Log in

Search

Latest topics

» My N-1R build logby roddie Yesterday at 9:29 pm

» Funny what you find when you go looking

by rsv1cox Yesterday at 3:21 pm

» Landing-gear tips

by 1975 control line guy Yesterday at 8:17 am

» Purchased the last of any bult engines from Ken Enya

by sosam117 Yesterday at 7:45 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

» My current avatar photo

by roddie Mon Nov 18, 2024 9:05 pm

» My latest doodle...

by TD ABUSER Mon Nov 18, 2024 11:30 am

» Brushless motors?

by rsv1cox Sun Nov 17, 2024 6:40 pm

» Free Flight Radio Assist

by rdw777 Sun Nov 17, 2024 6:03 pm

» Tribute Shoestring build

by amurphy6812 Sun Nov 17, 2024 5:43 pm

Cox Engine of The Month

A custom SIG Skyray

Page 2 of 2

Page 2 of 2 •  1, 2

1, 2

Re: A custom SIG Skyray

Re: A custom SIG Skyray

KariFS wrote:

But... 80 Mpg! That's better than the Babe Bee on your plane

I'd say 40 miles to the field, 40 miles back, plus a gallon of glow fuel used. Wow, your Babe Bee certainly gets through the fuel.

(Anyway, what would I know? Our Gallons are bigger than yours).

Oldenginerod- Top Poster

- Posts : 4018

Join date : 2012-06-15

Age : 62

Location : Drouin, Victoria

Re: A custom SIG Skyray

Re: A custom SIG Skyray

I have a Honda Insight, first generation. It seems to really like slow crowded freeways, but I helped a lot with my driving.

David Ingham- Silver Member

- Posts : 86

Join date : 2017-03-30

Age : 82

Location : Mountsin View, California, USA

David Ingham- Silver Member

- Posts : 86

Join date : 2017-03-30

Age : 82

Location : Mountsin View, California, USA

Re: A custom SIG Skyray

Re: A custom SIG Skyray

I tried flying it this morning. First it wouldn't start, then the security guard came along. First I tried the DMV, but there were cars parked, so probably people were inside working and I would have disturbed them. Then I tried the lot in the Lockheed area. The guard seemed sympathetic and called his supervisor, but the supervisor had him ask me to leave. He said the lot belongs to "Juniper". So I lost one of my only three hard to find flying sites.

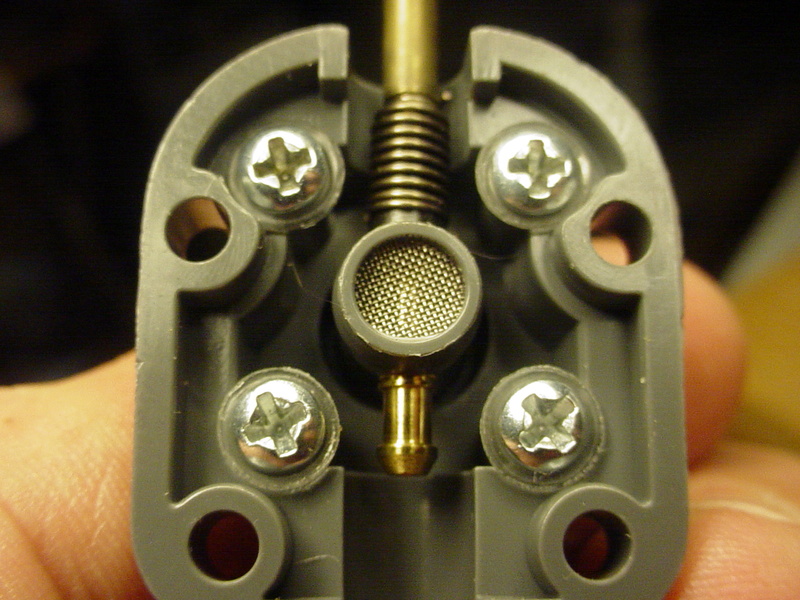

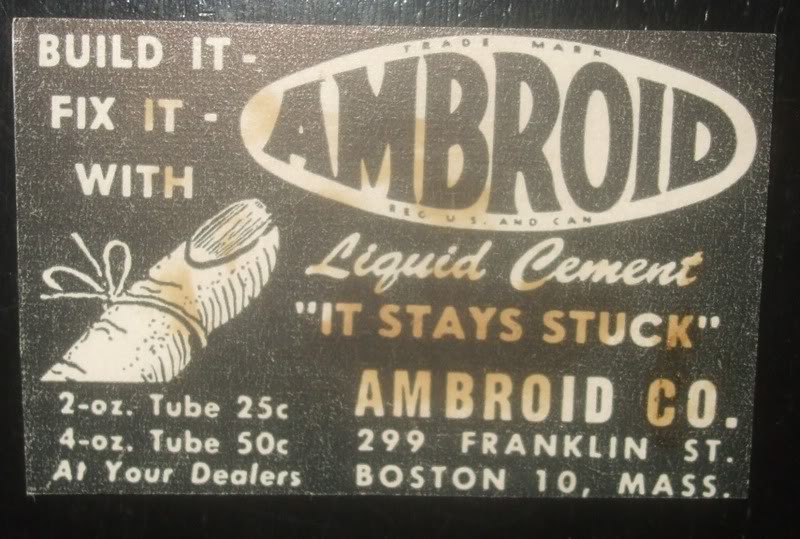

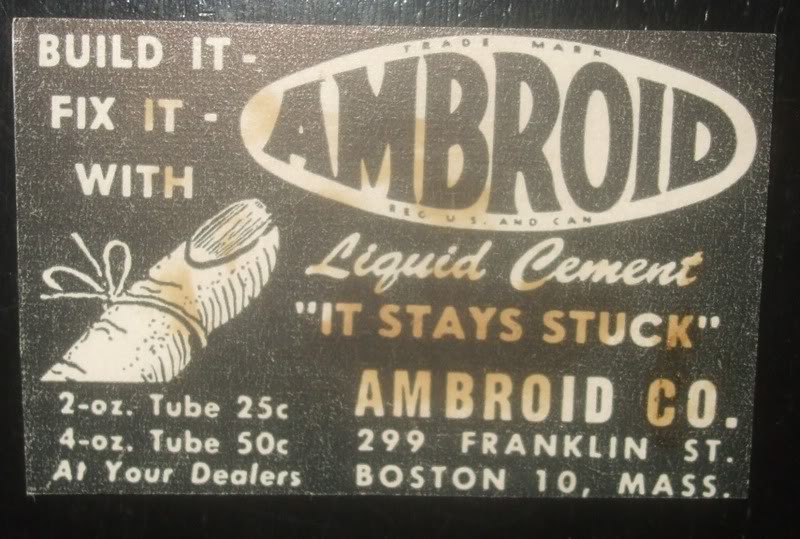

I took the engine apart and cleaned and oiled it. At least, the reed was suck closed. I guess I didn't oil it as well as the muffled engine when I stopped using it. I also replaced the crank case gasket, which was missing the part that keeps fuel from leaking out the screw openings. Then I went back and oiled the muffled one better. I am using a 40 year old can of 3 In 1 Oil. I still have Ambroid in my flight kit too.

I took the engine apart and cleaned and oiled it. At least, the reed was suck closed. I guess I didn't oil it as well as the muffled engine when I stopped using it. I also replaced the crank case gasket, which was missing the part that keeps fuel from leaking out the screw openings. Then I went back and oiled the muffled one better. I am using a 40 year old can of 3 In 1 Oil. I still have Ambroid in my flight kit too.

David Ingham- Silver Member

- Posts : 86

Join date : 2017-03-30

Age : 82

Location : Mountsin View, California, USA

Re: A custom SIG Skyray

Re: A custom SIG Skyray

You'll find a spot to fly.. I'm sure David. I've always used 3-in-One oil.. but a lot of the guys here on the forum use "air-tool" oil (as an after-run/storage-lubricant) and say that it's superior to anything else.

I also have some tubes of "old" Ambroid cement. The old (original) formula was being made in Taunton, MA.. but became unavailable for a while. When it did become available again, the formula had changed to a thinner/runny consistency and there are mixed emotions as to how well it works. I don't know at what point that happened, but some newer tubes are marked as being made in Lowell, MA., Swanzey, NH and apparently later somewhere in Canada. Chances are; if you have a tube that was made in Taunton.. it's the original thicker formula. It was first made in Boston, MA by Howe and French Co. in the early 1900's for repairing Birch and canvas canoes.

Good read here.. though a bit dated..

http://www.ottertooth.com/Canoe_pages/ambroid.htm

I also have some tubes of "old" Ambroid cement. The old (original) formula was being made in Taunton, MA.. but became unavailable for a while. When it did become available again, the formula had changed to a thinner/runny consistency and there are mixed emotions as to how well it works. I don't know at what point that happened, but some newer tubes are marked as being made in Lowell, MA., Swanzey, NH and apparently later somewhere in Canada. Chances are; if you have a tube that was made in Taunton.. it's the original thicker formula. It was first made in Boston, MA by Howe and French Co. in the early 1900's for repairing Birch and canvas canoes.

Good read here.. though a bit dated..

http://www.ottertooth.com/Canoe_pages/ambroid.htm

Re: A custom SIG Skyray

Re: A custom SIG Skyray

Thanks. DMV still works, but maybe I won't push mu luck by flying there on week days.

I flew there this morning and everything seemed to go wrong, except what went wrong yesterday. The engine is not sorted out yet. It seemed to be leaking fuel. The mixture was unstable, and I had to open the needle valve too much. The stooge line somehow got tangled on the control lines or the airplane and wrapped around me. I got the handle up side down and it taxied very fast along the pavement until I turned it right. But the model still looks cherry (uh pristine)! And it now can fly up near the top of the hemisphere without the lines getting slack. I think it is going to do loops and wingovers when I get it sorted out, without my having to buy a Black Widow or steal one from my P 40. I used to run 40% nitro and a TD head in this engine on my Stuntman, though I never got it running right with that head.

I flew there this morning and everything seemed to go wrong, except what went wrong yesterday. The engine is not sorted out yet. It seemed to be leaking fuel. The mixture was unstable, and I had to open the needle valve too much. The stooge line somehow got tangled on the control lines or the airplane and wrapped around me. I got the handle up side down and it taxied very fast along the pavement until I turned it right. But the model still looks cherry (uh pristine)! And it now can fly up near the top of the hemisphere without the lines getting slack. I think it is going to do loops and wingovers when I get it sorted out, without my having to buy a Black Widow or steal one from my P 40. I used to run 40% nitro and a TD head in this engine on my Stuntman, though I never got it running right with that head.

David Ingham- Silver Member

- Posts : 86

Join date : 2017-03-30

Age : 82

Location : Mountsin View, California, USA

Re: A custom SIG Skyray

Re: A custom SIG Skyray

David Ingham wrote:Thanks. DMV still works, but maybe I won't push mu luck by flying there on week days.

I flew there this morning and everything seemed to go wrong, except what went wrong yesterday. The engine is not sorted out yet. It seemed to be leaking fuel. The mixture was unstable, and I had to open the needle valve too much. The stooge line somehow got tangled on the control lines or the airplane and wrapped around me. I got the handle up side down and it taxied very fast along the pavement until I turned it right. But the model still looks cherry (uh pristine)! And it now can fly up near the top of the hemisphere without the lines getting slack. I think it is going to do loops and wingovers when I get it sorted out, without my having to buy a Black Widow or steal one from my P 40. I used to run 40% nitro and a TD head in this engine on my Stuntman, though I never got it running right with that head.

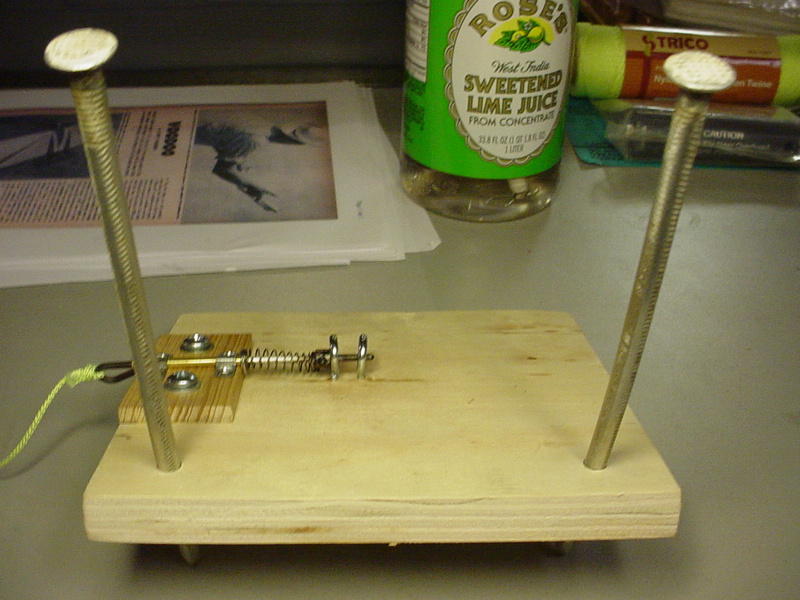

Wow.. you certainly have some exciting flying experiences David! You mentioned having issues with your stooge recently. I'm glad that you didn't get hurt today. I've had the pull-string to my stooge wrap around my foot before..

If you tie a rubber-band around the end of the pull-cord.. and pull "it".. then the string will recoil away from the center of the circle when released.. that is; if it's rigidly-mounted on the "model-end"..

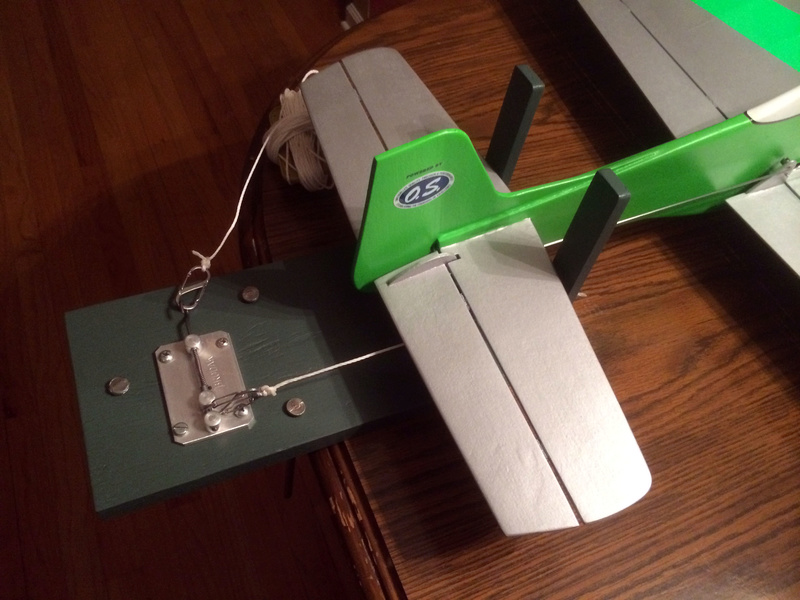

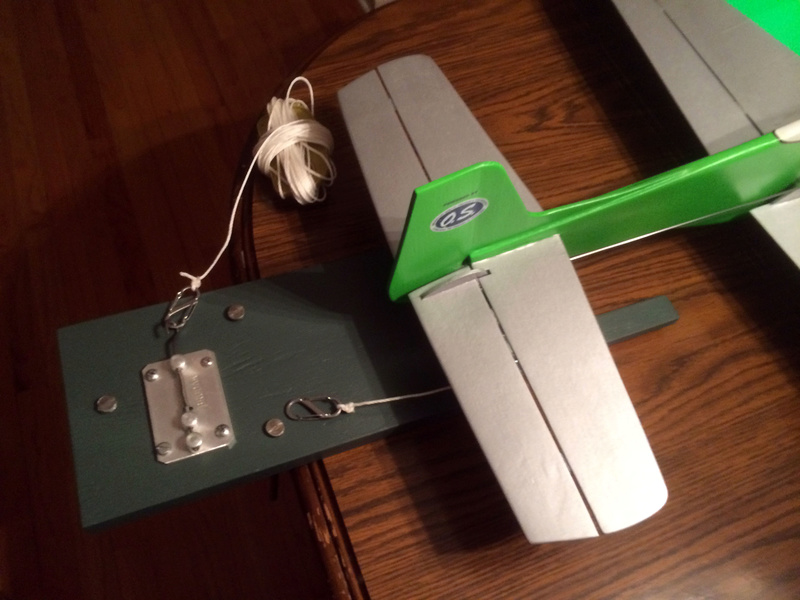

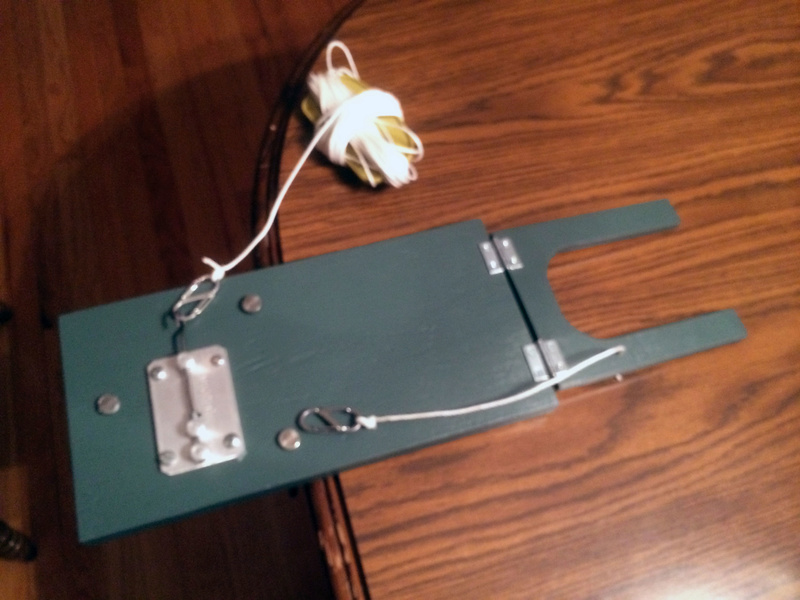

If you tie a rubber-band around the end of the pull-cord.. and pull "it".. then the string will recoil away from the center of the circle when released.. that is; if it's rigidly-mounted on the "model-end".. Here's a simple-stooge that I built 20+ years ago.. uses a music-wire pin through two small screw-eyes. Anchors to dirt/grass with long aluminum nails through angled-holes in the plate.

and a more recent design that uses a spring in the pin assembly..

I like the "fork-type" that straddles the fuse's tail-section "vertically"... with the L/E of the stabilizer against it. It flops-down when released.. and the model doesn't need any sort of link for a pin.

Re: A custom SIG Skyray

Re: A custom SIG Skyray

I flew it yesterday at DMV. Still problems with the badly stored engine. I got one flight. On taking it apart, I found that I had the reed in wrong.

I feel sore after bending over it to try to get it running. I don't remember having that problem when I was young.

I feel sore after bending over it to try to get it running. I don't remember having that problem when I was young.

David Ingham- Silver Member

- Posts : 86

Join date : 2017-03-30

Age : 82

Location : Mountsin View, California, USA

Re: A custom SIG Skyray

Re: A custom SIG Skyray

I fixed a problem with the old stunt engine. One of the back plate crank case screws was a full inch long and bottomed without putting pressure on the back plate. This was not a new problem and probably effected my flights with the club in Massachusetts.

David Ingham- Silver Member

- Posts : 86

Join date : 2017-03-30

Age : 82

Location : Mountsin View, California, USA

Re: A custom SIG Skyray

Re: A custom SIG Skyray

Hi David, stop me if you've heard this.  I went down this street many years ago, and

I went down this street many years ago, and

found it somewhat interesting. For some reason the crankcase holes weren't consistently

threaded fully to utilize 3/4" or 1" long tank screws (depending whether a 5 or 8cc tank is

being installed). In every case I've come across, the holes are drilled deep enough, but not

always threaded to the full depth. Cox actually used screws that were a few 32nds short of

3/4 or 1" to solve the machining snafu. Anyway, if you get a 2-56 bottoming tap(Amazon)

and tap the holes fully, you should alleviate the problem. Flushing the hole with an insulin

syringe and some fuel or something works well after tapping too.

https://www.amazon.com/Du-Bro-360-2-56-Tap-Drill/dp/B0006O4GYG/ref=pd_sim_328_2?_encoding=UTF8&pd_rd_i=B0006O4GYG&pd_rd_r=JPMJJHT13D2F5XWS8PM3&pd_rd_w=1rRXZ&pd_rd_wg=UK1j2&psc=1&refRID=JPMJJHT13D2F5XWS8PM3&dpID=31NVYEadt3L&preST=_SX342_QL70_&dpSrc=detail

You won't need the drill, but this is the best price I could find for a 2-56 tap.

Hope this helps, David.

Bob

I went down this street many years ago, and

I went down this street many years ago, andfound it somewhat interesting. For some reason the crankcase holes weren't consistently

threaded fully to utilize 3/4" or 1" long tank screws (depending whether a 5 or 8cc tank is

being installed). In every case I've come across, the holes are drilled deep enough, but not

always threaded to the full depth. Cox actually used screws that were a few 32nds short of

3/4 or 1" to solve the machining snafu. Anyway, if you get a 2-56 bottoming tap(Amazon)

and tap the holes fully, you should alleviate the problem. Flushing the hole with an insulin

syringe and some fuel or something works well after tapping too.

https://www.amazon.com/Du-Bro-360-2-56-Tap-Drill/dp/B0006O4GYG/ref=pd_sim_328_2?_encoding=UTF8&pd_rd_i=B0006O4GYG&pd_rd_r=JPMJJHT13D2F5XWS8PM3&pd_rd_w=1rRXZ&pd_rd_wg=UK1j2&psc=1&refRID=JPMJJHT13D2F5XWS8PM3&dpID=31NVYEadt3L&preST=_SX342_QL70_&dpSrc=detail

You won't need the drill, but this is the best price I could find for a 2-56 tap.

Hope this helps, David.

Bob

dckrsn- Diamond Member

- Posts : 2750

Join date : 2010-10-21

Age : 71

Location : Long Island, New York

Re: A custom SIG Skyray

Re: A custom SIG Skyray

I've run into that problem too David.. (including the sore back from bending-over.. ) If you can't source a 2-56 bottoming-type tap.. you can shorten your screws "slightly". It's best when cutting or grinding a machine-screw shorter; to FIRST thread a matching-size "nut" onto the screw which will remove a "burr" afterward.

A "Dremel-tool" with an abrasive cut-off wheel is a preferred way to cut a small screw shorter. You could use a fine metal-file if you had to. Just make sure that the screw-threads are clean of burrs before installing them into the engines' aluminum crankcase. I often use a lighted-magnifier or eye-loupe to inspect small parts.

I realize that 2-56 size nuts are somewhat of a commodity.. but "Dubro-products" available at your hobby shop might have them. Radio Shack used to sell small packets of 2-56 size machine-nuts. Many stores have closed.. but maybe there's one near you?

A "Dremel-tool" with an abrasive cut-off wheel is a preferred way to cut a small screw shorter. You could use a fine metal-file if you had to. Just make sure that the screw-threads are clean of burrs before installing them into the engines' aluminum crankcase. I often use a lighted-magnifier or eye-loupe to inspect small parts.

I realize that 2-56 size nuts are somewhat of a commodity.. but "Dubro-products" available at your hobby shop might have them. Radio Shack used to sell small packets of 2-56 size machine-nuts. Many stores have closed.. but maybe there's one near you?

Re: A custom SIG Skyray

Re: A custom SIG Skyray

I filed the screw shorter with a mill file to match the others. I have done that a lot and it worked well. I rounded the tip a bit to make it easier to put in. Some time long ago I must have put it together without noticing the small difference in lengths.

David Ingham- Silver Member

- Posts : 86

Join date : 2017-03-30

Age : 82

Location : Mountsin View, California, USA

Re: A custom SIG Skyray

Re: A custom SIG Skyray

David Ingham wrote:I have a Honda Insight, first generation. It seems to really like slow crowded freeways, but I helped a lot with my driving.

When I saw the first gen Honda Insight Hybrid I thought it a cool looking vehicle with a promising future, then the Toyota Prius came along. I'm also a fan of the very similar Honda CRX.

It seems that you got over the dizzies quickly after your first flight. Good for you. I was one and done.

Bob

rsv1cox- Top Poster

Posts : 11244

Join date : 2014-08-18

Location : West Virginia

Re: A custom SIG Skyray

Re: A custom SIG Skyray

Glad you got that fixed Davd it is hard to tell some time if it's not tighten up on all the screws

getback- Top Poster

Posts : 10436

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: A custom SIG Skyray

Re: A custom SIG Skyray

Thanks Roddie. It was easier for me to shorten the screw as I am used to it and have been using files a lot recently. I guess that would be fuel tight, but they would have to be installed every time the back plate was off, while with the shorter screw it is as original.

David Ingham- Silver Member

- Posts : 86

Join date : 2017-03-30

Age : 82

Location : Mountsin View, California, USA

Page 2 of 2 •  1, 2

1, 2

Similar topics

Similar topics» Great video on building and flying the 1/2A Skyray and Skyray 35

» Got me a SkyRay !

» Sig Skyray/ Cox Silver Bee 049

» Sig Skyray

» Sig Skyray

» Got me a SkyRay !

» Sig Skyray/ Cox Silver Bee 049

» Sig Skyray

» Sig Skyray

Page 2 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules