Log in

Search

Latest topics

» Purchased the last of any bult engines from Ken Enyaby Coxfledgling Today at 4:18 am

» My N-1R build log

by roddie Today at 12:32 am

» Happy 77th birthday Andrew!

by akjgardner Today at 12:27 am

» TEE DEE Having issues

by TD ABUSER Yesterday at 9:43 pm

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» Roger Harris revisited

by TD ABUSER Yesterday at 2:13 pm

» Tee Dee .020 combat model

by Ken Cook Yesterday at 1:41 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Yesterday at 1:37 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

Cox Engine of The Month

Tips and Tricks -- what has worked well for you.

Page 1 of 1

Tips and Tricks -- what has worked well for you.

Tips and Tricks -- what has worked well for you.

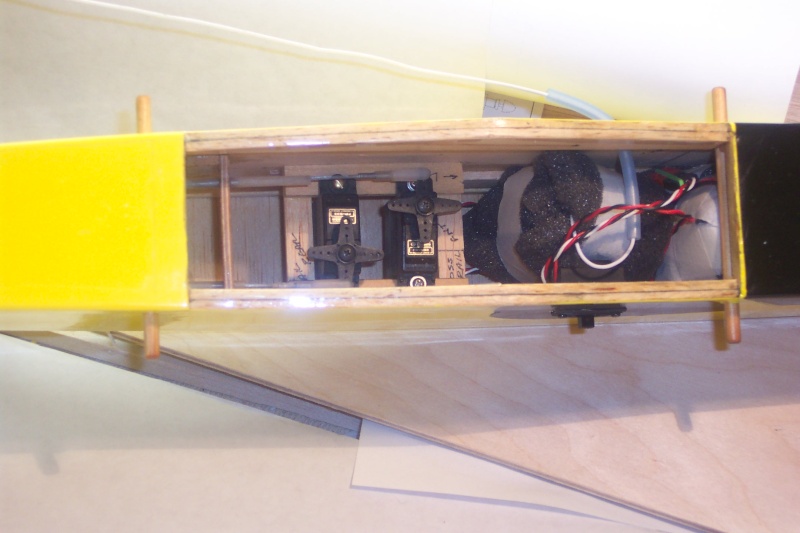

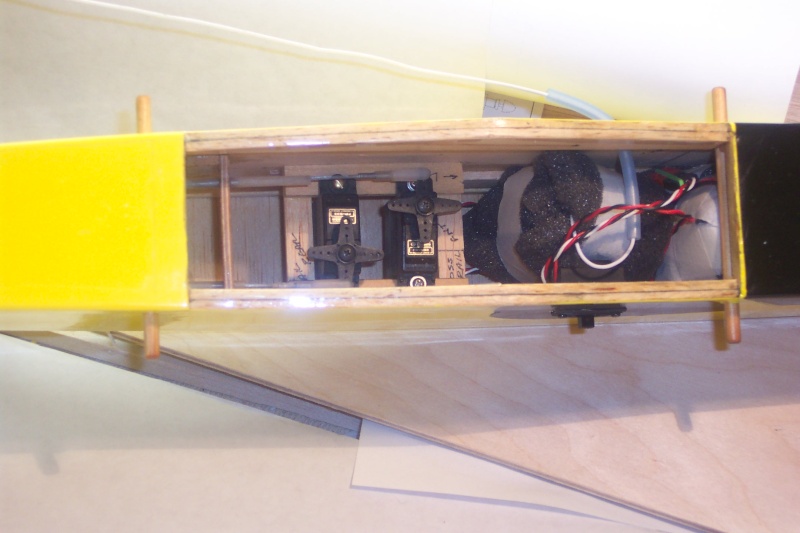

Over the years, I've replaced a number of 72 MHz Rx antennas for friends and club members. Some were broken due to crashes or collisions; some stress fractured due to vibration fatigue. With the introduction of 2.4GHz radios, most antenna problems have disappeared, but many of us are still flying with 72 MHz radios. Here's a couple of things I do to help reduce antenna breakage.

1. Stress fractures usually occur where the antenna makes a sharp bend and is either subjected to micro-bending or being pulled over a sharp edge. On all my planes where the antenna exits the fuselage, I run it thru a length of silicone fuel tubing. This gives the antenna a smooth exit radius and keeps it from being subjected to bending fatigue.

2. I don't like to have the entire length of the antenna flopping in the breeze while flying. A short portion is OK, but not the whole antenna. After the plane is finished, use a sharpened 1/8" OD brass tube to drill a vertical hole thru the leading edge of the stabilizer near the stab tip on the side of the antenna exit hole. Glue (CA works fine here) a piece of 1/8" dowel into the hole so it's flush with the bottom of the stab and protrudes about 1/4" out the top. Push a length of silicone fuel tubing over the dowel leaving about 3/16" extended beyond the end of the dowel --- you can experiment with dowel and tubing lengths to find what works best for you. I use a large darning needle to punch a hole all the way thru the fuel tubing. Push the end of your antenna thru this hole (this is the hardest part) and pull from the other side until most of the slack is taken out. The silicone tubing will have enough grip on the antenna to hold it in place, but it can easily pull free if the plane crashes or hits an object. I think this works better than rubber banding the end in place (bands tend to deteriorate quickly in the sun) and it just looks better.

1. Stress fractures usually occur where the antenna makes a sharp bend and is either subjected to micro-bending or being pulled over a sharp edge. On all my planes where the antenna exits the fuselage, I run it thru a length of silicone fuel tubing. This gives the antenna a smooth exit radius and keeps it from being subjected to bending fatigue.

2. I don't like to have the entire length of the antenna flopping in the breeze while flying. A short portion is OK, but not the whole antenna. After the plane is finished, use a sharpened 1/8" OD brass tube to drill a vertical hole thru the leading edge of the stabilizer near the stab tip on the side of the antenna exit hole. Glue (CA works fine here) a piece of 1/8" dowel into the hole so it's flush with the bottom of the stab and protrudes about 1/4" out the top. Push a length of silicone fuel tubing over the dowel leaving about 3/16" extended beyond the end of the dowel --- you can experiment with dowel and tubing lengths to find what works best for you. I use a large darning needle to punch a hole all the way thru the fuel tubing. Push the end of your antenna thru this hole (this is the hardest part) and pull from the other side until most of the slack is taken out. The silicone tubing will have enough grip on the antenna to hold it in place, but it can easily pull free if the plane crashes or hits an object. I think this works better than rubber banding the end in place (bands tend to deteriorate quickly in the sun) and it just looks better.

Re: Tips and Tricks -- what has worked well for you.

Re: Tips and Tricks -- what has worked well for you.

You can also (if room permits) spot glue an antenna tube inside the fuse and run the antenna through the tube and out of the bottom so you have bare minimum antenna hanging out of the fuse.

Here is an easy tip, when building planes with thinner control surfaces is to use Monokote for the hinges. It works and looks great. I have been doing that for the last 25 or so years and have never had an issue.

When your gluing in piano style hinges, use a straw to blow glue into the hinge slots. It's clean, simple and you don't have to worry about glue getting into the hinge pin.

Another way to cover with tissue if you don't have any Dope is to thin down some Elmer's White glue or equivalent with water, then use a small paint brush or Q-Tips to paint the thinned down glue onto the structure your covering. Then lay the tissue in place, then lightly spray the tissue with a spray bottle of water and then use a hair dryer on low speed to dry the tissue and watch it stretch. Then once dry, you can paint it with what ever colors you want. This technique is also kid / beginner friendly and you don't have that strong odor that Dope paint's have.

If you use rubber bands to hold the wing on your plane, you can recycle the rubber bands by washing them in Dawn dish soap and drying them with some paper towels. Once dry, put them into a small plastic Zip Lock container with some baby powder. Put the lid on the container, shake the rubber bands and powder and store them in the powder until your ready to use them again. A box of #64 rubber bands can last me up to 4 flying seasons.

I'll post more tips as I remember them LOL

Shawn

Here is an easy tip, when building planes with thinner control surfaces is to use Monokote for the hinges. It works and looks great. I have been doing that for the last 25 or so years and have never had an issue.

When your gluing in piano style hinges, use a straw to blow glue into the hinge slots. It's clean, simple and you don't have to worry about glue getting into the hinge pin.

Another way to cover with tissue if you don't have any Dope is to thin down some Elmer's White glue or equivalent with water, then use a small paint brush or Q-Tips to paint the thinned down glue onto the structure your covering. Then lay the tissue in place, then lightly spray the tissue with a spray bottle of water and then use a hair dryer on low speed to dry the tissue and watch it stretch. Then once dry, you can paint it with what ever colors you want. This technique is also kid / beginner friendly and you don't have that strong odor that Dope paint's have.

If you use rubber bands to hold the wing on your plane, you can recycle the rubber bands by washing them in Dawn dish soap and drying them with some paper towels. Once dry, put them into a small plastic Zip Lock container with some baby powder. Put the lid on the container, shake the rubber bands and powder and store them in the powder until your ready to use them again. A box of #64 rubber bands can last me up to 4 flying seasons.

I'll post more tips as I remember them LOL

Shawn

sdjjadk- Platinum Member

- Posts : 640

Join date : 2012-04-07

Location : Southern Maryland

Re: Tips and Tricks -- what has worked well for you.

Re: Tips and Tricks -- what has worked well for you.

Glad press-and-seal for covering plans and the pinboard prior to gluing. Glue releases well and it peels off the plans easily.

Phil

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: Tips and Tricks -- what has worked well for you.

Re: Tips and Tricks -- what has worked well for you.

Phil:

I've contributed a lot of "Tips for Newbs" over the past several years.

Don't know if they could be retreived ot not.

I've contributed a lot of "Tips for Newbs" over the past several years.

Don't know if they could be retreived ot not.

SuperDave- Rest In Peace

- Posts : 3552

Join date : 2011-08-13

Location : Washington (state)

Similar topics

Similar topics» Cox engine tips and tricks.

» Tips and tricks for getting that tinyt fuel line on the tiny fitting on the back of all.049s HELP!

» Saturday Morning Hijinks Out in the Shop...It Works...

» Looking for tips

» I don't think it worked.

» Tips and tricks for getting that tinyt fuel line on the tiny fitting on the back of all.049s HELP!

» Saturday Morning Hijinks Out in the Shop...It Works...

» Looking for tips

» I don't think it worked.

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules