Log in

Search

Latest topics

» Tee Dee .020 combat modelby 1/2A Nut Today at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» My latest doodle...

by batjac Yesterday at 9:47 pm

» My N-1R build log

by roddie Yesterday at 8:50 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

» My current avatar photo

by roddie Mon Nov 18, 2024 9:05 pm

Cox Engine of The Month

Engine Test Stands

Page 1 of 2

Page 1 of 2 • 1, 2

Engine Test Stands

Engine Test Stands

Been making adapters so my new M.E.C.O.A. Test Stands can be tried out. I found that the 1/2A model won't fit my beam mount engines without a ply pad with a shorter length / smaller diameter pin. In the Old Days, I would have just drilled out the engines', but I now try to resist enlarging the mounting holes in the engine's flanges. With the ply adapter, I was also able to relocate the pin's position to suit my little Gilbert Engines which, at this point, have a single small hole in the middle of their flange. Gonna also make some ply pads to lay on top of the flanges.

The larger stand is also gonna need it's pin ground down a bit to give it some clamping action on my .15's and little Foxes, and such. I could probably shim it up to take out the slack, or put a ply pad on top, but figure that, even big engines, the pin ought to still be tall enough to restrain them, and I like to have metal-to-metal clamping on the bigger dogs.

I really like the cool, "Rocketeer" retro look of these stands, but the 1/2A ones I get from Bernie just need a ply plate with four holes to make them engine-ready, and they're good to go in minutes with everything up through the .051's.

Just my thoughts on the subject.

Mo Better !!!!

The larger stand is also gonna need it's pin ground down a bit to give it some clamping action on my .15's and little Foxes, and such. I could probably shim it up to take out the slack, or put a ply pad on top, but figure that, even big engines, the pin ought to still be tall enough to restrain them, and I like to have metal-to-metal clamping on the bigger dogs.

I really like the cool, "Rocketeer" retro look of these stands, but the 1/2A ones I get from Bernie just need a ply plate with four holes to make them engine-ready, and they're good to go in minutes with everything up through the .051's.

Just my thoughts on the subject.

Mo Better !!!!

Last edited by Kim on Sun Jul 01, 2012 9:14 am; edited 1 time in total

Kim- Top Poster

Posts : 8625

Join date : 2011-09-06

Location : South East Missouri

Re: Engine Test Stands

Re: Engine Test Stands

Nice stands have you run and engine in them yet?

Also for your next MECOA order you could try those diesel heads you PM'd me about.

Also for your next MECOA order you could try those diesel heads you PM'd me about.

Re: Engine Test Stands

Re: Engine Test Stands

nitroairplane wrote:Nice stands have you run and engine in them yet?

Also for your next MECOA order you could try those diesel heads you PM'd me about.

Hey Nitro,

Thanks! Haven't run them yet, spent my morning messing with them and working to re-do the tailwheel steering on my Minnie Mambo so it'll be ready for the Traveling Propeller. It takes me a while to get up and rolling on this shift!

Yeah, considering my glut of heavy-duty cranks...think I will probably try an RJL diesel conversion. M.E.C.O.A.'s also advertising glowplug adapters for Wen Mac engines, among other cool stuff.

Don't remember if you said so...have you tried one of them?

Kim- Top Poster

Posts : 8625

Join date : 2011-09-06

Location : South East Missouri

Re: Engine Test Stands

Re: Engine Test Stands

Tried an RJL head?

No i have not but i have tried "O" ring heads and they are great.

No i have not but i have tried "O" ring heads and they are great.

Re: Engine Test Stands

Re: Engine Test Stands

I picked up one of these Jtec stand from Omni and so far it has worked out pretty good for my 15's and up. I havent bolted a 1/2a to it yet. I did have to relieve a area on one of the clamp pads to be able to get a z bent wire onto the carb linkage and have that wire run back. Also had to trim the bolts down about 1/2", just to make it a bit easier to work with. Coated the camp pads and stand around the mount pin with tool-dip/plasti-dip so they wouldn't dig into the motor cases and mark those up, and to give those pinch areas a bit more traction. There is a allen head bolt that is adjustable to set the droop or pinch of the clamp pad.

A little bit of customization, but it is a solid mount once everything is tightened down.

http://www3.omnimodels.com/cgi-bin/woi0001p?&I=JTCG6905&P=7

A little bit of customization, but it is a solid mount once everything is tightened down.

http://www3.omnimodels.com/cgi-bin/woi0001p?&I=JTCG6905&P=7

PV Pilot- High Tech Balsa Basher

- Posts : 1854

Join date : 2011-08-11

Age : 57

Location : The ragged end of the Universe.

Re: Engine Test Stands

Re: Engine Test Stands

Kim,

Those are some very un-Cox looking parts in the background. AR 15 bolt/charging handle assembly?

Bob

Those are some very un-Cox looking parts in the background. AR 15 bolt/charging handle assembly?

Bob

fit90- Diamond Member

- Posts : 1341

Join date : 2011-08-11

Location : Naples, Florida

Re: Engine Test Stands

Re: Engine Test Stands

nitroairplane wrote:Kim do the background parts belong to tigger?

GOOD EYE !!!!!!!!!!!!!!!!!!!!!!!

Yes...I've got a multi-cultural work bench !!!

Kim- Top Poster

Posts : 8625

Join date : 2011-09-06

Location : South East Missouri

Re: Engine Test Stands

Re: Engine Test Stands

fit90 wrote:Kim,

Those are some very un-Cox looking parts in the background. AR 15 bolt/charging handle assembly?

Bob

Yeah...my friends never believe me when I tell them it takes weeks for me to recover from one of our Gun Days. Shamefully, just NOW, getting everybody cleaned and put away...

Kim- Top Poster

Posts : 8625

Join date : 2011-09-06

Location : South East Missouri

Re: Engine Test Stands

Re: Engine Test Stands

PV Pilot wrote:I picked up one of these Jtec stand from Omni and so far it has worked out pretty good for my 15's and up. I havent bolted a 1/2a to it yet. I did have to relieve a area on one of the clamp pads to be able to get a z bent wire onto the carb linkage and have that wire run back. Also had to trim the bolts down about 1/2", just to make it a bit easier to work with. Coated the camp pads and stand around the mount pin with tool-dip/plasti-dip so they wouldn't dig into the motor cases and mark those up, and to give those pinch areas a bit more traction. There is a allen head bolt that is adjustable to set the droop or pinch of the clamp pad.

A little bit of customization, but it is a solid mount once everything is tightened down.

http://www3.omnimodels.com/cgi-bin/woi0001p?&I=JTCG6905&P=7

Looks pretty stout...may have to get one if all this engine craziness continues... !

Kim- Top Poster

Posts : 8625

Join date : 2011-09-06

Location : South East Missouri

Re: Engine Test Stands

Re: Engine Test Stands

nitroairplane wrote:I am just wondering what the smallest one of these is?

Not sure of your question...the smallest mount you can buy here or...?

Kim- Top Poster

Posts : 8625

Join date : 2011-09-06

Location : South East Missouri

Re: Engine Test Stands

Re: Engine Test Stands

Kim wrote:nitroairplane wrote:I am just wondering what the smallest one of these is?

Not sure of your question...the smallest mount you can buy here or...?

I am,

Here is the J-tec before I did all the mods to it. Looks like I ground the one clamp pad in this pic, but the pads are not dipped and the bolts are still tall. As you see the bolts come right up to a mid engine exhaust port and once you mount a Veco 19 RC exhaust pipe onto your McCoy 19 RC blue head,,it's just millimeters away from touching the manifold. You can just see the allen head height adjuster in between the clamp pad and stand. My double duty test bed for big and small motors, just flip it around in the bench vise. This piece of 2x6 will never, ever rot

PV Pilot- High Tech Balsa Basher

- Posts : 1854

Join date : 2011-08-11

Age : 57

Location : The ragged end of the Universe.

Re: Engine Test Stands

Re: Engine Test Stands

Kim wrote:nitroairplane wrote:I am just wondering what the smallest one of these is?

Not sure of your question...the smallest mount you can buy here or...?

I meant i wonder what the smallest engine mount is.

I gotta mount a blitz 0.05cc.

Re: Engine Test Stands

Re: Engine Test Stands

nitroairplane wrote:Kim wrote:nitroairplane wrote:I am just wondering what the smallest one of these is?

Not sure of your question...the smallest mount you can buy here or...?

I meant i wonder what the smallest engine mount is.

I gotta mount a blitz 0.05cc.

Oh...sorry for my "denseness" !!! Really, figure a chunk of channel aluminum could be easily chopped and hacked into a good test stand also !

Kim- Top Poster

Posts : 8625

Join date : 2011-09-06

Location : South East Missouri

Re: Engine Test Stands

Re: Engine Test Stands

Probably i need a big one to get a look at then maybe hack a smaller one out of aluminium.

Re: Engine Test Stands

Re: Engine Test Stands

Maybe a couple pieces of alum square stock.

PV Pilot- High Tech Balsa Basher

- Posts : 1854

Join date : 2011-08-11

Age : 57

Location : The ragged end of the Universe.

Re: Engine Test Stands

Re: Engine Test Stands

PV Pilot wrote:Maybe a couple pieces of alum square stock.

Yep and some nut and bolts some flat stock!

Re: Engine Test Stands

Re: Engine Test Stands

I've got a healthy piece of angle stock aluminum that's one of my buds is gonna cut up for me. Bolted to my test bench, ought to make great, simple test stands for backplate-type mountings. May polish up a couple for desk displays also.

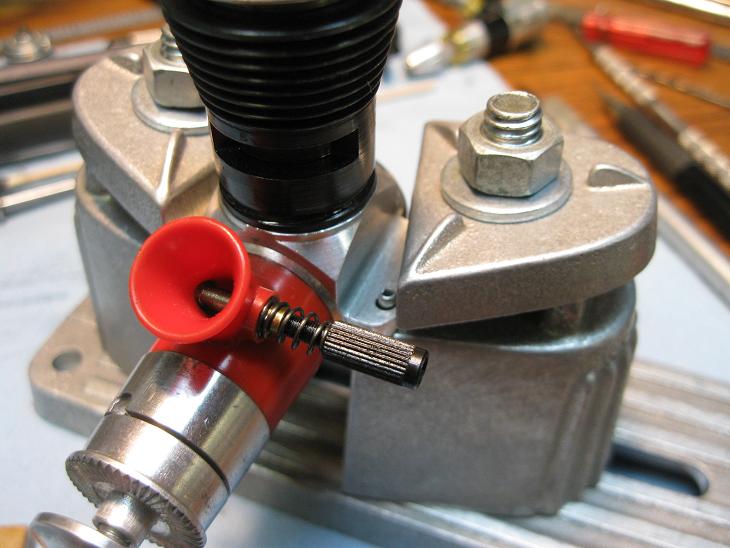

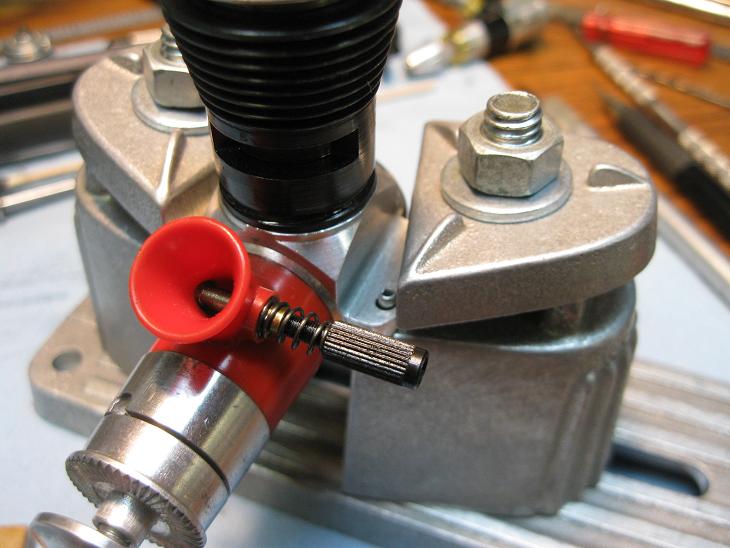

Speaking of tests and such....made myself a jig to better attempt converting some of these heads to glow plugs. I know...it's not the best centering job...but I think the case is pulled down pretty flat against the plate, and looks square...so, we'll see !

Speaking of tests and such....made myself a jig to better attempt converting some of these heads to glow plugs. I know...it's not the best centering job...but I think the case is pulled down pretty flat against the plate, and looks square...so, we'll see !

Kim- Top Poster

Posts : 8625

Join date : 2011-09-06

Location : South East Missouri

Re: Engine Test Stands

Re: Engine Test Stands

What size Norvel is that off to the right?

PV Pilot- High Tech Balsa Basher

- Posts : 1854

Join date : 2011-08-11

Age : 57

Location : The ragged end of the Universe.

Re: Engine Test Stands

Re: Engine Test Stands

PV Pilot wrote:What size Norvel is that off to the right?

That's a Brodak .049 I'm trying to get around to putting on a test stand. Got it years ago, and haven't run it yet. Gonna try, but will probably be next week.

I GOT to get this crap organized !

Kim- Top Poster

Posts : 8625

Join date : 2011-09-06

Location : South East Missouri

Re: Engine Test Stands

Re: Engine Test Stands

nitroairplane wrote:PV Pilot wrote:Maybe a couple pieces of alum square stock.

Yep and some nut and bolts some flat stock!

Some solid alum square stock, and run those lengths right back to a mount plate or lag/clamp them to a 2x4 or workbench.

PV Pilot- High Tech Balsa Basher

- Posts : 1854

Join date : 2011-08-11

Age : 57

Location : The ragged end of the Universe.

Re: Engine Test Stands

Re: Engine Test Stands

PV Pilot wrote:nitroairplane wrote:PV Pilot wrote:Maybe a couple pieces of alum square stock.

Yep and some nut and bolts some flat stock!

Some solid alum square stock, and run those lengths right back to a mount plate or lag/clamp them to a 2x4 or workbench.

Yes.

We got a product coming along here! Oh wait someone already invented it d'oh!

Re: Engine Test Stands

Re: Engine Test Stands

I decided to do a little re-furb with this thread, for the benefit of anyone new to our hobby, showing the flexibility of these little test stands I got from Bernie. They are drilled for all the "Small Block" Cox engines, and lend themselves handily for use with machine screws and nuts.

There was some concern (and rightfully so) in another thread of the safety of using self-tapping screws to secure an engine to a wooden stand for testing. I'd previously used socket head, self-tapping screws and plywood plates on the inside of these stands to save the fiddling with tiny machine nuts and washers. While I'd never had a problem with engines loosening themselves in run, I'm swapping out the ply plates out for hardwood blocks, obtained free from the scrap bin of my local cabinet shop.

These maple blocks are rock-hard and will not even hint at letting go of the screws' threads. Using the pre-drilled holes in Benie's test stand as jigs, you can quickly make up several sets. If you do a lot of swapping like I do, you can dramatically reduce the fiddling time between runs by not having to deal with tiny hardware changes. If you mount the block on the OUTSIDE of the stand, you then have a new flat plate for mounting other brands of engines without drilling new holes in the stands.

Crutches for various fuel tanks are easily made up from ply scraps, using 5-Minute Epoxy.

The photos show various applications for the Test Stands before the conversion to hardwood blocks.

Just some thoughts.

There was some concern (and rightfully so) in another thread of the safety of using self-tapping screws to secure an engine to a wooden stand for testing. I'd previously used socket head, self-tapping screws and plywood plates on the inside of these stands to save the fiddling with tiny machine nuts and washers. While I'd never had a problem with engines loosening themselves in run, I'm swapping out the ply plates out for hardwood blocks, obtained free from the scrap bin of my local cabinet shop.

These maple blocks are rock-hard and will not even hint at letting go of the screws' threads. Using the pre-drilled holes in Benie's test stand as jigs, you can quickly make up several sets. If you do a lot of swapping like I do, you can dramatically reduce the fiddling time between runs by not having to deal with tiny hardware changes. If you mount the block on the OUTSIDE of the stand, you then have a new flat plate for mounting other brands of engines without drilling new holes in the stands.

Crutches for various fuel tanks are easily made up from ply scraps, using 5-Minute Epoxy.

The photos show various applications for the Test Stands before the conversion to hardwood blocks.

Just some thoughts.

Last edited by Kim on Sun Jul 01, 2012 5:07 pm; edited 1 time in total

Kim- Top Poster

Posts : 8625

Join date : 2011-09-06

Location : South East Missouri

Page 1 of 2 • 1, 2

Similar topics

Similar topics» TIEBREAKER-POLL **COX-ENGINE-OF-THE-MONTH** (December 2022)

» Engine Display Stands

» Cox engine display stands

» New Engine Display Stands

» Engine Display Stands - Coming Soon!

» Engine Display Stands

» Cox engine display stands

» New Engine Display Stands

» Engine Display Stands - Coming Soon!

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules