Log in

Search

Latest topics

» My N-1R build logby KariFS Today at 1:56 pm

» New Model Build

by bsadonkill Today at 11:31 am

» Project Cox .049 r/c & Citabrian Champion

by MauricioB Today at 10:49 am

» Octura engines?

by UncleLumpy Today at 8:16 am

» Tatone EM-7

by sosam117 Today at 7:50 am

» Honoring All Who Served

by roddie Yesterday at 8:59 pm

» Cox NaBOO - Just in time for Halloween

by rsv1cox Yesterday at 3:30 pm

» Free Flight Radio Assist

by TD ABUSER Yesterday at 1:41 pm

» Cox 020 PeeWee rebuild questions

by balogh Yesterday at 1:36 pm

» K&B .09 Torpedo Engine

by LooseSpinner99 Yesterday at 12:01 pm

» 3D printing of parts?

by UncleLumpy Yesterday at 9:08 am

» L4 Grasshopper

by bottomgun Yesterday at 7:58 am

Cox Engine of The Month

AME 061 venturi relocation

Page 1 of 1

AME 061 venturi relocation

AME 061 venturi relocation

I have a std Norvel AME 061 (second hand ex the Bay-but in very nice order) that I'm tempted to put into use on a somewhat overweight 1/2A....it's one of the pre 'Revlite' series-(porobably the series immediately preceding the Revlite range)-but the venturi is fixed in place and the needle raked well back on the left-I need to have the fuel inlet on the left and needle on the right....for plumbing to a timer (FF remember....!)....obviously it is not possible to simple reverse the entire spraybar assembly as the needle will then project into the prop arc....due to the rake angle.

The question I have for the group is how is the venturi secured to the engine-is it glued in-or a tight press fit? And has anyone had any success in removing one and refitting it 180 degrees opposite the original alignment?

I can live with the fuel inlet on the right as a last resort-but it means a long length of fuel line from the timer-and consequently a lag in shutting off cleanly which wold have to be factored into the timer setup. I'd rather avoid that if possible.....

Any thoughts?

ChrisM

'ffkiwi'

The question I have for the group is how is the venturi secured to the engine-is it glued in-or a tight press fit? And has anyone had any success in removing one and refitting it 180 degrees opposite the original alignment?

I can live with the fuel inlet on the right as a last resort-but it means a long length of fuel line from the timer-and consequently a lag in shutting off cleanly which wold have to be factored into the timer setup. I'd rather avoid that if possible.....

Any thoughts?

ChrisM

'ffkiwi'

ffkiwi- Gold Member

- Posts : 398

Join date : 2018-07-10

Location : Wellington, NZ

Re: AME 061 venturi relocation

Re: AME 061 venturi relocation

First, the venturi on the early engines is glued in; it is a tight fit, but not an interference fit. If the engine has some run time, on occasion, the venturi will work loose, but that is the exception. If it is tight and the adhesive is still intact, they are usually very difficult to remove and usually, it will require sufficient heat to break it loose. Once loose, you will either have to glue it back in or drill thru the crankcase and venturi base and put a retaining bolt in, as used in later models. Unless you absolutely need to remove these older venturis, I would not recommend it.

However, even if you did remove it and turn it 180 degrees, it will not solve your problem because the needle will be even closer to the prop. I've attached a couple of pics with a Big Mig C/L venturi in the normal position and with the venturi rotated 180 degrees.

As you can see, the needle valve will interfere with the prop. Your most simple solution here would likely be to move your timer to the right side of the fuselage and deal with starting the timer on that side.

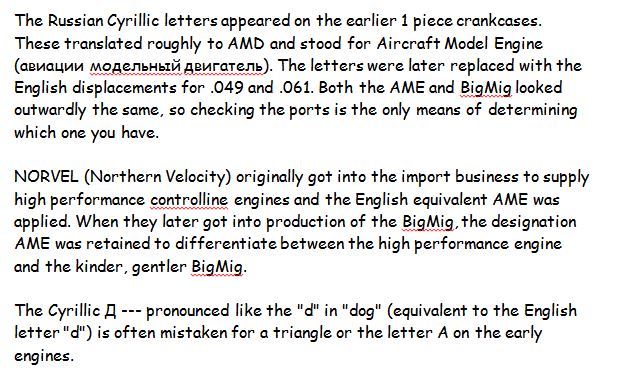

As an aside, have you counted the intake ports to ensure you ended up with an AME. I have bought engines off eBay where the seller claimed it was an AME, but turned out to be a standard Big Mig. On occasion, folks are misled by the Cyrillic markings on the side of the engine. Both the AME and the Big Mig look outwardly the same, so checking the ports is the only way the tell the difference.

However, even if you did remove it and turn it 180 degrees, it will not solve your problem because the needle will be even closer to the prop. I've attached a couple of pics with a Big Mig C/L venturi in the normal position and with the venturi rotated 180 degrees.

As you can see, the needle valve will interfere with the prop. Your most simple solution here would likely be to move your timer to the right side of the fuselage and deal with starting the timer on that side.

As an aside, have you counted the intake ports to ensure you ended up with an AME. I have bought engines off eBay where the seller claimed it was an AME, but turned out to be a standard Big Mig. On occasion, folks are misled by the Cyrillic markings on the side of the engine. Both the AME and the Big Mig look outwardly the same, so checking the ports is the only way the tell the difference.

Re: AME 061 venturi relocation

Re: AME 061 venturi relocation

You've confirmed my suspicions that the venturi is glued in...but what shape is the stem?-if it is round then you should be able to re-locate the NVA at any desired angle (within reason) including the 90 degree position.....if the spigot is non circular then I can understand the point. As I'm a right hander there is no point whatsoever in locating a timer on the right side of the fuselage-precious seconds of run time would be lost in starting the timer and then reorienting to launch...seconds which are not lost in a conventional (for a RHer) left side fuselage position as the timer is initiated by the left hand prior to release from the right hand.

I've never checked whether its the AME it was sold to me as, or a Big Mig-it is certainly similar to the one you posted in the photos.

ChrisM

'ffkiwi'

I've never checked whether its the AME it was sold to me as, or a Big Mig-it is certainly similar to the one you posted in the photos.

ChrisM

'ffkiwi'

ffkiwi- Gold Member

- Posts : 398

Join date : 2018-07-10

Location : Wellington, NZ

Re: AME 061 venturi relocation

Re: AME 061 venturi relocation

I realized that I should have posted a pic of the venturi base after I had reassembled the motor -- my apologies. The base is symmetrical, but shaped like a bathtub with slightly rounded ends, consequently, your only option is a 180° rotation. Looking at the engine from the side and from the front, you'll be able to see that the base is not round. Here is snip from an instruction sheet -- it should be clear enough for you to see the crankcase opening. This one is bolted in, but the earlier glued in versions have the same shape.

I've never read the reason for this design, but I suspect that they were able to increase the carb throat cross-section without making the entrance wider than the crankshaft diameter.

I've never read the reason for this design, but I suspect that they were able to increase the carb throat cross-section without making the entrance wider than the crankshaft diameter.

Re: AME 061 venturi relocation

Re: AME 061 venturi relocation

OK-quite clear now. In light of your earlier response I took the head off last evening....it turns out to be a Big Mig version not the AME, as it has the twin hole transfer ports not the oval slots of the AME. Pity-as I bought it as an AME, but it will still prove useful for something.

ChrisM

'ffkiwi'

ChrisM

'ffkiwi'

ffkiwi- Gold Member

- Posts : 398

Join date : 2018-07-10

Location : Wellington, NZ

Re: AME 061 venturi relocation

Re: AME 061 venturi relocation

FFKiwi/Chris,

Aren't you also on RCG?

What size is your engine? I suspect .049 cid/.08 cc based on your port count. I doubt Norvel could introduce 5 ports in the smaller engine.

Quick reference:

https://www.rcgroups.com/forums/showthread.php?1119447-Cox-Norvell

I think you could heat the case (small butane torch) and spin the "bathtub" venturi around, but then you may need to remove the muffler. Heat and solvent may just pop it loose. I seem to remember JB Weld as the fix for gluing the venturi back in. While running a bolt across the intake is a much more secure solution, I'd go with a slightly more work-intensive, but less invasive solution. Check out how AP secures their venturi with two set screws that thread into the block on either side of the venturi without penetrating/interfering with the intake port. I will say I almost lost an AP venturi when the set screws worked loose. I did find the venturi (but obviously not the set screws) and substituted screws from a laptop to perform the same task. If set screws don't work, then go ahead and cross-drill for a retaining bolt after the set screws aggravate you.

Additionally, note my experience with Norvel is primarily with Rev-Lites. So take the following as you feel. I will say I made a point of searching/buying Big Migs based on the words (Big Mig) cast into the lugs. The few Norvels in my possession with AMx and hand-inked displacements came by means other than "seek and buy." I think I have one or two pre-Rev-Lites (.049s) and around three or four each of Big-Mig marked .061s, .074s, three .15s (at least one is a Big Mig), and three .25s with one being a Big Mig.

However, I wonder if you do indeed have an AMx variant. I say AM"x" because Norvels have several markers indictating their higher performance engines with Cyrillic castings and hand-inked displacements...AMA, AME, and AM(funny-shaped D). I may be off on that last one. You indicate having fewer than the magic 5 ports of the Big Migs.

The Big Migs usually have BIG MIG cast into a mounting lug, and no hand-inking on them. Their displacements are stamped, not inked. I'll check my stash, however I don't think I've ever seen a Big Mig with any hand-inking on them.

Big Migs are to Norvel as Medallions are to Cox. AMx is to Norvel as Tee Dee is to Cox.

Lastly, NVEngines.com still shows parts for Big Migs and AMx engines. Peeking at their parts images may help ID your engine.

I only added all this because of your observation of TWO ports, and that got my curiosity going. You may want to search the forum here and RCG for all Norvel posts. The search feature is at the top-left corner above the "Latest Topics." Please keep us (me) in the loop as you go through this excersize. Who knows...I may want to reclock some of my intakes.

Aren't you also on RCG?

What size is your engine? I suspect .049 cid/.08 cc based on your port count. I doubt Norvel could introduce 5 ports in the smaller engine.

Quick reference:

https://www.rcgroups.com/forums/showthread.php?1119447-Cox-Norvell

I think you could heat the case (small butane torch) and spin the "bathtub" venturi around, but then you may need to remove the muffler. Heat and solvent may just pop it loose. I seem to remember JB Weld as the fix for gluing the venturi back in. While running a bolt across the intake is a much more secure solution, I'd go with a slightly more work-intensive, but less invasive solution. Check out how AP secures their venturi with two set screws that thread into the block on either side of the venturi without penetrating/interfering with the intake port. I will say I almost lost an AP venturi when the set screws worked loose. I did find the venturi (but obviously not the set screws) and substituted screws from a laptop to perform the same task. If set screws don't work, then go ahead and cross-drill for a retaining bolt after the set screws aggravate you.

Additionally, note my experience with Norvel is primarily with Rev-Lites. So take the following as you feel. I will say I made a point of searching/buying Big Migs based on the words (Big Mig) cast into the lugs. The few Norvels in my possession with AMx and hand-inked displacements came by means other than "seek and buy." I think I have one or two pre-Rev-Lites (.049s) and around three or four each of Big-Mig marked .061s, .074s, three .15s (at least one is a Big Mig), and three .25s with one being a Big Mig.

However, I wonder if you do indeed have an AMx variant. I say AM"x" because Norvels have several markers indictating their higher performance engines with Cyrillic castings and hand-inked displacements...AMA, AME, and AM(funny-shaped D). I may be off on that last one. You indicate having fewer than the magic 5 ports of the Big Migs.

The Big Migs usually have BIG MIG cast into a mounting lug, and no hand-inking on them. Their displacements are stamped, not inked. I'll check my stash, however I don't think I've ever seen a Big Mig with any hand-inking on them.

Big Migs are to Norvel as Medallions are to Cox. AMx is to Norvel as Tee Dee is to Cox.

Lastly, NVEngines.com still shows parts for Big Migs and AMx engines. Peeking at their parts images may help ID your engine.

I only added all this because of your observation of TWO ports, and that got my curiosity going. You may want to search the forum here and RCG for all Norvel posts. The search feature is at the top-left corner above the "Latest Topics." Please keep us (me) in the loop as you go through this excersize. Who knows...I may want to reclock some of my intakes.

_________________

Never enough time to build them all...always enough time to smash them all!

944_Jim- Diamond Member

Posts : 2021

Join date : 2017-02-08

Age : 59

Location : NE MS

Re: AME 061 venturi relocation

Re: AME 061 venturi relocation

A Big Mig does not need to say Big Mig on the case. Pre-Revlite engines were sold many times unmarked and improperly packaged. The early versions were branded AME which later became the name of the porting. Then the company became Northern Velocity which later became known as Norvel. There's only one way to tell what you have as Chris mentioned, remove the head. 5 cutouts in the liner is a Big Mig and 3 is a AME. Later engines had a straight through needle valve assembly not a angled swept back version. These engines changed many times and the size of the needle valve assembly diameter also changed. Some Pre-Revlite crankcases used a yellowish epoxy to hold in the venturi as mentioned. There's also a through hole which a needle can fit through but it gets filled with epoxy during the glue up process.

Ken Cook- Top Poster

- Posts : 5633

Join date : 2012-03-27

Location : pennsylvania

Re: AME 061 venturi relocation

Re: AME 061 venturi relocation

[quote="944_Jim"]FFKiwi/Chris,

Aren't you also on RCG?

(1) YES-I am on RCG-and quite a few other fora as 'ffkiwi'.....unlike some here, I don't see the need to adopt a new identity for each forum I join.

(2) My engine IS a pre revlite series 061, and is so marked (in Indian ink) at the top of the transfer bulge (as was the norm at the time) 'AME' is cast on said bulge.....BUT on inspecting the cylinder with the head removed, there are five transfers-the fore and aft transfers being in the form of two holes rather than an elongated slot-and that makes it a Big Mig, not the AME variant. The boost port-opposite the exhaust, is a single elongated hole.

(3) b]My experience with AMEs/Norvels goes back 30 years or so-and includes the very first model AME 049 (less than stellar)-the intermediate models of 049 and 061 (one of which is the subject of this thread), Revlite 074 heli versions, and Revlite 15s-one AME BB and one Big Mig PB....all of them non throttled[/b]

(4) The simplest way of solving the problem is to mount the engine sideways, which I can do, since the model uses a radial mount-and that simple exercise will allow the fuel line from the timer to adopt a less circuitous route than if the engine is mounted upright (which is my preferred arrangement-simply because it reduces the chances of getting debris in it should it glide in, rather than DT down.

Aren't you also on RCG?

(1) YES-I am on RCG-and quite a few other fora as 'ffkiwi'.....unlike some here, I don't see the need to adopt a new identity for each forum I join.

(2) My engine IS a pre revlite series 061, and is so marked (in Indian ink) at the top of the transfer bulge (as was the norm at the time) 'AME' is cast on said bulge.....BUT on inspecting the cylinder with the head removed, there are five transfers-the fore and aft transfers being in the form of two holes rather than an elongated slot-and that makes it a Big Mig, not the AME variant. The boost port-opposite the exhaust, is a single elongated hole.

(3) b]My experience with AMEs/Norvels goes back 30 years or so-and includes the very first model AME 049 (less than stellar)-the intermediate models of 049 and 061 (one of which is the subject of this thread), Revlite 074 heli versions, and Revlite 15s-one AME BB and one Big Mig PB....all of them non throttled[/b]

(4) The simplest way of solving the problem is to mount the engine sideways, which I can do, since the model uses a radial mount-and that simple exercise will allow the fuel line from the timer to adopt a less circuitous route than if the engine is mounted upright (which is my preferred arrangement-simply because it reduces the chances of getting debris in it should it glide in, rather than DT down.

ffkiwi- Gold Member

- Posts : 398

Join date : 2018-07-10

Location : Wellington, NZ

Re: AME 061 venturi relocation

Re: AME 061 venturi relocation

For Ken and Chris,

You now have me completely convinced that an AMx can be Big Mig or Not be Big Mig. So I won't assume an AMx is NOT necessarily a Big Mig any longer.

But does that also mean that conversely a Big Mig-marked case can be a three port higher performance engine built in a Big Mig case? Or am I safe to assume it must be, can only be a Big Mig if marked as such? In other words, if it is marked Big Mig, must it be a Big Mig?

I ask because I've always bought a Big Mig-marked engine expecting it to be a Big Mig. As I mentioned...the others basically fell in my lap.

Thanks for the lesson.

You now have me completely convinced that an AMx can be Big Mig or Not be Big Mig. So I won't assume an AMx is NOT necessarily a Big Mig any longer.

But does that also mean that conversely a Big Mig-marked case can be a three port higher performance engine built in a Big Mig case? Or am I safe to assume it must be, can only be a Big Mig if marked as such? In other words, if it is marked Big Mig, must it be a Big Mig?

I ask because I've always bought a Big Mig-marked engine expecting it to be a Big Mig. As I mentioned...the others basically fell in my lap.

Thanks for the lesson.

_________________

Never enough time to build them all...always enough time to smash them all!

944_Jim- Diamond Member

Posts : 2021

Join date : 2017-02-08

Age : 59

Location : NE MS

Re: AME 061 venturi relocation

Re: AME 061 venturi relocation

ffkiwi wrote:

(2) My engine IS a pre revlite series 061, and is so marked (in Indian ink) at the top of the transfer bulge (as was the norm at the time) 'AME' is cast on said bulge.....BUT on inspecting the cylinder with the head removed, there are five transfers-the fore and aft transfers being in the form of two holes rather than an elongated slot-and that makes it a Big Mig, not the AME variant. The boost port-opposite the exhaust, is a single elongated hole.

I had recognized your moniker from RCU and RCG from a long time ago. Like you, I have tried to retain the same name, but many times Andrew is taken, consequently I've been forced to add some digits to the end in some forums.

I'm attaching a copy of a post I had published in RCU quite some time ago that gives a short explanation of the early castings and the later use of AME vs Big Mig. Hopefully, it will help clear up the Cyrillic letters and porting that you have in your engine.

I have just pulled out an earlier model that has the Russian lettering on the transfer port bulge, but is of Big Mig porting. This model is later than yours since 0.8 (.049 equivalent) is embossed above the 3 letters.

Last edited by andrew on Fri Aug 19, 2022 11:00 pm; edited 1 time in total

Re: AME 061 venturi relocation

Re: AME 061 venturi relocation

Andrew-I've been at this game a long time-some 58 years....as my cylinder index at left indicates (and no it isn't a typo-though its probably closer to 800 than 700 now-and I still have the second and third engines I ever acquired over 50 years ago..though not the first...which I swapped to get the second!) and on quite a few forums here and there-especially RCU RCG-though mainly the latter these days since RCU seems to have withered on the vine a bit-and some, such as the 049 Collectors group...seem to have faded away.

ffkiwi- Gold Member

- Posts : 398

Join date : 2018-07-10

Location : Wellington, NZ

Similar topics

Similar topics» Anyone know how to put this screen in properly/

» OK Cub venturi insert

» Nead info on diesel engine irvine .40 and other stuf

» WTB: Cox TD .09 venturi and NV spring

» AP.15 Hornet NEED VENTURI

» OK Cub venturi insert

» Nead info on diesel engine irvine .40 and other stuf

» WTB: Cox TD .09 venturi and NV spring

» AP.15 Hornet NEED VENTURI

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules