Log in

Search

Latest topics

» My N-1R build logby KariFS Today at 1:56 pm

» New Model Build

by bsadonkill Today at 11:31 am

» Project Cox .049 r/c & Citabrian Champion

by MauricioB Today at 10:49 am

» Octura engines?

by UncleLumpy Today at 8:16 am

» Tatone EM-7

by sosam117 Today at 7:50 am

» Honoring All Who Served

by roddie Yesterday at 8:59 pm

» Cox NaBOO - Just in time for Halloween

by rsv1cox Yesterday at 3:30 pm

» Free Flight Radio Assist

by TD ABUSER Yesterday at 1:41 pm

» Cox 020 PeeWee rebuild questions

by balogh Yesterday at 1:36 pm

» K&B .09 Torpedo Engine

by LooseSpinner99 Yesterday at 12:01 pm

» 3D printing of parts?

by UncleLumpy Yesterday at 9:08 am

» L4 Grasshopper

by bottomgun Yesterday at 7:58 am

Cox Engine of The Month

Ringmaster

Page 1 of 2

Page 1 of 2 • 1, 2

Ringmaster

Ringmaster

Could someone please shoe me how to install the bell crank assembly on the old sterling ringmaster, it’s not the floating bell crank

Please I would really appreciate any and all help. And if There is a better way I am up for any improvements. And the horn also it’s the old wooden horn. The instructions aren’t very clear to me I’m sorry

Please I would really appreciate any and all help. And if There is a better way I am up for any improvements. And the horn also it’s the old wooden horn. The instructions aren’t very clear to me I’m sorry

Onelife- Gold Member

- Posts : 193

Join date : 2022-09-20

Age : 67

Location : United States

Re: Ringmaster

Re: Ringmaster

@Onelife, which Ringmaster are you building? Is your's the 42" wingspan one?

I have the original Kit S-1, bellcrank is mounted to a plywood platform with a bolt through the bellcrank bearing between ribs. (Reason for the odd patching is this was one already framed but not finished, mailed to me by a friend. I did a correction to building error to remove a wing warp and finished it. Photos of it are on Outerzone.)

I think that the plan on Outerzone for the later S-1A (revision, wing has planked leading edge), uses same bellcrank arrangement.

A later one revised by Pat King (plan on Outerzone) used a floating arrangement.

I have the original Kit S-1, bellcrank is mounted to a plywood platform with a bolt through the bellcrank bearing between ribs. (Reason for the odd patching is this was one already framed but not finished, mailed to me by a friend. I did a correction to building error to remove a wing warp and finished it. Photos of it are on Outerzone.)

I think that the plan on Outerzone for the later S-1A (revision, wing has planked leading edge), uses same bellcrank arrangement.

A later one revised by Pat King (plan on Outerzone) used a floating arrangement.

GallopingGhostler- Top Poster

Posts : 5700

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Ringmaster

Re: Ringmaster

Thank you that’s it. Now is that plywood platform cemented to the center sheathing or is it going through the number 2 rib and cemented there?

That question might be confusing I mean is the rib notched out and the platform slid in the rib for extra support?

That question might be confusing I mean is the rib notched out and the platform slid in the rib for extra support?

Onelife- Gold Member

- Posts : 193

Join date : 2022-09-20

Age : 67

Location : United States

Re: Ringmaster

Re: Ringmaster

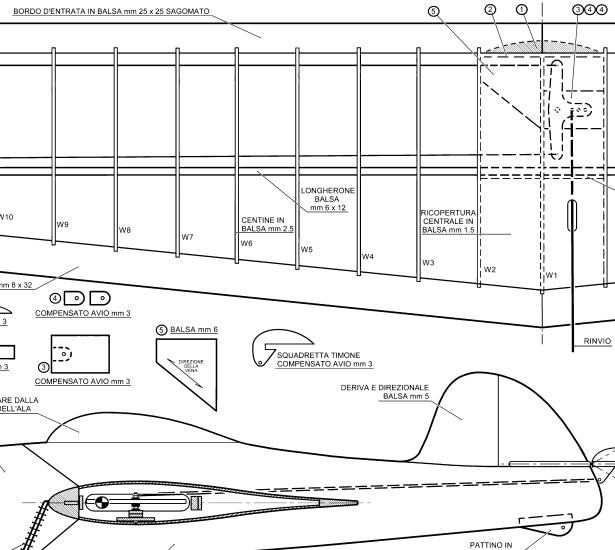

Following is a redrawn plan of the original S-1 plan in Italian, available on Hip Pocket Aeronautics. It numbers the plywood pieces as #3 and #4, and shows how they are assembled.

It is slightly different that mine, because I used a SIG bellcrank, which has a sufficient standoff.

You can obtain the drawing if you register (free) at Hip Pocket.

GallopingGhostler- Top Poster

Posts : 5700

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Ringmaster

Re: Ringmaster

Thank you I appreciate the help. I see you used the hole for the lead out as per plan. I seen another drawing somewhere that should 2 different place for leadouts but when I went to save the drawing I lost the page and now I can find it. Just my luck.

Onelife- Gold Member

- Posts : 193

Join date : 2022-09-20

Age : 67

Location : United States

Re: Ringmaster

Re: Ringmaster

was it on this site >> https://outerzone.co.uk/search/results.asp?keyword=ringmaster+

getback- Top Poster

Posts : 10428

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Ringmaster

Re: Ringmaster

I found it

http://www.vuelocircular.es/RINGMASTER.pdf

Thank you. I’m still debating on location of leadouts. Either to go with the old plan or to modify it as on this plane. Any and all comments appreciated. Thanks again.

http://www.vuelocircular.es/RINGMASTER.pdf

Thank you. I’m still debating on location of leadouts. Either to go with the old plan or to modify it as on this plane. Any and all comments appreciated. Thanks again.

Onelife- Gold Member

- Posts : 193

Join date : 2022-09-20

Age : 67

Location : United States

Re: Ringmaster

Re: Ringmaster

I can offer some suggestions. For starters, the Ringmaster in particular is not a terrific flying plane or even by design. Changing the leadout position would do little to nothing if your not a well seasoned pilot. What needs to happen with a Ringmaster is too slow the elevator down. This is accomplished by putting the control wire closest to the center of pivot in the bellcrank and using at least a 3" bellcrank. In addition, lose the wood control horn. This by far was a ingenious design by Sterling. Using the wood horn results in a crashed plane and you then buy another. The glue joint fails or the wood fails where the wire goes through.

Using a large nylon horn is the ticket and use the hole furthest away from the hinge line to start. In addition, use a handle with 4" or less spacing. If the elevator is traveling more than 30 degrees each way, it's too much.

Having the proper engine on the Ring is also important. If this is a stock Sterling S1, keep the period engines, Mccoy's, Fox's, etc. These engines are 7oz's. Sterling used complete crap for plywood doublers and it's heavy. These can be substituted for 1/16" ply and the 1 1/2" motor mounts which are useless can also be lengthened into the fuse for better engine runs.

Foam wheels, no spinners, wood props, plastic tank, no rudder offset or engine offset all results in better performance than moving the leadouts.

If you haven't already, the spar in the Ringmaster is useless. I never use a spar in these type of wings because it only adds unnecessary weight. The solid leading edge is the backbone to this wing. The stock spar does nothing to strengthen the wing, it breaks every rib in the plane if you hit the ground. It's referred to as the "Rib Ripper". I fiberglass the trailing edge joint to prevent the wing from going forward in case of a strike.

Using a large nylon horn is the ticket and use the hole furthest away from the hinge line to start. In addition, use a handle with 4" or less spacing. If the elevator is traveling more than 30 degrees each way, it's too much.

Having the proper engine on the Ring is also important. If this is a stock Sterling S1, keep the period engines, Mccoy's, Fox's, etc. These engines are 7oz's. Sterling used complete crap for plywood doublers and it's heavy. These can be substituted for 1/16" ply and the 1 1/2" motor mounts which are useless can also be lengthened into the fuse for better engine runs.

Foam wheels, no spinners, wood props, plastic tank, no rudder offset or engine offset all results in better performance than moving the leadouts.

If you haven't already, the spar in the Ringmaster is useless. I never use a spar in these type of wings because it only adds unnecessary weight. The solid leading edge is the backbone to this wing. The stock spar does nothing to strengthen the wing, it breaks every rib in the plane if you hit the ground. It's referred to as the "Rib Ripper". I fiberglass the trailing edge joint to prevent the wing from going forward in case of a strike.

Ken Cook- Top Poster

- Posts : 5633

Join date : 2012-03-27

Location : pennsylvania

Re: Ringmaster

Re: Ringmaster

Wow great advice I seen a picture of a person extending the hard wood miter mount back about a 1/3 of the fuselage I like the idea but I had already glued my little 2 in in so I’m stuck now wish I would have waited. And also I don’t know we’re to buy the wood. And as far as the spar you are so correct I don’t no abou it tearing out the ribs yet but I spent a good couple hours getting it somewhere straight and then the holes all seemed different and made it very hard to assemble but I got it along with : tubes of testers glue. And I will leave the leadout as per plan then but I might attempt a adjustable guild I’m by far a seasonal pilot. I also seen hole drilled into fuselage to lose some weight and then it looked like the carbon fiber the edges it was pretty sharp. Thank you for the ideals. I didn’t know that the motor mounts would help the engine out I really wish I would have done that I’m going with the old fox 35. I love them Engines. Thanks again. Keep them coming but I think you covered all the base’s

Onelife- Gold Member

- Posts : 193

Join date : 2022-09-20

Age : 67

Location : United States

Re: Ringmaster

Re: Ringmaster

As above. thanks heaps Ken!Ken Cook wrote:I can offer some suggestions. For starters, the ....................

I am about to start building a baby ringmaster from Outerzone plans and your thoughts and advice are greatly helpful to me also

I am about to start building a baby ringmaster from Outerzone plans and your thoughts and advice are greatly helpful to me also

This type of advive is priceless as it helps me end up with a better model and I wont spend time doing things whilst building it that are going to directly contribute to its likely early demise. As you know, the build part is not my favourite part of the hobby.

This type of advive is priceless as it helps me end up with a better model and I wont spend time doing things whilst building it that are going to directly contribute to its likely early demise. As you know, the build part is not my favourite part of the hobby.  , simply as I just find it really hard to make things work out and align properly etc. And its the flying that gives me the rush, satisfaction and happiness.

, simply as I just find it really hard to make things work out and align properly etc. And its the flying that gives me the rush, satisfaction and happiness.  Your thoughts on the spars are very instructive and qualift my own thoughts on smallish built up wings as I tend not to use spars at all, and if necessary put small triangulated gussets on the front and back of the ribs on both sides. I have found doing this on my 15 Enya type Dominator and Warlord to provide a very solid and strong wing, hence I was going to take this approach to the baby ringmaster also.

Your thoughts on the spars are very instructive and qualift my own thoughts on smallish built up wings as I tend not to use spars at all, and if necessary put small triangulated gussets on the front and back of the ribs on both sides. I have found doing this on my 15 Enya type Dominator and Warlord to provide a very solid and strong wing, hence I was going to take this approach to the baby ringmaster also.Mine will not have wheels as it will have a TD049 that launchs straight from the edge of a launch table.

Thanks for contributing this type of advice!

Its this type of stuff that many new to the sport and old farts like me coming back to the sport really get value from as to many of us, it is not intuitive, and having it explained helps produce better and easier builds and get to the part, well in my case anyway, that I love. Which is flying them, and even more I love is completing Unpowered Landings

Its this type of stuff that many new to the sport and old farts like me coming back to the sport really get value from as to many of us, it is not intuitive, and having it explained helps produce better and easier builds and get to the part, well in my case anyway, that I love. Which is flying them, and even more I love is completing Unpowered Landings

Thanks Ken

Yabby

Yabby- Platinum Member

Posts : 712

Join date : 2021-06-08

Location : Yorke Peninsula South Australia

Re: Ringmaster

Re: Ringmaster

any hinges you recommend?

Onelife- Gold Member

- Posts : 193

Join date : 2022-09-20

Age : 67

Location : United States

Re: Ringmaster

Re: Ringmaster

I use nylon pin hinges on practically everything I build nowadays. The problem with doing so on a Ringmaster is that the stock wood is only 1/8". I rarely use the stock wood and generally go with 3/16" which I select lighter wood. This enables me to properly center the hinge without it coming out the top or bottom. Now I have used cloth hinges as well and to do so, I ensure that they're tight and free. Most of my flying friends use stitched hinges due to having them free. This takes a bit of practice but they used unwaxed dental floss to do so. Whenever I do this, I prefer a small strip of hard balsa or bass glued to the edges to offer resistance against tear out.

When I use nylon hinges, I inspect every hinge and move each one in my hand first. There's flash on all of them and this won't wear in. Each hinge needs to be de flashed around the barrels. You can feel the hinge click as it snags the flash. I use 6 hinges for a Ring elevator. After it's cleaned up, I rough all sides of the hinge with coarse sandpaper, I then open every hole up with a small pin vise. I then oil the barrel and then I clean all glued edges of the hinge with lacquer thinner to remove oil and clean the glue surface.

Prepare the stab to elevator properly which means that the two have to meet perfectly square. Radius both leading edges. In addition, on the elevator half, I sink the barrels into leading edge. This not only looks better but it insures that there will be no binding after assembled. I glue the hinges in one side at a time.

Once the epoxy is mixed, it's important to have a Q-tip ready and some alcohol during this process. You don't need lots of epoxy, you just need to insure that you have enough to coat both sides and I use a thin metal spatula to insert the epoxy into the grooves. Thin 1/64 " ply can used in the form of a spreader as well to get the epoxy deep into the grooves. Once the grooves are filled up, hit this edge with a heat gun which will make the epoxy runny and water like. Now clean up the leading edge prior to inserting the hinge so that when you push the hinge into the groove, squeeze out won't go into the barrel. Make certain that each hinge is projecting out of the stab equally and it's at a right angle to the part to insure no binds will take place. All this sounds complicated but it's quite easy.

When I use nylon hinges, I inspect every hinge and move each one in my hand first. There's flash on all of them and this won't wear in. Each hinge needs to be de flashed around the barrels. You can feel the hinge click as it snags the flash. I use 6 hinges for a Ring elevator. After it's cleaned up, I rough all sides of the hinge with coarse sandpaper, I then open every hole up with a small pin vise. I then oil the barrel and then I clean all glued edges of the hinge with lacquer thinner to remove oil and clean the glue surface.

Prepare the stab to elevator properly which means that the two have to meet perfectly square. Radius both leading edges. In addition, on the elevator half, I sink the barrels into leading edge. This not only looks better but it insures that there will be no binding after assembled. I glue the hinges in one side at a time.

Once the epoxy is mixed, it's important to have a Q-tip ready and some alcohol during this process. You don't need lots of epoxy, you just need to insure that you have enough to coat both sides and I use a thin metal spatula to insert the epoxy into the grooves. Thin 1/64 " ply can used in the form of a spreader as well to get the epoxy deep into the grooves. Once the grooves are filled up, hit this edge with a heat gun which will make the epoxy runny and water like. Now clean up the leading edge prior to inserting the hinge so that when you push the hinge into the groove, squeeze out won't go into the barrel. Make certain that each hinge is projecting out of the stab equally and it's at a right angle to the part to insure no binds will take place. All this sounds complicated but it's quite easy.

Ken Cook- Top Poster

- Posts : 5633

Join date : 2012-03-27

Location : pennsylvania

Re: Ringmaster

Re: Ringmaster

Yabby, a few things to note in regards to the Baby Ring. Starting with the .35 sized Ring, it flies well and does what its supposed to do but it's not real agile. As this model was scaled down to the Jr, and the Baby, the flying characteristics actually became worse. The Jr. is very nose heavy and the wingspan is lacking. All of them will fly better if made as light as possible. Your rib gussets front and rear are totally unnecessary and are doing nothing more than adding weight as it does little to nothing in providing strength. A rib does nothing more than hold the shape of the airfoil. The gussets your suggesting would only be effective to prevent the wing from side racking. The wing isn't subjected to these loads and are only placed in this situation if it bounces on it's wing tip. Perimeter gussets in the corners of the leading and trailing edge would be more then adequate.

Therefore, you don't need ribs that are 1/8" thick and solid. All you need is 3/32" on a .35 size model, 1/16" on a .15 size and you can even get by with 1/32" on a 1/2A. I prefer 1/16" just due to handling and sanding. You can remove almost the entire center of the rib and not compromise the compression strength. The triangulated gussets if one was requiring them would only be needed in the outside corners of the wing. As I mentioned above in my post is that the Ringmaster needs all the strength you can offer it in the trailing edge center joint. If it fails the entire wing goes forward and hinges on the center of the leading edge joint. You want the leading edge joint to break. If it breaks, it becomes a easy repair only requiring the sheeting to be fixed and not destructing the leading edge which is the strength of the final wing.

A 1/2A is a different story and it generally doesn't have enough momentum to totally destroy itself. Not that it can't happen. Bob Hunt has a great saying that is a tough one to swallow. If your plane survives a crash, it's built too heavy. Unfortunately, this is totally accurate.

Therefore, you don't need ribs that are 1/8" thick and solid. All you need is 3/32" on a .35 size model, 1/16" on a .15 size and you can even get by with 1/32" on a 1/2A. I prefer 1/16" just due to handling and sanding. You can remove almost the entire center of the rib and not compromise the compression strength. The triangulated gussets if one was requiring them would only be needed in the outside corners of the wing. As I mentioned above in my post is that the Ringmaster needs all the strength you can offer it in the trailing edge center joint. If it fails the entire wing goes forward and hinges on the center of the leading edge joint. You want the leading edge joint to break. If it breaks, it becomes a easy repair only requiring the sheeting to be fixed and not destructing the leading edge which is the strength of the final wing.

A 1/2A is a different story and it generally doesn't have enough momentum to totally destroy itself. Not that it can't happen. Bob Hunt has a great saying that is a tough one to swallow. If your plane survives a crash, it's built too heavy. Unfortunately, this is totally accurate.

Ken Cook- Top Poster

- Posts : 5633

Join date : 2012-03-27

Location : pennsylvania

Re: Ringmaster

Re: Ringmaster

Thank you again I’m going to try the nylon hinges. And hope I don’t do to much damage the cloth well it’s not to eye pleasing but it’s probably better to have a sturdy strong build then a pretty one. I don’t understand what you mean by gluing one side at a time.

[url=https://servimg.com/view/20452297/20][img]https://i.servimg.com/u/f18/20/45/22/97/

[url=https://servimg.com/view/20452297/20][img]https://i.servimg.com/u/f18/20/45/22/97/

Oh never mind I figured it out you mean like just glue it to the stap and then the elevator. Got it

[url=https://servimg.com/view/20452297/20][img]https://i.servimg.com/u/f18/20/45/22/97/

[url=https://servimg.com/view/20452297/20][img]https://i.servimg.com/u/f18/20/45/22/97/Oh never mind I figured it out you mean like just glue it to the stap and then the elevator. Got it

Onelife- Gold Member

- Posts : 193

Join date : 2022-09-20

Age : 67

Location : United States

Re: Ringmaster

Re: Ringmaster

Ken Cook wrote:Yabby, a few things to note in regards to the Baby Ring. Starting with the .35 sized Ring, it flies well and does what its supposed to do but it's not real agile. As this model was scaled down to the Jr, and the Baby, the flying characteristics actually became worse. The Jr. is very nose heavy and the wingspan is lacking. All of them will fly better if made as light as possible. Your rib gussets front and rear are totally unnecessary and are doing nothing more than adding weight as it does little to nothing in providing strength. A rib does nothing more than hold the shape of the airfoil. The gussets your suggesting would only be effective to prevent the wing from side racking. The wing isn't subjected to these loads and are only placed in this situation if it bounces on it's wing tip. Perimeter gussets in the corners of the leading and trailing edge would be more then adequate.

Therefore, you don't need ribs that are 1/8" thick and solid. All you need is 3/32" on a .35 size model, 1/16" on a .15 size and you can even get by with 1/32" on a 1/2A. I prefer 1/16" just due to handling and sanding. You can remove almost the entire center of the rib and not compromise the compression strength. The triangulated gussets if one was requiring them would only be needed in the outside corners of the wing. As I mentioned above in my post is that the Ringmaster needs all the strength you can offer it in the trailing edge center joint. If it fails the entire wing goes forward and hinges on the center of the leading edge joint. You want the leading edge joint to break. If it breaks, it becomes a easy repair only requiring the sheeting to be fixed and not destructing the leading edge which is the strength of the final wing.

A 1/2A is a different story and it generally doesn't have enough momentum to totally destroy itself. Not that it can't happen. Bob Hunt has a great saying that is a tough one to swallow. If your plane survives a crash, it's built too heavy. Unfortunately, this is totally accurate.

Excellent Thanks Ken!! the explanation as to building built up Wings makes great sense and is very helpful guidance in general for building ribbed wings.

i am going to build a half A version and I will definitely take note of your advice in respect to building it as light as possible. I do have a pair of Enya 15-III 3303 engines from my youth that I couldnt destroy with a 100 ton press.

i am going to build a half A version and I will definitely take note of your advice in respect to building it as light as possible. I do have a pair of Enya 15-III 3303 engines from my youth that I couldnt destroy with a 100 ton press.  and a newish OS 15, but they are sitting on the front of old school combat wings. :-) even if the Half A Ringmaster doesnt fly that great, it will be good to build one and have a go.

and a newish OS 15, but they are sitting on the front of old school combat wings. :-) even if the Half A Ringmaster doesnt fly that great, it will be good to build one and have a go.  That very much resonates with an old finished up Bike racer like myself. Much like a top racer told me when I was starting out, If you dont crash twice a season, your not going fast enough Both very realistic, pragmatic, and sometimes hard to swallow.

That very much resonates with an old finished up Bike racer like myself. Much like a top racer told me when I was starting out, If you dont crash twice a season, your not going fast enough Both very realistic, pragmatic, and sometimes hard to swallow.

Yabby

Yabby- Platinum Member

Posts : 712

Join date : 2021-06-08

Location : Yorke Peninsula South Australia

Re: Ringmaster

Re: Ringmaster

One other thing I didn't mention on the Ring was the Ringmaster ply doublers. While these will work in stock form, they're too short and stop at the leading edge. If the plane hits nose first, the entire nose breaks right at this point. This can even happen in a flip over landing. This is a poor design and the doublers should be extended back to the high point of the wing. I prefer the inboard doubler to be full and not cutout in the motor mount area. Profiles are subjected to a lot of side vibration and this can certainly prevent some of the vibes. Essentially in stock form, you have a tuning fork. This is why I like to lengthen the beams and make the inboard solid. In doing so when using a Fox .35, this will require the outboard side to have pads under the engine lugs because of the case on the Fox. This might also require a hole in the inboard doubler for the lower backplate lug to project through.

Ken Cook- Top Poster

- Posts : 5633

Join date : 2012-03-27

Location : pennsylvania

Re: Ringmaster

Re: Ringmaster

thanks heaps Ken!  Although as you know. i never Crash

Although as you know. i never Crash  Great heads up, I will mod my build accordingly as it makes sense as you have explained. And flipping over on landing and landing nose sort of first can happen and that does stress the fuse between the engine and the wing. Especially if the doubler stops at the wing, its like a perferated tear here line.

Great heads up, I will mod my build accordingly as it makes sense as you have explained. And flipping over on landing and landing nose sort of first can happen and that does stress the fuse between the engine and the wing. Especially if the doubler stops at the wing, its like a perferated tear here line.

Ive learnt more about building models in the past two days here, than in the past fourty years. Thanks!

Yabby

Great heads up, I will mod my build accordingly as it makes sense as you have explained. And flipping over on landing and landing nose sort of first can happen and that does stress the fuse between the engine and the wing. Especially if the doubler stops at the wing, its like a perferated tear here line.

Great heads up, I will mod my build accordingly as it makes sense as you have explained. And flipping over on landing and landing nose sort of first can happen and that does stress the fuse between the engine and the wing. Especially if the doubler stops at the wing, its like a perferated tear here line.

Ive learnt more about building models in the past two days here, than in the past fourty years. Thanks!

Yabby

Yabby- Platinum Member

Posts : 712

Join date : 2021-06-08

Location : Yorke Peninsula South Australia

Re: Ringmaster

Re: Ringmaster

How about if you just put a 25 on it ? The reason I ask is because I already have my engine blocks in. I could cut them out but I am pretty sure I will not get a nice tight fit

Onelife- Gold Member

- Posts : 193

Join date : 2022-09-20

Age : 67

Location : United States

Re: Ringmaster

Re: Ringmaster

Are you saying that you glued everything together and never checked your beam to beam spacing? Just for the record and future builds, Use 1 3/16" beam to beam spacing for a Fox .35. If I ever need to take a pass on the beams, I set up a router with a straight cutter and take a pass. You can freehand this if the fuse is clamped down and with a bold pencil line and a light touch, you can easily mill out the mount. You can also tack glue some balsa to the fuse and use a straight edge parallel to the beam and ride your straight edge. I usually glue the straight edge with hot glue so that it doesn't move. This can also be accomplished by using a Dremel and a burr bit.

If you have none of these items, you can go caveman style and use the "Nicholson Mill". This is a great term I learned from Larry Scarinzi. The Nicholson is a file. Larry always makes me laugh when he's asked how did he shape the creations he made and he says the "Nicholson mill".

If you have none of these items, you can go caveman style and use the "Nicholson Mill". This is a great term I learned from Larry Scarinzi. The Nicholson is a file. Larry always makes me laugh when he's asked how did he shape the creations he made and he says the "Nicholson mill".

Ken Cook- Top Poster

- Posts : 5633

Join date : 2012-03-27

Location : pennsylvania

Re: Ringmaster

Re: Ringmaster

I did dry fit everything and made sure there was enough meat to attach engine, that I did , but I didn’t use longer hardwood mounts I only ran across that info after I glued the stock pieces in. I got rid of a lot of my power tools awhile back. I used to fly when I was about 14 that was over 50 years ago and then life happened and I but the plane away. I was diagnosed with cancer and given 6 months to live about 10 months ago so I wanted something to do to keep my mind what’s left of it lol to do to help keep me out of depression and I went on a search for the old Carl Goldbergs shoestring and Fox 35 and I found one put it together and been flying when I can now. I’m hooked again. Then I seen this ringmaster on eBay and I got it. And I also bought ever Fox I could get my hands on lol. I kind of over did it like I always do when I’m interested n something. I even have the black 50th Anniversary Fox 35 which I don’t know what to do with now

But anyway I have a Scroll saw I could probably break up some kind of fence to cut them mounts out and add longer ones what do you think? Well sorry to bore you with my baggage but I appreciate your knowledge thanks.

But anyway I have a Scroll saw I could probably break up some kind of fence to cut them mounts out and add longer ones what do you think? Well sorry to bore you with my baggage but I appreciate your knowledge thanks.

Onelife- Gold Member

- Posts : 193

Join date : 2022-09-20

Age : 67

Location : United States

Re: Ringmaster

Re: Ringmaster

In stock form, everything will still work. When you initially posted in regards to making a improvement to the leadouts, I added a few other improvements that would be good. As is, the Ringmaster works out of the box. If it's built and assembled, I would continue on and go fly it. The wood control horn is the only real major change I would make. I built them at 12 years old and succeeded.I've built close to 10 Ringmaster's over a 40 year period. I just gave my oldest one away. I also enjoy the Fox .35 and I have several. I've learned all kinds of tips and tricks for the Fox over the years. I currently have switched many of them over to ABC piston liner configurations. One of my favorite Ringmaster's is my foam winged version. It works exceptionally well. I had the foam wing hollowed out and it uses internal controls.

Ken Cook- Top Poster

- Posts : 5633

Join date : 2012-03-27

Location : pennsylvania

Re: Ringmaster

Re: Ringmaster

That #16 is a beautiful airplane OL. Good luck with your build and your struggle.

Bob

Bob

rsv1cox- Top Poster

Posts : 11214

Join date : 2014-08-18

Location : West Virginia

Re: Ringmaster

Re: Ringmaster

Thanks Bob , for the compliment on the plane a few times I had to walk away from it getting that finish on it trust me. And Ken thank you for all the info I bet you got some well oiled ships , me on the other end was the kid in school always having a hard time at everything , but that Fox was the first and only Engine for me.

Feel free to share some info on the 35 to please thank you. I went and got new NVA and gaskets for them and only run Brodak’s 29 % castor still runs like a champ.

Feel free to share some info on the 35 to please thank you. I went and got new NVA and gaskets for them and only run Brodak’s 29 % castor still runs like a champ.

Onelife- Gold Member

- Posts : 193

Join date : 2022-09-20

Age : 67

Location : United States

Re: Ringmaster

Re: Ringmaster

What’s a good setup for bellcrank and pushrod? I was thinking of some kind of clevis instead of just having the bent music wire hanging there?

Onelife- Gold Member

- Posts : 193

Join date : 2022-09-20

Age : 67

Location : United States

Re: Ringmaster

Re: Ringmaster

Onelife wrote:What’s a good setup for bellcrank and pushrod? I was thinking of some kind of clevis instead of just having the bent music wire hanging there?

The metal (plastics are to clunky) ones on a threaded rod work well, metal to metal contact not being a problem in C/L. Also allows for some ajdustment. But the rods are generally to large in diameter to fit in the bell cranks hole, you would have to drill it out. Slide a sleeve over the clevis.

rsv1cox- Top Poster

Posts : 11214

Join date : 2014-08-18

Location : West Virginia

Page 1 of 2 • 1, 2

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules