Log in

Search

Latest topics

» Roger Harris revisitedby rsv1cox Today at 3:38 pm

» My N-1R build log

by GallopingGhostler Today at 3:04 pm

» Tee Dee .020 combat model

by 1/2A Nut Today at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» My latest doodle...

by batjac Yesterday at 9:47 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

Cox Engine of The Month

Cylinder Shims

Page 1 of 1

Cylinder Shims

Cylinder Shims

There seems to be some confusion on what a cylinder shim does, so i thought i'd start a new thread. Here's a note from Kustom Kraftmanship that might clear it up.

Re: Cylinder Shims

Re: Cylinder Shims

Cool I've done something similar with my TD's what it is is a go no go gauge used to adjust piston crown to deck (shoulder) height the only difference between my way and theirs is I use a stop screw with no gasket while they use the copper disk which would be easier to do. (Bandit)

TDbandit- Platinum Member

- Posts : 897

Join date : 2014-12-01

Age : 53

Location : Riverdale Georgia

Re: Cylinder Shims

Re: Cylinder Shims

The last part of KK's instructions is the suggestion to have approx .012" sub induction. From my experiences I have found that .012's was too much sub induction . I've had better results in raising the cylinder even higher. I was using the TD on foamies so I was also using the shims to orientate the cylinder to prevent my wing from melting. However I was keeping all of the above in mind. In order to benefit from sub induction, my results were far better when I had only a tiny bit of light showing under the skirt of the piston. Ken

Ken Cook- Top Poster

- Posts : 5637

Join date : 2012-03-27

Location : pennsylvania

Re: Cylinder Shims

Re: Cylinder Shims

I think the COX Int'l description on the purpose of the shims is self-explanatory. My only comment would be that shims can be used for all 049/050/051 engines and not fot TeeDee-s only.

http://coxengines.ca/cox-.049-tee-dee-timing-shims.html

http://coxengines.ca/cox-.049-tee-dee-timing-shims.html

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Cylinder Shims

Re: Cylinder Shims

Yup they can, there just not quite as effective on reedies as they are on engines with rotary valves (TD, Medallion and RR1)balogh wrote:I think the COX Int'l description on the purpose of the shims is self-explanatory. My only comment would be that shims can be used for all 049/050/051 engines and not fot TeeDee-s only.

http://coxengines.ca/cox-.049-tee-dee-timing-shims.html

As far as SPI goes, I agree with ken .012 is a bit much. Mine has about .008.

(Bandit)

TDbandit- Platinum Member

- Posts : 897

Join date : 2014-12-01

Age : 53

Location : Riverdale Georgia

Re: Cylinder Shims

Re: Cylinder Shims

Ken Cook wrote: The last part of KK's instructions is the suggestion to have approx .012" sub induction. From my experiences I have found that .012's was too much sub induction . I've had better results in raising the cylinder even higher. I was using the TD on foamies so I was also using the shims to orientate the cylinder to prevent my wing from melting. However I was keeping all of the above in mind. In order to benefit from sub induction, my results were far better when I had only a tiny bit of light showing under the skirt of the piston. Ken

I'm now wondering if this may be contributing to the trouble I am having with my Reed Speed engine. The engine is a "Bear" to start... hot or cold.

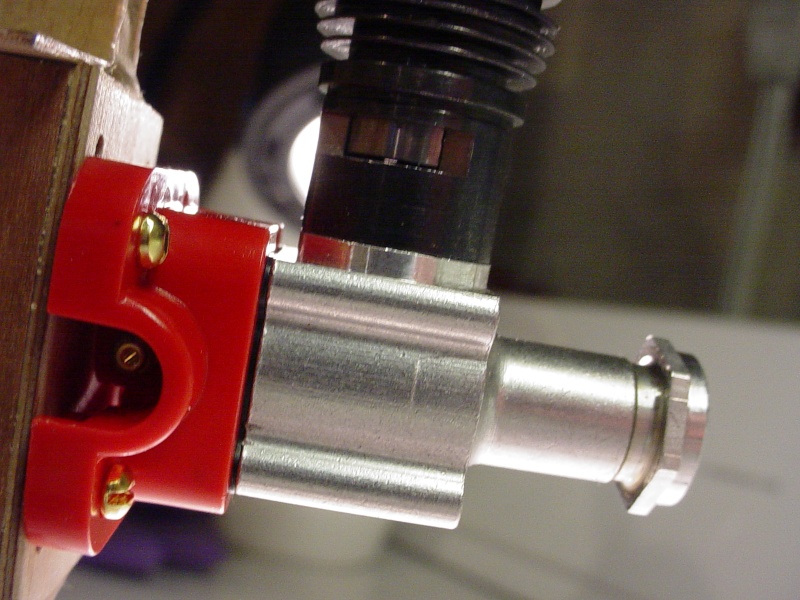

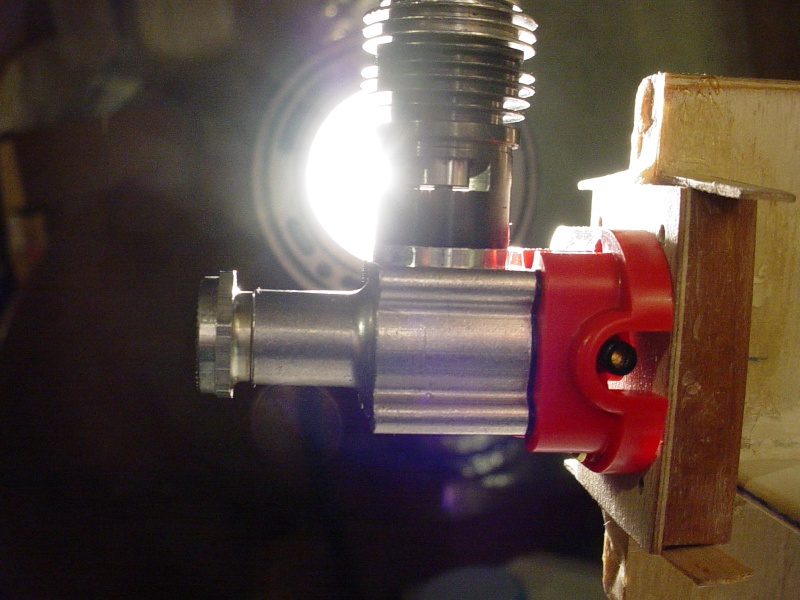

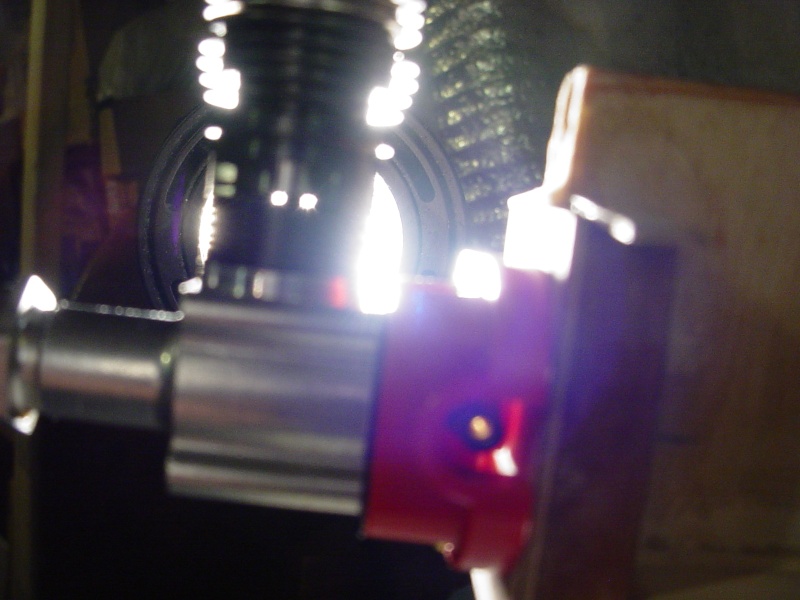

Here's a couple TDC shots.

The focus is off on this photo (below).. but it really shows the extreme..

It's a brand new repro Tee Dee .049 cylinder/piston set and Killer-Bee style backplate/needle from Cox International. I was using a standard glowhead, single head-gasket and Sig Champion "25" fuel. I figured that one head gasket and a standard compression head on 25% nitro would put me in the ballpark. I don't possess any cylinder shims.

Does the SPI gap under the piston-skirt look like it's too much; given the top-end components?

As far as the erratic running I'm experiencing.. I also suspect the backplate to case seal. I'm using the flanged (black) plastic reed-retainer without any other gasket(s). This was a subject of debate back when I was getting the engine ready for the first Speed contest. Some people said they didn't use a gasket with the retainer.. and some said they did.. or it didn't matter much. I had a flanged-retainer already.. so I didn't buy a new one. I suppose if the flange is bad.. (hairline crack or scratch that I didn't notice) it may not be sealing the crankcase completely.

I notice now.. that Cox international shows that backplate "assembly" with a gasket forward of the retainer.

Re: Cylinder Shims

Re: Cylinder Shims

roddie wrote:Ken Cook wrote: The last part of KK's instructions is the suggestion to have approx .012" sub induction. From my experiences I have found that .012's was too much sub induction . I've had better results in raising the cylinder even higher. I was using the TD on foamies so I was also using the shims to orientate the cylinder to prevent my wing from melting. However I was keeping all of the above in mind. In order to benefit from sub induction, my results were far better when I had only a tiny bit of light showing under the skirt of the piston. Ken

I'm now wondering if this may be contributing to the trouble I am having with my Reed Speed engine. The engine is a "Bear" to start... hot or cold.

Here's a couple TDC shots.

The focus is off on this photo (below).. but it really shows the extreme..

It's a brand new repro Tee Dee .049 cylinder/piston set and Killer-Bee style backplate/needle from Cox International. I was using a standard glowhead, single head-gasket and Sig Champion "25" fuel. I figured that one head gasket and a standard compression head on 25% nitro would put me in the ballpark. I don't possess any cylinder shims.

Does the SPI gap under the piston-skirt look like it's too much; given the top-end components?

As far as the erratic running I'm experiencing.. I also suspect the backplate to case seal. I'm using the flanged (black) plastic reed-retainer without any other gasket(s). This was a subject of debate back when I was getting the engine ready for the first Speed contest. Some people said they didn't use a gasket with the retainer.. and some said they did.. or it didn't matter much. I had a flanged-retainer already.. so I didn't buy a new one. I suppose if the flange is bad.. (hairline crack or scratch that I didn't notice) it may not be sealing the crankcase completely.

I notice now.. that Cox international shows that backplate "assembly" with a gasket forward of the retainer.

Its been my experience the cylinders you speak of have too much SPI, but I only tested one.

crankbndr- Top Poster

- Posts : 3109

Join date : 2011-12-10

Location : Homestead FL

Re: Cylinder Shims

Re: Cylinder Shims

Same here my tach race engine has too much and I'm out of shims  my TD however has around .008 One way to find out is to take a feeler gauge used for adjusting points gap or valve tappets and with the crank at TDC measure the gap keep in mind any ball/socket slop you might have to remove the head and while holding the prop insert your finger and lightly press down on the piston while you take the measurement to keep the piston from lifting any as to keep from spoiling the reading. (Bandit)

my TD however has around .008 One way to find out is to take a feeler gauge used for adjusting points gap or valve tappets and with the crank at TDC measure the gap keep in mind any ball/socket slop you might have to remove the head and while holding the prop insert your finger and lightly press down on the piston while you take the measurement to keep the piston from lifting any as to keep from spoiling the reading. (Bandit)

TDbandit- Platinum Member

- Posts : 897

Join date : 2014-12-01

Age : 53

Location : Riverdale Georgia

Similar topics

Similar topics» 051 Head Scratcher

» cylinder shims

» Cox Tee Dee .15 Mark II cylinder shims

» Cylinder Performance Figures

» how many shims

» cylinder shims

» Cox Tee Dee .15 Mark II cylinder shims

» Cylinder Performance Figures

» how many shims

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules