Log in

Search

Latest topics

» My N-1R build logby roddie Today at 12:32 am

» Happy 77th birthday Andrew!

by akjgardner Today at 12:27 am

» TEE DEE Having issues

by TD ABUSER Yesterday at 9:43 pm

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» Roger Harris revisited

by TD ABUSER Yesterday at 2:13 pm

» Tee Dee .020 combat model

by Ken Cook Yesterday at 1:41 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Yesterday at 1:37 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Fri Nov 22, 2024 11:32 am

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

Cox Engine of The Month

Wedge Tank build

Page 2 of 2

Page 2 of 2 •  1, 2

1, 2

Re: Wedge Tank build

Re: Wedge Tank build

Brass however splits easier on it's seam vs copper which is why copper is a better choice. If you internally soldered your pickup, this will give it much more longevity than leaving it like a tuning fork inside the tank.

Ken Cook- Top Poster

- Posts : 5640

Join date : 2012-03-27

Location : pennsylvania

Re: Wedge Tank build

Re: Wedge Tank build

Ken has just pointed out something I failed to mention.

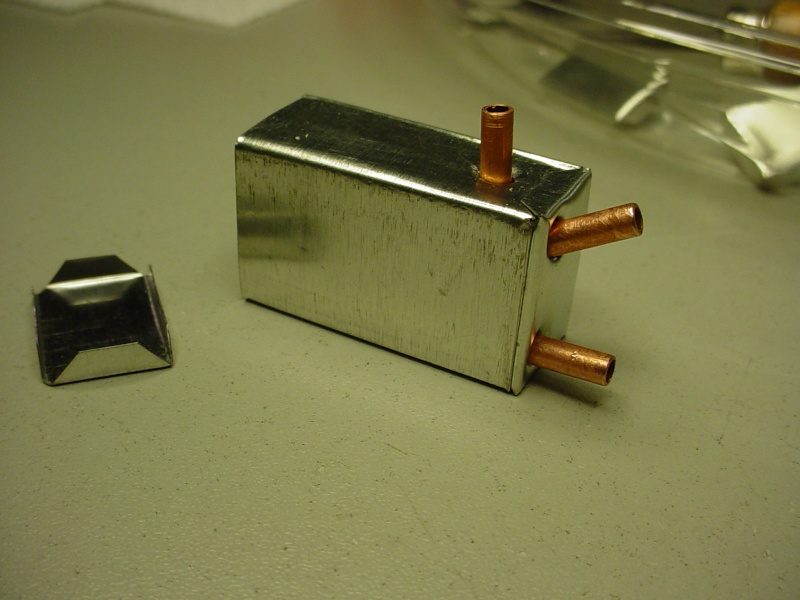

On the tank build - I solder tack the fee pipe to the tank side and the uniflo pipe to the feed pipe. If it was a stunt tank, I would tack the two vent pipes together.

On the tank build - I solder tack the fee pipe to the tank side and the uniflo pipe to the feed pipe. If it was a stunt tank, I would tack the two vent pipes together.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Wedge Tank build

Re: Wedge Tank build

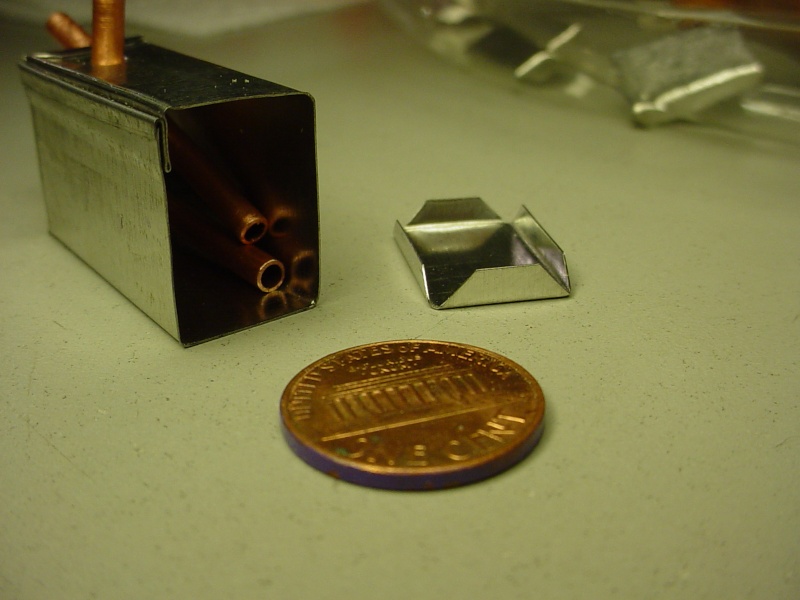

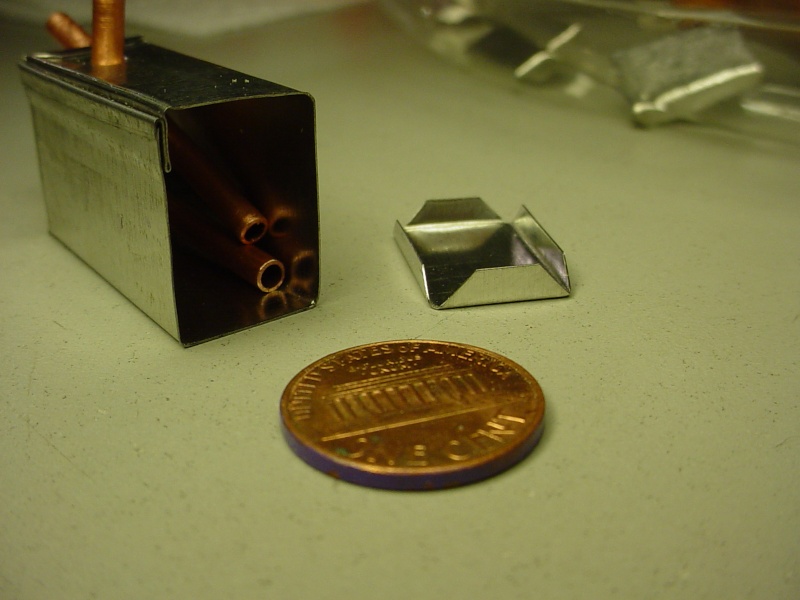

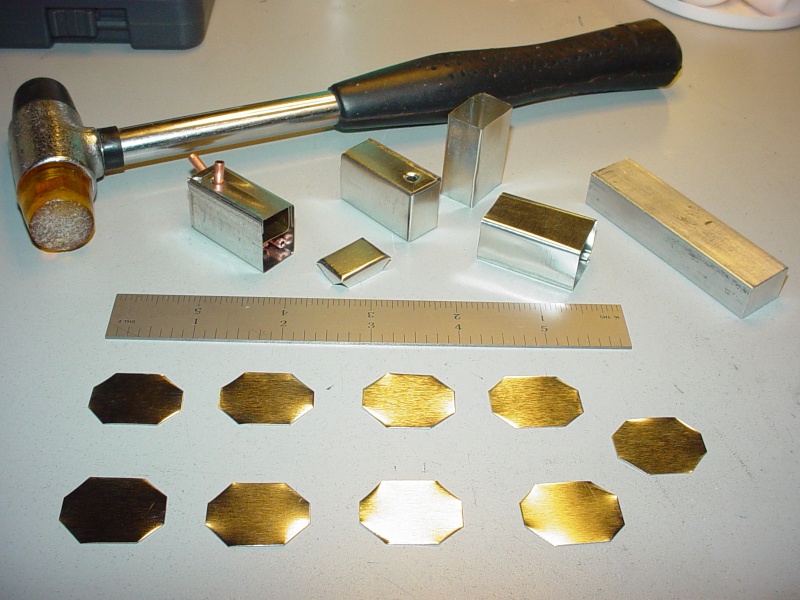

I assume that the automotive store 1/8" copper tubing for gages that I bought, is annealed.. because it is supplied in a 4 inch coil. All my tank-tubes were straight and none of them were longer than 1.5" so it was very easy to straighten them after cutting, by rolling a block over them on a nice flat surface. I also used emery cloth to clean the tubes..

My first attempt at a uniflow.

After building the first tank.. I had gotten the methods down and it became fun.

4.6cc (left pair) 7.7cc (right pair)

My first attempt at a uniflow.

After building the first tank.. I had gotten the methods down and it became fun.

4.6cc (left pair) 7.7cc (right pair)

Re: Wedge Tank build

Re: Wedge Tank build

The tanks that Roddie has made and shown here are very neat. The smaller the tank the more difficult it is to make.

On larger tanks - adjusting fits because of bends and overlaps is much easier than on tiny tanks.

On larger tanks - adjusting fits because of bends and overlaps is much easier than on tiny tanks.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Wedge Tank build

Re: Wedge Tank build

ian1954 wrote:The tanks that Roddie has made and shown here are very neat. The smaller the tank the more difficult it is to make.

On larger tanks - adjusting fits because of bends and overlaps is much easier than on tiny tanks.

On tiny tanks it may be easier to start a part over than to correct a bend...

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: Wedge Tank build

Re: Wedge Tank build

Roddie, those are really good looking tanks! Do you somehow arrange an overlap of the two sheets in the corners or is it just a really good fit?

Rectangular ones seem easier to mount and allow a bigger volume of fuel in compact dimensions. I guess they won't work inverted, or do they? Inside loops probably are still doable?

Neat stuff all in all, shows how many sides there is in the "old school" model hobby.

Rectangular ones seem easier to mount and allow a bigger volume of fuel in compact dimensions. I guess they won't work inverted, or do they? Inside loops probably are still doable?

Neat stuff all in all, shows how many sides there is in the "old school" model hobby.

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Re: Wedge Tank build

Re: Wedge Tank build

I'll second that.....Outstanding workmanshipKariFS wrote:Roddie, those are really good looking tanks! Do you somehow arrange an overlap of the two sheets in the corners or is it just a really good fit?

Rectangular ones seem easier to mount and allow a bigger volume of fuel in compact dimensions. I guess they won't work inverted, or do they? Inside loops probably are still doable?

Neat stuff all in all, shows how many sides there is in the "old school" model hobby.

akjgardner- Diamond Member

Posts : 1602

Join date : 2014-12-28

Age : 65

Location : Greensberg Indiana

Re: Wedge Tank build

Re: Wedge Tank build

KariFS wrote:Roddie, those are really good looking tanks! Do you somehow arrange an overlap of the two sheets in the corners or is it just a really good fit?

Rectangular ones seem easier to mount and allow a bigger volume of fuel in compact dimensions. I guess they won't work inverted, or do they? Inside loops probably are still doable?

Neat stuff all in all, shows how many sides there is in the "old school" model hobby.

Thank you. Ian made (3-D printed) die-presses to form his wedge's end-caps so they'd fit well to the body. That's a lot harder than what I did. I consulted Ian, Ken Cook and Paul Gibeault on my tanks.. as I had never attempted building one before.. and had no hard-soldering experience. Actually not a whole lot of electrical soldering experience either..

Mine are Speed tanks.. not meant for stunting. To answer your question Kari, I was careful when forming the bodies, to form all the bends squarely. This is accomplished using a block (wood or aluminum) the approx. size of the body on a hard/flat surface (tabletop) and small C-clamps to hold the .008" tin-sheet square to the block. Firm/even downward-pressure on the block to the table to make the first corner-bend. I then lightly and evenly tap across the bend using a plastic-faced hammer, which forms a nice tight 90 degree corner over/around the block. This gets you started more accurately. Once two corners of the body are made in this manner, the clamps can be removed because the block/plug will keep the tin from creeping while forming the remaining two corners. I allowed for extra stock for the joint on the final corner. Nothing fancy needed here. My first two tanks used a folded lock-seam.. but the smaller two that I built afterward used a simple 1/4" overlap.

End-caps were cut 1/4" longer overall, to allow 1/8" "tabs" to be formed on all sides. All 4 corners of the end-caps get 45 degree reliefs using scissors.

The caps can be formed over the same block used to form the body. I clamped the block (end facing up) in a bench-vise, hold the cap-panel on top with my fingers and used the plastic hammer to gently bend the tabs down around the block. Remove the block from the vise afterward and finish tapping/forming with it on the tabletop; one side at a time until all tabs form tight corners. With some tanks, I tucked the tabs inside the tank body.. and some were on the outside. The corners will all inadvertently have a pinhole size gap. The smaller this gap/hole.. the better the fit and likelihood of sealing when soldering.

A great method for installing the tubes is to layout/mark the locations once the front end-cap is soldered on and drill the tube-holes approx. half the size of your tube's diameter. Use an awl to gradually open them up until you can force the tube tightly through the hole from the outside. You'll see that this forms a nice little pocket for solder to pool; both strengthening the joint and providing for much better sealing against leaks.

I should have taken more photos of each step.. I know it's hard to picture from my writing about my methods.. but hopefully I'm a descriptive writer. Rusty said I should do a tutorial-thread back a while ago.

Page 2 of 2 •  1, 2

1, 2

Similar topics

Similar topics» retarded,and i need photos

» vent in my wedge tank

» Q Tee 2ch RC sport model with Cox 049 and home brew tank.

» How and where to fit the external wedge fuel tank to cox. 049 sure start

» Guillows Cessna 150 build circa 1970 (Build Log)

» vent in my wedge tank

» Q Tee 2ch RC sport model with Cox 049 and home brew tank.

» How and where to fit the external wedge fuel tank to cox. 049 sure start

» Guillows Cessna 150 build circa 1970 (Build Log)

Page 2 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules