Log in

Search

Latest topics

» Tee Dee .020 combat modelby roddie Today at 1:34 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» My latest doodle...

by batjac Yesterday at 9:47 pm

» My N-1R build log

by roddie Yesterday at 8:50 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

» My current avatar photo

by roddie Mon Nov 18, 2024 9:05 pm

Cox Engine of The Month

Making mufflers for thin-walled cylinders.

Page 1 of 1

Making mufflers for thin-walled cylinders.

Making mufflers for thin-walled cylinders.

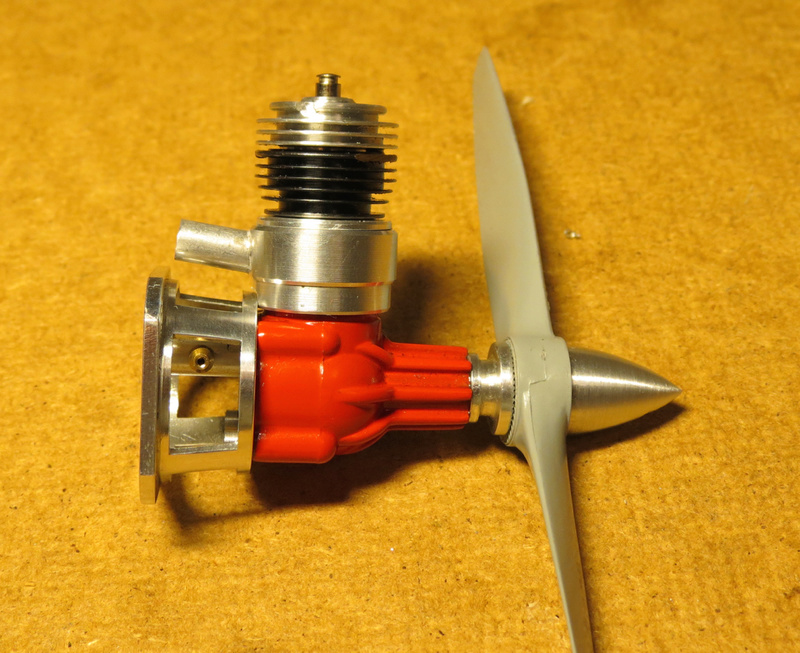

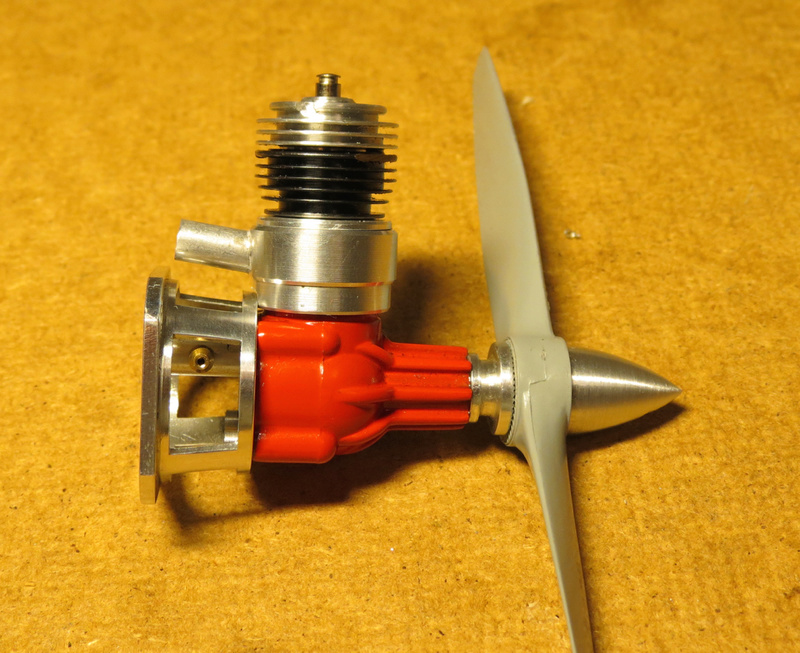

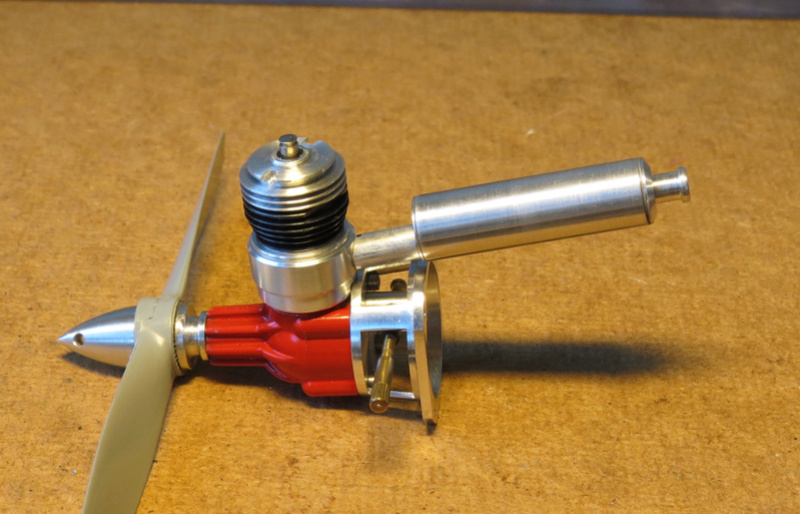

I have had some time to play with the lathe and made a few parts in order to get a muffler/exhaust collector for a thin-walled cylinder .049 engine.

Compared to the thick-walled cylinders, this one will need to have a split top or split ring somewhere. Rather than splitting the whole top part I made a minimum size ring that I could split and then keep it together with a second washer/ring. Works quite well actually and wasn't too hard to make, except for all the parts being rather tiny...

I did misjudged how much material the cutting disc would removed, so although I made it over-size and then squeezed it together after the splitting. It did come out a little too short... But sealing that with some JB weld might be good enough on this one. Can always have another go at later, trying make one just right, but this seems close enough.

The lower part is made larger than needed, which leaves enough material for a flat spot on it, which will stop the whole thing from rotating. Here one could also put down some more flat spots at different angles in order too use different outlet directions.

Below are some pictures of the "contraption" so far, I might add a second muffler on the outlet later on too.

Compared to the thick-walled cylinders, this one will need to have a split top or split ring somewhere. Rather than splitting the whole top part I made a minimum size ring that I could split and then keep it together with a second washer/ring. Works quite well actually and wasn't too hard to make, except for all the parts being rather tiny...

I did misjudged how much material the cutting disc would removed, so although I made it over-size and then squeezed it together after the splitting. It did come out a little too short... But sealing that with some JB weld might be good enough on this one. Can always have another go at later, trying make one just right, but this seems close enough.

The lower part is made larger than needed, which leaves enough material for a flat spot on it, which will stop the whole thing from rotating. Here one could also put down some more flat spots at different angles in order too use different outlet directions.

Below are some pictures of the "contraption" so far, I might add a second muffler on the outlet later on too.

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Making mufflers for thin-walled cylinders.

Re: Making mufflers for thin-walled cylinders.

Spectacular, very good work, my friend!

Spectacular, very good work, my friend!

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-16

Age : 53

Location : ARG

Re: Making mufflers for thin-walled cylinders.

Re: Making mufflers for thin-walled cylinders.

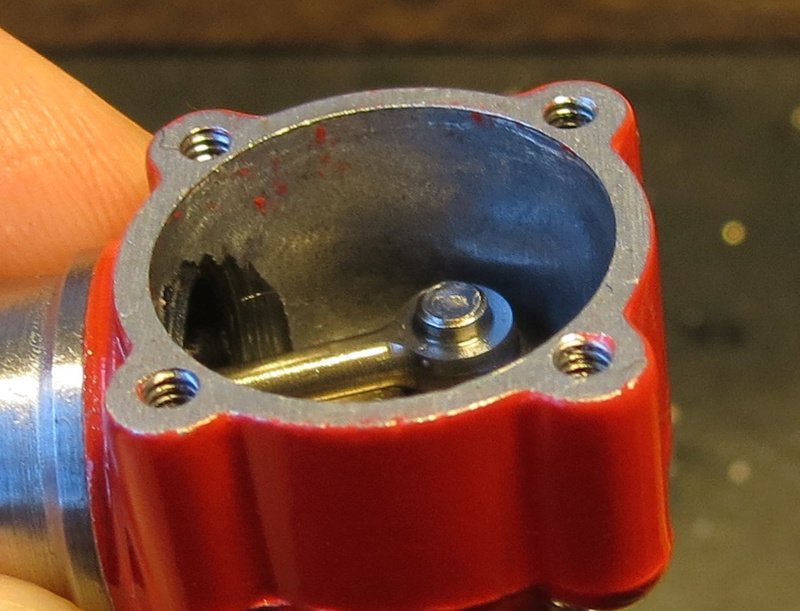

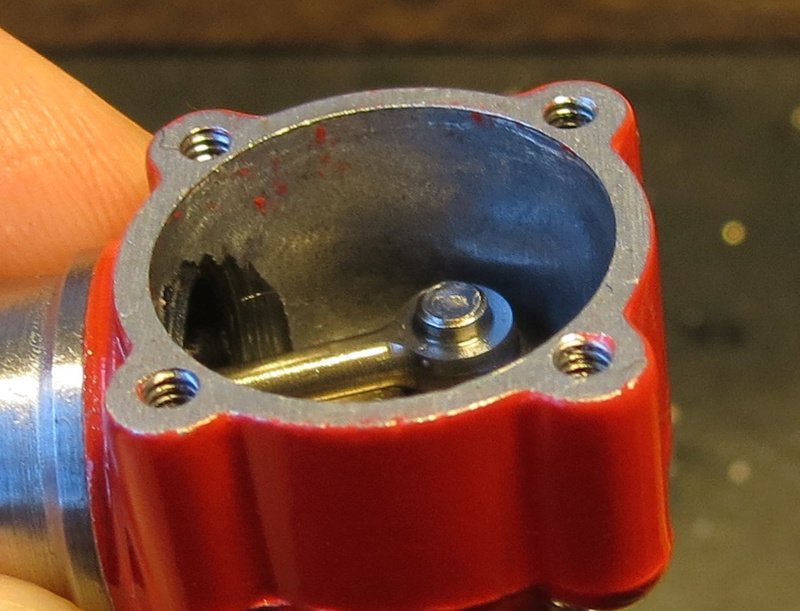

Very Nice Krister! It looks like it would seal nicely. If so; maybe a tuned-pipe might be in its future?  I like the cage-style back-end. Do you have any photos of that part unassembled? Is there a NV/reed-holder/venturi that's integral to it?

I like the cage-style back-end. Do you have any photos of that part unassembled? Is there a NV/reed-holder/venturi that's integral to it?

I like the cage-style back-end. Do you have any photos of that part unassembled? Is there a NV/reed-holder/venturi that's integral to it?

I like the cage-style back-end. Do you have any photos of that part unassembled? Is there a NV/reed-holder/venturi that's integral to it?  Re: Making mufflers for thin-walled cylinders.

Re: Making mufflers for thin-walled cylinders.

I will put some kind of muffler at the end I think, but not a tuned pipe as that requires a different exhaust timing to give any gain, appart from a sound effect....

The engine is actually a "Speed Bee" from Ronald Valentine and it uses a rotor disc for the intake;

The engine is actually a "Speed Bee" from Ronald Valentine and it uses a rotor disc for the intake;

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Making mufflers for thin-walled cylinders.

Re: Making mufflers for thin-walled cylinders.

That is a neat piece of work. I like the use of the split ring.

The last time I went for a split ring, I tried splitting the bar stock before machining. It worked but I wasted a lot of material clamping everything together.

Now I would probably use a fine jewellers saw.

The last time I went for a split ring, I tried splitting the bar stock before machining. It worked but I wasted a lot of material clamping everything together.

Now I would probably use a fine jewellers saw.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Making mufflers for thin-walled cylinders.

Re: Making mufflers for thin-walled cylinders.

Yes splitting it before the machining could be an good idea, if this one doesn't seal well enough I might try that. I'm now working on a muffler in thin-walled aluminium that can go on the outlet, should have something ready soon.

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Making mufflers for thin-walled cylinders.

Re: Making mufflers for thin-walled cylinders.

LOOKS GOOD !! I was wondering about that rear end of the engine and if you had made the cage, All you lathe people !!

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Making mufflers for thin-walled cylinders.

Re: Making mufflers for thin-walled cylinders.

I only have a small hobby lathe, so I'm limited to making small things out of soft metals. That's fine for cox engines and other small engines.

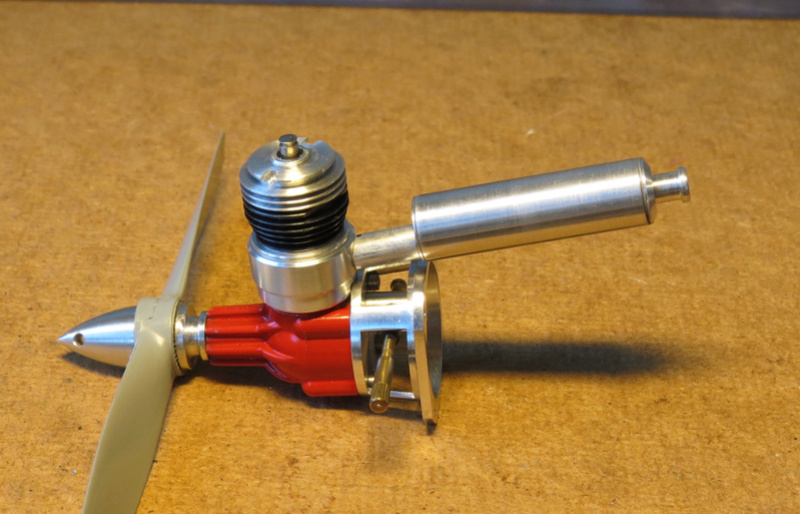

Here is a first stab at thin-walled muffler for it. I will keep it removable so that I can still give it a port prime for starting, and then attach it ones the engine is up and running. I don't think I could ever start it otherwise...

Here is a first stab at thin-walled muffler for it. I will keep it removable so that I can still give it a port prime for starting, and then attach it ones the engine is up and running. I don't think I could ever start it otherwise...

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Making mufflers for thin-walled cylinders.

Re: Making mufflers for thin-walled cylinders.

It is like a piece of jewelry for a piece of jewelry.

Phil

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: Making mufflers for thin-walled cylinders.

Re: Making mufflers for thin-walled cylinders.

Nice Kris did you get a lathe for Christmas = )

You could add a pressure tap for priming the cylinder or block the muffler

with your finger to induce prime through the NV assembly. Are the parts press

fit or screwed on? When ready post a vid of it running would be great to hear how it sounds.

You could add a pressure tap for priming the cylinder or block the muffler

with your finger to induce prime through the NV assembly. Are the parts press

fit or screwed on? When ready post a vid of it running would be great to hear how it sounds.

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Making mufflers for thin-walled cylinders.

Re: Making mufflers for thin-walled cylinders.

That is a very nice project and a sound basis for experimenting.

Without complicating things by introducing "baffles" - you will find that being able to adjust the diameter of the silencer outlet beneficial as well as the diameter of the main body. I have found that there is no hard and fast rule for working out the volume of the "can" and it is a matter of trial and error.

Quiet versus a performance hit? - Who knows until you try it out! What I do know is that the clubs on the UK won't let you on the field with an unsilenced engine (unless, of course, it is a diesel!)

The visual you have created is appealing just for the look of it. I have made a few where the body is two tubes of a sliding fit so that I could expand and contract the volume while the engine is running but have to say that it made no discernible difference other than managing to burn my fingers.

I did find that the outlet makes a difference - not only the opening area but also the exit angle. Some of the quietest silencers I have seen have the outlet exiting from the side of the can at the rear. Doesn't look nice though.

A pal took one of my creations and added a tube bent at 45 deg to the outlet and that made a big difference.

No matter what - congratulations on a fine creation and enter it in the picture contest.

Without complicating things by introducing "baffles" - you will find that being able to adjust the diameter of the silencer outlet beneficial as well as the diameter of the main body. I have found that there is no hard and fast rule for working out the volume of the "can" and it is a matter of trial and error.

Quiet versus a performance hit? - Who knows until you try it out! What I do know is that the clubs on the UK won't let you on the field with an unsilenced engine (unless, of course, it is a diesel!)

The visual you have created is appealing just for the look of it. I have made a few where the body is two tubes of a sliding fit so that I could expand and contract the volume while the engine is running but have to say that it made no discernible difference other than managing to burn my fingers.

I did find that the outlet makes a difference - not only the opening area but also the exit angle. Some of the quietest silencers I have seen have the outlet exiting from the side of the can at the rear. Doesn't look nice though.

A pal took one of my creations and added a tube bent at 45 deg to the outlet and that made a big difference.

No matter what - congratulations on a fine creation and enter it in the picture contest.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Making mufflers for thin-walled cylinders.

Re: Making mufflers for thin-walled cylinders.

I do believe many thin-walled cylinders have SPI. A muffler of any kind may seriously affect the performance.

Oldenginerod- Top Poster

- Posts : 4018

Join date : 2012-06-15

Age : 62

Location : Drouin, Victoria

Re: Making mufflers for thin-walled cylinders.

Re: Making mufflers for thin-walled cylinders.

Oldenginerod wrote:I do believe many thin-walled cylinders have SPI. A muffler of any kind may seriously affect the performance.

I haven't checked my other engines with thin-walled cylinders, but this one does not have any SPI. This particular one may well have started out as a regular cylinder that has been machined down by Ron Valentine.

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Making mufflers for thin-walled cylinders.

Re: Making mufflers for thin-walled cylinders.

1/2A Nut wrote:Nice Kris did you get a lathe for Christmas = )

Ha ha, no but I had some spare time to use it.

It can be time consuming to make something complicated to exact measures, where the right lathe-tools are also need and have to be made. But playing around in aluminium with a rough sketch only is quite fun. With the right tools and correct rotation speed it very smooth and it is a bit like carving away in balsa.

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Making mufflers for thin-walled cylinders.

Re: Making mufflers for thin-walled cylinders.

Surfer_kris wrote:Oldenginerod wrote:I do believe many thin-walled cylinders have SPI. A muffler of any kind may seriously affect the performance.

I haven't checked my other engines with thin-walled cylinders, but this one does not have any SPI. This particular one may well have started out as a regular cylinder that has been machined down by Ron Valentine.

The exhaust slot is more narrow than the slot on SPI cylinders. It's probably a nr6 cylinder. The one of my QZ is a nr6 thick wall and looks the same. Great job on the muffler!!

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

Re: Making mufflers for thin-walled cylinders.

Re: Making mufflers for thin-walled cylinders.

The box says it's 0.83cc, that would be about .0506 CID

Nice work Kris

Nice work Kris

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Re: Making mufflers for thin-walled cylinders.

Re: Making mufflers for thin-walled cylinders.

KariFS wrote:The box says it's 0.83cc, that would be about .0506 CID

Yes, I think it might be a missprint and it really should say 0.803cc...

Thank you all for the nice comments!

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Making mufflers for thin-walled cylinders.

Re: Making mufflers for thin-walled cylinders.

ian1954 wrote:

I did find that the outlet makes a difference - not only the opening area but also the exit angle. Some of the quietest silencers I have seen have the outlet exiting from the side of the can at the rear. Doesn't look nice though.

A pal took one of my creations and added a tube bent at 45 deg to the outlet and that made a big difference.

Yes, I saw that once a commercial car muffler and I've made a bent tube inside a Mousse-can muffler and it is one of the most quiet mufflers that I have. It is good for around .12-.15 sized engines (shown in the photo below). I've also made some tuned mufflers, similar to the minipipes from MVVS, but these are rather noisy and doesn't really give much gain.

Total length, volume, and exit hole size all matters, and when it works it can make a large difference on the power. The long "scruffy" thing below on the VA engine works really well. The engine is not really timed for a tuned pipe (and I haven't played with the conrod length) but the long "muffler" gives me about the same rpm readings as an open face (i.e. no header even on the outlet), but a more stable running and better throttling as it also provides muffler pressure. On 10% nitro it now spins an APC 5.7x3 at around 19500rpm (stock muffler gives about 17500rpm), that's close to 100W from a throttled .049 engine (!)

On the .049 cox engines I've just tried to minimize the resistance, the blow-down time is much too short to get any type of "gain" from the exhaust or pipe. Some goo controll and a slightly softer exhasut note is good enough for me. To get any type of gain from the exhast would require a custom made cylinder, or at least some raised exhaust ports in a regular one. That could be done I guess...

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Making mufflers for thin-walled cylinders.

Re: Making mufflers for thin-walled cylinders.

Just a little update. The muffler was not on tight enough before and it needed a clamp to keep it in place when it gets soaked in oil. So here is what it looks like know with a music wire clamp. The idea is to have it easy removable/attachable so that one can give the engine a port prime through the "header", then mount the muffler and start the engine;

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Similar topics

Similar topics» Thin-walled tanks?

» Early thin walled cylinder??

» Mufflers for Tee Dee .020

» Thin Wall Cylinders

» What mufflers are these?

» Early thin walled cylinder??

» Mufflers for Tee Dee .020

» Thin Wall Cylinders

» What mufflers are these?

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules