Log in

Search

Latest topics

» Chocolate chip cookie dough.........by rsv1cox Today at 10:20 am

» Tee Dee .020 combat model

by rsv1cox Today at 10:07 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» My latest doodle...

by batjac Yesterday at 9:47 pm

» My N-1R build log

by roddie Yesterday at 8:50 pm

» Purchased the last of any bult engines from Ken Enya

by getback Yesterday at 12:05 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

» My current avatar photo

by roddie Mon Nov 18, 2024 9:05 pm

Cox Engine of The Month

Help, the vent hole on my GoldenBee plastic backplate opened up.

Page 2 of 2

Page 2 of 2 •  1, 2

1, 2

Re: Help, the vent hole on my GoldenBee plastic backplate opened up.

Re: Help, the vent hole on my GoldenBee plastic backplate opened up.

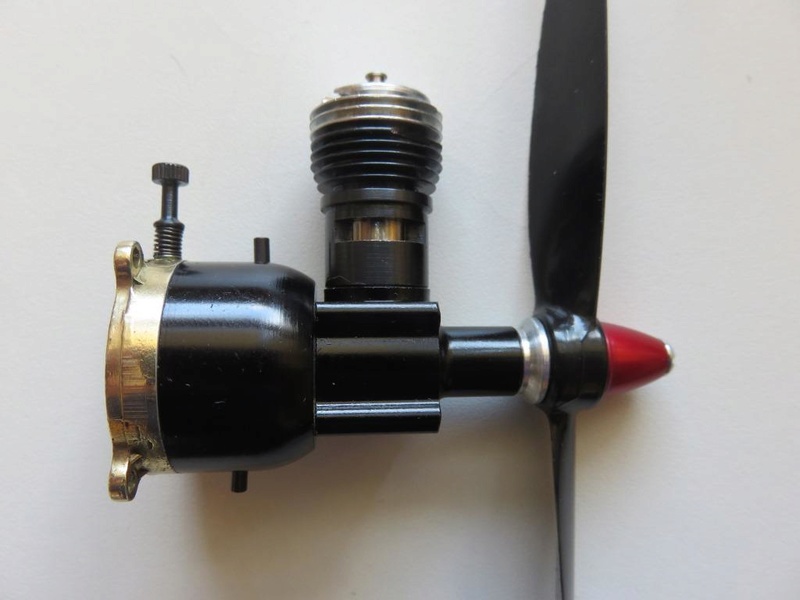

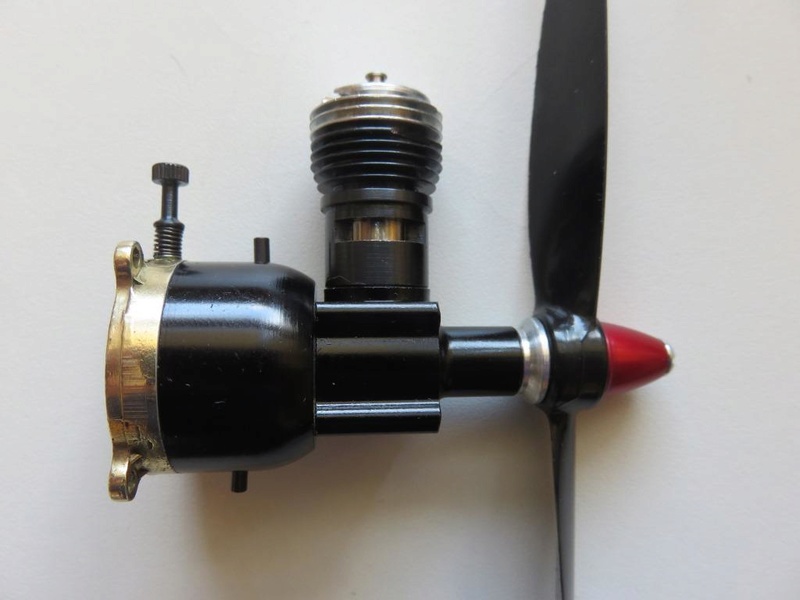

Well I bought on eBay an original NIB Black Widow. I'm not sure if this engine is completely original but now I have a metal (looks like brass anodized steel) backplate for stunt fuel tanks.

Looks like a Babe Bee backplate whose vent holes have been "filled" with a drop of brass or another metal? Funny.

Looks like a Babe Bee backplate whose vent holes have been "filled" with a drop of brass or another metal? Funny.

Paul_BB- Bronze Member

- Posts : 59

Join date : 2015-03-16

Age : 61

Re: Help, the vent hole on my GoldenBee plastic backplate opened up.

Re: Help, the vent hole on my GoldenBee plastic backplate opened up.

The metal backs are die cast zinc alloy. There were a number of different molds used over the years, and that one was altered from having the fill tubes cast, instead of the fill tubes being cut off in a later machining step.

The brass color is a plating treatment that extends the life of the metal.

Phil

The brass color is a plating treatment that extends the life of the metal.

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: Help, the vent hole on my GoldenBee plastic backplate opened up.

Re: Help, the vent hole on my GoldenBee plastic backplate opened up.

pkrankow wrote:The metal backs are die cast zinc alloy. There were a number of different molds used over the years, and that one was altered from having the fill tubes cast, instead of the fill tubes being cut off in a later machining step.

The brass color is a plating treatment that extends the life of the metal.

Phil

Thanks for the information Phil.

So this backplate is an original one?

Paul_BB- Bronze Member

- Posts : 59

Join date : 2015-03-16

Age : 61

Re: Help, the vent hole on my GoldenBee plastic backplate opened up.

Re: Help, the vent hole on my GoldenBee plastic backplate opened up.

I have another question.

When I look at the cylinder list on the Cox model engine Wikipedia page:

https://en.wikipedia.org/wiki/Cox_model_engine

I see that the Black Widow pre 96 cylinder has:

- a thick wall

- open exhaust ports

- two bypass ports

- Sub Piston Injection

- number #1 engraved on the cylinder

- no bypass booster

And the Black Widow post 96 cylinder has:

- a thick wall

- slit exhaust ports

- two bypass ports

- no Sub Piston Injection

- no number engraved on the cylinder

- one bypass booster

But my cylinder has:

- a thick wall

- open exhaust ports

- two bypass ports

- Sub Piston Injection

- no number engraved on the cylinder

- no bypass booster

So I what the heck?

When I look at the cylinder list on the Cox model engine Wikipedia page:

https://en.wikipedia.org/wiki/Cox_model_engine

I see that the Black Widow pre 96 cylinder has:

- a thick wall

- open exhaust ports

- two bypass ports

- Sub Piston Injection

- number #1 engraved on the cylinder

- no bypass booster

And the Black Widow post 96 cylinder has:

- a thick wall

- slit exhaust ports

- two bypass ports

- no Sub Piston Injection

- no number engraved on the cylinder

- one bypass booster

But my cylinder has:

- a thick wall

- open exhaust ports

- two bypass ports

- Sub Piston Injection

- no number engraved on the cylinder

- no bypass booster

So I what the heck?

Paul_BB- Bronze Member

- Posts : 59

Join date : 2015-03-16

Age : 61

Re: Help, the vent hole on my GoldenBee plastic backplate opened up.

Re: Help, the vent hole on my GoldenBee plastic backplate opened up.

That is a good looking Black Widow. As for the number on the cylinder, sometimes it is not very deeply punched or engraved. Look closely on the sides of the exhaust ports, sometimes the number is stamped there.

I would say, if your engine is an NIB, that it is from the early eighties. You have the round prop drive, aluminum spinner and the metal backplate. Somewhere there is a list of changes on the Black Widows, not sure when the aluminum spinner was brought to replace the rubber one.

The metal backplates on all the tanked engines are rather crudely made and finished if you compare them to the rest of the engine But your backplate most likely is in its original condition, since the gold-colour plating on it is intact. Besides, I don't think the backplate metal can be soldered, brazed or welded.

But your backplate most likely is in its original condition, since the gold-colour plating on it is intact. Besides, I don't think the backplate metal can be soldered, brazed or welded.

I have a later "pre 1996" BW, it has the similar cylinder (with a very faint "1" on it), plastic backplate and a hex driveplate. And also the aluminum spinner.

I would say, if your engine is an NIB, that it is from the early eighties. You have the round prop drive, aluminum spinner and the metal backplate. Somewhere there is a list of changes on the Black Widows, not sure when the aluminum spinner was brought to replace the rubber one.

The metal backplates on all the tanked engines are rather crudely made and finished if you compare them to the rest of the engine

But your backplate most likely is in its original condition, since the gold-colour plating on it is intact. Besides, I don't think the backplate metal can be soldered, brazed or welded.

But your backplate most likely is in its original condition, since the gold-colour plating on it is intact. Besides, I don't think the backplate metal can be soldered, brazed or welded.I have a later "pre 1996" BW, it has the similar cylinder (with a very faint "1" on it), plastic backplate and a hex driveplate. And also the aluminum spinner.

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Re: Help, the vent hole on my GoldenBee plastic backplate opened up.

Re: Help, the vent hole on my GoldenBee plastic backplate opened up.

Thanks for the reply Kari

Last edited by Paul_BB on Thu Sep 01, 2016 5:44 am; edited 1 time in total

Paul_BB- Bronze Member

- Posts : 59

Join date : 2015-03-16

Age : 61

Re: Help, the vent hole on my GoldenBee plastic backplate opened up.

Re: Help, the vent hole on my GoldenBee plastic backplate opened up.

I also read on Martin Hepperle's site that one cannot put a muffler around a SPI cylinder because it will kill its performance.

Paul_BB- Bronze Member

- Posts : 59

Join date : 2015-03-16

Age : 61

Re: Help, the vent hole on my GoldenBee plastic backplate opened up.

Re: Help, the vent hole on my GoldenBee plastic backplate opened up.

http://www.mh-aerotools.de/airfoils/index.htm Go to Cox engines scroll down on the BEE 's to the BW for more info // I have never seen a NIB BW that the filler tubes have been removed and filled in , don't make since that they would go to that much labor $$ when they could just use the correct one . That one looks to have came from a non stunt tank engine ? But I don't know for a fact , Mark B. or Mud would probably have better info on this > .

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Help, the vent hole on my GoldenBee plastic backplate opened up.

Re: Help, the vent hole on my GoldenBee plastic backplate opened up.

Thanks getback,

You must be right, I have been tricked. With all the engines and the engines parts around, it's easy to find a sucker. Oh well...

You must be right, I have been tricked. With all the engines and the engines parts around, it's easy to find a sucker. Oh well...

Paul_BB- Bronze Member

- Posts : 59

Join date : 2015-03-16

Age : 61

Re: Help, the vent hole on my GoldenBee plastic backplate opened up.

Re: Help, the vent hole on my GoldenBee plastic backplate opened up.

Paul_BB wrote:I also read on Martin Hepperle's site that one cannot put a muffler around a SPI cylinder because it will kill its performance.

Yes and no... You will loose some performance due to loss of the fresh air intake through the exhaust port during SPI. Instead you will have exhaust gas recirculation (EGR). The engine will run fine. (It may even throttle better on an intake throttle, but with a lower peak rpm)

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: Help, the vent hole on my GoldenBee plastic backplate opened up.

Re: Help, the vent hole on my GoldenBee plastic backplate opened up.

pkrankow wrote:Paul_BB wrote:I also read on Martin Hepperle's site that one cannot put a muffler around a SPI cylinder because it will kill its performance.

Yes and no... You will loose some performance due to loss of the fresh air intake through the exhaust port during SPI. Instead you will have exhaust gas recirculation (EGR). The engine will run fine. (It may even throttle better on an intake throttle, but with a lower peak rpm)

Phil

Thanks Phil.

Paul_BB- Bronze Member

- Posts : 59

Join date : 2015-03-16

Age : 61

Re: Help, the vent hole on my GoldenBee plastic backplate opened up.

Re: Help, the vent hole on my GoldenBee plastic backplate opened up.

Not to worry, its a good looking engine use it for what it was intended for or you may can find another back plate to replace that one if you don't want to run it ,Paul_BB wrote:Thanks getback,

You must be right, I have been tricked. With all the engines and the engines parts around, it's easy to find a sucker. Oh well...

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Help, the vent hole on my GoldenBee plastic backplate opened up.

Re: Help, the vent hole on my GoldenBee plastic backplate opened up.

Thats just a casting flaw, I have a few the same.

crankbndr- Top Poster

- Posts : 3109

Join date : 2011-12-10

Location : Homestead FL

Re: Help, the vent hole on my GoldenBee plastic backplate opened up.

Re: Help, the vent hole on my GoldenBee plastic backplate opened up.

For what it's worth...... when Estes purchased Cox Hobbies.. there were some unorthodox combos of engines being produced. I don't really know.. but from what I've read; engine parts were mixed without regard for "functionality". The Cox engineers who had been involved in the "evolution" of the engines.. were "likely" no longer employed by Estes. The Estes guys were "rocket" people.. and certainly not glow-engine proficient. I would imagine that they were given the task of liquidating the engine parts.. without regard for important technical data. Worse still.. there may have not have been much presence of engineering at all. Engines were likely assembled by untrained workers that were given parts that had not been batched/checked by QC. Estes' glow-engine production of the leftover Cox engine parts-stock didn't last for very long. I'd venture to guess that scads of parts were sold-off.. which is evident by what we've seen emerge from various vendors over the last couple of decades.

The "Black Widow" and "Killer-Bee" were the most ambitious high-performance reed-valve engines that Cox produced in their later years. Kustom-Kraftmanship (KK) was a cottage-industry devoted to the further performance enhancements of the Cox engines. Those were certainly the "golden-years". Cox had produced the "Golden-Bee .049 reed-valve engine with integral stunt-vented tank.. which was basically a "Babe-Bee" that could fly inverted.. without fuel leaking out of the tank vents.. and an additional 3cc's worth of fuel. It was a breakthrough in 1/2A stunt engines that would enjoy many years of success. I believe that this engine underwent some changes in it's final year(s) of production; that included increasing the ID of the venturi.. and a more aggressive intake-ported cylinder. This (I believe..) lead to the production of the "Black-Widow" engine.

I have two Golden-Bee engines; one having a backplate with an .062" air-take.. and the other having an .082" air-intake.. (the .082" air-intake has a matched-size venturi-tube on the tank.. and is "gold" anodized on the inside.. and "not" drilled-out)

I've posted these pics a few times.. but I think that they may have some evolutionary merit.

The backplates..

The tanks..

Unfortunately.. I do not recall the cylinder-porting configurations between the two engines. They've been disassembled several times and their parts interchanged before I knew the importance of archiving their original configuration. These two engines have been in my family for 40+ years.

I honestly don't know what to make of your Black Widow's backplate. It's obviously a Babe Bee part that has had the two vent-tubes cut-off and filled by some means. Possibly brazed? Not sure.. but it looks to be of a good molten-metal seal. Much better; that it's a metal backplate though. It will outlast a plastic one indefinitely. That metal is known as "Zamac" (I believe..) which is similar to "white" or "pot" metal.. and was cast into that shape.. then machined. They have survived the test of time. Scoop them up if you can find them.. if you want to run your "tanked" Bee engines into the future!

The "Black Widow" and "Killer-Bee" were the most ambitious high-performance reed-valve engines that Cox produced in their later years. Kustom-Kraftmanship (KK) was a cottage-industry devoted to the further performance enhancements of the Cox engines. Those were certainly the "golden-years". Cox had produced the "Golden-Bee .049 reed-valve engine with integral stunt-vented tank.. which was basically a "Babe-Bee" that could fly inverted.. without fuel leaking out of the tank vents.. and an additional 3cc's worth of fuel. It was a breakthrough in 1/2A stunt engines that would enjoy many years of success. I believe that this engine underwent some changes in it's final year(s) of production; that included increasing the ID of the venturi.. and a more aggressive intake-ported cylinder. This (I believe..) lead to the production of the "Black-Widow" engine.

I have two Golden-Bee engines; one having a backplate with an .062" air-take.. and the other having an .082" air-intake.. (the .082" air-intake has a matched-size venturi-tube on the tank.. and is "gold" anodized on the inside.. and "not" drilled-out)

I've posted these pics a few times.. but I think that they may have some evolutionary merit.

The backplates..

The tanks..

Unfortunately.. I do not recall the cylinder-porting configurations between the two engines. They've been disassembled several times and their parts interchanged before I knew the importance of archiving their original configuration. These two engines have been in my family for 40+ years.

I honestly don't know what to make of your Black Widow's backplate. It's obviously a Babe Bee part that has had the two vent-tubes cut-off and filled by some means. Possibly brazed? Not sure.. but it looks to be of a good molten-metal seal. Much better; that it's a metal backplate though. It will outlast a plastic one indefinitely. That metal is known as "Zamac" (I believe..) which is similar to "white" or "pot" metal.. and was cast into that shape.. then machined. They have survived the test of time. Scoop them up if you can find them.. if you want to run your "tanked" Bee engines into the future!

Re: Help, the vent hole on my GoldenBee plastic backplate opened up.

Re: Help, the vent hole on my GoldenBee plastic backplate opened up.

I agree, although I don't have any like that pictured. It looks to me like the casting "pattern" was modified to delete the nipples and what you see on this backplate is the post-casting result.crankbndr wrote:Thats just a casting flaw, I have a few the same.

Oldenginerod- Top Poster

- Posts : 4018

Join date : 2012-06-15

Age : 62

Location : Drouin, Victoria

Re: Help, the vent hole on my GoldenBee plastic backplate opened up.

Re: Help, the vent hole on my GoldenBee plastic backplate opened up.

I too am pretty sure that Paul's backplate is not a modified Babe Bee one. Looks like it is made of the same casting though, with the original fill nipple not drilled through but instead cut off. Later Babe Bee metal ones only have one nipple and a small hole right next to it. The small hole would be in the flat area on the left side of Paul's backplate, right next to where the nipple would be. I see no signs of plug or mod in that area. The indentation on the right side could be some crap in the mold, or maybe the mold was modified or repaired, or some residue was left in there from a previous casting. In any case I am sure the part came out of the plant like that. This is of course just a theory, and something only a former Cox employee could confirm.

This engine is probably one of the last ones to get a metal backplate, so the molds were already beginning to wear out, and often you can see that the line where the mold halves were joined shows as a visible ridge on the sides of the backplate.

Roddie, I think your "golden" large-venturi stunt tank could be a Black Widow one that was anodized in gold colour either by a mistake by the anodizing company, or by Cox. So there was a batch of "more powerful than usual" Golden Bees out there at some time

This engine is probably one of the last ones to get a metal backplate, so the molds were already beginning to wear out, and often you can see that the line where the mold halves were joined shows as a visible ridge on the sides of the backplate.

Roddie, I think your "golden" large-venturi stunt tank could be a Black Widow one that was anodized in gold colour either by a mistake by the anodizing company, or by Cox. So there was a batch of "more powerful than usual" Golden Bees out there at some time

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Re: Help, the vent hole on my GoldenBee plastic backplate opened up.

Re: Help, the vent hole on my GoldenBee plastic backplate opened up.

Thanks for all the informations guys. There is a picture in the instruction manual and I can clearly see that my cylinder is the same as that on the picture. I was suspicious because of the lack of rust on the cylinder, but they use to make good steel back then.

I'm back from breaking-in my Black Widow. I use only 12% Nitro and a Cox black 6x3 prop. I got a steady max rpm of around 13500 which is nice I think. Very steady and not sensitive.

I tried out the muffler and the max rpm dropped to 1200 which is not too bad but the peak is not really steady, pretty sensitive.

I'm back from breaking-in my Black Widow. I use only 12% Nitro and a Cox black 6x3 prop. I got a steady max rpm of around 13500 which is nice I think. Very steady and not sensitive.

I tried out the muffler and the max rpm dropped to 1200 which is not too bad but the peak is not really steady, pretty sensitive.

Paul_BB- Bronze Member

- Posts : 59

Join date : 2015-03-16

Age : 61

Page 2 of 2 •  1, 2

1, 2

Similar topics

Similar topics» No mounting hole horseshoe backplate

» Black Widow Run time

» tee dee vent

» Black Widow tank vent repair.

» Green vent..

» Black Widow Run time

» tee dee vent

» Black Widow tank vent repair.

» Green vent..

Page 2 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules