Log in

Search

Latest topics

» Cox films/videos...by Coxfledgling Today at 4:46 am

» Purchased the last of any bult engines from Ken Enya

by Coxfledgling Today at 4:18 am

» My N-1R build log

by roddie Today at 12:32 am

» Happy 77th birthday Andrew!

by akjgardner Today at 12:27 am

» TEE DEE Having issues

by TD ABUSER Yesterday at 9:43 pm

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» Roger Harris revisited

by TD ABUSER Yesterday at 2:13 pm

» Tee Dee .020 combat model

by Ken Cook Yesterday at 1:41 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Yesterday at 1:37 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 9:24 am

Cox Engine of The Month

Building light and strong.

Page 1 of 1

Building light and strong.

Building light and strong.

I have never been a fan of ARF planes but sometimes it is too tempting and easy to just order one covered and almost ready to fly. I have a Thunder Tiger Scooter that has always been surprisingly tailheavy, and I've never really understood why. But as I wanted to change the tailfeathers, to larger controll surfaces, I though that I would do some weight comparisons. The result is quite an eye opener, and I just thought I would share the results here.

The stock stabiliser is made from one sheet of balsa that has been drilled out in order to save weight (but it also makes it a lot weaker). I've now made a built up version with the same thickness of the balsa, but a slightly larger total area as I have increased the control surface.

Here is the stock one 24g (about 0.85 oz);

Here is the replacement with the same thickness of the balsa (not even handpicked for quality/weight) at 14g (about 0.5 oz)

I guess one shouldn't really be surprised at this, but it shows why scratch built planes in general will be so much lighter and fly better.

Looking at the distance to CG, saving 10g at the tail will correspond to more than twice that mass in the front of the plane. So without moving the CG one could in theory reduce the total weight by more than 30g ( >1oz).

The stock stabiliser is made from one sheet of balsa that has been drilled out in order to save weight (but it also makes it a lot weaker). I've now made a built up version with the same thickness of the balsa, but a slightly larger total area as I have increased the control surface.

Here is the stock one 24g (about 0.85 oz);

Here is the replacement with the same thickness of the balsa (not even handpicked for quality/weight) at 14g (about 0.5 oz)

I guess one shouldn't really be surprised at this, but it shows why scratch built planes in general will be so much lighter and fly better.

Looking at the distance to CG, saving 10g at the tail will correspond to more than twice that mass in the front of the plane. So without moving the CG one could in theory reduce the total weight by more than 30g ( >1oz).

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Building light and strong.

Re: Building light and strong.

Your newly rebuilt stab is similar in construction to a method I've applied to several of my sheet-wing designs with good success.

When I designed/scratch-built some of my 1/2A C/L airplanes which "would-be" sheet-wing type models, I applied flat-framed construction rather than using large-solid sheets to make-up the span/chord of the wing. This naturally requires "covering".. but results in a lighter-weight and warp-free construction.

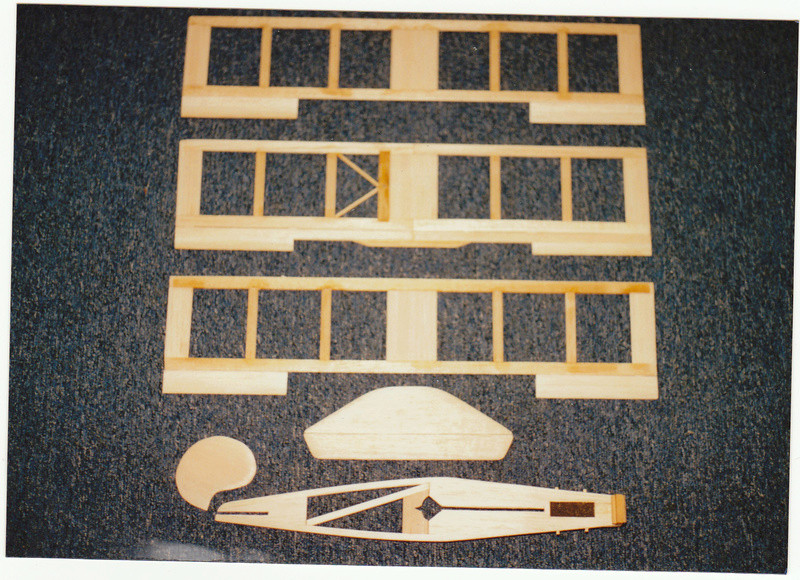

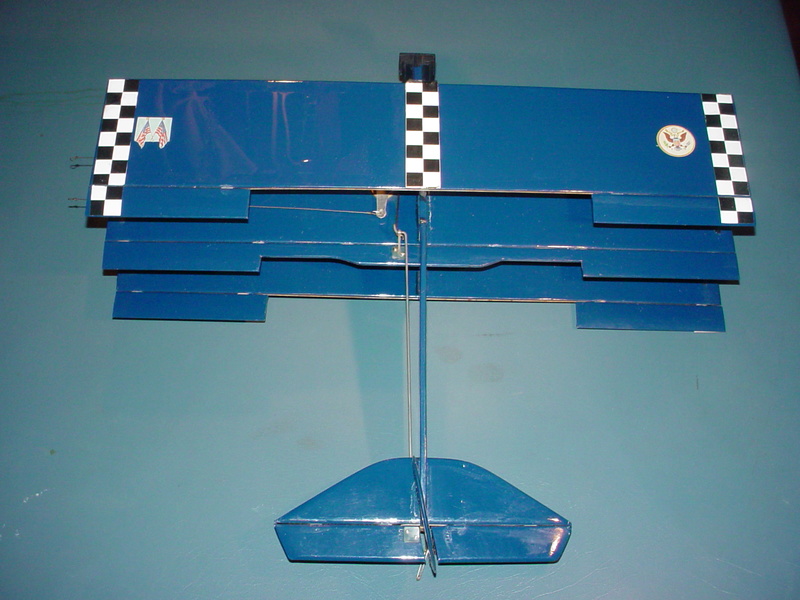

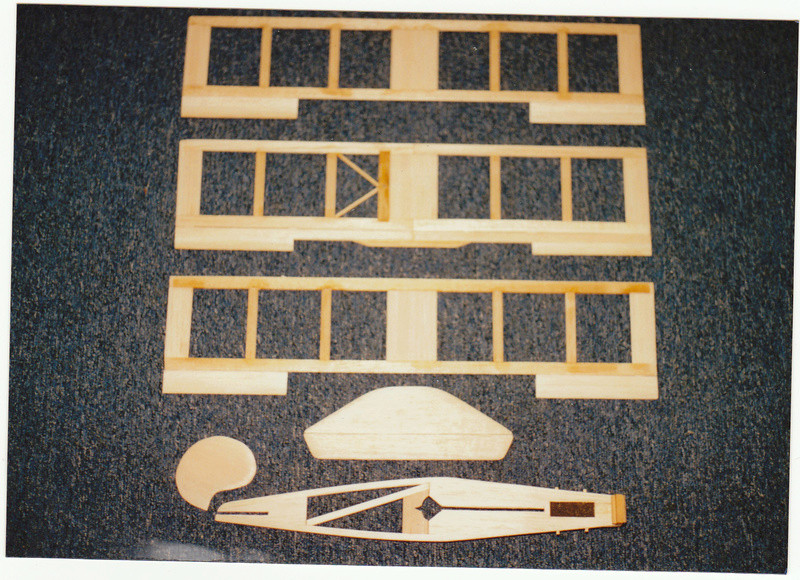

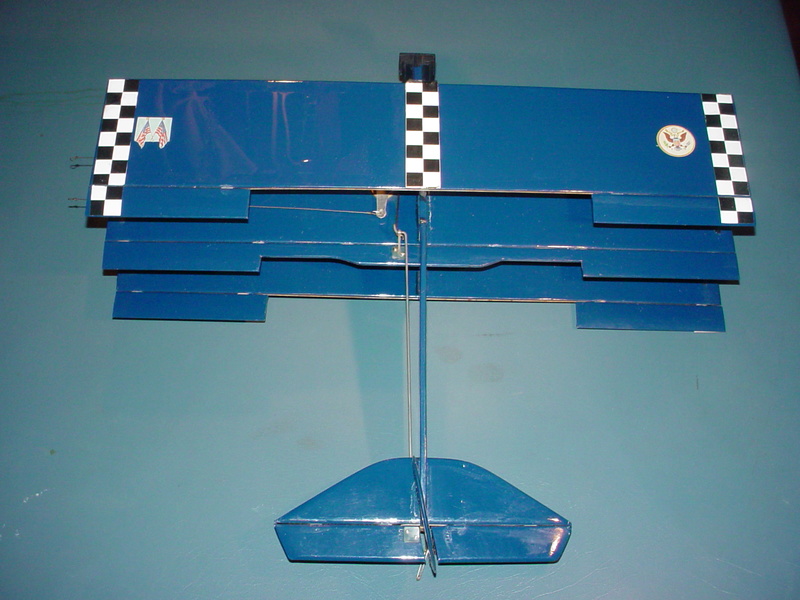

I built this triplane using that technique. The perpendicular bracing running chord-wise along with the wingtips, keeps the wings from warping.. and the entire wing uses "strips" of wood; maximizing the amount of wood in a sheet.

Those 1/8 (3mm) balsa-frames were built over a glass-platen by assembling/establishing the "perimeter" first.. along with the bellcrank-platform which is plywood and dado-jointed into the L/E and T/E. The remaining bracing is then fitted-in using simple butt-joints. CA glue provides for rapid-assembly.

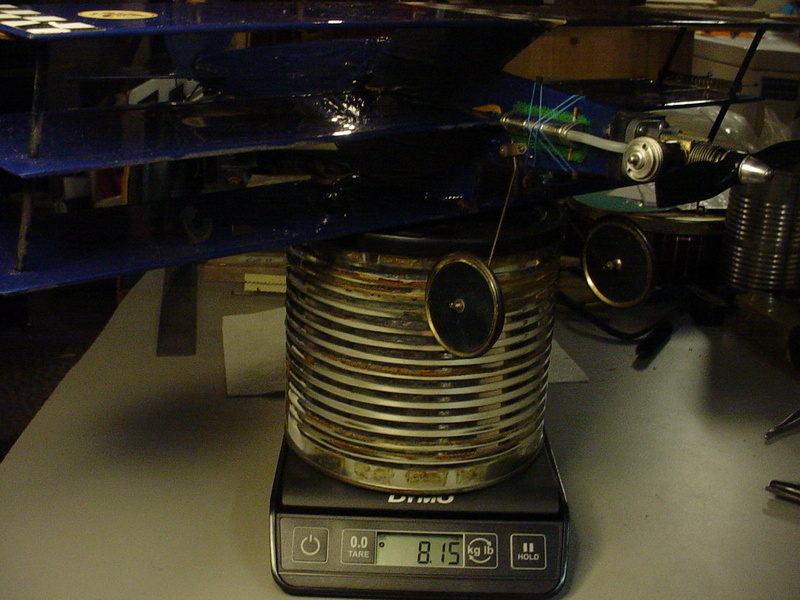

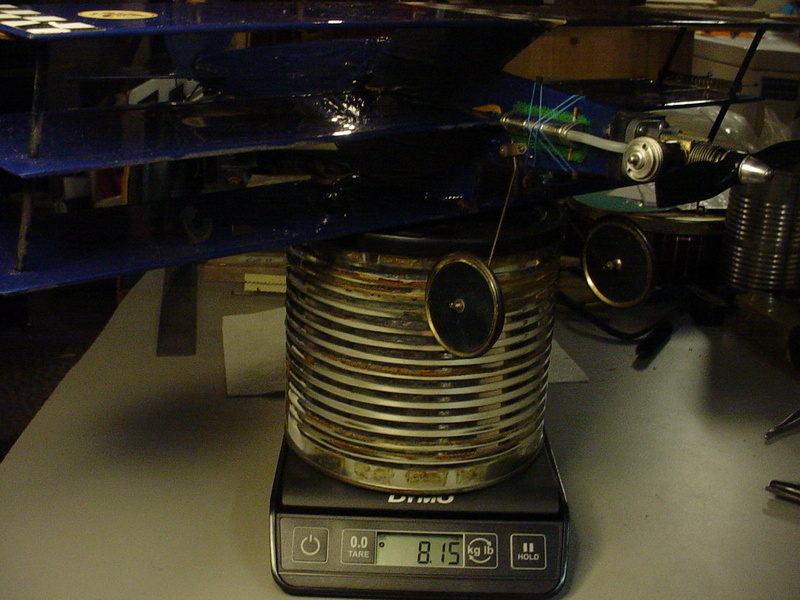

The models' RTF weight (8.15oz.) is fairly light for a triplane having 240 total inches of wing-area. (20" span/4" chord)

ARF's are great for modelers with time-constraints.. but building your own assemblies can almost always yield a better structure having hand-selected materials.. and the assurance that it was assembled with care.

When I designed/scratch-built some of my 1/2A C/L airplanes which "would-be" sheet-wing type models, I applied flat-framed construction rather than using large-solid sheets to make-up the span/chord of the wing. This naturally requires "covering".. but results in a lighter-weight and warp-free construction.

I built this triplane using that technique. The perpendicular bracing running chord-wise along with the wingtips, keeps the wings from warping.. and the entire wing uses "strips" of wood; maximizing the amount of wood in a sheet.

Those 1/8 (3mm) balsa-frames were built over a glass-platen by assembling/establishing the "perimeter" first.. along with the bellcrank-platform which is plywood and dado-jointed into the L/E and T/E. The remaining bracing is then fitted-in using simple butt-joints. CA glue provides for rapid-assembly.

The models' RTF weight (8.15oz.) is fairly light for a triplane having 240 total inches of wing-area. (20" span/4" chord)

ARF's are great for modelers with time-constraints.. but building your own assemblies can almost always yield a better structure having hand-selected materials.. and the assurance that it was assembled with care.

Re: Building light and strong.

Re: Building light and strong.

I have often wondered about lightening holes like on the original stab. They make the construction a lot weaker but not much lighter. Holes are fine and beneficial with cross-laminated sheets such as plywood, or with metal, but plain wood has its grain direction as we all know.

Nice work with the new stab Kris. Looks a lot more like a proper model airplane.

Nice work with the new stab Kris. Looks a lot more like a proper model airplane.

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Re: Building light and strong.

Re: Building light and strong.

On a few planes... once built and covered, I discovered the engine of choice needed lead in the aft to balance....

I loath adding lead, so I remade the Rudder, elevators with heavier wood

And like a lot of us, I ended the other direction because of a too light engine...for the design.. tail heavy

That is where my stash of proper grain Contest balsa from Stunt Hanger Hobby (Tom Morris) gets used

The very best builders pre plan a lot of this up front and select the wood and finish to be very close

A few fuss with changing nose or aft fuse length

I am not gifted enough to do the math first... mostly because I have no consistent finishing technique

Rustoleum over papered, filled, sanded, and primed balsa...vs filled, sanded, and plastic, VS CF, filled, sanded, and dope.... I have no earthly clue what final weight back there will be...

I loath adding lead, so I remade the Rudder, elevators with heavier wood

And like a lot of us, I ended the other direction because of a too light engine...for the design.. tail heavy

That is where my stash of proper grain Contest balsa from Stunt Hanger Hobby (Tom Morris) gets used

The very best builders pre plan a lot of this up front and select the wood and finish to be very close

A few fuss with changing nose or aft fuse length

I am not gifted enough to do the math first... mostly because I have no consistent finishing technique

Rustoleum over papered, filled, sanded, and primed balsa...vs filled, sanded, and plastic, VS CF, filled, sanded, and dope.... I have no earthly clue what final weight back there will be...

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: Building light and strong.

Re: Building light and strong.

Yes, with high quality "competition grade" balsa I'm sure one can improve on this even further. Here I just took a sheet that I had laying around and used the softer part for cutting the wood strips.

The finishing method is also important for the final weight. I did weight the wooden structure before covering, and while my scale is not very accurate it showed about 11g before covering and 14g after covering. So the Oralight covering used here doesn't add much weight. I have also used this covering a lot in the past, it is easy to work with and one can combine it fully opaque patches for more colour.

Below is an example of that, it is a "Yellow Jacket" from Morris Hobbies that came out at about 10oz with a Norvel .061 engine in the front (a little higher weight with the Cox .05RC engine shown below). It has the best vertical performance that I have ever had in a 1/2a plane.

The finishing method is also important for the final weight. I did weight the wooden structure before covering, and while my scale is not very accurate it showed about 11g before covering and 14g after covering. So the Oralight covering used here doesn't add much weight. I have also used this covering a lot in the past, it is easy to work with and one can combine it fully opaque patches for more colour.

Below is an example of that, it is a "Yellow Jacket" from Morris Hobbies that came out at about 10oz with a Norvel .061 engine in the front (a little higher weight with the Cox .05RC engine shown below). It has the best vertical performance that I have ever had in a 1/2a plane.

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Building light and strong.

Re: Building light and strong.

You know home built is the best and sometimes they just come out right to perfection for the flyer,,, Nice looking aeroplane !!It has the best vertical performance that I have ever had in a 1/2a plane. Smile wrote:

getback- Top Poster

Posts : 10442

Join date : 2013-01-18

Age : 67

Location : julian , NC

Similar topics

Similar topics» Ring Master Gold KIt

» Cox Space Station

» Another proposed design by Roddie

» My N-1R build log

» Glow Plugs Weak Or Strong

» Cox Space Station

» Another proposed design by Roddie

» My N-1R build log

» Glow Plugs Weak Or Strong

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules