Log in

Search

Latest topics

» My latest doodle...by batjac Today at 10:05 pm

» Retail price mark-up.. how much is enough?

by gkamysz Today at 9:29 pm

» Happy 77th birthday Andrew!

by roddie Today at 9:22 pm

» Roger Harris revisited

by rsv1cox Today at 3:38 pm

» My N-1R build log

by GallopingGhostler Today at 3:04 pm

» Tee Dee .020 combat model

by 1/2A Nut Today at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

Cox Engine of The Month

General Golden Bee Engine Health

Page 1 of 1

General Golden Bee Engine Health

General Golden Bee Engine Health

Have a golden bee that is running seemingly ok. It peaks out at about 15k rpm. After ensuring that the Venturi gasket and pickup tube are in good health. Proceed to fly. After about 1/2 fly time usual for an 8CC tank the motor will burn out the fuel. The engine performance deteriorates a bit as well during it's 50% flight time. I guess I am curious. The compression feels reasonable but not crazy strong. How is a way to determine if the cylinder is too low compression and hotter cylinder is expanding? I've had really bad cylinders before and you could hear them slow down as they heated. However this one feels like it should have enough compression to go the full time.

Any Thoughts?

Thanks

Iceberg

Any Thoughts?

Thanks

Iceberg

Iceberg- Gold Member

- Posts : 382

Join date : 2018-11-03

Location : Suva Fiji Islands

Re: General Golden Bee Engine Health

Re: General Golden Bee Engine Health

Hi Darren,

I believe the thermal expansion will impact the piston and cylinder similarly, they are exposed to similar operating temperatures and made of similar steel materials that have the same or similar thermal expansion coefficients. I do not think the fit will dramatically change when the engine is hot. It is rather the castor oil that gets thin when hot and seals less than when cold. (Although the tapered cylinder bore and piston are known to somewhat improve the high-temp sealing)

I also noted, though with a well used TD that has many hundreds of hours on its clock, that when the plane climbs, the engine will loose some rpm because the increased shaft load will resist the piston thrust and allow more blow-by of gases if the cylinder/piston fit is worn. That engine has a piston with a brown strip of burnt castor around its top, indicating advanced blow-by.

The blow-by losses are significantly less when the engine runs near peak rpm than when you just manually crank it, so an engine that produces blow-by when hand-cranked may still run OK at high speed.. The time for the gases to escape as blow-by in a 1/500 second time lag i.e. while the piston moves downwards at a 15k rpm is just minimal. Even worn engines that can only be started by electric starter may run fine at high rpm and low shaft load. In the mouse race I understand the almost slack piston to cylinder fit is the secret of high engine rpm. https://coxengines.ca/files/MRP.pdf

"Piston Fit: Optimum piston to cylinder fit needs to be checked with parts being absolutely

clean and dry. To check the fit, slide the piston up the cylinder bore (with no finger prints!)

until it sticks. Ideally, it should stick flush with the glow plug land or even slightly higher.

Now with a slight tap of the finger, the piston should fall right out of the cylinder. If the fit is

slightly looser this may be OK, unless starting consistency deteriorates..."

Your problem with the engine running erratically may have something to do with the orientation of the fuel pick-up line in the tank? The fuel pick up in a C/L Bee application should point outwards when looked from the center of the circle.

You may also want to check if the crankcase is not worn along crankshaft due to e.g unbalanced propeller use. The engine heats up and the worn aluminum crankcase will really over-expand the steel shaft and the seal of the crankcase may be compromised, leading to poor charge of the cylinder.

Sorry if I added no-brainer here.

I believe the thermal expansion will impact the piston and cylinder similarly, they are exposed to similar operating temperatures and made of similar steel materials that have the same or similar thermal expansion coefficients. I do not think the fit will dramatically change when the engine is hot. It is rather the castor oil that gets thin when hot and seals less than when cold. (Although the tapered cylinder bore and piston are known to somewhat improve the high-temp sealing)

I also noted, though with a well used TD that has many hundreds of hours on its clock, that when the plane climbs, the engine will loose some rpm because the increased shaft load will resist the piston thrust and allow more blow-by of gases if the cylinder/piston fit is worn. That engine has a piston with a brown strip of burnt castor around its top, indicating advanced blow-by.

The blow-by losses are significantly less when the engine runs near peak rpm than when you just manually crank it, so an engine that produces blow-by when hand-cranked may still run OK at high speed.. The time for the gases to escape as blow-by in a 1/500 second time lag i.e. while the piston moves downwards at a 15k rpm is just minimal. Even worn engines that can only be started by electric starter may run fine at high rpm and low shaft load. In the mouse race I understand the almost slack piston to cylinder fit is the secret of high engine rpm. https://coxengines.ca/files/MRP.pdf

"Piston Fit: Optimum piston to cylinder fit needs to be checked with parts being absolutely

clean and dry. To check the fit, slide the piston up the cylinder bore (with no finger prints!)

until it sticks. Ideally, it should stick flush with the glow plug land or even slightly higher.

Now with a slight tap of the finger, the piston should fall right out of the cylinder. If the fit is

slightly looser this may be OK, unless starting consistency deteriorates..."

Your problem with the engine running erratically may have something to do with the orientation of the fuel pick-up line in the tank? The fuel pick up in a C/L Bee application should point outwards when looked from the center of the circle.

You may also want to check if the crankcase is not worn along crankshaft due to e.g unbalanced propeller use. The engine heats up and the worn aluminum crankcase will really over-expand the steel shaft and the seal of the crankcase may be compromised, leading to poor charge of the cylinder.

Sorry if I added no-brainer here.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: General Golden Bee Engine Health

Re: General Golden Bee Engine Health

Are you launching at peak rpm? If so it may be going lean in flight.

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: General Golden Bee Engine Health

Re: General Golden Bee Engine Health

Keep a spare 5 cc or 10 cc syringe loaded with fuel during your next operating period. Once the engine dies out, try to fill the tank, and record just how much fuel it took to fill.

If the tank takes a short fill, then the fuel pickup is in the wrong spot, or the venturi sealing ring between the backplate and tank has shrunk.

The Paul Gilbert mouse racing engine guide will indicate how to fix both symptoms.

If the tank takes a short fill, then the fuel pickup is in the wrong spot, or the venturi sealing ring between the backplate and tank has shrunk.

The Paul Gilbert mouse racing engine guide will indicate how to fix both symptoms.

944_Jim- Diamond Member

Posts : 2022

Join date : 2017-02-08

Age : 59

Location : NE MS

Re: General Golden Bee Engine Health

Re: General Golden Bee Engine Health

It would be nice to have such a question answered with a simple solution. Unfortunately, that's typically not the scenario. You have offered a very limited amount of information. There were so many variants of golden bee offerings, it's difficult to determine without knowledge of what you have. In other words, your 15k rpm info isn't considerably poor if you own a early single ported golden bee. However, you didn't mention the prop size or type you were using. Engine sag can be a result of various issues such as mismatched parts, air leaks, over propped, too much compression, too much nitro, new or newer engine ( Not run in.) When a reed valve is installed, always check doing a blow and suck test with a syringe on the venturi. You shouldn't be able to withdraw the syringe plunger AT ALL.

In addition, older bees could have congealed castor within the case, it frees up initially, when hot it just robs rpm's. Complete crank removal is a must here and a thorough cleaning. Some of the older thin walled cylinders may have been removed improperly which in turn has somewhat distorted the cylinder just enough to allow it to run but it's actually pinching the piston when heated. I've seen this when the Cox wrench has been used through the exhaust ports.

Integral tanked bees are in my opinion just a huge pain in the rear. I have some that work well but it takes 10 to receive that pleasure. I've experienced brand new engines right out of the box that just wouldn't run a full tank.

The main problem is air leaks, these are a real pain to deal with at times. Don't think that a metal backplate is superior to a plastic one, they're both poor and while one has it's advantages, the other doesn't. Metal backplates crack around the screw bosses as well as the early plastic versions from the 80's. A air test will reveal cracks and I've found them in just as many metal versions vs plastic. Screws leak all the time and this is a bit problematic to fix. The simple fix is to try a new screw not using old ones. When I find a stubborn one, I strip a bit of cotton from a Q-tip and wrap a few strands under the screw head in the same way one applies Teflon tape to avoid it from becoming undone. Sealers can be used provided they're compatible with glow fuel but this makes it much harder to deal with later on. It really is the recommended solution though. Keeping in mind that contractors grade silicone generates acetic acid while curing and this will eat the zinc plating up on the screws in short order. Some of the newer screws are stainless. RTV silicone used by mechanics is the preferred choice.

You can use a piece of dental floss in the v-groove of your tank as a gasket. This is another pain to do but it does work. I use oil to hold it into place. Wearing nitrile gloves prevents the floss from snagging on rough skin and prevents you from pulling it out of the groove. Make certain the proper tubing is being used on the fuel nipple and if needed, wire tie it onto the nipple insuring it's placement. Double check your venturi o-ring seal by running down the needle until it bottoms and pressurize your tank lending your ear to the venturi screen. You will hear it leaking out the screen if the seal is no good. You may hear it from all of the above that I've mentioned.

In addition, older bees could have congealed castor within the case, it frees up initially, when hot it just robs rpm's. Complete crank removal is a must here and a thorough cleaning. Some of the older thin walled cylinders may have been removed improperly which in turn has somewhat distorted the cylinder just enough to allow it to run but it's actually pinching the piston when heated. I've seen this when the Cox wrench has been used through the exhaust ports.

Integral tanked bees are in my opinion just a huge pain in the rear. I have some that work well but it takes 10 to receive that pleasure. I've experienced brand new engines right out of the box that just wouldn't run a full tank.

The main problem is air leaks, these are a real pain to deal with at times. Don't think that a metal backplate is superior to a plastic one, they're both poor and while one has it's advantages, the other doesn't. Metal backplates crack around the screw bosses as well as the early plastic versions from the 80's. A air test will reveal cracks and I've found them in just as many metal versions vs plastic. Screws leak all the time and this is a bit problematic to fix. The simple fix is to try a new screw not using old ones. When I find a stubborn one, I strip a bit of cotton from a Q-tip and wrap a few strands under the screw head in the same way one applies Teflon tape to avoid it from becoming undone. Sealers can be used provided they're compatible with glow fuel but this makes it much harder to deal with later on. It really is the recommended solution though. Keeping in mind that contractors grade silicone generates acetic acid while curing and this will eat the zinc plating up on the screws in short order. Some of the newer screws are stainless. RTV silicone used by mechanics is the preferred choice.

You can use a piece of dental floss in the v-groove of your tank as a gasket. This is another pain to do but it does work. I use oil to hold it into place. Wearing nitrile gloves prevents the floss from snagging on rough skin and prevents you from pulling it out of the groove. Make certain the proper tubing is being used on the fuel nipple and if needed, wire tie it onto the nipple insuring it's placement. Double check your venturi o-ring seal by running down the needle until it bottoms and pressurize your tank lending your ear to the venturi screen. You will hear it leaking out the screen if the seal is no good. You may hear it from all of the above that I've mentioned.

Ken Cook- Top Poster

- Posts : 5637

Join date : 2012-03-27

Location : pennsylvania

Re: General Golden Bee Engine Health

Re: General Golden Bee Engine Health

Reed valve tanked engine can be very persnickety or cantancorus...grin

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: General Golden Bee Engine Health

Re: General Golden Bee Engine Health

Ken Cook wrote:...... Some of the older thin walled cylinders may have been removed improperly which in turn has somewhat distorted the cylinder just enough to allow it to run but it's actually pinching the piston when heated. I've seen this when the Cox wrench has been used through the exhaust ports.......

..and be careful when you describe in your native English how the wrench is applied, because some folks here - former army instructors-may yell at you if you write "through the exhaust port"

https://www.coxengineforum.com/t13698-piston-service-without-cylinder-removal

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: General Golden Bee Engine Health

Re: General Golden Bee Engine Health

I use a strap wrench but I do use THROUGH THE EXHAUST port method. The older jewel case wrenches not the thin black Cox wrenches work well for this. The wrench is actually a quality piece which doesn't bend and it's thicker than the black. The edges have a radius on the inside flats. I use it for thin wall cylinders in conjunction to my strap.

Ken Cook- Top Poster

- Posts : 5637

Join date : 2012-03-27

Location : pennsylvania

Re: General Golden Bee Engine Health

Re: General Golden Bee Engine Health

Thanks, Ken, I agree, the black COX wrenches are too soft and bend, my experience with the silver, galvanized wrenches is much better...

What I was referring to ironically is the preposition one is supposed to use when describing how the wrench is to be applied relative to the exhaust ports..."through" (used by me, a non-native speaker, and by you, a native English speaker) and any other preposition are forbidden, as I was taught there ...ACROSS, as my obviously poor and ridiculous Hunglish was corrected in the other post, is the only acceptable preposition...

Otherwise someone may misunderstand your and my description of how to use the wrench THROUGH the ports, and as the American legend quotes, someone will put a cat into the microwave oven because the manual did not explicitly ban

to do so......

What I was referring to ironically is the preposition one is supposed to use when describing how the wrench is to be applied relative to the exhaust ports..."through" (used by me, a non-native speaker, and by you, a native English speaker) and any other preposition are forbidden, as I was taught there ...ACROSS, as my obviously poor and ridiculous Hunglish was corrected in the other post, is the only acceptable preposition...

Otherwise someone may misunderstand your and my description of how to use the wrench THROUGH the ports, and as the American legend quotes, someone will put a cat into the microwave oven because the manual did not explicitly ban

to do so......

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: General Golden Bee Engine Health

Re: General Golden Bee Engine Health

But "across" is synonym of "through". Isn't it?

Levent Suberk- Diamond Member

- Posts : 2265

Join date : 2017-12-24

Location : Türkiye

Re: General Golden Bee Engine Health

Re: General Golden Bee Engine Health

OK...I'll play:

I crossed the river by:

a) going through the water

b) going across the bridge

c) getting punched in the nose so hard I landed on the other side

Isn't English wonderful? It certainly can be colourful, ummm, colorful.

I just wonder if now would be a good time to indicate this may possibly be covered in one of the Cox manuals hosted here.

I crossed the river by:

a) going through the water

b) going across the bridge

c) getting punched in the nose so hard I landed on the other side

Isn't English wonderful? It certainly can be colourful, ummm, colorful.

I just wonder if now would be a good time to indicate this may possibly be covered in one of the Cox manuals hosted here.

944_Jim- Diamond Member

Posts : 2022

Join date : 2017-02-08

Age : 59

Location : NE MS

Re: General Golden Bee Engine Health

Re: General Golden Bee Engine Health

"Placing wrench on exhaust slits" is right?

Levent Suberk- Diamond Member

- Posts : 2265

Join date : 2017-12-24

Location : Türkiye

Re: General Golden Bee Engine Health

Re: General Golden Bee Engine Health

Placing the wrench into the exhaust is not correct. Can it be done using it, yes if one is careful.

Ken Cook- Top Poster

- Posts : 5637

Join date : 2012-03-27

Location : pennsylvania

944_Jim- Diamond Member

Posts : 2022

Join date : 2017-02-08

Age : 59

Location : NE MS

944_Jim- Diamond Member

Posts : 2022

Join date : 2017-02-08

Age : 59

Location : NE MS

Re: General Golden Bee Engine Health

Re: General Golden Bee Engine Health

For tough cylinders, I prefer heat, lube, the piston up at top of the bore, and wide jaw pliars with a heavy leather wrap between the pliars and the top several fins. The piston at TDC helps prevent squashing the top of the cylinder. My last leather wrap came from a trashed pair of leather work gloves, so I still have 9 "wraps" remaining!

Maybe some day I'll convert the leather wrap into a strap.wrench for just this purpose.

Maybe some day I'll convert the leather wrap into a strap.wrench for just this purpose.

944_Jim- Diamond Member

Posts : 2022

Join date : 2017-02-08

Age : 59

Location : NE MS

Re: General Golden Bee Engine Health

Re: General Golden Bee Engine Health

944_Jim wrote:Keep a spare 5 cc or 10 cc syringe loaded with fuel during your next operating period. Once the engine dies out, try to fill the tank, and record just how much fuel it took to fill.

If the tank takes a short fill, then the fuel pickup is in the wrong spot, or the venturi sealing ring between the backplate and tank has shrunk.

The Paul Gilbert mouse racing engine guide will indicate how to fix both symptoms.

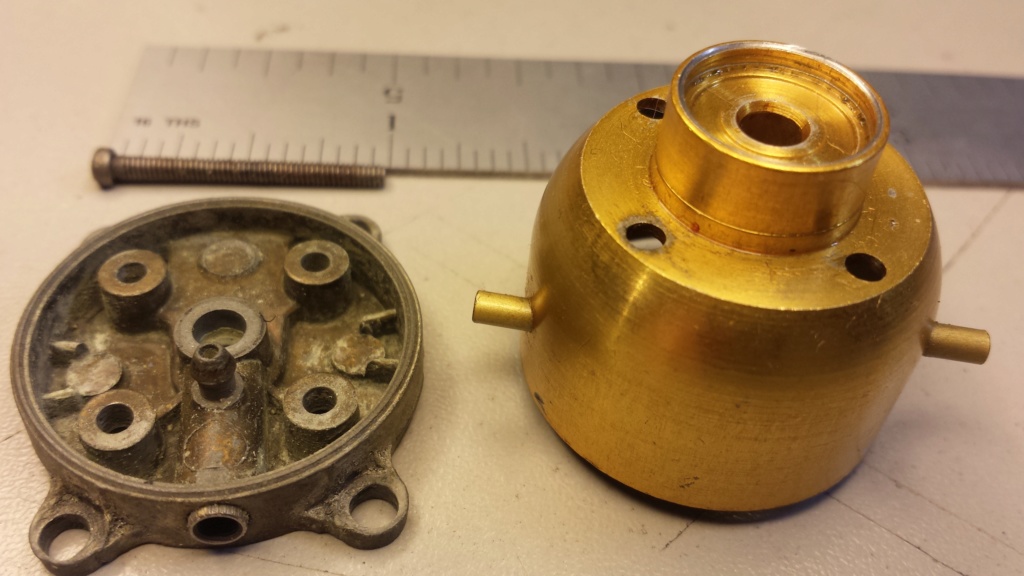

I also, was wondering if you'd actually measured the fuel amounts between runs. The sealing of Cox's 5 and 8cc integral aluminum tank-bowls.. combined with their respective pot-metal back-plates.. is always an area to pay attention to when rebuilding. There's also a venturi-gasket between these two components.

There are four #2-56 x 1" long "Fillister-head' screws that assemble the tank-mount to your Golden Bee engines' crankcase. Where those screw-heads seat as well as all sealing areas, are areas of concern with these integrally-tanked engines.

Leaks (of any kind) are often the cause of erratic running-conditions.. and sometimes only affect the model when it's moving or in flight.

aspeed- Platinum Member

- Posts : 796

Join date : 2013-01-18

Location : Leamington Ont. Can.

Dave P.- Gold Member

- Posts : 477

Join date : 2017-07-31

Age : 67

Location : Durham, NC

Re: General Golden Bee Engine Health

Re: General Golden Bee Engine Health

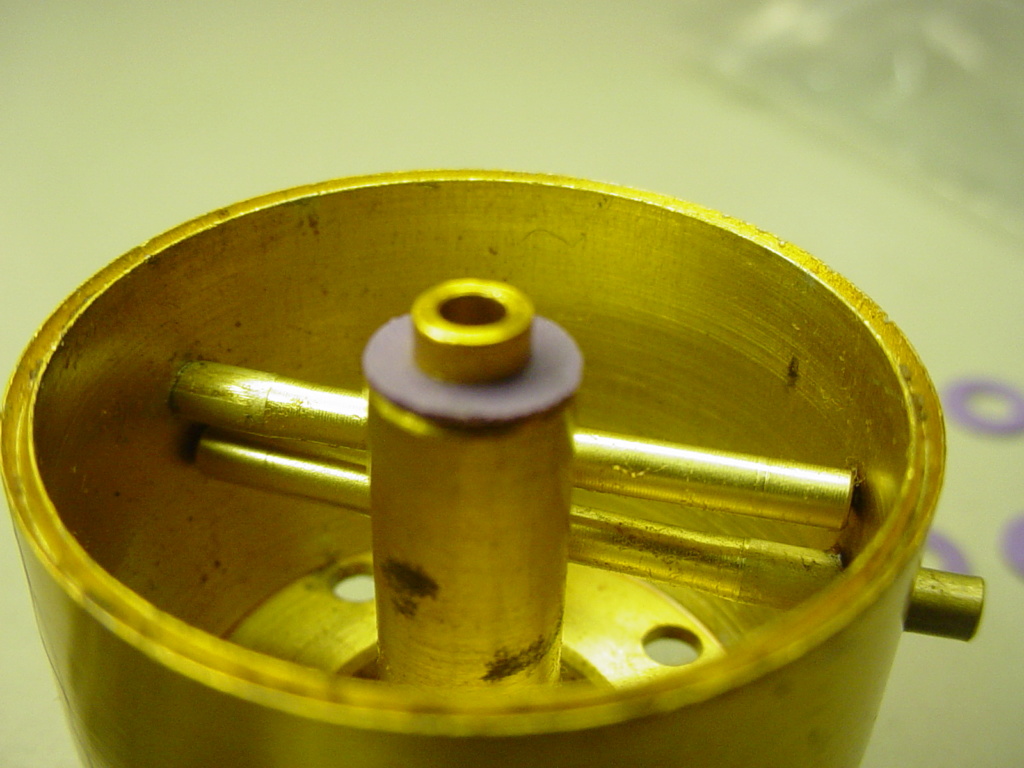

I like that pic. Custom prop driver. Not much compression. I will maybe use the cylinder for machining some ports or something.

aspeed- Platinum Member

- Posts : 796

Join date : 2013-01-18

Location : Leamington Ont. Can.

Re: General Golden Bee Engine Health

Re: General Golden Bee Engine Health

-When dissembling a engine, heat, heat and heat. Hot to the point it would hurt a little to pick up, so not super hot.

-If your gonna use a wrench in exhaust port (get hot/really warm first) add some masking tape to wrench face.

-As a rule of thumb, looser piston/cylinders turn higher than tight ones. Keep piston clean!

-Dart O-rings (2b) make nice gaskets for backplate/tank.

-If your gonna use a wrench in exhaust port (get hot/really warm first) add some masking tape to wrench face.

-As a rule of thumb, looser piston/cylinders turn higher than tight ones. Keep piston clean!

-Dart O-rings (2b) make nice gaskets for backplate/tank.

Re: General Golden Bee Engine Health

Re: General Golden Bee Engine Health

balogh wrote:Hi Darren,

I believe the thermal expansion will impact the piston and cylinder similarly, they are exposed to similar operating temperatures and made of similar steel materials that have the same or similar thermal expansion coefficients. I do not think the fit will dramatically change when the engine is hot. It is rather the castor oil that gets thin when hot and seals less than when cold. (Although the tapered cylinder bore and piston are known to somewhat improve the high-temp sealing)

I also noted, though with a well used TD that has many hundreds of hours on its clock, that when the plane climbs, the engine will loose some rpm because the increased shaft load will resist the piston thrust and allow more blow-by of gases if the cylinder/piston fit is worn. That engine has a piston with a brown strip of burnt castor around its top, indicating advanced blow-by.

The blow-by losses are significantly less when the engine runs near peak rpm than when you just manually crank it, so an engine that produces blow-by when hand-cranked may still run OK at high speed.. The time for the gases to escape as blow-by in a 1/500 second time lag i.e. while the piston moves downwards at a 15k rpm is just minimal. Even worn engines that can only be started by electric starter may run fine at high rpm and low shaft load. In the mouse race I understand the almost slack piston to cylinder fit is the secret of high engine rpm. https://coxengines.ca/files/MRP.pdf

"Piston Fit: Optimum piston to cylinder fit needs to be checked with parts being absolutely

clean and dry. To check the fit, slide the piston up the cylinder bore (with no finger prints!)

until it sticks. Ideally, it should stick flush with the glow plug land or even slightly higher.

Now with a slight tap of the finger, the piston should fall right out of the cylinder. If the fit is

slightly looser this may be OK, unless starting consistency deteriorates..."

Your problem with the engine running erratically may have something to do with the orientation of the fuel pick-up line in the tank? The fuel pick up in a C/L Bee application should point outwards when looked from the center of the circle.

You may also want to check if the crankcase is not worn along crankshaft due to e.g unbalanced propeller use. The engine heats up and the worn aluminum crankcase will really over-expand the steel shaft and the seal of the crankcase may be compromised, leading to poor charge of the cylinder.

Sorry if I added no-brainer here.

yep, 'looser' is better, the piston does seem to expand more then the cylinder and will tighten up somewhat, putting more stress on the ball joint. Also, cleaning up piston periodically removing caster build up will make a big diff.

Similar topics

Similar topics» Cox Golden Bee .049 engine.

» "Racket Is Golden" Bernie's Backplate on a Golden Bee

» General TD 049 Assembly

» Cox Sure Start Engines~General Help With Them!

» Restoring Cox Engines in general

» "Racket Is Golden" Bernie's Backplate on a Golden Bee

» General TD 049 Assembly

» Cox Sure Start Engines~General Help With Them!

» Restoring Cox Engines in general

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules