Log in

Search

Latest topics

» Tee Dee .020 combat modelby roddie Today at 1:34 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» My latest doodle...

by batjac Yesterday at 9:47 pm

» My N-1R build log

by roddie Yesterday at 8:50 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

» My current avatar photo

by roddie Mon Nov 18, 2024 9:05 pm

Cox Engine of The Month

Wrench/exhaust web question

Page 1 of 1

Wrench/exhaust web question

Wrench/exhaust web question

I have 2 older Cox wrenches with cylinder removal spanners measuring .282 and .289 widths.

My old GB cylinder's webs measure .271 so no problem.

I have 2 cylinders (both #1) with exhaust port webs measuring .291-.298, depending on which web I measure.

I can dress the spanners with a file, but for you fellows who can make precise measurements I'm curious what your wrenches and webs measure.

My old GB cylinder's webs measure .271 so no problem.

I have 2 cylinders (both #1) with exhaust port webs measuring .291-.298, depending on which web I measure.

I can dress the spanners with a file, but for you fellows who can make precise measurements I'm curious what your wrenches and webs measure.

wha-tah-hey- Rest In Peace

- Posts : 264

Join date : 2013-12-04

Location : Elgin, Al

Re: Wrench/exhaust web question

Re: Wrench/exhaust web question

I can see a potential for another "Cox accuracy" discussion here

Checking two of my tools (both unused) I get the following numbers:

Black tool: 0.310"

Shiny metal: 0.282"

This likely shows some evolvement through out the years, and measuring on a few "thicker walled" (with and without a step) cylinders gives me typical values between 0.298-0.304" i.e. fine for the blackened tool. Only the earlier thin walled cylinders (at least out of my engines) have a width of about 0.270 (i.e. suitable for the older shiny metal tool).

The best way is never to use the tool anyway, as you risk to damage the cylinder if you do. In any case, do heat up the cylinder and case first (with a heat gun) as that really lower the force needed to loosen cylinders and heads.

Checking two of my tools (both unused) I get the following numbers:

Black tool: 0.310"

Shiny metal: 0.282"

This likely shows some evolvement through out the years, and measuring on a few "thicker walled" (with and without a step) cylinders gives me typical values between 0.298-0.304" i.e. fine for the blackened tool. Only the earlier thin walled cylinders (at least out of my engines) have a width of about 0.270 (i.e. suitable for the older shiny metal tool).

The best way is never to use the tool anyway, as you risk to damage the cylinder if you do. In any case, do heat up the cylinder and case first (with a heat gun) as that really lower the force needed to loosen cylinders and heads.

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Wrench/exhaust web question

Re: Wrench/exhaust web question

I opened one wrench with a file to .303" then noticed the jaws barely extended past the cylinder bore on the opposite side, so I filed the slot 1/16" deeper (to 17/32") so that it fits all the way across the cylinder.

A round needle file cut in the center rear let's it fit even better.

Took about 5-6 mins.

It may not completely prevent web damage but with care to fit the wrench in position properly and a little heat it should minimize it.

A round needle file cut in the center rear let's it fit even better.

Took about 5-6 mins.

It may not completely prevent web damage but with care to fit the wrench in position properly and a little heat it should minimize it.

wha-tah-hey- Rest In Peace

- Posts : 264

Join date : 2013-12-04

Location : Elgin, Al

Re: Wrench/exhaust web question

Re: Wrench/exhaust web question

The old tool has shorter jaws as it was intended for the thin walled cylinders, while the later "black" tool has longer jaws to match the thick walled cylinder in you picture.

I prefer to cut two flats on the top cylinder cooling flange and use the tool there instead. Much lower risk of damaging anything...

I prefer to cut two flats on the top cylinder cooling flange and use the tool there instead. Much lower risk of damaging anything...

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Wrench/exhaust web question

Re: Wrench/exhaust web question

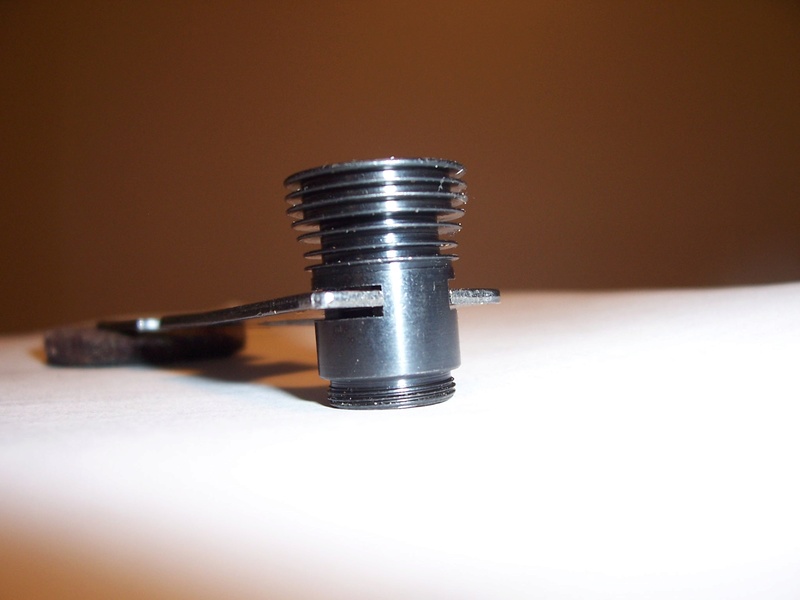

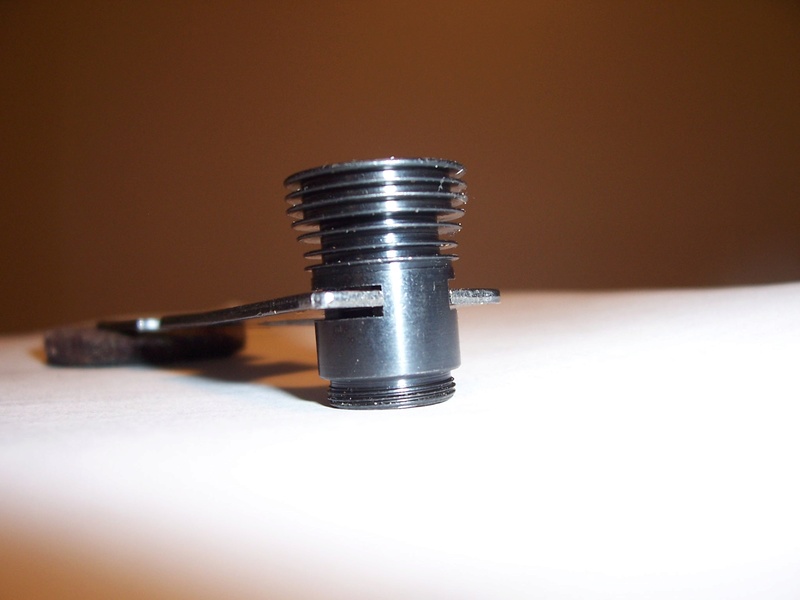

That's a modified black tool in the pic, Kris, I suppose older and made for the stepped cylinder?

Here's before.

Here's before.

wha-tah-hey- Rest In Peace

- Posts : 264

Join date : 2013-12-04

Location : Elgin, Al

Re: Wrench/exhaust web question

Re: Wrench/exhaust web question

I would advise not using one of the tools to remove a cylinder using the exhaust ports. The cylinders are relatively soft metal and easily damaged.

Fine if you are going to replace the cylinder and throw the old one away but some of the cylinders are not easily replaceable. I use a leather strap around the cylinder after heating the crankcase but even that requires care.

I also use nylon and teflon bars machines the fit exactly and patience with soaking and heating.

It is easy to end up with a burr inside the exhaust port and even distort the cylinder with too much force. Especially the thin walled cylinders.

Fine if you are going to replace the cylinder and throw the old one away but some of the cylinders are not easily replaceable. I use a leather strap around the cylinder after heating the crankcase but even that requires care.

I also use nylon and teflon bars machines the fit exactly and patience with soaking and heating.

It is easy to end up with a burr inside the exhaust port and even distort the cylinder with too much force. Especially the thin walled cylinders.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Wrench/exhaust web question

Re: Wrench/exhaust web question

The only times I have used the exhaust port fork, I clamped the tool horizontally in my big vice so it was held lengthwise against both narrow sides of the tool, preventing the fork from spreading. Then, holding the crankcase, I slid the exhaust slits between the trapped fork and turned the crankcase. Don't take this as an endorsement of the tool, but it's the safest way I know of, if you do want to try it. The fork can not spread while applying leverage this way.

Rusty

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Similar topics

Similar topics» Tee Dee .09 question

» Another Question?.

» Oriental ARF assembly

» Please, need some help to identify a Baby Bee ?

» Medallion needle

» Another Question?.

» Oriental ARF assembly

» Please, need some help to identify a Baby Bee ?

» Medallion needle

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules