Log in

Search

Latest topics

» Tee Dee .020 combat modelby roddie Today at 1:34 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» My latest doodle...

by batjac Yesterday at 9:47 pm

» My N-1R build log

by roddie Yesterday at 8:50 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

» My current avatar photo

by roddie Mon Nov 18, 2024 9:05 pm

Cox Engine of The Month

Thanks again rsv1cox "Bob"

Page 1 of 1

Thanks again rsv1cox "Bob"

Thanks again rsv1cox "Bob"

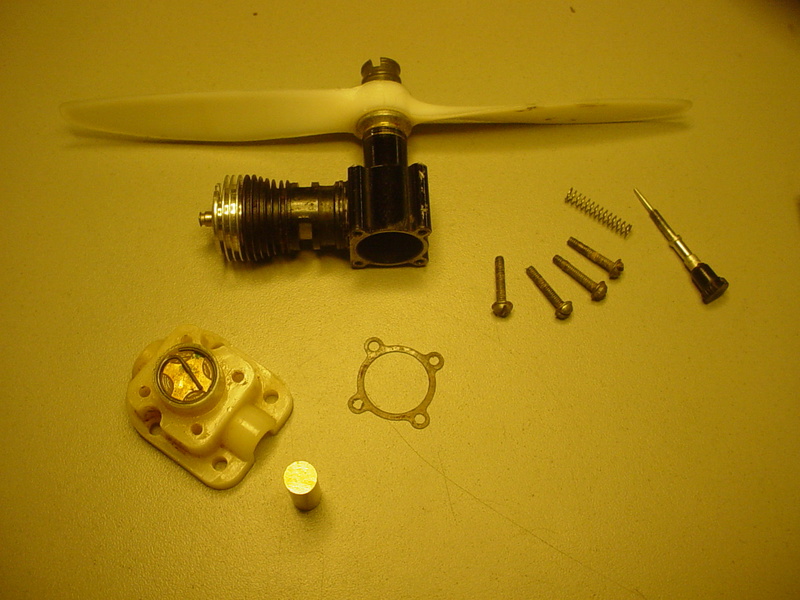

Bob had recently sent me some "parts-engines" that he thought I might be able to use to get my Testors/McCoy .049 repaired. Bob threw-in a few other engines as well. Three of them were Cox .049 reed-valve engines. Today I got curious about their condition(s).

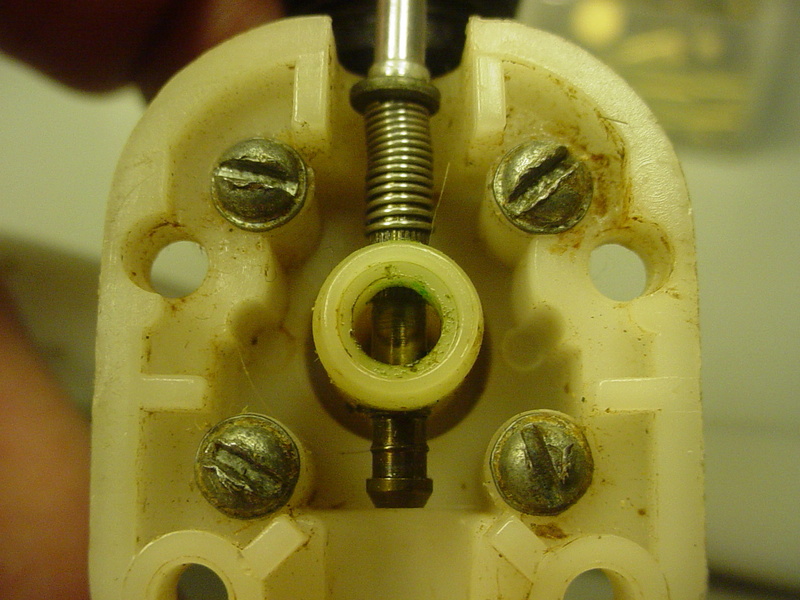

This one was a little stiff/sticky.. and is an odd mix of parts.. but was complete except for a needle-spring. The glowhead looked brand-new.. and was loose enough to remove by hand. There were x2 gaskets installed under it. Black-anodized (or painted) case.. with round drive-plate, early horseshoe-style backplate with aluminum needle and a copper-star reed.

#1 cylinder..

I oiled it with some very light "instrument-oil".. and she loosened-up with excellent compression. I pulled the backplate, smoothed-out the case over some 600 grit paper.. and freed-up the reed. The needle needed a spring.. so I got out my compression-spring jar and found one that should work.

This engine should now be ready to run! It came with a nice Tornado 6 x 3 prop mounted.

This one was a little stiff/sticky.. and is an odd mix of parts.. but was complete except for a needle-spring. The glowhead looked brand-new.. and was loose enough to remove by hand. There were x2 gaskets installed under it. Black-anodized (or painted) case.. with round drive-plate, early horseshoe-style backplate with aluminum needle and a copper-star reed.

#1 cylinder..

I oiled it with some very light "instrument-oil".. and she loosened-up with excellent compression. I pulled the backplate, smoothed-out the case over some 600 grit paper.. and freed-up the reed. The needle needed a spring.. so I got out my compression-spring jar and found one that should work.

This engine should now be ready to run! It came with a nice Tornado 6 x 3 prop mounted.

Re: Thanks again rsv1cox "Bob"

Re: Thanks again rsv1cox "Bob"

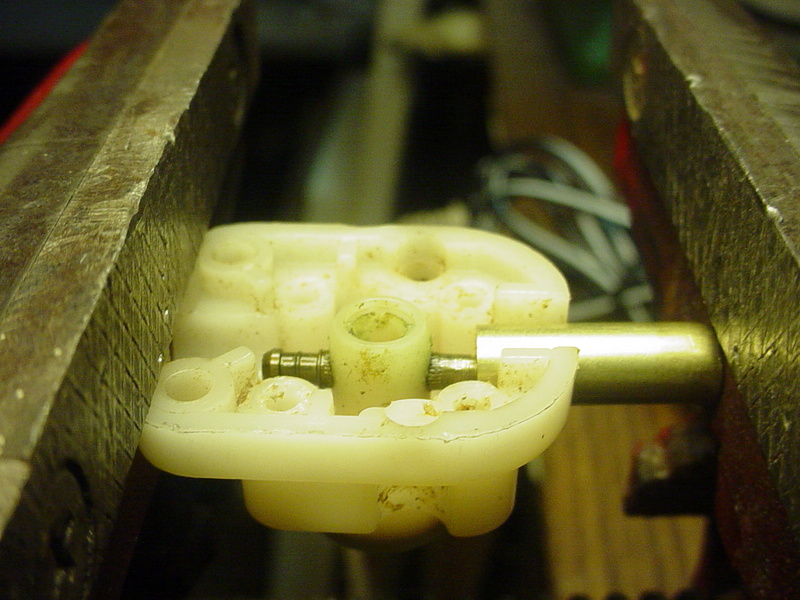

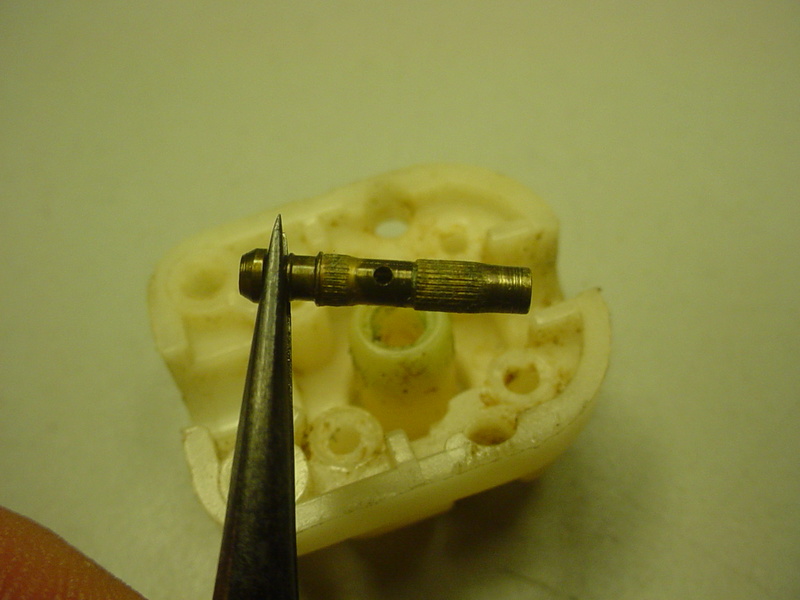

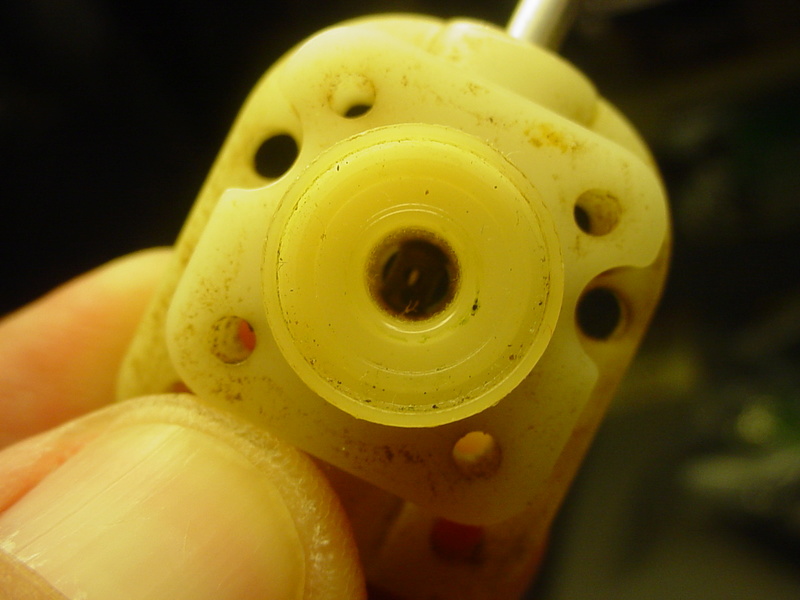

Roddie. Looking at your bottom picture, the spray hole is looking right out at ya. The tube (spray bar) will need to be reversed in the backplate, with the spray hole pointing at the reed. Looks like it might be a Black Widow with the tank swapped.

Oldenginerod- Top Poster

- Posts : 4018

Join date : 2012-06-15

Age : 62

Location : Drouin, Victoria

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Thanks again rsv1cox "Bob"

Re: Thanks again rsv1cox "Bob"

It is the high performance pressure bladder arrangement

I jest, of course.

Phil

I jest, of course.

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: Thanks again rsv1cox "Bob"

Re: Thanks again rsv1cox "Bob"

Somewhere around here, I have a backplate with the

spraybar drilled clean through. I forget whether was a

product or postage stamp plate.

Bob

spraybar drilled clean through. I forget whether was a

product or postage stamp plate.

Bob

dckrsn- Diamond Member

- Posts : 2750

Join date : 2010-10-21

Age : 71

Location : Long Island, New York

Re: Thanks again rsv1cox "Bob"

Re: Thanks again rsv1cox "Bob"

dckrsn wrote:Somewhere around here, I have a backplate with the

spraybar drilled clean through. I forget whether was a

product or postage stamp plate.

Bob

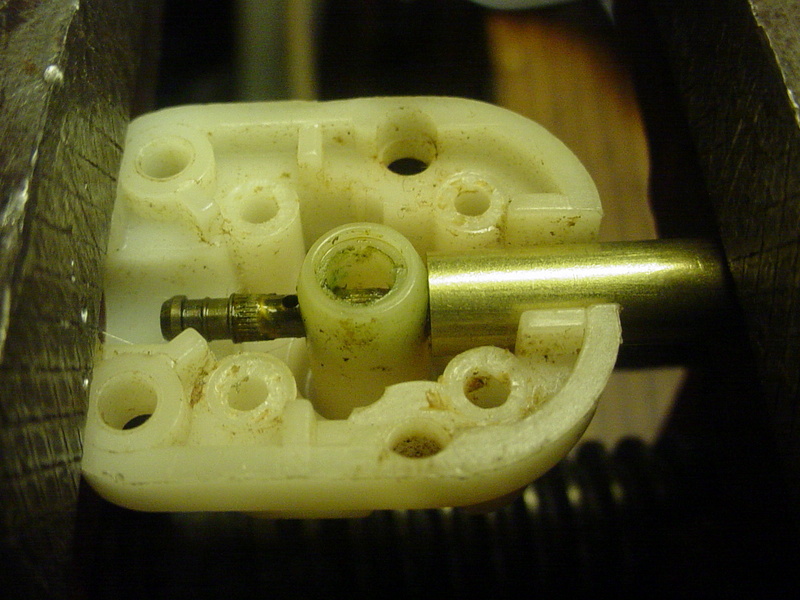

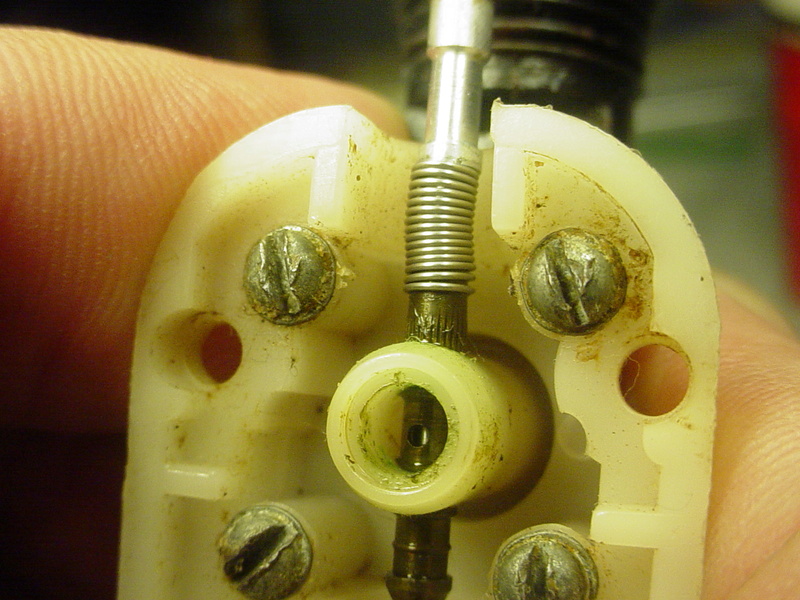

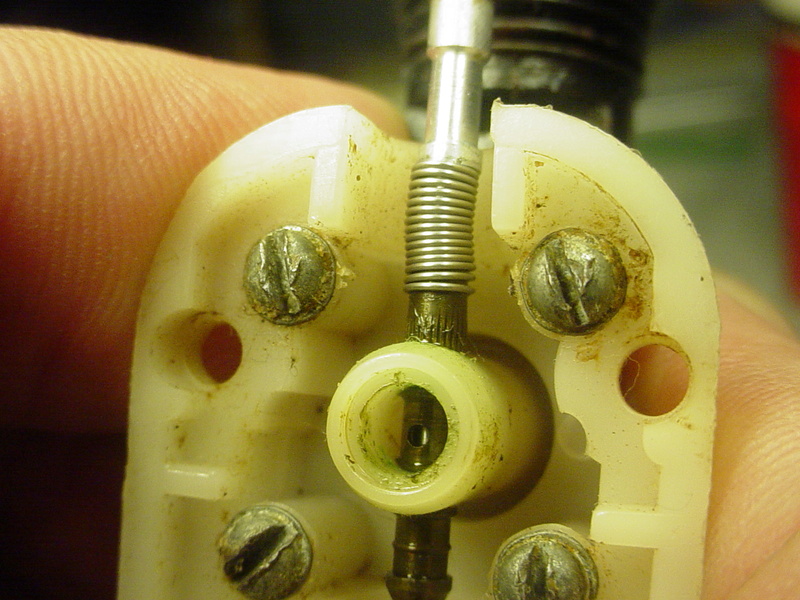

It seems to me that I've also seen that.... but I can't dispute the fact that this one's in there backwards. I only had two other horseshoe backplates to check, which do NOT have mesh-screens on the air-intake. One is a red high-flow "Killer Bee" clone.. and the other is almost identical to this one in question.. (white-plastic with an aluminum needle).

Here's the other white one..

That pretty-much confirms it.. I just checked a "postie".. and it's the same.. and has only one spray-hole. Same with the high-flow back-plate.

I hadn't removed the reed from Bob's engine.. because it seemed to operate properly. Had I done that.. or taken a look at this other backplate; I might have noticed it.

I've never removed a spray-bar from one of these.. but I guess I'm gonna' have to try it. I would assume that I should try to align the "splines" when pressing it back in? I've read about swapping-in a fine-thread NVA, so maybe this will be good practice for when that time comes..

Anyway...... "THANKS" for saving me some grief, because I was anxious to bench-run it later-on today.

Re: Thanks again rsv1cox "Bob"

Re: Thanks again rsv1cox "Bob"

There are those who will tell you that there is an optimal angle for the spray hole to be on, which is not "perfectly-centered".

Some claim 15 degrees from perpendicular to the air flow for a Cox engine.

Personally, knowing full-well that we have discussed this at length before, uncovering a plethora of opinions, I would put it as close to centre as I could, being the position that I have personally witnessed most factory installations to use.

Oldenginerod- Top Poster

- Posts : 4018

Join date : 2012-06-15

Age : 62

Location : Drouin, Victoria

Re: Thanks again rsv1cox "Bob"

Re: Thanks again rsv1cox "Bob"

Oldenginerod wrote:

There are those who will tell you that there is an optimal angle for the spray hole to be on, which is not "perfectly-centered".

Some claim 15 degrees from perpendicular to the air flow for a Cox engine.

Personally, knowing full-well that we have discussed this at length before, uncovering a plethora of opinions, I would put it as close to centre as I could, being the position that I have personally witnessed most factory installations to use.

Yes, I remember some conversation about that. Allow me to inject my own thoughts and blabber on this subject..

Being that the tanked reedies' non-obstructing fuel spray-hole is exactly perpendicular to the airflow, there's probably some logic there. The product (tank-less) back-plate is a different animal though. What puzzles me is; the tanked engines' venturi-shape is the reverse of a conventional velocity-stack. Maybe it has to be, because of the fuel-jet's location? Turbulent-airflow occurs immediately as it enters the backplate and fuel-atomization is probably further enhanced by a pressure-wave produced by the megaphone-effect as it approaches the reed.

The product (tank-less) back-plate has to rely more on the spray-bar to augment laminar-flow into turbulent-flow for fuel-atomization.. but has the advantage of flowing a higher volume.

Whatever the case.. there's no disputing that these little engines are engineering marvels!

Re: Thanks again rsv1cox "Bob"

Re: Thanks again rsv1cox "Bob"

It seems I got all those engines in the right hands, I know that you guys are enjoying them.

Many came with other engines, lets say Enya's as a package and I just set them aside. I still have scads to clean up, if I start now, maybe by Christmas next year.

as a package and I just set them aside. I still have scads to clean up, if I start now, maybe by Christmas next year.

Many came with other engines, lets say Enya's

rsv1cox- Top Poster

Posts : 11247

Join date : 2014-08-18

Location : West Virginia

Re: Thanks again rsv1cox "Bob"

Re: Thanks again rsv1cox "Bob"

Gone for a while now but the kid in Noosa Australia got a bunch of my similarly acquired engines

I still have a box full of questionable engine stuff from LOT buys...

I still have a box full of questionable engine stuff from LOT buys...

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: Thanks again rsv1cox "Bob"

Re: Thanks again rsv1cox "Bob"

rsv1cox wrote:It seems I got all those engines in the right hands, I know that you guys are enjoying them.

Many came with other engines, lets say Enya'sas a package and I just set them aside. I still have scads to clean up, if I start now, maybe by Christmas next year.

"Let's say Enya's"...

Lots of cool parts there! I think that the backplate is fitted with a fine-thread NVA.

Lots of cool parts there! I think that the backplate is fitted with a fine-thread NVA.

I'm not sure about that.. but it looks like one. If it is; it's the only horseshoe-style backplate that I have, that sports one.

Sooner or later.. I'll want to try running a pressure-bladder fuel-feed.. and a fine-threaded NVA would be the ticket. That aside; there's other interesting aspects to this engine. The heat-sink.. and muffler.. the flywheel/fan assembly.. and the I believe it may have a H/D crankshaft. Cool stuff! I'm not sure of the cylinder-porting.. but the CEF "cylinder-identification" archive might give a clue.

The engine is "stuck".. but may only be castor-seized. I'll probably tear it down this weekend to find out more.

Similar topics

Similar topics» for Bob aka rsv1cox

» Is this a cox engine?

» "Big Otto and Bernie's Xtreme .049" !!

» Anyone heard from Bob (rsv1cox) lately?

» Happy Birthday Robert ( Rsv1cox )

» Is this a cox engine?

» "Big Otto and Bernie's Xtreme .049" !!

» Anyone heard from Bob (rsv1cox) lately?

» Happy Birthday Robert ( Rsv1cox )

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules