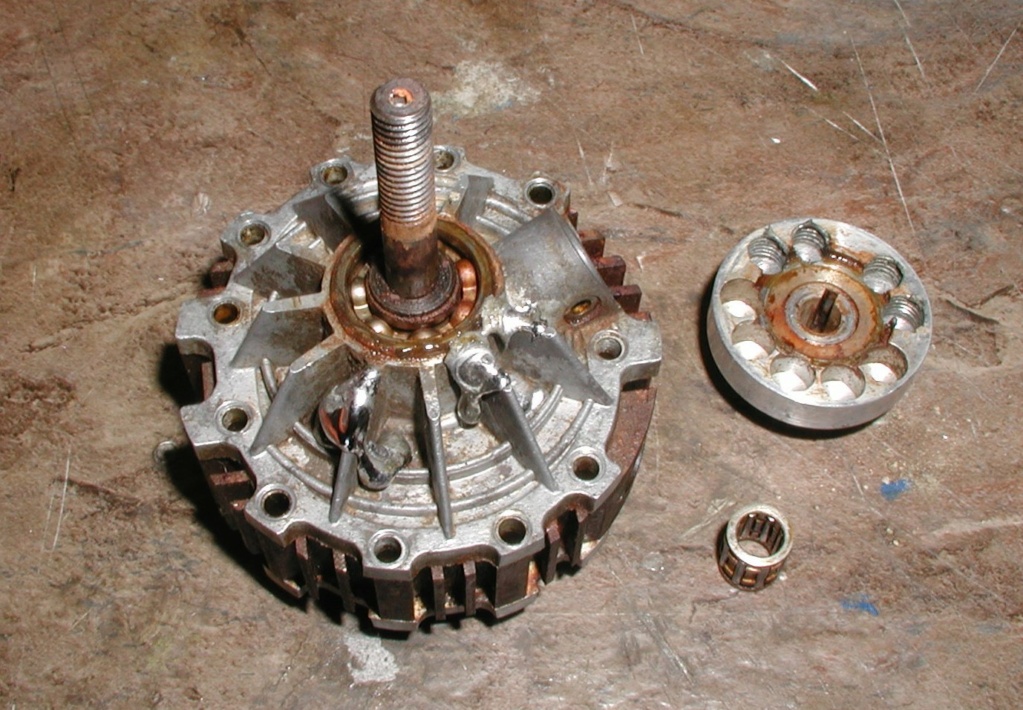

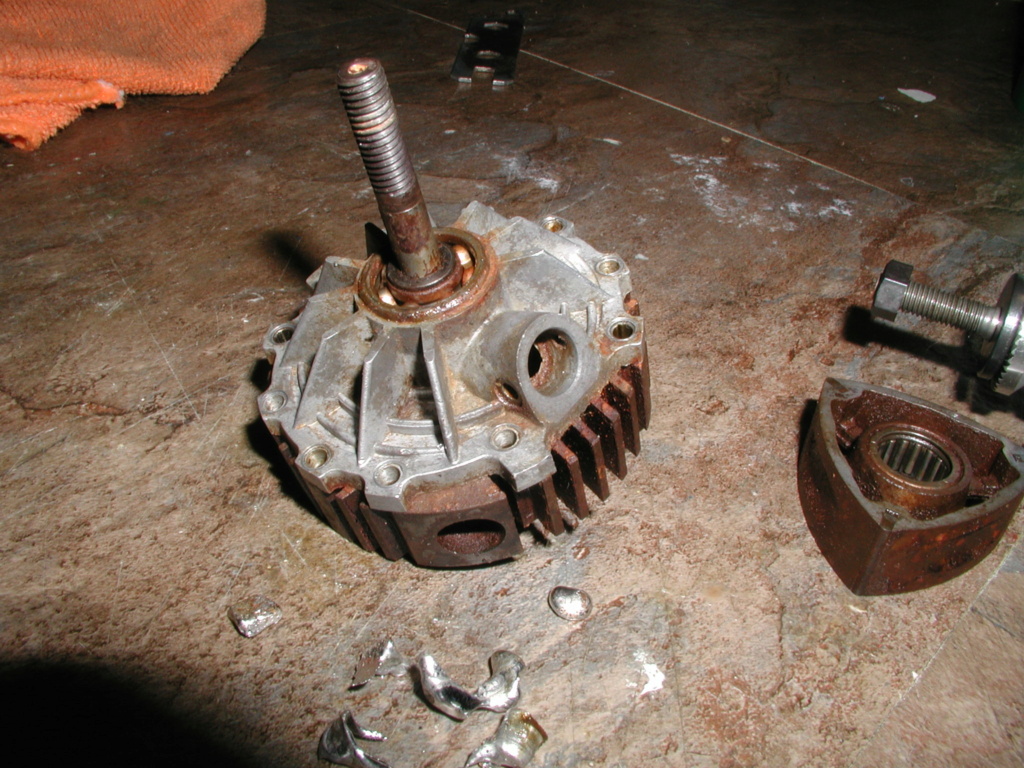

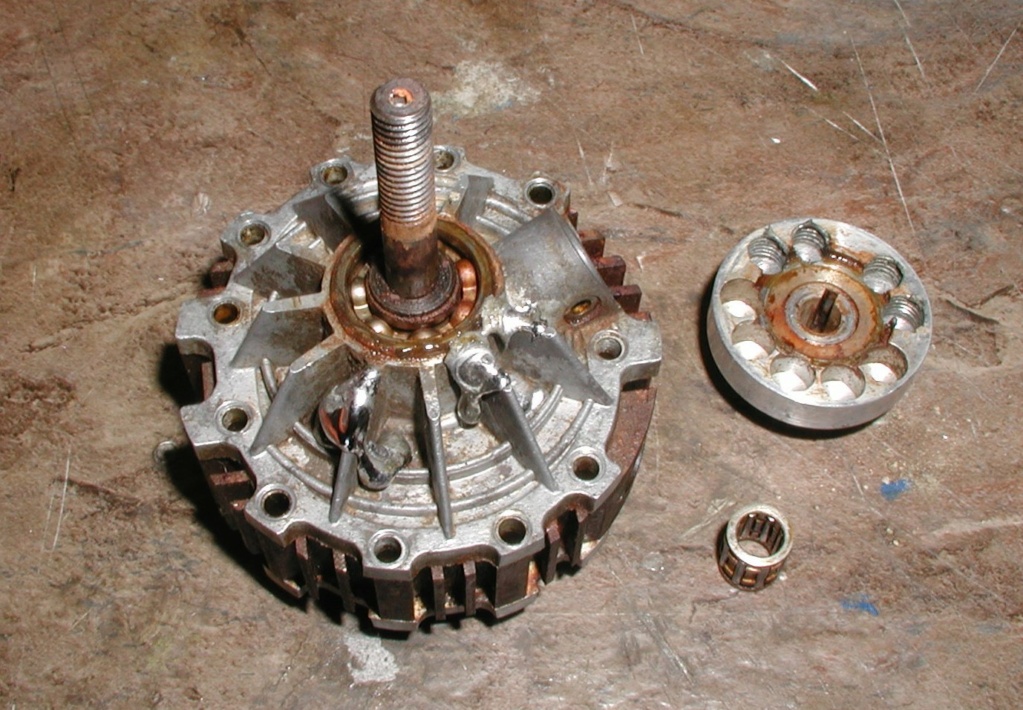

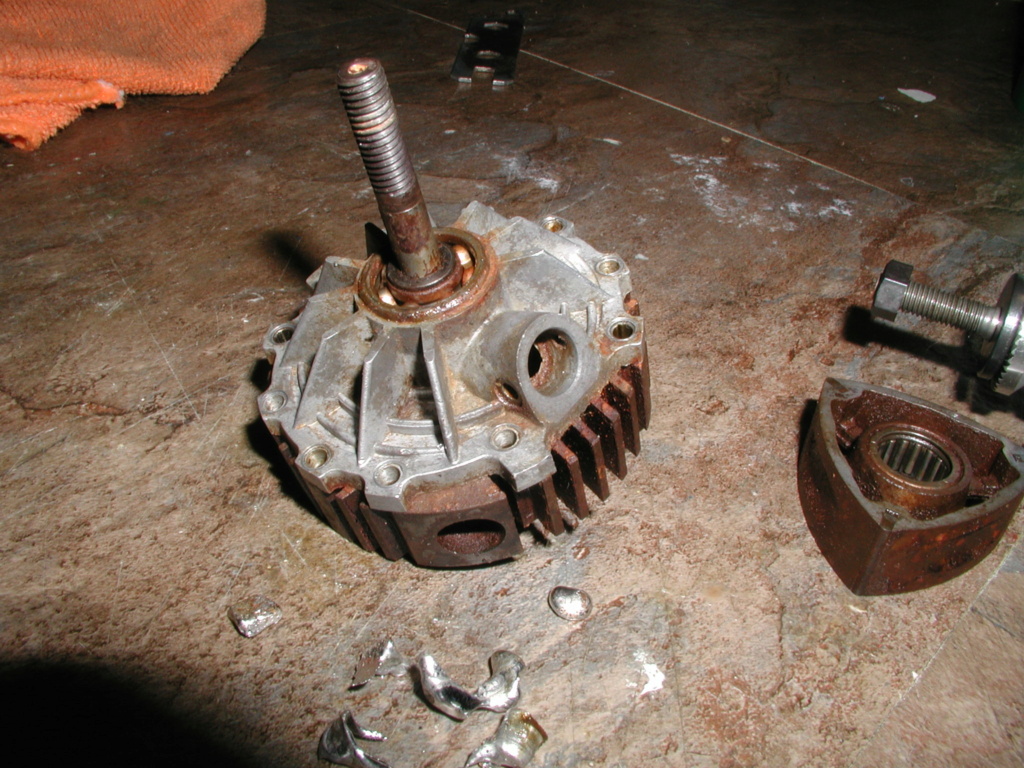

I am an impatient person, and a not so intelligent one. A bad combination. I also do not like being defeated. So with a buffer nut off my OS LA 40, some heat, a tapping hammer and a vice..............

Which revealed gobs of solder.

Which just popped off, revealing ........... nothing. Beauty and the beast.

Oh, now I see...........solder came from the holes in the drive washer melted by the heat. Balancing I would think. May have to put them back. I will have to check the video, or maybe a PO mod.

Edit: Checked the video. At 1:11 shows a counterweight.

So true.

I am an impatient person, and a not so intelligent one. A bad combination. I also do not like being defeated. So with a buffer nut off my OS LA 40, some heat, a tapping hammer and a vice..............

Which revealed gobs of solder.

Which just popped off, revealing ........... nothing. Beauty and the beast.

Oh, now I see...........solder came from the holes in the drive washer melted by the heat. Balancing I would think. May have to put them back. I will have to check the video, or maybe a PO mod.

Edit: Checked the video. At 1:11 shows a counterweight.

Last edited by rsv1cox on Mon Dec 12, 2022 8:36 am; edited 1 time in total

rsv1cox- Top Poster

Posts : 11214

Join date : 2014-08-18

Location : West Virginia

Re: OS/Graupner Wankel - It had to happen

Re: OS/Graupner Wankel - It had to happen

Bob, once something similar happened to me with my MVVS 58cc, I give you the details of how I did it:

1- With an iron, make a U just the diameter of the anchor of the piece to be removed.

2- Place the flat iron in the bench drill.

3- Place the Wanquel motor on the plate, just where the part to be removed fits.

4- Apply temperature to the piece of aluminum alloy, it will expand perfectly.

5- Apply lubricant

6- Apply the torch to the piece of aluminum alloy again.

7- Now press the mandrel closed on the crankshaft.

8- If it does not loosen, repeat the operation.

I bet he does it in a few minutes!

1- With an iron, make a U just the diameter of the anchor of the piece to be removed.

2- Place the flat iron in the bench drill.

3- Place the Wanquel motor on the plate, just where the part to be removed fits.

4- Apply temperature to the piece of aluminum alloy, it will expand perfectly.

5- Apply lubricant

6- Apply the torch to the piece of aluminum alloy again.

7- Now press the mandrel closed on the crankshaft.

8- If it does not loosen, repeat the operation.

I bet he does it in a few minutes!

MauricioB- Top Poster

- Posts : 3709

Join date : 2016-02-16

Age : 53

Location : ARG

Re: OS/Graupner Wankel - It had to happen

Re: OS/Graupner Wankel - It had to happen

Yes Bob, the (planchuela AL AL) Fhoto 1, is also used to carry the heat elsewhere and thus the engine is not directly transmitted.

Now it will be a matter of placing a propeller and balancing the system...nice little precision work, friend!

Now it will be a matter of placing a propeller and balancing the system...nice little precision work, friend!

MauricioB- Top Poster

- Posts : 3709

Join date : 2016-02-16

Age : 53

Location : ARG

Re: OS/Graupner Wankel - It had to happen

Re: OS/Graupner Wankel - It had to happen

Oh No!  I guess that's another difference. At least it should be an easy fix. Later versions have cast bronze hubs with counterweight molded in.

I guess that's another difference. At least it should be an easy fix. Later versions have cast bronze hubs with counterweight molded in.

gkamysz- Gold Member

- Posts : 414

Join date : 2018-02-22

Location : Chicagoland

Re: OS/Graupner Wankel - It had to happen

Re: OS/Graupner Wankel - It had to happen

Bob, for a 4-cycle, the .30 Wankel is very compact when compared with your OS .40LA R/C engine.

Bob, shades of exposure to water moisture, a quaint reminder of my Stallion .35 restoration 4 years ago. Would be interesting to know the history of what caused the engine to be so rusted. Was it a field find? Makes me wonder.

Fortunately, someone didn't bead blast the rust off and tried to pass it off as earlier OS casting technology with "surface casting imperfections (occlusions)", like they did with my K&B .35 Stallion buy.

https://www.coxengineforum.com/t12115-kb-35-stallion-acquisition

Cleaned up crankcase with corrosion removal.

Steel fin cylinder shows considerable surface rust.

Piston is rusted all over similar to Bob's OS Wankel rotor.

Inside of crankshaft and counter balance weight shows surface rust.

Certainly seems both engines took a similar damp path during their life.

GallopingGhostler- Top Poster

Posts : 5700

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: OS/Graupner Wankel - It had to happen

Re: OS/Graupner Wankel - It had to happen

gkamysz wrote:Oh No!I guess that's another difference. At least it should be an easy fix. Later versions have cast bronze hubs with counterweight molded in.

Pretty apparent which holes were filled. Removed the Woodruff, heated the shaft and tapped it out. Pretty sticky. Berryman's and lightly applied low-volume compressend air sandblasted (aluminum oxide) should make a big difference. Bearings pressed out or protected of course. New seals coming.

#3 arrived today. Well packed again. Some people just know how to ebay. Locked up, but I didn't force it. Perry carb, must be a PO substitute? One fin relieved for the fuel nipple.

I will be interesting to see if this one differs. Maybe just heat the shaft instead of the drive washer.

Between these and the RX-7 adventures this morning, I'm bushed. Nap time...........................................

rsv1cox- Top Poster

Posts : 11214

Join date : 2014-08-18

Location : West Virginia

Re: OS/Graupner Wankel - It had to happen

Re: OS/Graupner Wankel - It had to happen

What you have melted is lead and not solder.

The pure lead is heavier than the solder which will have some tin in it.

Newer lead is "lead free".

So, when you balance it use pure lead and not solder.

Looking at your photos and checking where the lead could have melted out.

It looks that the lead was poured into the four holes by the keyway slot. (Two on either side of the keyway slot).

Those also have it where the holes have like a threading to them to grasp the lead so it would retain it and not fly out.

The other hole are smooth and have no ridges in them?

If you need more lead, go to a tire shop/garage and ask for the used tire weights. (That is where I get my lead from.)

You could try to balance the prop driver using a propeller balancer.

Like the Du-Bro prop balancer. I have one of those magnetic ones and it doesn't do as well as my Du-Bro.

In the video at 1:06 shows where the counterweight should be. On the side of the keyway.

The pure lead is heavier than the solder which will have some tin in it.

Newer lead is "lead free".

So, when you balance it use pure lead and not solder.

Looking at your photos and checking where the lead could have melted out.

It looks that the lead was poured into the four holes by the keyway slot. (Two on either side of the keyway slot).

Those also have it where the holes have like a threading to them to grasp the lead so it would retain it and not fly out.

The other hole are smooth and have no ridges in them?

If you need more lead, go to a tire shop/garage and ask for the used tire weights. (That is where I get my lead from.)

You could try to balance the prop driver using a propeller balancer.

Like the Du-Bro prop balancer. I have one of those magnetic ones and it doesn't do as well as my Du-Bro.

In the video at 1:06 shows where the counterweight should be. On the side of the keyway.

sosam117- Diamond Member

- Posts : 1345

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Re: OS/Graupner Wankel - It had to happen

Re: OS/Graupner Wankel - It had to happen

For the lead weights poured embedded in the balance holes to melt meant the engine severely overheated. Someone had mentioned, forgot who (sorry!) that he saw a cowled scale aircraft severely overheat, ruining the engine.

This may explain the severe rusting of the rotor. With all the oil content cooked off, there was no residue oil to protect the rotor and inside of the cylinder chamber. Over time, water moisture took its toll in corroding the unprotected steel surfaces.

Earlier Wankel requires a higher content Castor based fuel. Similar to the Coxes, I'd think that today one may be OK with a 50% Castor and 50% Synth mix, but with that said, one is on their own to find out. Engine is expensive enough that may not be worth risking since it is easy to cook.

2001 instructions state, "FUEL. For this engine, use top quality methanol-based model engine fuel containing approximately 25% castor-oil and between 5% and 15% nitromethane."

2006 instructions for the Type II state, "FEATURES. o Commercially available top-quality model engine fuel containing 15% oil, either synthetic or castor, can be used." It must have had some changes to its metallurgy (or perhaps they chrome plated the surfaces?) to tolerate standard R/C fuel mixtures.

The apparent tendency for the earlier version Wankel to overheat and its unique metallurgy may explain the required higher Castor oil content in the fuel. I am told that similar requirements for the K&B Sportster Schneurles requiring higher Castor content fuel, not the 2% Castor and 16% Synth in standard R/C fuels just don't cut it either, and one similarly does not overheat this engine either, for similar catastrophic results.

I only speculate, but wonder if this Wankel was run on modern R/C fuel with low or no Castor oil content and was run lean, or perhaps was cowled in, or perhaps a combination of the two.

Bob, if you can restore this damaged engine to a decent runner will mean you are a genius!

This may explain the severe rusting of the rotor. With all the oil content cooked off, there was no residue oil to protect the rotor and inside of the cylinder chamber. Over time, water moisture took its toll in corroding the unprotected steel surfaces.

Earlier Wankel requires a higher content Castor based fuel. Similar to the Coxes, I'd think that today one may be OK with a 50% Castor and 50% Synth mix, but with that said, one is on their own to find out. Engine is expensive enough that may not be worth risking since it is easy to cook.

2001 instructions state, "FUEL. For this engine, use top quality methanol-based model engine fuel containing approximately 25% castor-oil and between 5% and 15% nitromethane."

2006 instructions for the Type II state, "FEATURES. o Commercially available top-quality model engine fuel containing 15% oil, either synthetic or castor, can be used." It must have had some changes to its metallurgy (or perhaps they chrome plated the surfaces?) to tolerate standard R/C fuel mixtures.

The apparent tendency for the earlier version Wankel to overheat and its unique metallurgy may explain the required higher Castor oil content in the fuel. I am told that similar requirements for the K&B Sportster Schneurles requiring higher Castor content fuel, not the 2% Castor and 16% Synth in standard R/C fuels just don't cut it either, and one similarly does not overheat this engine either, for similar catastrophic results.

I only speculate, but wonder if this Wankel was run on modern R/C fuel with low or no Castor oil content and was run lean, or perhaps was cowled in, or perhaps a combination of the two.

Bob, if you can restore this damaged engine to a decent runner will mean you are a genius!

GallopingGhostler- Top Poster

Posts : 5700

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: OS/Graupner Wankel - It had to happen

Re: OS/Graupner Wankel - It had to happen

The old McCoy and Fox stunt engines required 25% castor oil.

If you didn't, they would cease up and score the piston/sleeve.

Those engines loved the oil like a slobbering mouth on a dog and it took 1/2 a roll and 1/2 the bottle of cleaner to clean your plane off at the end of the day.

If you didn't, they would cease up and score the piston/sleeve.

Those engines loved the oil like a slobbering mouth on a dog and it took 1/2 a roll and 1/2 the bottle of cleaner to clean your plane off at the end of the day.

sosam117- Diamond Member

- Posts : 1345

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Page 2 of 6 •  1, 2, 3, 4, 5, 6

1, 2, 3, 4, 5, 6

Similar topics

Similar topics» OS graupner wankel 1-49

» Graupner Wankel Typ 7/67 Prototype

» A butane torch, containers, some lead and my Graupner Wankel

» Those things that you don't know why happen... but they happen.

» OS Wankel engine

» Graupner Wankel Typ 7/67 Prototype

» A butane torch, containers, some lead and my Graupner Wankel

» Those things that you don't know why happen... but they happen.

» OS Wankel engine

Page 2 of 6

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules