Log in

Search

Latest topics

» Tee Dee .020 combat modelby roddie Today at 1:34 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» My latest doodle...

by batjac Yesterday at 9:47 pm

» My N-1R build log

by roddie Yesterday at 8:50 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

» My current avatar photo

by roddie Mon Nov 18, 2024 9:05 pm

Cox Engine of The Month

Outside Loops

Page 1 of 2

Page 1 of 2 • 1, 2

Outside Loops

Outside Loops

A few years ago Ken Burdick caused me to get started on a project we ended up calling the Wido Satan. It was intended as an easy to build and operate 1/2A combat model. It's documented on Flying Lines http://flyinglines.org/kb.widosatan.html . The easy to build was no problem. The easy to operate, not so much. I cannot get an integral tank Cox .049 to run through outside loops. I've used Babe Bees set up both upright and as described in the Carl Goldberg Lil Satan plans. I have used Black Widows set up both upright and as described in the Carl Goldberg Lil Satan plans. I've used other various Cox integral tank setups. I can get all of them to run fine level and through inside loops. I can even get them to run inverted. Down elevator for long enough to do a compete loop is at best enough to slow the engine severely. Most time it will kill the engine leaving the plane to fall straight down from the top of the circle. For the fuel pickup I've used clear nylon tubing as per the stock setup. I've used metal tubing per Paul Gibealut's mouse race article. I've used silicone tubing. In all cases, the pickup was located to the outboard portion of the tank. I close the needle, then submerge and pressurize the tank to test for leaks before running. Reed valve Cox .049's running on surgical tubing bladders work great. You can see the model at the end of the article http://flyinglines.org/gp.col3.html I suppose there may be some reason the integral won't work no matter what I try, but I'm open to all input. If you have an integral tank Cox .049 that works for doing outside loops and flying inverted, please post the particulars of the engine. What kind of head, what kind of tank. what kind of cylinder, what kind of reed, what kind of fuel, anything else you think may be important. Thanks in advance,

Gene Pape

Gene Pape

CheapImitation- New Member

- Posts : 3

Join date : 2013-12-28

Re: Outside Loops

Re: Outside Loops

Hi there. First off, welcome to the forum. Secondly it is quite funny that you are here, as I just found the Widow Satan article you linked to this past weekend and printed out a copy of the plans. Looks like a good little project. But unfortunately I can't answer your question but just wanted to say hi.

new222

new222

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: Outside Loops

Re: Outside Loops

Is it imperative that that a tanked engine be used? If so; can the tank be bypassed for more capacity through the use of an external tank? It can help for a more rearward CG. (there's a recent thread on Bee fuel-capacity) If backplate options are open.. try a standard horseshoe backplate/NVA using some alternate-vent wedge-tanks.

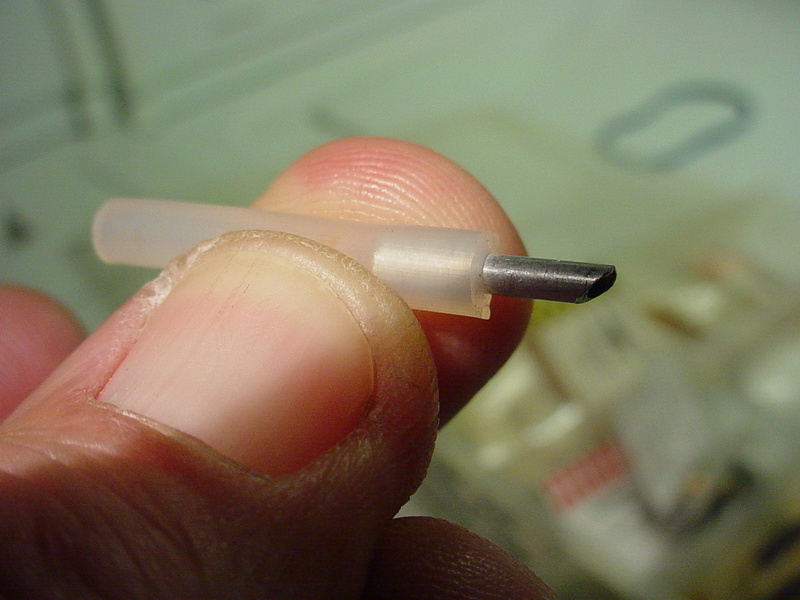

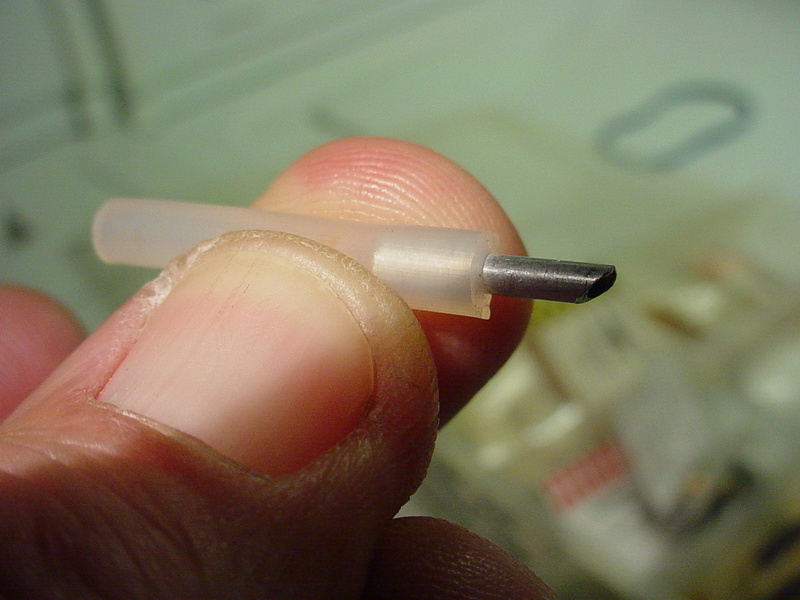

Some pics for 5cc integral-tank fuel pick-up mods. Just random ideas.. not all tested.

another approach.. using a compression-fitting. Some modelers' swear to the inclusion of the tiny/fragile spring contained in the stock pick-up line. It's been the subject of debate. Capillary-action supports some theory.. anti-kink would have been a side benefit... then there's the flow-stabilization properties involved. Fuel-bubbles mainly. It's not likely that they'd make their way past that spring.. into the venturi.

then there's the flow-stabilization properties involved. Fuel-bubbles mainly. It's not likely that they'd make their way past that spring.. into the venturi.

Some pics for 5cc integral-tank fuel pick-up mods. Just random ideas.. not all tested.

another approach.. using a compression-fitting. Some modelers' swear to the inclusion of the tiny/fragile spring contained in the stock pick-up line. It's been the subject of debate. Capillary-action supports some theory.. anti-kink would have been a side benefit...

Re: Outside Loops

Re: Outside Loops

I have had many successful runs with integral type tanks. Unfortunately, none of them were very long. I have experienced issues in the Cox like a Fox .35 where the engine wants to load and burp on the outside maneuvers. Nothing special in my setups. I was using Black Widows from the late 80's early 90's. Over and under venting and not the plastic tank. Air leak checks are a must. This is why I'm a fan of the plastic backplate because the screws are less susceptible to leaking at the rear of the backplate, however in the years I mentioned, the backplates would fail around the internal screw bosses. Seeing that the plastic is black, the cracks are usually undetectable until you air check the tank or overtighten the screws . The placement of the pickup is critical and getting it to stay put is a real test of patience. I have drilled holes in the metal ones where the area is gated in the middle of the tank to retain the fuel tubing and wire tied the pickup. The best tubing I have ever found to work was a sample that Davis Diesel provided me with. It would hold very tight on the nipple and wouldn't harden or flare out on the ends when installed. Many times I've seen the ends all distorted and not holding tight on the nipple.

Inverted flights are generally ok I wouldn't give them the 2 thumbs up, I limit my time inverted because it tends to generally starve for fuel. I mix up the maneuvers a good bit and I get the best of all. Having a new glow plug is key, even if the plug is glowing bright. They're just fickle and as expensive as they may seem, it makes a difference in the engine quality run. I mostly use stock Cox but I have used the Nelson and Merlin setups as well. I used Sig 35% for years, I have since backed off and went to the new Cox 25%. I like it a lot. Some of the best runs I had was using 45% Byron castor fuel. This was old fuel but worked great. Not made any longer but Randy Ritch can match that fuel. A gallon though is going to be quite a bit of money.

The main problem I have found with my old engines is in the crank area. The old castor burnished onto the crankshaft needs to be manually removed. While I can take them out of storage and run them immediately, when I put them to the test, sagging usually results when I push them through the harder maneuvers. I feel the castor starts heating up and acting like a brake on the shaft. A good polishing in a drill press rids the shaft of this . If you want to dive deeper into this, you can lap the lower portion of the cylinder using the piston upside down in the cylinder using Mother's aluminum polish. Take a piece of K&S 3/8" tubing wrap tape around the top and insert the piston onto it with the rod dropped into the center. The tape will cause a friction fit on the piston allowing you to spin the tube. Place the piston into the cylinder upside down and using the skirt only not the crown work the polish into the cylinder. Move up and down while twirling. Essentially, your tapering the lower portion of the cylinder. This is not necessary, just something I like to do as I feel that it prevents heat buildup. Any drag is a problem and the smaller the engine, the worse it becomes.

As your probably aware, keep the prop load light. A 3 pitch is in order to sustain drive even if the engine is running high rpm's. The Cox black 5x3 works great ( Not the safety tip) . I dislike the safety tip and found them very inefficient. Keep in mind that you can have 10 of these engines and 2 will generally stand out above the rest. They're the two your in search off. I also found the clear Mylar reed to work best, it is short lived over the others. This isn't the white Teflon reed. I like the Mylar because I can tell if it's working because it has a tendency to chirp during flipping. Not all do it, only some but most of the time it lets me know .

Roddie makes mention of the wedge tank, not always a easy install in a Lil Satan and the tank design itself doesn't prove worthy of combat maneuvering. The fuel will run away from the pickup causing overlean runs and unpredicted shut offs. A bladder is far superior. I've toyed with the idea of making the Cox tank uniflow to improve the engine runs. That being said, it's easier and more economical to bolt a Norvel on and go fly. I do like to tinker but these can test your patience and your plane's construction or I should say destruction. Good luck, Ken

Inverted flights are generally ok I wouldn't give them the 2 thumbs up, I limit my time inverted because it tends to generally starve for fuel. I mix up the maneuvers a good bit and I get the best of all. Having a new glow plug is key, even if the plug is glowing bright. They're just fickle and as expensive as they may seem, it makes a difference in the engine quality run. I mostly use stock Cox but I have used the Nelson and Merlin setups as well. I used Sig 35% for years, I have since backed off and went to the new Cox 25%. I like it a lot. Some of the best runs I had was using 45% Byron castor fuel. This was old fuel but worked great. Not made any longer but Randy Ritch can match that fuel. A gallon though is going to be quite a bit of money.

The main problem I have found with my old engines is in the crank area. The old castor burnished onto the crankshaft needs to be manually removed. While I can take them out of storage and run them immediately, when I put them to the test, sagging usually results when I push them through the harder maneuvers. I feel the castor starts heating up and acting like a brake on the shaft. A good polishing in a drill press rids the shaft of this . If you want to dive deeper into this, you can lap the lower portion of the cylinder using the piston upside down in the cylinder using Mother's aluminum polish. Take a piece of K&S 3/8" tubing wrap tape around the top and insert the piston onto it with the rod dropped into the center. The tape will cause a friction fit on the piston allowing you to spin the tube. Place the piston into the cylinder upside down and using the skirt only not the crown work the polish into the cylinder. Move up and down while twirling. Essentially, your tapering the lower portion of the cylinder. This is not necessary, just something I like to do as I feel that it prevents heat buildup. Any drag is a problem and the smaller the engine, the worse it becomes.

As your probably aware, keep the prop load light. A 3 pitch is in order to sustain drive even if the engine is running high rpm's. The Cox black 5x3 works great ( Not the safety tip) . I dislike the safety tip and found them very inefficient. Keep in mind that you can have 10 of these engines and 2 will generally stand out above the rest. They're the two your in search off. I also found the clear Mylar reed to work best, it is short lived over the others. This isn't the white Teflon reed. I like the Mylar because I can tell if it's working because it has a tendency to chirp during flipping. Not all do it, only some but most of the time it lets me know .

Roddie makes mention of the wedge tank, not always a easy install in a Lil Satan and the tank design itself doesn't prove worthy of combat maneuvering. The fuel will run away from the pickup causing overlean runs and unpredicted shut offs. A bladder is far superior. I've toyed with the idea of making the Cox tank uniflow to improve the engine runs. That being said, it's easier and more economical to bolt a Norvel on and go fly. I do like to tinker but these can test your patience and your plane's construction or I should say destruction. Good luck, Ken

Ken Cook- Top Poster

- Posts : 5637

Join date : 2012-03-27

Location : pennsylvania

Re: Outside Loops

Re: Outside Loops

Thanks for the replies. As to why integral tank engines, I thought they would be easy. I appear to have been wrong. Two things struck me from the replies. I have also learned that glow plugs and the number of gaskets under them have a big effect on the way the engines run in general, not just the amount of power they make. I will pursue this further. Also, the specific problem I am having seems to be related to the fuel pickup in the tank. I've tried lots of things, but you've given me some new ideas to try. It will take a few weeks, but I'll report back.

Gene

Gene

CheapImitation- New Member

- Posts : 3

Join date : 2013-12-28

Re: Outside Loops

Re: Outside Loops

The only thing I can add is my recent experience with my Tee Dee .051. It runs fast and mean upright and turns inside loops just fine. It will fly inverted if you ease it over and wait for it to recover from the burp, but any hard outside g-force like a loop will shut it off.

Its piston and cylinder is so worn out that with the super high compression Merlin head, I only use one copper gasket. I think what's happening is during outside loops it's letting fuel slip past the sides of the piston(probably right above the bypasses) and drown the plug. I plan to put a new Tee Dee .049 P/C on it before flying it again.

Rusty

Its piston and cylinder is so worn out that with the super high compression Merlin head, I only use one copper gasket. I think what's happening is during outside loops it's letting fuel slip past the sides of the piston(probably right above the bypasses) and drown the plug. I plan to put a new Tee Dee .049 P/C on it before flying it again.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Outside loops

Outside loops

HI Gene,

HMmmm! I have not noticed this phenomena on my Cox powered "Flip" model. BUT...although figure 8's are NO problem, I can't remember if I've done consecutive outside's. I think it will do it but will test this Spring. Nonetheless, the only thing that comes to mind is your venturi size. The Golden Bee's tank venturi is .062" I.D. whereas the Black Widow's venturi is .082". I'm just curious if this venturi size difference makes a difference in your particular case...

OH...and one other item. I think your engine cylinder should be UPRIGHT. I can't explain why, but engines with cylinders on the side, just don't run that stable.

That is UNLESS you convert your tank to a proper uniflow, then it will work fine & you'll have a longer run time.

Wish I lived closer to you combat guys in the NW! Good luck.

Cheers, Paul

HMmmm! I have not noticed this phenomena on my Cox powered "Flip" model. BUT...although figure 8's are NO problem, I can't remember if I've done consecutive outside's. I think it will do it but will test this Spring. Nonetheless, the only thing that comes to mind is your venturi size. The Golden Bee's tank venturi is .062" I.D. whereas the Black Widow's venturi is .082". I'm just curious if this venturi size difference makes a difference in your particular case...

OH...and one other item. I think your engine cylinder should be UPRIGHT. I can't explain why, but engines with cylinders on the side, just don't run that stable.

That is UNLESS you convert your tank to a proper uniflow, then it will work fine & you'll have a longer run time.

Wish I lived closer to you combat guys in the NW! Good luck.

Cheers, Paul

Paulgibeault- Gold Member

- Posts : 259

Join date : 2011-09-24

Location : Leduc, Alberta Canada

Re: Outside Loops

Re: Outside Loops

lol, I remember my first outside loops (6th grade) using a Golden Bee on a Jimmy Walker Firebird, i thought i was really something being able to do consecutive outside loops, don't recall engine issues other then not as long of run time as i wished..

Re: Outside Loops

Re: Outside Loops

Yes, my thoughts on drowning the glow plug only applies to my sideways cylinder, and that wasn't a Bee either, rather a beam mounted Tee Dee. So lots of different possibilities.Paulgibeault wrote:HI Gene,

... I think your engine cylinder should be UPRIGHT. I can't explain why, but engines with cylinders on the side, just don't run that stable.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Outside Loops

Re: Outside Loops

Hi again Gene, My first experience flying inverted was with a Golden Bee. I'd previously had the engine apart and replaced the fuel pick-up with Dubro sm. size silicone fuel line. I think it's a smaller ID than stock. I cut an angle on the pick-up end.. and located it outboard when assembling. Nothing special.. no internal spring. IIRC.. the cylinder was upright. I flew with 25' lines.. so centrifugal-force could have factored-in. I hadn't performed any consecutive outsides.. but the engine ran seamlessly when transitioning to inverted for a few laps.. and all through pulling back up and over. It was a flapped sheet-wing model of my own design.. not that it would matter.

At that time I had two Golden Bees. I only recently learned (still have both engines..) that they are very different. One has a .082" venturi. Cylinders were interchanged/mixed-up and undocumented unfortunately. So I can't tell you which venturi-size/cylinder-porting was used when I flew that model. I usually ran 6 x 3 Zinger wood props in those days.. on Cox Superfuel or Sig Champion 25. Stock glowplug/single head-gasket. I didn't know then, of the tips for sealing the tank/needle-valve against air-leaks. I just assembled the engine (usually with just a new case-gasket) being mindful to tighten the case-screws evenly and alternately. The Copper reed was standard. Can't think of much else.. other than placing a few drops of 3-in-One oil on the drive-plate/case junction, as I often used a small electric-starter.

If you suspect the fuel pick-up.. then the aforementioned Dubro line would be an easy/cheap thing to try. I mentioned cutting an angle in the pick-up end. It's just a safeguard in case the pick-up seats against an obstruction once the tank is assembled.

At that time I had two Golden Bees. I only recently learned (still have both engines..) that they are very different. One has a .082" venturi. Cylinders were interchanged/mixed-up and undocumented unfortunately. So I can't tell you which venturi-size/cylinder-porting was used when I flew that model. I usually ran 6 x 3 Zinger wood props in those days.. on Cox Superfuel or Sig Champion 25. Stock glowplug/single head-gasket. I didn't know then, of the tips for sealing the tank/needle-valve against air-leaks. I just assembled the engine (usually with just a new case-gasket) being mindful to tighten the case-screws evenly and alternately. The Copper reed was standard. Can't think of much else.. other than placing a few drops of 3-in-One oil on the drive-plate/case junction, as I often used a small electric-starter.

If you suspect the fuel pick-up.. then the aforementioned Dubro line would be an easy/cheap thing to try. I mentioned cutting an angle in the pick-up end. It's just a safeguard in case the pick-up seats against an obstruction once the tank is assembled.

Re: Outside Loops

Re: Outside Loops

I'm working on a uniflow setup that runs on exhaust pressure. I hope to have it in the air Friday. Will keep you posted.

Jim

Jim

JPvelo- Diamond Member

- Posts : 1972

Join date : 2011-12-02

Age : 57

Location : Colorado

Re: Outside Loops

Re: Outside Loops

I won't suggest that uniflow won't work. I will say the problem with the feed is the shape of the tank. Fuel gets pinned to the side wall and many times the pickup is hard bent to the back of the backplate. This is where the problem starts. Many times racing style tanks don't have the pickup hard into the rear corner like a stunt tank. The tank feeds when it's full but it quickly becomes starved when the fuel doesn't have the pickup submerged.

Ken Cook- Top Poster

- Posts : 5637

Join date : 2012-03-27

Location : pennsylvania

Uniflow on a Cox Black Widow.

Uniflow on a Cox Black Widow.

Here's just one example of a reed valve tank converted to uniflow & a tire valve as an overflow vent. Works perfectly & gives superior range.

Note important sealant required to make this work properly, no leaks can be tolerated.

Cheers, Paul

Paulgibeault- Gold Member

- Posts : 259

Join date : 2011-09-24

Location : Leduc, Alberta Canada

Another uniflow for a Babe Bee

Another uniflow for a Babe Bee

Here's another way. Note: The uniflow vent must be located next to the fuel pick up. Better range (longer engine run) & stable needle setting throughout the tank run is the reward. Of course, tank MUST be sealed. J-B Weld holds the uniflow pipe vent in place.

Should work great for stunt I would think...

Cheers, Paul

Paulgibeault- Gold Member

- Posts : 259

Join date : 2011-09-24

Location : Leduc, Alberta Canada

Backplate pick up detail

Backplate pick up detail

This is one easy method of keeping the fuel pick up in the proper place which is the most outboard part of the tank. 3/32" O.D. tubing seems to be quite adequate, for all uses including aerobatics. Attach fuel line (whatever you decide to use) MUST fit the pick up & backplate nipple firmly. No leak can be tolerated here.

Cheers, Paul

Paulgibeault- Gold Member

- Posts : 259

Join date : 2011-09-24

Location : Leduc, Alberta Canada

Re: Outside Loops

Re: Outside Loops

Here's what I came up with. I'm curious to see if it chokes on its own regurgitated castor. Should have a chance to run it tomorrow after the permatex drys.

JPvelo- Diamond Member

- Posts : 1972

Join date : 2011-12-02

Age : 57

Location : Colorado

Re: Outside Loops

Re: Outside Loops

That's pretty ingenious, Jim. Keeping the tank slightly pressurized can't hurt. Even if it's an SPI engine, I don't think it'll choke on its own sputum too badly, especially with the opposite port facing straight into the propwash. I'll be intereste to see how it runs.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Outside Loops

Re: Outside Loops

JPvelo wrote:Here's what I came up with. I'm curious to see if it chokes on its own regurgitated castor. Should have a chance to run it tomorrow after the permatex drys.

I liked this when you first posted before assembly. Neat work Jim! Do you have any spare cylinder-shims to experiment with? My thought is that you could index the exhaust ports closer-to or at 90 degrees to the crankshaft, to see if it makes a difference in the run. IDK how thick the shims are.. but maybe adding just one would turn/aim that rear-facing port back square with the deflector and its' vent-tube. Maybe that's unnecessary.. but you could actually end up with a swirl/siphoning-effect caused by the curvature of the deflector.

Of course; shims would also reduce any SPI and slightly reduce compression.

It would be something to try though if the engine doesn't run smoothly.

It would be something to try though if the engine doesn't run smoothly. After all that work, it would be good to have a simple tweak to try.

Re: Outside Loops

Re: Outside Loops

Ran the Uni-FLOWBEE, good consistent runs for two tanks. Will try and fly it next week.

Jim

Jim

JPvelo- Diamond Member

- Posts : 1972

Join date : 2011-12-02

Age : 57

Location : Colorado

Re: Outside Loops

Re: Outside Loops

Excellent. No gurgling or choking on it's oily exhaust?

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Outside Loops

Re: Outside Loops

Cool stuff Jim bee looking for the report , i persome you are after inverted and outside loops

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Outside Loops

Re: Outside Loops

It ran great after I sealed a leak, it needs gaskets where the plastic reed retainer meets the tank and at the exhaust deflector as well. It was only turning 16k so drilled the texaco tank Venturi to 5/64. Also it turns out JB weld is not fuel proof so I had to re glue the vent tube. It should be fine for test flights but the concept will need a better execution to be viable.RknRusty wrote:Excellent. No gurgling or choking on it's oily exhaust?

I'll be trying this concept on a horseshoe engine with a separate tank as well. If it works as well as I hope I may build this to fly in Old Time Stunt at the southwest regionals:

http://www.outerzone.co.uk/plan_details.asp?ID=2905

I'll start a seperate thread for the horseshoe project so I don't further hijack this thread.

Jim

JPvelo- Diamond Member

- Posts : 1972

Join date : 2011-12-02

Age : 57

Location : Colorado

Re: Outside Loops

Re: Outside Loops

Here's one from the "why didn't I think of that before" department. Instead of drilling holes in tanks and JB welding tubes you could just mount a stunt tank sideways with the vents on top. The rearward vent tube would be placed in a "close enough" uniflow position. Vent the back tube to my exhaust deflector or simply into the prop blast above the full fuel height. Block the front vent and go fly.

JPvelo- Diamond Member

- Posts : 1972

Join date : 2011-12-02

Age : 57

Location : Colorado

Re: Outside Loops

Re: Outside Loops

I have done dozens of J&B weld adaptations and so far NO experience with glow fuel up to 35% deteriorating the weld

I mix by weight on a scale

I spend a lot of time making it all same color and NONE left unmixed

I scrape or sand the accepting surface

I alcohol wash the surface

I acetone wash the surface

I wear gloves to prevent any Skin oil contamination

I always let set for a full 24 hours before even touching the parts

I have used J&B weld to recreate drilled and tapped areas that I am confident are as strong as the cast or machined area

The few times I used J&B to set a C/L carb or other Nitro/glow fuel contact area, I never experienced any deterioration of the part(s)

OK what I am saying is that ....properly measured and mixed...I find the J&B weld product to be rather Glow fuel agnostic..non reactive, and still just as secure as before any fuel contamination

I know there are many J&B products so I am talking about the TYPICAL two tube STEEL version

I mix by weight on a scale

I spend a lot of time making it all same color and NONE left unmixed

I scrape or sand the accepting surface

I alcohol wash the surface

I acetone wash the surface

I wear gloves to prevent any Skin oil contamination

I always let set for a full 24 hours before even touching the parts

I have used J&B weld to recreate drilled and tapped areas that I am confident are as strong as the cast or machined area

The few times I used J&B to set a C/L carb or other Nitro/glow fuel contact area, I never experienced any deterioration of the part(s)

OK what I am saying is that ....properly measured and mixed...I find the J&B weld product to be rather Glow fuel agnostic..non reactive, and still just as secure as before any fuel contamination

I know there are many J&B products so I am talking about the TYPICAL two tube STEEL version

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: Outside Loops

Re: Outside Loops

I agree with Fred.

I have used JB Weld countless times but would like to add that it must be mixed really well before applying.

It is also more resistant to heat than common epoxies and will survive temperatures over 200 deg C. I have used it on silencers/mufflers and it has held.

As Fred recommends, the surfaces to be "stuck" need to be spotlessly clean and given a rough and even scratched surface to help the bond.

I have used JB Weld countless times but would like to add that it must be mixed really well before applying.

It is also more resistant to heat than common epoxies and will survive temperatures over 200 deg C. I have used it on silencers/mufflers and it has held.

As Fred recommends, the surfaces to be "stuck" need to be spotlessly clean and given a rough and even scratched surface to help the bond.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Page 1 of 2 • 1, 2

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules