Log in

Search

Latest topics

» Cox films/videos...by Coxfledgling Today at 4:46 am

» Purchased the last of any bult engines from Ken Enya

by Coxfledgling Today at 4:18 am

» My N-1R build log

by roddie Today at 12:32 am

» Happy 77th birthday Andrew!

by akjgardner Today at 12:27 am

» TEE DEE Having issues

by TD ABUSER Yesterday at 9:43 pm

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» Roger Harris revisited

by TD ABUSER Yesterday at 2:13 pm

» Tee Dee .020 combat model

by Ken Cook Yesterday at 1:41 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Yesterday at 1:37 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 9:24 am

Cox Engine of The Month

any tricks on covering EPS foam with low-heat covering?

Page 1 of 1

any tricks on covering EPS foam with low-heat covering?

any tricks on covering EPS foam with low-heat covering?

I should mention that I have two rolls of "Towerkote".. which could very well be a TopFlite product.. and purchased it direct from Tower-Hobbies in 2012. I haven't used any of it yet.

My principle intended-use is for covering an "Ace" foam-core. Other than light sanding for prep.; should I consider treating the core-surface with anything that would promote better/lasting adhesion? My product is "white". Can it be spray-painted? If so; what would the proper prep. be?

Thanks in advance!

My principle intended-use is for covering an "Ace" foam-core. Other than light sanding for prep.; should I consider treating the core-surface with anything that would promote better/lasting adhesion? My product is "white". Can it be spray-painted? If so; what would the proper prep. be?

Thanks in advance!

Re: any tricks on covering EPS foam with low-heat covering?

Re: any tricks on covering EPS foam with low-heat covering?

Towerkote works on foam however, it can be very short lived. When the seams start peeling, which they will, the top shiny clear plastic comes off. This leaves the color on the surface which begins to smear when fuel hits it.I like to cover leaving the seams just at the leading and trailing edge and cover those with a high quality packing tape. I cut the tape down to 3/4" and iron it down. This is a difficult task due to the packing tape sticking to the covering which can't be repositioned. As with all iron on coverings, smoothness and cleanliness is of the utmost importance. Block sand the foam and use fine paper to smooth it out.

Ken Cook- Top Poster

- Posts : 5640

Join date : 2012-03-27

Location : pennsylvania

Re: any tricks on covering EPS foam with low-heat covering?

Re: any tricks on covering EPS foam with low-heat covering?

Minwax Polycryllic appears to he heat sensitive at the temperatures involved. My results have been rather excellent with adhesive films. The polycryllic will soak into the foam stabilizing and hardening the surface. This does add an amount of weight, so don't over do it.

I have used this with Phil Cartier's SLC over foam and with Monokote on wood. I do not have a lot of flights on any of these planes so I don't know if it has added long term durability.

Phil

I have used this with Phil Cartier's SLC over foam and with Monokote on wood. I do not have a lot of flights on any of these planes so I don't know if it has added long term durability.

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: any tricks on covering EPS foam with low-heat covering?

Re: any tricks on covering EPS foam with low-heat covering?

Prep is important.

Filling the Foam "Grain" is a tedious process* to "TRY" to end up with a film covered panel that does not have the Foam bead pattern... a lot like we TRY to fill balsa or other wood so not see the grain

On the combat planes I did not care so just covered the sanded raw foam. BUT learned a hard lesson...if you fail to blow/suck/wipe and wipe again...ALL the dust off the panel.... the covering will not adhere properly

Good clean dust free area to start. Static of the film and static of the foam wings (as they get wiped down) attracts a lot of dust and goobers

I found after trying first to do normal adhering (corners, middle, edges of the perimeter) that too much air gets trapped in the middle areas even leaving various escape openings in the perimeter

Now I lay film out the panel and tape it down near the root /fuselage line... then start gluing it down in the middle and work toward the edges....hot enough to stick and not so hot it shrinks the film.. solves 99% of any trapped air problems

If you linger too long, and put too much pressure on an area, the foam beads shrink away from each other and you WILL see the grain of the foam in the film

* Filling the grain

I read Phil Cartier's method in the instruction for the Rigged Stunt Trainers... a mix of light weight Spackle thinned with water based polyurethane varnish the was thinned 50% with denatured alcohol then slathered on, scrapped thin/off, and once dry, sanded off. This worked perfect on one plane ---and was a grand mess on another.

Seems all light weight Spackle is not the same. Some brands dry nice and hard just like sheet rock and sand very easy.... even when thinned some----- other brands have some additive or something in the formula that used straight on a wall as intended...they dry and sand just fine....BUT right out of the tub are very hard to smooth in a thin layer on the panel .... thinning with the varnish alcohol mix just makes it rubbery and NEVER dry enough to be sand able

I have used different brands of light weight Spackle and least trouble was the DAP product...I think Red Devil was the brand I had trouble with

Filling the Foam "Grain" is a tedious process* to "TRY" to end up with a film covered panel that does not have the Foam bead pattern... a lot like we TRY to fill balsa or other wood so not see the grain

On the combat planes I did not care so just covered the sanded raw foam. BUT learned a hard lesson...if you fail to blow/suck/wipe and wipe again...ALL the dust off the panel.... the covering will not adhere properly

Good clean dust free area to start. Static of the film and static of the foam wings (as they get wiped down) attracts a lot of dust and goobers

I found after trying first to do normal adhering (corners, middle, edges of the perimeter) that too much air gets trapped in the middle areas even leaving various escape openings in the perimeter

Now I lay film out the panel and tape it down near the root /fuselage line... then start gluing it down in the middle and work toward the edges....hot enough to stick and not so hot it shrinks the film.. solves 99% of any trapped air problems

If you linger too long, and put too much pressure on an area, the foam beads shrink away from each other and you WILL see the grain of the foam in the film

* Filling the grain

I read Phil Cartier's method in the instruction for the Rigged Stunt Trainers... a mix of light weight Spackle thinned with water based polyurethane varnish the was thinned 50% with denatured alcohol then slathered on, scrapped thin/off, and once dry, sanded off. This worked perfect on one plane ---and was a grand mess on another.

Seems all light weight Spackle is not the same. Some brands dry nice and hard just like sheet rock and sand very easy.... even when thinned some----- other brands have some additive or something in the formula that used straight on a wall as intended...they dry and sand just fine....BUT right out of the tub are very hard to smooth in a thin layer on the panel .... thinning with the varnish alcohol mix just makes it rubbery and NEVER dry enough to be sand able

I have used different brands of light weight Spackle and least trouble was the DAP product...I think Red Devil was the brand I had trouble with

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: any tricks on covering EPS foam with low-heat covering?

Re: any tricks on covering EPS foam with low-heat covering?

Filling the grain of the foam is overrated. Well, in my opinion at least. I break stuff too fast.

However after sanding, vacuuming, wiping, vacuuming, wiping again... etc, a coat of polycryllic seals all that pesky dust in place never to bother you again.

Phil

However after sanding, vacuuming, wiping, vacuuming, wiping again... etc, a coat of polycryllic seals all that pesky dust in place never to bother you again.

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: any tricks on covering EPS foam with low-heat covering?

Re: any tricks on covering EPS foam with low-heat covering?

fredvon4 wrote:Prep is important.

Filling the Foam "Grain" is a tedious process* to "TRY" to end up with a film covered panel that does not have the Foam bead pattern... a lot like we TRY to fill balsa or other wood so not see the grain

On the combat planes I did not care so just covered the sanded raw foam. BUT learned a hard lesson...if you fail to blow/suck/wipe and wipe again...ALL the dust off the panel.... the covering will not adhere properly

Good clean dust free area to start. Static of the film and static of the foam wings (as they get wiped down) attracts a lot of dust and goobers

I found after trying first to do normal adhering (corners, middle, edges of the perimeter) that too much air gets trapped in the middle areas even leaving various escape openings in the perimeter

Now I lay film out the panel and tape it down near the root /fuselage line... then start gluing it down in the middle and work toward the edges....hot enough to stick and not so hot it shrinks the film.. solves 99% of any trapped air problems

If you linger too long, and put too much pressure on an area, the foam beads shrink away from each other and you WILL see the grain of the foam in the film

* Filling the grain

I read Phil Cartier's method in the instruction for the Rigged Stunt Trainers... a mix of light weight Spackle thinned with water based polyurethane varnish the was thinned 50% with denatured alcohol then slathered on, scrapped thin/off, and once dry, sanded off. This worked perfect on one plane ---and was a grand mess on another.

Seems all light weight Spackle is not the same. Some brands dry nice and hard just like sheet rock and sand very easy.... even when thinned some----- other brands have some additive or something in the formula that used straight on a wall as intended...they dry and sand just fine....BUT right out of the tub are very hard to smooth in a thin layer on the panel .... thinning with the varnish alcohol mix just makes it rubbery and NEVER dry enough to be sand able

I have used different brands of light weight Spackle and least trouble was the DAP product...I think Red Devil was the brand I had trouble with

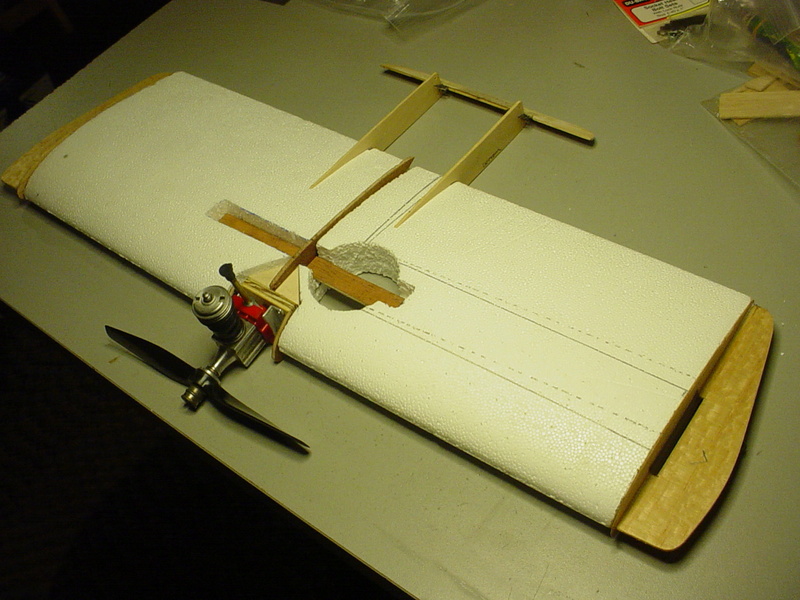

Thanks Phred! My query is in regards to "Phred's Phault"... which I'm hell-bent on finishing. I "will" need to cover the wing.. because of the sections that I routed-out.. and also the built-up balsa wing-tips.

I'm not sure what to do with the bell-crank pocket and lead-out channel.

I need to "bridge" that channel.. so that the covering conforms the airfoil. The tip-rib will help.. but only at the tip. I have a lot to work-out before covering.. but want to know what does and doesn't work, in order to proceed in some areas of construction. I only need "shrinking" covering for the wing-tips.. and would rather not apply any heat to the foam-structure.. if I can help it.

Besides using the Towerkote.. I also asked if it could be painted.. and haven't gotten any info on that yet. My preferred-choice of colors for this model is an antique-white.. or "cream/beige" base-color, with burgundy trim/ tail-feathers. I have burgundy "MonoKote" that I could finish the balsa wing-tips with.. before I install them.

As for the foam-wing....

there's that bell-crank pocket and lead-out channel that I need to cover. I was wondering whether "tissue" (silkspan.. of which I have a lot of..) could be applied to the foam, using thinned white-glue (??) enough to create a barrier to accept a rattle-can paint-finish that might otherwise attack the foam??

there's that bell-crank pocket and lead-out channel that I need to cover. I was wondering whether "tissue" (silkspan.. of which I have a lot of..) could be applied to the foam, using thinned white-glue (??) enough to create a barrier to accept a rattle-can paint-finish that might otherwise attack the foam??  Re: any tricks on covering EPS foam with low-heat covering?

Re: any tricks on covering EPS foam with low-heat covering?

pkrankow wrote:Filling the grain of the foam is overrated. Well, in my opinion at least. I break stuff too fast.

However after sanding, vacuuming, wiping, vacuuming, wiping again... etc, a coat of polycryllic seals all that pesky dust in place never to bother you again.

Phil

I want to test the MinWax Poly-crylic product Phil. It is available in an aerosol. If you read my last post; I ask about the viability of applying/adhering "tissue" as opposed to heat-shrink film; over areas that require a "bridge".. and also being able to spray-paint a color of my choice.. without it attacking the raw-foam. I'm not real concerned with "filling the foam-grain" either.. but if I can manage it.. and kill "three" birds with one stone.. why not try? Weight is obviously a factor.. but I need to cover certain areas.. and I also want to paint a custom-color.. not available in a low-heat film.

Re: any tricks on covering EPS foam with low-heat covering?

Re: any tricks on covering EPS foam with low-heat covering?

Paint on top of a lot of films works with the correct prep

LusterCote was designed to be color matching to MonoKote

I prefer to paint the underlying plane and cover with clear Super Lite Covering SLC from Phil Cartier Core House.. cheap and easy to use

On that small a plane I would just cover the wing and ignore the cutout out areas...we core big holes in combat wings all the time to lighten and just cover over the open hole... yes the airfoil is flat in that area

Many guys manage to spray paint over films with good de wax de grease and light scuff with scotch brite green pad the clean again and paint.... one problem seem to recur...masking to add other colors has the tape usually lifting the first paint layer off if not real careful on how it is pulled

Of course all this adds a lot of weight

Some guys go get a free sample pint of some color at Home depot or Lowe's...say Cream colored latex house paint... paint the plane and cover in clear...SLC or docuLam hint

Yes Virginia Latex un thinned can be rather heavy

LusterCote was designed to be color matching to MonoKote

I prefer to paint the underlying plane and cover with clear Super Lite Covering SLC from Phil Cartier Core House.. cheap and easy to use

On that small a plane I would just cover the wing and ignore the cutout out areas...we core big holes in combat wings all the time to lighten and just cover over the open hole... yes the airfoil is flat in that area

Many guys manage to spray paint over films with good de wax de grease and light scuff with scotch brite green pad the clean again and paint.... one problem seem to recur...masking to add other colors has the tape usually lifting the first paint layer off if not real careful on how it is pulled

Of course all this adds a lot of weight

Some guys go get a free sample pint of some color at Home depot or Lowe's...say Cream colored latex house paint... paint the plane and cover in clear...SLC or docuLam hint

Yes Virginia Latex un thinned can be rather heavy

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: any tricks on covering EPS foam with low-heat covering?

Re: any tricks on covering EPS foam with low-heat covering?

I like the idea of the SLC.. I read a little about it tonight over on Stunthanger. A 10ft. $6 sample-piece from the Corehouse is all I'd need.

Thanks again Phred!

Thanks again Phred!

Similar topics

Similar topics» Foam wing iron on covering

» Removing covering over covering or One bad bird!

» Cox engine tips and tricks.

» Tips and Tricks -- what has worked well for you.

» Removing seized glow head...any tricks?

» Removing covering over covering or One bad bird!

» Cox engine tips and tricks.

» Tips and Tricks -- what has worked well for you.

» Removing seized glow head...any tricks?

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules