Log in

Search

Latest topics

» Roger Harris revisitedby rsv1cox Today at 3:38 pm

» My N-1R build log

by GallopingGhostler Today at 3:04 pm

» Tee Dee .020 combat model

by 1/2A Nut Today at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» My latest doodle...

by batjac Yesterday at 9:47 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

Cox Engine of The Month

Kirn NVA Issues

Page 1 of 1

Kirn NVA Issues

Kirn NVA Issues

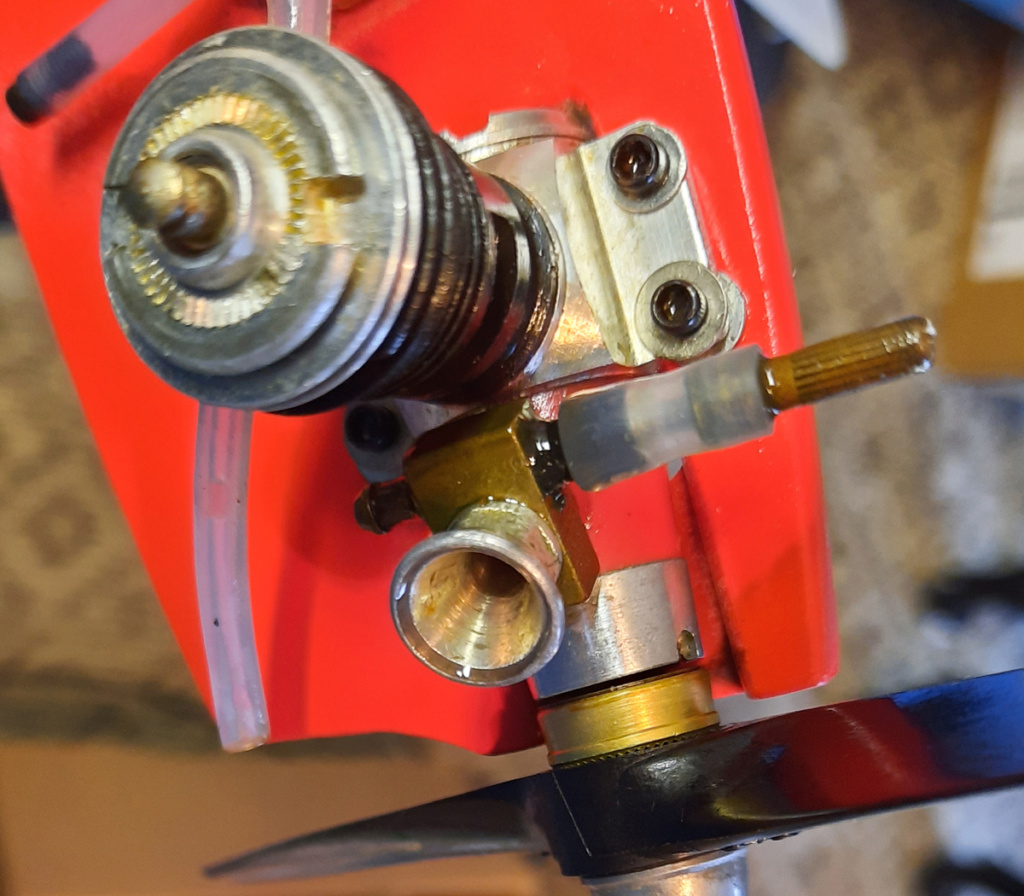

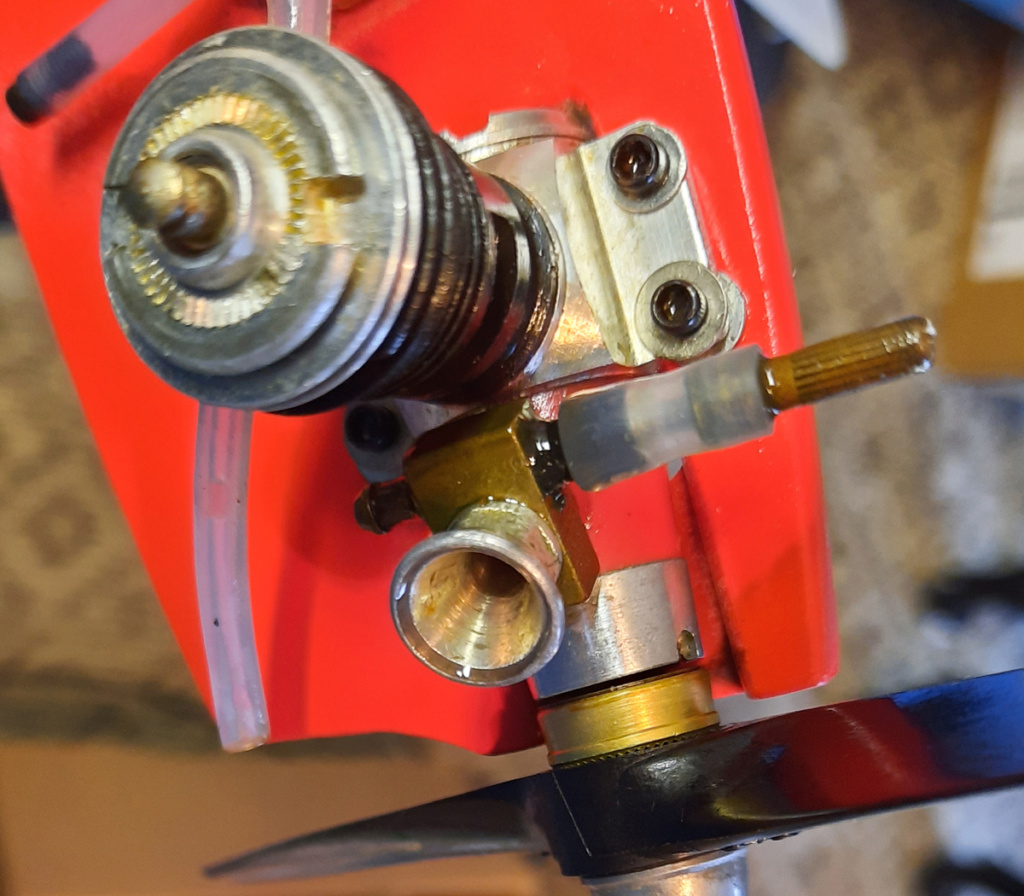

One of the TD's I have has a Kirn NV. I have tried a few times to get the engine to run, however it only runs on a prime. This is using a small Perfect brand tank. I have disassembled and cleaned the NV three times and am at a loss.

Also, as I received the engine, it has a small piece of silicone fuel line on it. I would assume this may be for a seal or to keep the NV from rotating during operation.

Someone in my club told me with this NVA it needs to be run on a bladder.

I think I will take it to work and put it under the shop microscope to have a close look at it. Maybe even give it an ultrasonic bath.

Any advice appreciated!

Also, as I received the engine, it has a small piece of silicone fuel line on it. I would assume this may be for a seal or to keep the NV from rotating during operation.

Someone in my club told me with this NVA it needs to be run on a bladder.

I think I will take it to work and put it under the shop microscope to have a close look at it. Maybe even give it an ultrasonic bath.

Any advice appreciated!

Aero- Silver Member

- Posts : 73

Join date : 2014-08-10

Location : Southern IN

Re: Kirn NVA Issues

Re: Kirn NVA Issues

Clean the 3 small holes in the venturi with a small wire. Also make sure you can see light through the needle valve body with the needle removed. Shine a flashlight in and you should also see light out the small hole in the center of the needle valve body. It looks varnished up so I would soak that in denatured alcohol and clean it up.

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: Kirn NVA Issues

Re: Kirn NVA Issues

Flushing with a syringe will immediately tell you if the spraybar is clogged which more than likely it is.

Ken Cook- Top Poster

- Posts : 5637

Join date : 2012-03-27

Location : pennsylvania

Re: Kirn NVA Issues

Re: Kirn NVA Issues

Thanks for the replies!

I will give the body, needle, and venturi a thorough cleaning.

I will give the body, needle, and venturi a thorough cleaning.

Aero- Silver Member

- Posts : 73

Join date : 2014-08-10

Location : Southern IN

Re: Kirn NVA Issues

Re: Kirn NVA Issues

Hello Allen , The KK don't have to have a Bladder to run But will bee your go to for a Bladder run if you ever decide to try one .  The above response should take care of ur problem , let us know .

The above response should take care of ur problem , let us know .

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Kirn NVA Issues

Re: Kirn NVA Issues

Don't forget that these are FINE THREAD needle valve assemblies...128 TPI.....so you need to open the needle about double the number of turns you would with a standard Cox TD 049 needle assembly-which for the latter is about 5 turns open for starting, from memory....so with the KK assembly, all things being equal...ie clean and no blockages...you could expect to need it open 9-10 turns for starting (NOTE-I'm talking suction feed settings here, not pressure!)

So if you only opened it the usual number of turns-the engine would not draw enough fuel to run-so runs out the prime and stops. In standard form, these KK assemblies had a small cylindrical nylon seal that abutted the brass body to act as an airseal on the needle OD. These did wear and leak-and quite a few users simply replaced them or supplemented them with a short length of silicone fuel line over the needle and the needle inlet-exactly as yours has. Part of the problem is caused by quite a long needle valve overhang-which accelerates the wear-hence the original seals often wear out, letting air in-which is bad enough on suction-and far worse on any pressure system.

As a bonus, the piece of fuel tube also helps the locking effect of the seal, so the needle valve usually stays where you set it, without creep. One final thing to check-these needles are only brass-and relatively easily bent in a crash-so if your needle is bent that might well affect the way it adjusts-though any bend is likely to occur where it exits the metering block; likewise check the very tip to see that it is not bent or burred (unlikely-but not impossible....)

Normally these are good units-and virtually all my TD 049s/051s are fitted either with these or the Ace R/C unit-which is effectively the same but with a plastic rather than brass body.

ChrisM

'ffkiwi'

So if you only opened it the usual number of turns-the engine would not draw enough fuel to run-so runs out the prime and stops. In standard form, these KK assemblies had a small cylindrical nylon seal that abutted the brass body to act as an airseal on the needle OD. These did wear and leak-and quite a few users simply replaced them or supplemented them with a short length of silicone fuel line over the needle and the needle inlet-exactly as yours has. Part of the problem is caused by quite a long needle valve overhang-which accelerates the wear-hence the original seals often wear out, letting air in-which is bad enough on suction-and far worse on any pressure system.

As a bonus, the piece of fuel tube also helps the locking effect of the seal, so the needle valve usually stays where you set it, without creep. One final thing to check-these needles are only brass-and relatively easily bent in a crash-so if your needle is bent that might well affect the way it adjusts-though any bend is likely to occur where it exits the metering block; likewise check the very tip to see that it is not bent or burred (unlikely-but not impossible....)

Normally these are good units-and virtually all my TD 049s/051s are fitted either with these or the Ace R/C unit-which is effectively the same but with a plastic rather than brass body.

ChrisM

'ffkiwi'

ffkiwi- Gold Member

- Posts : 398

Join date : 2018-07-10

Location : Wellington, NZ

Re: Kirn NVA Issues

Re: Kirn NVA Issues

If ever needed, Cox international has the black plastic NV seal

https://coxengines.ca/cox-.049-.074-spray-bar-seal-10.html

https://coxengines.ca/cox-.049-.074-spray-bar-seal-10.html

Last edited by fredvon4 on Tue Nov 03, 2020 10:24 am; edited 1 time in total

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: Kirn NVA Issues

Re: Kirn NVA Issues

fredvon4 wrote:If ever needed Cox international has the black plastic NV seal

https://coxengines.ca/cox-.049-.074-spray-bar-seal-10.html

It's always a good idea (just in case), after cleaning to replace gasket/seals. Most common place for leaks.

That black plastic NV seal gets hard and brittle. that's why you'll see a piece of fuel line over the NV and black seal.

sosam117- Diamond Member

- Posts : 1350

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Re: Kirn NVA Issues

Re: Kirn NVA Issues

sosam117 wrote:fredvon4 wrote:If ever needed Cox international has the black plastic NV seal

https://coxengines.ca/cox-.049-.074-spray-bar-seal-10.html

It's always a good idea (just in case), after cleaning to replace gasket/seals. Most common place for leaks.

That black plastic NV seal gets hard and brittle. that's why you'll see a piece of fuel line over the NV and black seal.

Yep. Looks like I may need to place an order or two for parts. I have a few reedys that need some attention, too.

Aero- Silver Member

- Posts : 73

Join date : 2014-08-10

Location : Southern IN

Re: Kirn NVA Issues

Re: Kirn NVA Issues

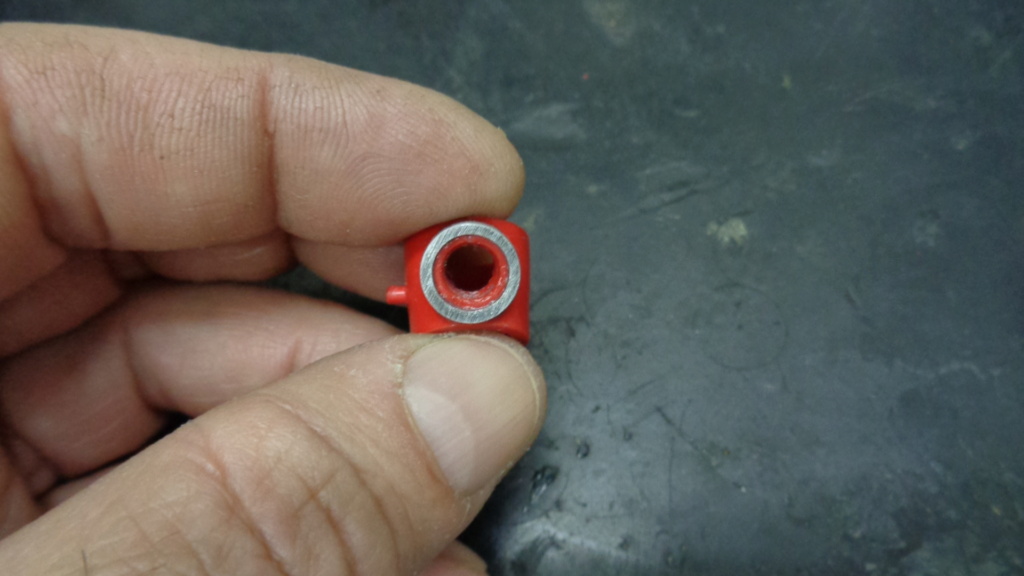

If you have problems with the crack, clean the engine well (alcohol or acetone?) to remove any oil residue.

Then using JB Weld, try to push the JB Weld into the crack.

It's only a temporary fix.

It is better to purchase the aluminum venturi body from our Cox vendors.

sosam117- Diamond Member

- Posts : 1350

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Re: Kirn NVA Issues

Re: Kirn NVA Issues

In a thread Mauricio made a ring to fit on a cracked venturi. However I couldn't find that thread.

Levent Suberk- Diamond Member

- Posts : 2265

Join date : 2017-12-24

Location : Türkiye

Re: Kirn NVA Issues

Re: Kirn NVA Issues

That’s a different engine than what was originally posted. Either way I prefer the plastic carb bodies vs the aluminum ones. Air leaks between the aluminum carb body and crankcase were problems on the ones I tried. Maybe the newer aluminum ones addressed that issue.

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: Kirn NVA Issues

Re: Kirn NVA Issues

Jason_WI wrote:That’s a different engine than what was originally posted. Either way I prefer the plastic carb bodies vs the aluminum ones. Air leaks between the aluminum carb body and crankcase were problems on the ones I tried. Maybe the newer aluminum ones addressed that issue.

Jason,

I use the "black" Permatex (very small amount using a toothpick to apply) on either end of the aluminum carb body and have had no problems.

The black Permatex is rubbery and stays that way. I've used it on PAW mufflers to seal the muffler to the head without any leakage.

Nice thing about the car body is that it tapers, so you can get the sealant on the crank case then slide the venturi body up into place.

sosam117- Diamond Member

- Posts : 1350

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Re: Kirn NVA Issues

Re: Kirn NVA Issues

Levent Suberk wrote:In a thread Mauricio made a ring to fit on a cracked venturi. However I couldn't find that thread.

Here I am friend, I will share photos again.

The previous thread is in the forum, but I have not looked for it ...

ring made of aluminum alloy, filed and adapted by hand, glued with epoxy.

Definitive solution, you will never have problems again!

You can do it in bronze too ... I have done it and it gives a very good appearance, especially if the crankcase is black!

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-16

Age : 53

Location : ARG

Re: Kirn NVA Issues

Re: Kirn NVA Issues

here you have an engine Tee Dee .049, to which I made the repair of the crankcase with an aluminum alloy ring and I also made a bronze acceleration ring!

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-16

Age : 53

Location : ARG

Re: Kirn NVA Issues

Re: Kirn NVA Issues

The original carb body was cracked and I happened to have a new black one to replace it with. I don't have much of a spare parts bin. I assumed the red and black ones were the same. I should have explained it a bit more. I will try the fixes you all have posted to have the cracked one for a spare. Sorry about that.

Aero- Silver Member

- Posts : 73

Join date : 2014-08-10

Location : Southern IN

Re: Kirn NVA Issues

Re: Kirn NVA Issues

Just litle trick for plastiques part make them like new use wd40 it help flexibilité of matériel old plastiques part tend To dry if Not used for very long it crack in displays case just spray on part let it wit t'il its dry part gain flexibilité bad point if part is alredy crack is To late it can help new Not used engine plastiques part

davidll1984- Diamond Member

- Posts : 2327

Join date : 2020-02-12

Age : 39

Location : shawinigan

Re: Kirn NVA Issues

Re: Kirn NVA Issues

Another thing to watch for is Dale made venturis with larger id for pressure fuel systems. If all is clear and it draws fuel but doesn't do it well enough to take off and flames out on take off you might check it against a stocker to see if it's oversized.

Chris...

Chris...

stuntflyr- Gold Member

- Posts : 266

Join date : 2012-01-18

Age : 65

Location : Tucson, Arizona

Similar topics

Similar topics» Dale Kirn has passed on

» RC Bee issues

» Kirn Kraft Products- Whats that thing??

» Cool Bonus KK Needle Valve

» Cox Motor Issues

» RC Bee issues

» Kirn Kraft Products- Whats that thing??

» Cool Bonus KK Needle Valve

» Cox Motor Issues

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules