Log in

Search

Latest topics

» Cox films/videos...by Coxfledgling Today at 4:46 am

» Purchased the last of any bult engines from Ken Enya

by Coxfledgling Today at 4:18 am

» My N-1R build log

by roddie Today at 12:32 am

» Happy 77th birthday Andrew!

by akjgardner Today at 12:27 am

» TEE DEE Having issues

by TD ABUSER Yesterday at 9:43 pm

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» Roger Harris revisited

by TD ABUSER Yesterday at 2:13 pm

» Tee Dee .020 combat model

by Ken Cook Yesterday at 1:41 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Yesterday at 1:37 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 9:24 am

Cox Engine of The Month

Oriental ARF assembly

Page 1 of 5

Page 1 of 5 • 1, 2, 3, 4, 5

Oriental ARF assembly

Oriental ARF assembly

I won't seriously get started until the new Skyray is off my table, pretty soon I hope. But if I need to upgrade some parts, I should start hunting them down now. Some of it is obvious like CF tube and ball links, and real hinges to replace the CA strips.

I see that it has a 4" bellcrank installed. Since I will be remaking the leadouts, I'm considering replacing the bellcrank with a 3" one. I read that the kit Oriental has a 3" crank, but the ARC and ARF have a 4"(I know why). As I write this, it occurs to me that a 3" may not easily fit if the holes in the ribs aren't lined up. I know the wing covering needs some attention to prevent it from shedding, but I am really hoping to not remove it yet. Anyone know if this is a quick swap, or should I just plan on using a wide handle and leave it alone? If necessary I can do exploratory surgery to answer this question, I'm just hoping someone already knows the short answer.

Rusty

P.S.: I'm driving up to Joe Nall to pick up my Magnum Saturday. Hoping it'll go into my Mazda P5. Wayne called and said it flies like a dream.

I see that it has a 4" bellcrank installed. Since I will be remaking the leadouts, I'm considering replacing the bellcrank with a 3" one. I read that the kit Oriental has a 3" crank, but the ARC and ARF have a 4"(I know why). As I write this, it occurs to me that a 3" may not easily fit if the holes in the ribs aren't lined up. I know the wing covering needs some attention to prevent it from shedding, but I am really hoping to not remove it yet. Anyone know if this is a quick swap, or should I just plan on using a wide handle and leave it alone? If necessary I can do exploratory surgery to answer this question, I'm just hoping someone already knows the short answer.

Rusty

P.S.: I'm driving up to Joe Nall to pick up my Magnum Saturday. Hoping it'll go into my Mazda P5. Wayne called and said it flies like a dream.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Oriental ARF assembly

Re: Oriental ARF assembly

Well,

If your handle is spaced 4" and your bellcrank is too then that is a good thing. Why do you want to change?

Not being a smarty pants just wondering.

Looking forward to seeing the Magnum up close!

Ron

If your handle is spaced 4" and your bellcrank is too then that is a good thing. Why do you want to change?

Not being a smarty pants just wondering.

Looking forward to seeing the Magnum up close!

Ron

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Oriental ARF assembly

Re: Oriental ARF assembly

I just don't want it to be sluggish. But I suppose the wide handle takes care of that. Do any of your planes have a 4" crank? I know you like a wide handle like the Hotrock.Cribbs74 wrote:Well,

If your handle is spaced 4" and your bellcrank is too then that is a good thing. Why do you want to change?

Not being a smarty pants just wondering.

Looking forward to seeing the Magnum up close!

Ron

Yeah I'm excited about the Magnum too. I'll get it on video when I fly it Saturday. Wayne and Will say it's really sweet. They told me I'd want to throw my Skyray away.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Oriental ARF assembly

Re: Oriental ARF assembly

In my opinion 1:1 seems like an ideal situation. It may take some adjustment, but I bet you will like it in the long run.

Yes I use a Hot Rock as I like the fat grip and although tight it fits my hand well

My Cardinal has a 4" bellcrank and it responds well to input. Very rarely do I ever have to give it full wrist to do what I want.

Ron

Yes I use a Hot Rock as I like the fat grip and although tight it fits my hand well

My Cardinal has a 4" bellcrank and it responds well to input. Very rarely do I ever have to give it full wrist to do what I want.

Ron

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Oriental ARF assembly

Re: Oriental ARF assembly

While that is an ideal situation, the Oriental can be problematic with the large bellcrank. I know it sounds like a perfect situation and theoretically Ron your correct. Replacing the bellcrank in this plane is a bit difficult to do. A simpler solution is to move the pushrod out on the flap horn one more hole than what is suggested on the plans. You really need to know which engine your using in addition. A FP.40 , LA .40 is going to require at least 2.5-3 ounces of tail weight and this is using a light tongue muffler. There's not a lot of room in the tail of the Oriental. I split the glue joint at the very rear of the fuse and placed a piece of 1/4"x1/4" back there to spread the fuse apart a bit more. This allowed easier access to the elevator horn. I chose to use a clevis there and this gave it slightly more room. Cutting a hole in the side of the fuse very neatly allowed a door to access the horn and also add weight internally.

I will add this, while my comments aren't explaining clearly as to why the 3" vs the 4" if this plane isn't balanced and set up correctly it will be very hard to control due to the extremely slow turning rate. When this plane is setup as the instructions indicate you need an extremely large handle to make the plane fly. All I can suggest is to use caution when doing maneuvers until you get used to it. When setup properly the Oriental can turn some extremely tight corners. I've built the Oriental in kit form and have had several ARF's. The kit built version comes with the 3" bellcrank. I found this to be a far superior turning plane and flyer.

I will add this, while my comments aren't explaining clearly as to why the 3" vs the 4" if this plane isn't balanced and set up correctly it will be very hard to control due to the extremely slow turning rate. When this plane is setup as the instructions indicate you need an extremely large handle to make the plane fly. All I can suggest is to use caution when doing maneuvers until you get used to it. When setup properly the Oriental can turn some extremely tight corners. I've built the Oriental in kit form and have had several ARF's. The kit built version comes with the 3" bellcrank. I found this to be a far superior turning plane and flyer.

Ken Cook- Top Poster

- Posts : 5640

Join date : 2012-03-27

Location : pennsylvania

Re: Oriental ARF assembly

Re: Oriental ARF assembly

I'll call yesterday, 8/28 the project start date since I actually did more than just open the box and talk about it.

Step 1 is to shrink the wrinkles out of the Monokote. Skipping that for later, step 2 is to bore the engine mounting holes and ream them to accept the blind nuts. I had to sand the beams to widen them to fit the fp40, and one of them has the intense odor of mouthwash. I guess so it'll be all minty fresh for when it kisses the ground. The other one is a different color and smells like wood.

In it's previous life someone had hogged out the engine's screw holes, so to make sure my drill was aligned with the hole centers, I found some brass tubes that fit tightly, and used an appropriate sized pointed wood bit to make the marks.

The instructions said to leave about 1/4" clearance between the firewall and the engine. I hope that didn't include the backplate bolts because I just made it 1/4" from the backplate itself. Someone please holler now if that sounds wrong.

I test fit the engine and all seems well so I'm going to paint some thin epoxy on the beams and firewall to fuelproof it.

I'm moving slowly since I still have a bad right arm, but slow is my usual speed anyway. Maybe I'll get back to it later tonight.

Rusty

Step 1 is to shrink the wrinkles out of the Monokote. Skipping that for later, step 2 is to bore the engine mounting holes and ream them to accept the blind nuts. I had to sand the beams to widen them to fit the fp40, and one of them has the intense odor of mouthwash. I guess so it'll be all minty fresh for when it kisses the ground. The other one is a different color and smells like wood.

In it's previous life someone had hogged out the engine's screw holes, so to make sure my drill was aligned with the hole centers, I found some brass tubes that fit tightly, and used an appropriate sized pointed wood bit to make the marks.

The instructions said to leave about 1/4" clearance between the firewall and the engine. I hope that didn't include the backplate bolts because I just made it 1/4" from the backplate itself. Someone please holler now if that sounds wrong.

I test fit the engine and all seems well so I'm going to paint some thin epoxy on the beams and firewall to fuelproof it.

I'm moving slowly since I still have a bad right arm, but slow is my usual speed anyway. Maybe I'll get back to it later tonight.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Oriental ARF assembly

Re: Oriental ARF assembly

Rusty, while the instructions are helpful if you never built one of these, they're very vague and not 100% clear all the time. Here's my take, seeing your using a FP.40, get the engine back as far as possible. The wood used for the engine bearers are fragile and will act like a tuning fork if you put it out too far. The FP.40 is heavy and wasn't designed for this plane so keep it back as close to the firewall as possible. Unfortunately, this can mean jamming on the weak fiberglass cowling so that the drive plate extends out far enough for the spinner backplate I used. Use caution here as it can split. Just remember about the FP weight. This is going to require some 2.5-3 oz's of tail weight. You want the bearers as close to the engine case as possible, you don't want the bearers touching the case with the exception of the mounting lugs. PUT ON YOUR MUFFLER YOUR GOING TO USE to see if it clears F-1 firewall. This can cause bad vibrations if things are touching and a lot of black oil everywhere. My suggestion is to follow your blind nuts up with 4-40 Nyloc's used for jam nuts. A #30 drill bit is a good choice for bolt holes. The wood as you mentioned reminded me of eucalyptus. It made me cough so bad I had to leave for an hour.

As for ironing, I wouldn't go crazy here. The China Kote covering is not very good and it's going to sag and come off regardless. Ironing can make the bubbling worse at times as this stuff is low heat covering. The best thing to do is cut small strips of clear packing tape 1' wide and cover the seams at the leading edge. You can also scuff the covering and shoot clear Lusterkote on the fuse prior to wing assembly. Flaps and elevators are notorious for the covering coming off and I redo those prior to assembly. Ken

As for ironing, I wouldn't go crazy here. The China Kote covering is not very good and it's going to sag and come off regardless. Ironing can make the bubbling worse at times as this stuff is low heat covering. The best thing to do is cut small strips of clear packing tape 1' wide and cover the seams at the leading edge. You can also scuff the covering and shoot clear Lusterkote on the fuse prior to wing assembly. Flaps and elevators are notorious for the covering coming off and I redo those prior to assembly. Ken

Ken Cook- Top Poster

- Posts : 5640

Join date : 2012-03-27

Location : pennsylvania

Re: Oriental ARF assembly

Re: Oriental ARF assembly

The crankcase is pretty close to touching the beams with a tiny amount of wiggle room. I'll check and make sure there's no contact. I'm glad you mentioned the muffler, I'll check that too.Ken Cook wrote:...You want the bearers as close to the engine case as possible, you don't want the bearers touching the case with the exception of the mounting lugs. PUT ON YOUR MUFFLER YOUR GOING TO USE to see if it clears F-1 firewall. This can cause bad vibrations if things are touching and a lot of black oil everywhere.... The wood as you mentioned reminded me of eucalyptus. It made me cough so bad I had to leave for an hour.

Lol, eucalyptus is supposed to soothe coughing. I wonder where they get that Chinese wood. I'm betting it isn't Rock Maple.

I see where the seams are on the wing's LE, what a dumb place to make that. That'll get tape, and I'll see where else needs to be masked for a shot of Lustrekote. Or fingernail clear for small areas.Ken Cook wrote:...scuff the covering and shoot clear Lusterkote on the fuse prior to wing assembly. Flaps and elevators are notorious for the covering coming off and I redo those prior to assembly.

I'm glad you told me it was low temperature covering before I assaulted it with high heat like you have to do with Monokote.

I've got to make some decent leadout connections and am almost out of the 28g spool of copper wire Larry Wilkes gave me, so I'll be going to the tackle shop for some more. I bet 6' of .027 wire in the leadout kits from sig and Brodak is too short, so I better shop for some of that too.

Maybe I should add some top bracing to the bellcrank pivot while I'm at it.

Thanks for the input.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Oriental ARF assembly

Re: Oriental ARF assembly

I fuelproofed the beams, firewall and anything that seemed exposed in the engine area. I mixed 30 minute epoxy and brushed it on thin, occasionally dipping the tip of the brush in acetone to keep it flowing thin. Then I barely dampened a paper towel with alcohol and wiped it mostly off. Before it set I pulled the 4-40 blind nuts tightly into their seats. I'll do the same for the fuel compartment but not before working on the LG reinforcement. As I understand it, some triangle ply needs to be added, but I have to figure out where that goes.

I removed the bellcrank so I can remake the leadouts, brass bushed and copper wrapped. I'm glad I did because the washers were rusted. I threw them away and will use stainless steel instead.

Rusty

I removed the bellcrank so I can remake the leadouts, brass bushed and copper wrapped. I'm glad I did because the washers were rusted. I threw them away and will use stainless steel instead.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Oriental ARF assembly

Re: Oriental ARF assembly

Since my last post I have slotted the flaps to accept 5/8" Dubro pin hinges. Thanks to Windy I know how to make nice neat identical slots now. The existing slits were for CA hinges and way too long and not at all straight. They were only razor slits, not even gouged, so I had to do all that. Here's the slotted flaps ready for the hinges to be glued in.

.

Opening up the existing slits in the wing with an emery board.

.

Scar the tabs of the hinges to grip the glue, smear Vaseline on the joints with a toothpick, flow it into the joints with a heat gun, clean with acetone, and 30 minute epoxy in place. Set the hinge depth against a flat surface like glass, and it should be a straight line of non binding hinges, ready to be assembled to the control horn and glued to the wing. While gluing the hinges, I smeared a thin coat of epoxy along the Monokote seam on the edge of the flaps between the hinges to keep it from detaching in flight. I also put a strip of clear tape along the TE of the wing before adding the flaps for the same reason.

.

I did decide to put a 3" bellcrank in it. I test fit the wing, and it doesn't come close to matching the contour of the cutout in the fuselage, so I guess I'll put some sawdust filler in the epoxy when I glue it in place. It also doesn't want to sit straight at right angles to the fuselage, so some shaping will be needed. I hope people who aren't experienced builders don't expect it to just fall together.

.

Opening up the existing slits in the wing with an emery board.

.

Scar the tabs of the hinges to grip the glue, smear Vaseline on the joints with a toothpick, flow it into the joints with a heat gun, clean with acetone, and 30 minute epoxy in place. Set the hinge depth against a flat surface like glass, and it should be a straight line of non binding hinges, ready to be assembled to the control horn and glued to the wing. While gluing the hinges, I smeared a thin coat of epoxy along the Monokote seam on the edge of the flaps between the hinges to keep it from detaching in flight. I also put a strip of clear tape along the TE of the wing before adding the flaps for the same reason.

.

I did decide to put a 3" bellcrank in it. I test fit the wing, and it doesn't come close to matching the contour of the cutout in the fuselage, so I guess I'll put some sawdust filler in the epoxy when I glue it in place. It also doesn't want to sit straight at right angles to the fuselage, so some shaping will be needed. I hope people who aren't experienced builders don't expect it to just fall together.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Oriental ARF assembly

Re: Oriental ARF assembly

Looks like a pro job Rusty.

I have one thing to add though, I nearly lost the Super Clown when a flap came off in flight last time I flew it. If I were to do it again I would drill a hole through the TE and through the hinge at the same time. Then push a toothpick in the hole and epoxy. The plastic does not always adhere to the Epoxy.

My go to hinge is now going to be the stitched hinge. They never fail!

OTOH on a contest plane I'll probably go with pin hinges because of the clean look.

I have one thing to add though, I nearly lost the Super Clown when a flap came off in flight last time I flew it. If I were to do it again I would drill a hole through the TE and through the hinge at the same time. Then push a toothpick in the hole and epoxy. The plastic does not always adhere to the Epoxy.

My go to hinge is now going to be the stitched hinge. They never fail!

OTOH on a contest plane I'll probably go with pin hinges because of the clean look.

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Oriental ARF assembly

Re: Oriental ARF assembly

Rusty, I add more wood on top (provide more glue area) of what's already present on the top sheeting used for a key. If you have some silicone spray(don't use grease), now would be a good time to hit the flap horn connection and bellcrank pivot points with lube prior to fuse to wing assembly. In addition when the belly pan goes on the bottom I do some more reinforcing in the front joint. However, this requires taking the covering back a 1"on the fuse and the belly pan. I lay a strip of epoxy and glass cloth over the joint and up both sides of the joint to the leading edge of the wing.This also serves as a double standard to prevent oil migration into that joint. This a non issue with the kit as the wire gear is bolted to #2 firewall up high and in the top of the fuse. My belly pan also required the need for a piece of 1/64" ply on the firewall bulkhead so that the fit was better. The gear mounts in front of this joint on the bottom of the fuse. When the plane hits down on a hard landing, it can break the fuse free from the wing joint on top. Once the fuse is glued, I like to use epoxy and a heat gun and allow the epoxy to run into the joint from leading edge to trailing edge. I do a little at a time cleaning with a Q-tip and rubbing alcohol. Make sure it doesn't flow into the flap jointer horn and glue the controls. A drop of oil in between the hinge gap operating the controls a few times can insure that epoxy doesn't stick to the wire if it does go down into there. You can also finish the joint with some clear silicone caulk neatly installed at this juncture to seal off any oil migration into this area and keep the covering down. Ken

Last edited by Ken Cook on Sat Jan 03, 2015 11:09 pm; edited 1 time in total

Ken Cook- Top Poster

- Posts : 5640

Join date : 2012-03-27

Location : pennsylvania

Re: Oriental ARF assembly

Re: Oriental ARF assembly

Ron I've never pinned them before, but since I don't know exactly what I've glued them into in this wing's TE I will consider it. I think the only thing they might be attached to is the "V" where the TE sheets mate, and that isn't much wood. Thanks for the suggestion.

Ken, I've copied your post into my Oriental build folder with others, some of which are from you too. When I print them and go back to work on it, if I can't visualize any of it, I'll give you a holler. Over at Stunthangar there is a thread in which three of us are building the same plane, and I'm posting some of what I'm doing, but saving my questions for CEF.

Thanks

Rusty

Ken, I've copied your post into my Oriental build folder with others, some of which are from you too. When I print them and go back to work on it, if I can't visualize any of it, I'll give you a holler. Over at Stunthangar there is a thread in which three of us are building the same plane, and I'm posting some of what I'm doing, but saving my questions for CEF.

Thanks

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Oriental ARF assembly

Re: Oriental ARF assembly

Rusty, the trailing edge is comprised of 3 pieces and not just the upper and lower sheeting glued together. In addition, some of the time they provided an additional 1/4" x 1/4" x 2" piece glued to the inside. Many times these will break loose and flop around inside the wing. There were 2 generations of Oriental planes. I can't remember which one has the glue blocks, my P-40 has them as well. Your method of installation is the exact method I use and I never had a failure. The flap horn however should be secured to the trailing edge. Brodak makes a brass jointer piece, but I usually bend a piece of music wire 1/16" x 1/2" or smaller into a U. Using it like a staple, I rough the ends up and epoxy it into the trailing edge and push it tight against the flap horn. This keeps the flap horn pivoting on it's centerline and doesn't allow it to travel on a arc. If the flap horn travels on a arc path, it eventually makes the first hinge closest to it on the inboard and outboard flap fail and pull out of it's glue joint. Ken

Ken Cook- Top Poster

- Posts : 5640

Join date : 2012-03-27

Location : pennsylvania

Re: Oriental ARF assembly

Re: Oriental ARF assembly

Good idea, I'll add a retainer loop on each side of the horn.

The only problem I had with the hinges is that the LE of the flap isn't beveled like I do when I make hinged flaps. It is rounded, but I was correctly expecting it to not be enough Therefore after a certain amount of throw up or down, the wing and flap surfaces meet and cause some pull-out of the hinges. It's mostly noticeable at the two innermost hinges and almost, but not quite negligible at the outermost hinges. After an hour of experimentation I had to make a decision. Rather than removing the covering and sanding a V bevel into the flap LE, I just decided how much maximum deflection was necessary and judged that the amount of gap that that much pullout caused was acceptable. I can always seal it with tape later. So when I glued them in place, I carefully moved the flaps through their throw and let them set their own happy position. If you look at my picture, it's barely noticeable and will be fine, probably with no hinge tape.

I could have possibly shaped the flap edges some with a flat tool and a whammer... naah!

Rusty

The only problem I had with the hinges is that the LE of the flap isn't beveled like I do when I make hinged flaps. It is rounded, but I was correctly expecting it to not be enough Therefore after a certain amount of throw up or down, the wing and flap surfaces meet and cause some pull-out of the hinges. It's mostly noticeable at the two innermost hinges and almost, but not quite negligible at the outermost hinges. After an hour of experimentation I had to make a decision. Rather than removing the covering and sanding a V bevel into the flap LE, I just decided how much maximum deflection was necessary and judged that the amount of gap that that much pullout caused was acceptable. I can always seal it with tape later. So when I glued them in place, I carefully moved the flaps through their throw and let them set their own happy position. If you look at my picture, it's barely noticeable and will be fine, probably with no hinge tape.

I could have possibly shaped the flap edges some with a flat tool and a whammer... naah!

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Oriental ARF assembly

Re: Oriental ARF assembly

Rusty, did you recess the barrel into the flap? I built one of my Oriental planes with quickness in mind. I didn't sand bevels or round edges or even tighten up the hinge gaps. It fly reasonably well. This is also one of the heaviest Oriental planes I built. While many would be concerned, I had no issues with it in terms of flyability. I certainly wouldn't allow the flap to bind on the hinge or pull out will result. I hope the flaps are good and solid on your ARF. I've seen some of the flutter due to being rather soft and light. The last re ARF I just did, I cut 1" off of the existing flap and added some heavier balsa and re cut the hinge pockets. At that point, I also had the covering off so I added a piece of 1/4 maple block for the flap horn to go into. Sometimes and I found this to be true with my last few was that I needed to tweak the outboard flap slightly higher than the inboard to assist in leveling the plane out in flight. The low quality flap horn wire used needs to be adjust prior to flight anyhow. Looking at the plane with the nose down and tail pointed up sight both your elevators and flaps to insure they look straight and parallel to each other. This is a really cool plane and I certainly hope it brings you a good deal of satisfaction in your goal. Ken

Ken Cook- Top Poster

- Posts : 5640

Join date : 2012-03-27

Location : pennsylvania

Re: Oriental ARF assembly

Re: Oriental ARF assembly

Ken

I'm on my phone which is a struggle for me.

I did recess the hinges into the LE of the flap, as shown in my first picture in yesterdays first post. Ï had read about flimsy flaps so I checked and they seemed stiff enough. There's almost no gap except near the innermost hinge, and even less when deflected. No binding. Gravity makes them fall fully both ways. I tweaked the horn before installing it and they have even deflection now.

EDIT:

The center raised sheeting that keys the wing is crooked by several degrees, so when I build it up for more gluing contact area I can adjust that for proper wing alignment. I can't believe they would botch it that badly. I feel bad for someone who just blindly builds one of these ARFs trusting it to be right.

I bought some B'Laster industrial strength silicone lube at the auto parts store. I'll lube the internal control assembly before I seal it up. It smells like petroleum, so I checked the label and it does have some sort of petro chemical in it.

Rusty

I'm on my phone which is a struggle for me.

I did recess the hinges into the LE of the flap, as shown in my first picture in yesterdays first post. Ï had read about flimsy flaps so I checked and they seemed stiff enough. There's almost no gap except near the innermost hinge, and even less when deflected. No binding. Gravity makes them fall fully both ways. I tweaked the horn before installing it and they have even deflection now.

EDIT:

The center raised sheeting that keys the wing is crooked by several degrees, so when I build it up for more gluing contact area I can adjust that for proper wing alignment. I can't believe they would botch it that badly. I feel bad for someone who just blindly builds one of these ARFs trusting it to be right.

I bought some B'Laster industrial strength silicone lube at the auto parts store. I'll lube the internal control assembly before I seal it up. It smells like petroleum, so I checked the label and it does have some sort of petro chemical in it.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Question of the day

Question of the day

One question came up today after Ken suggested lubricating the controls with silicone spray lube.

I would like to lube where the bellcrank pivot sits on a washer and that sits on the ply platform. I have the 6-32 nylock nut on top of the pivot spindle as tight as is possible without the crank motion stiffening(+ enough for a hot day). The nut is epoxied in place. If I spray the joint at the other end, I'm concerned the ply crank base may swell, putting more pressure on and fouling the bellcrank. As slight as it may be... I like my controls free.

I started trying to figure out the shape the crooked center section needs to be in order to hold the wing straight. Keyed in place like it is, the outboard wing diverges from perpendicular enough to be more than an inch aft at the tip. That's 2" total the wingtips are out of place related to each other. Two freakin' inches. If I'd known sooner I would have called Brodak and gotten a replacement wing. Ah hell. I'll fix it, but I was klutzing it up pretty good in the shop so I quit for the day. Time to chill and watch some trash TV.

See y'all in the funny pages.

Rusty

I would like to lube where the bellcrank pivot sits on a washer and that sits on the ply platform. I have the 6-32 nylock nut on top of the pivot spindle as tight as is possible without the crank motion stiffening(+ enough for a hot day). The nut is epoxied in place. If I spray the joint at the other end, I'm concerned the ply crank base may swell, putting more pressure on and fouling the bellcrank. As slight as it may be... I like my controls free.

I started trying to figure out the shape the crooked center section needs to be in order to hold the wing straight. Keyed in place like it is, the outboard wing diverges from perpendicular enough to be more than an inch aft at the tip. That's 2" total the wingtips are out of place related to each other. Two freakin' inches. If I'd known sooner I would have called Brodak and gotten a replacement wing. Ah hell. I'll fix it, but I was klutzing it up pretty good in the shop so I quit for the day. Time to chill and watch some trash TV.

See y'all in the funny pages.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Oriental ARF assembly

Re: Oriental ARF assembly

Rusty, if the key is off center it was designed like that. It sounds like the plane was designed with asymmetrical wing panels. The inboard wing is as you mentioned 2-2 1/4" longer which is essentially one rib bay. You could probably count them . My kit built version is equal panels and so is my latest ARF just because I rebuilt the entire wing. My 1st ARF was built new from the box and I changed very little until problems started happening. I can say for a fact that I didn't change the wing panels. I have many stunters with the inboard wing longer than the outboard as it was a common practice back in the day. I can say from the standpoint of the Oriental being a plane that can be flown in several events, this idea was probably due to the original having the longer panel and Brodak was staying true to the design. The theory is the inboard panel is flying faster due to it flying in a smaller circumference. The longer and faster wing panel now generates more lift reducing the outboard tip weight. Wild Bill Netzeband I believe was responsible for this and it was a practice that went on for many years. However, I think it might be one that's overdone and can possibly do more for rolling up vs assisting it through the maneuvers smoothly. A simple small area tab on the outboard flap can easily assist this. I personally would keep rolling forward as this should be a non issue. Ken

Ken Cook- Top Poster

- Posts : 5640

Join date : 2012-03-27

Location : pennsylvania

Re: Oriental ARF assembly

Re: Oriental ARF assembly

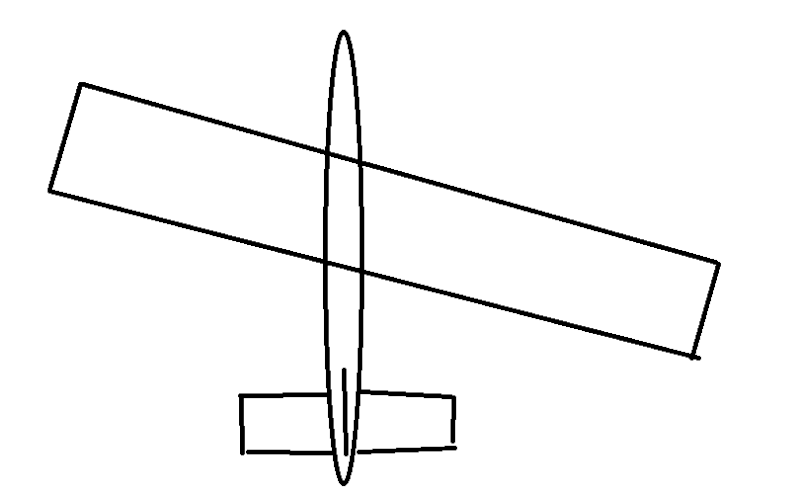

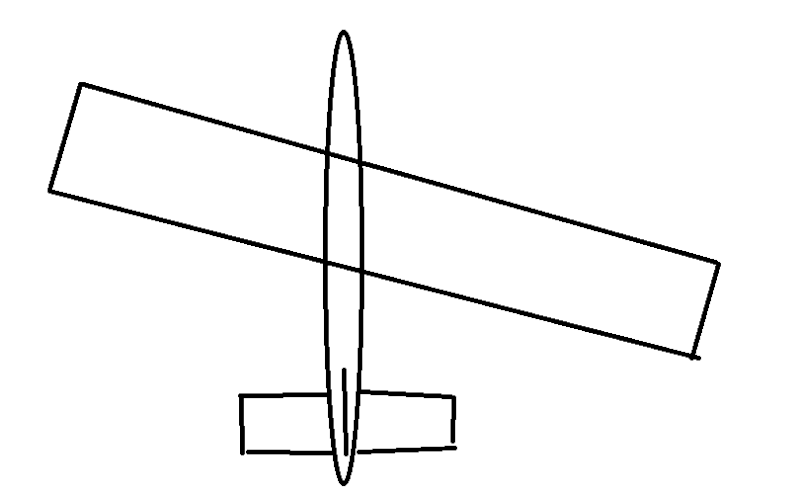

I hadn't noticed one side was longer, I'm familiar with that practice. Here is a crude pic of what I have:

This is of course exaggerated:

This is of course exaggerated:

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Oriental ARF assembly

Re: Oriental ARF assembly

Yes, that will be an issue. Certainly that needs to be addressed or you won't be happy. Will the covering be exposed on one side once this correction is addressed? Back to your original question in regards to lubing the bellcrank. The bellcrank itself is a bearing so little lube is needed on the pivot. I like to give the flap horn a good shot which is where more metal to metal contact takes place. I don't use grease of any kind, just a shot of silicone spray which is more of a dry lubricant. I never had a issue with a bell crank platform swelling. I also don't hose the area.

Ken Cook- Top Poster

- Posts : 5640

Join date : 2012-03-27

Location : pennsylvania

Re: Oriental ARF assembly

Re: Oriental ARF assembly

Rusty,

You made reference to knowing how to slot hinges after watching the windy video. Do you have a link to the video? Or maybe you could do short tutorial for the rest of us?

Thanks?

Jim

You made reference to knowing how to slot hinges after watching the windy video. Do you have a link to the video? Or maybe you could do short tutorial for the rest of us?

Thanks?

Jim

JPvelo- Diamond Member

- Posts : 1972

Join date : 2011-12-02

Age : 57

Location : Colorado

Re: Oriental ARF assembly

Re: Oriental ARF assembly

Ken Cook wrote: Yes, that will be an issue. Certainly that needs to be addressed or you won't be happy. Will the covering be exposed on one side once this correction is addressed?....

No, it's only a few degrees of skew, but it adds up along the length of the wing. Wayne says his Smoothie and Vector were both a little askew, so I was just expecting too much of an ARF. This is still the old generation too. When do I ever build without getting all freaked out about something.

I'll remove enough of the alignment strip so the wing can be positioned straight, and figure out where I need to glue some new alignment keys that will provide the strength necessary when assembled.

It's in one of is 2 hour videos that Paul Taylor posted. "Ptay" on Youtube, I think. I'll see if I can find it. It's a simple sanding bar that I can draw if I can't find it. Ian has used it too. I just used the idea and half freehanded it.JPvelo wrote:Rusty,

You made reference to knowing how to slot hinges after watching the windy video. Do you have a link to the video? Or maybe you could do short tutorial for the rest of us?

Thanks?

Jim

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Oriental ARF assembly

Re: Oriental ARF assembly

Thanks Ian.

And there you have it! You stick the sandpaper to a block that is as deep and wide as the hinge barrel(maybe +1mm wider), glue that to a wide top block that limits the depth of the slot. Make sure there are no ragged edges.

I do the slot gouging first, next I sand the leading edge of the flap into a V for non-binding throw. This also makes for no hinge-line gap and free movement. Then sand the recess.

Leave the TE of the wing flat with only hinge slots and no recesses.

Rusty

And there you have it! You stick the sandpaper to a block that is as deep and wide as the hinge barrel(maybe +1mm wider), glue that to a wide top block that limits the depth of the slot. Make sure there are no ragged edges.

I do the slot gouging first, next I sand the leading edge of the flap into a V for non-binding throw. This also makes for no hinge-line gap and free movement. Then sand the recess.

Leave the TE of the wing flat with only hinge slots and no recesses.

Rusty

Last edited by RknRusty on Tue Jan 06, 2015 10:30 am; edited 1 time in total

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Page 1 of 5 • 1, 2, 3, 4, 5

Similar topics

Similar topics» 1/2A Nobler & 1/2A Oriental - foam wings, profile

» Skitzoid Phred here with Brodak ARC Oriental addition to the growing fleet

» My Oriental's OS 40fp spraybar

» First patterns with the Oriental - Video

» Another Oriental shakedown flight

» Skitzoid Phred here with Brodak ARC Oriental addition to the growing fleet

» My Oriental's OS 40fp spraybar

» First patterns with the Oriental - Video

» Another Oriental shakedown flight

Page 1 of 5

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules