Log in

Search

Latest topics

» Cox films/videos...by Coxfledgling Today at 3:46 am

» Purchased the last of any bult engines from Ken Enya

by Coxfledgling Today at 3:18 am

» My N-1R build log

by roddie Yesterday at 11:32 pm

» Happy 77th birthday Andrew!

by akjgardner Yesterday at 11:27 pm

» TEE DEE Having issues

by TD ABUSER Yesterday at 8:43 pm

» Landing-gear tips

by roddie Yesterday at 5:17 pm

» Roger Harris revisited

by TD ABUSER Yesterday at 1:13 pm

» Tee Dee .020 combat model

by Ken Cook Yesterday at 12:41 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Yesterday at 12:37 pm

» My latest doodle...

by roddie Yesterday at 9:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 12:13 pm

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 8:24 am

Cox Engine of The Month

RSM P51d build

Page 1 of 2

Page 1 of 2 • 1, 2

RSM P51d build

RSM P51d build

I have had this build "on the go" since August and first mentioned it when I used a profile sanding block.

https://www.coxengineforum.com/t7104-leading-edge-profile-sander

I have kept a track of it and noted some of the issues I had (all minor). The first thing to note is that the materials are excellent but I had trouble following the instructions. Like most kits, I have come to the conclusion that they are often written in hindsight by skilled builders (or designers) and a degree of knowledge or aptitude is often assumed.

Pictures are worth a thousand words!

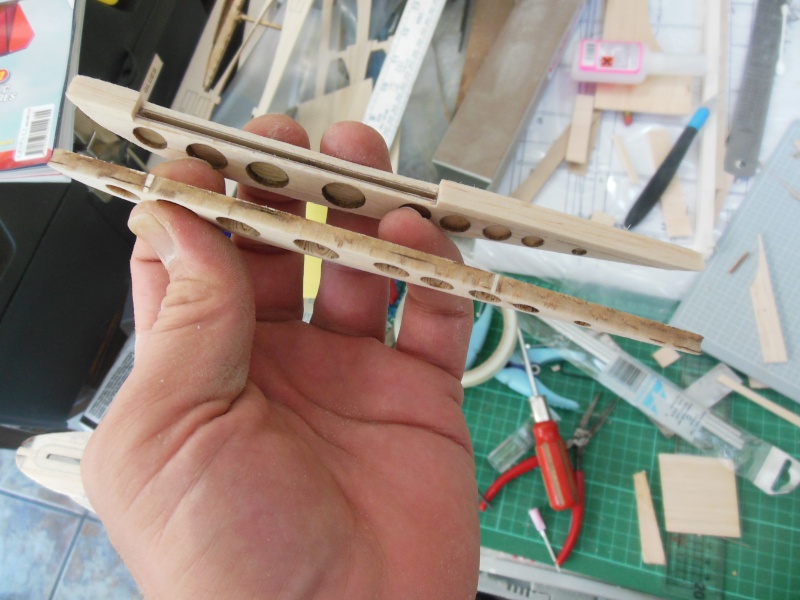

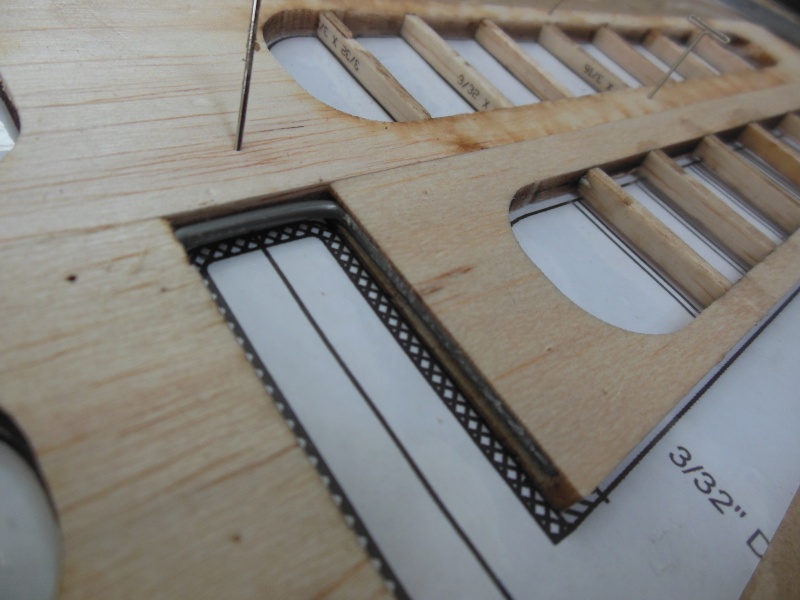

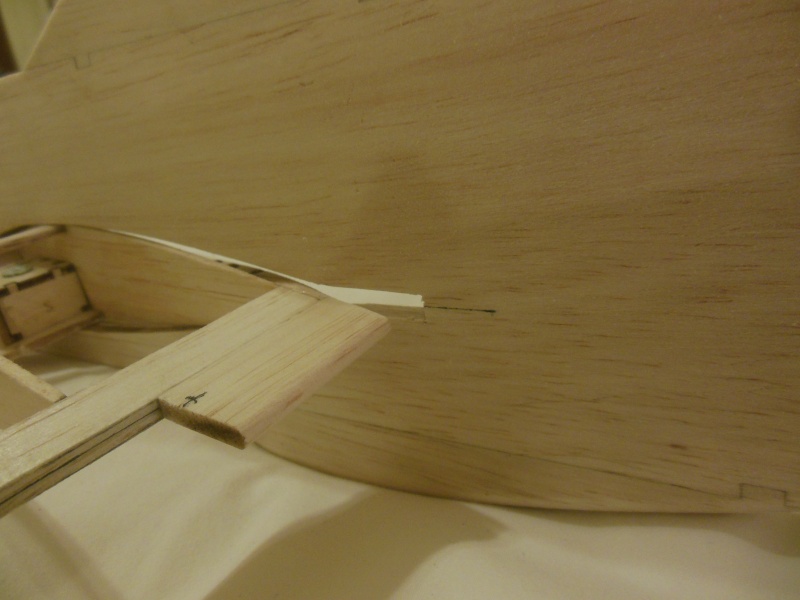

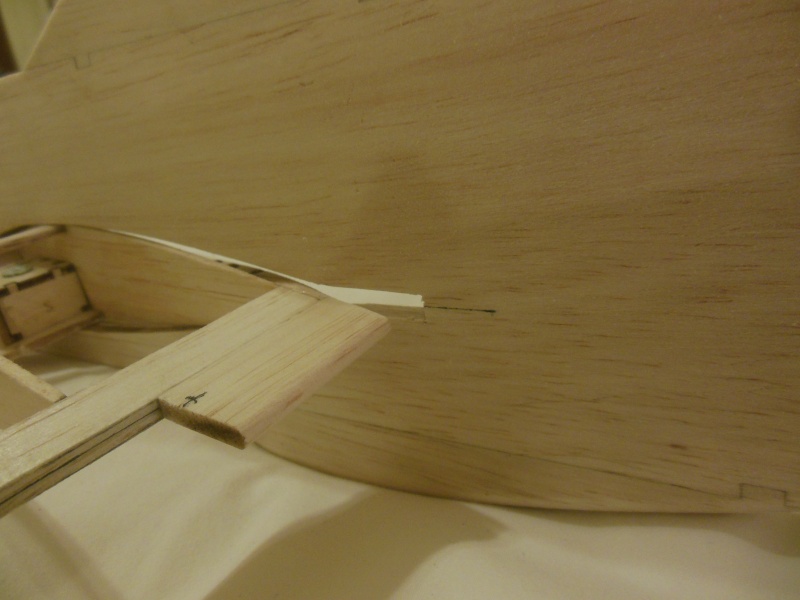

The wings were an easy build until it came to the tips. The kit was supplied with adjustable lead out. It was rectangular in shape but only just larger than the slot cut in the ribs. So I shaved off a smidgen along the length and rounded the edges.

This enabled it to fit neatly into the rib.

There was also a wing tip weight box

I didn't want it proud of the wing surface and so I trimmed it to fit the rib shape. Should allow me to cover the wing neatly just leaving the lid (I also curved the edge of this)

The bellcrank fitted neatly

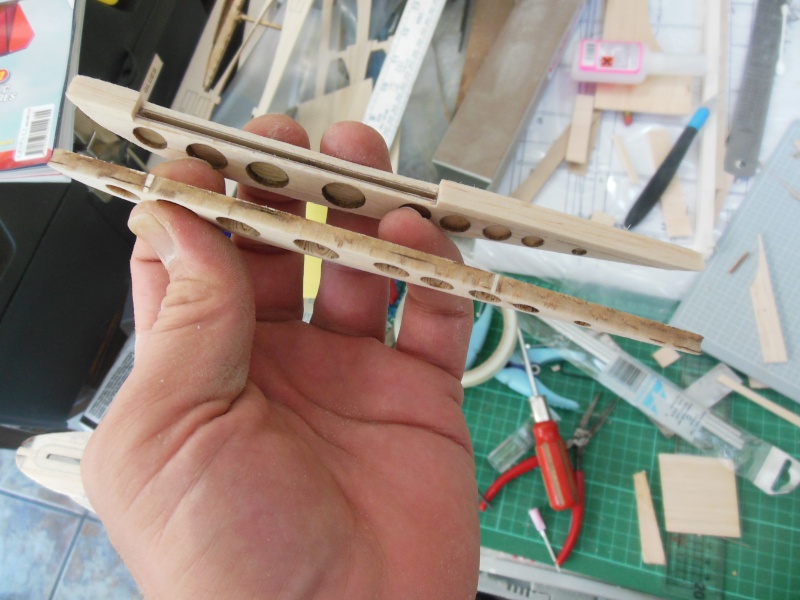

Webbing and sheeting

Then I came to another tricky bit. The wing tips - all ready cut and lightened - How can you place these centrally without interfering with the lead outs?

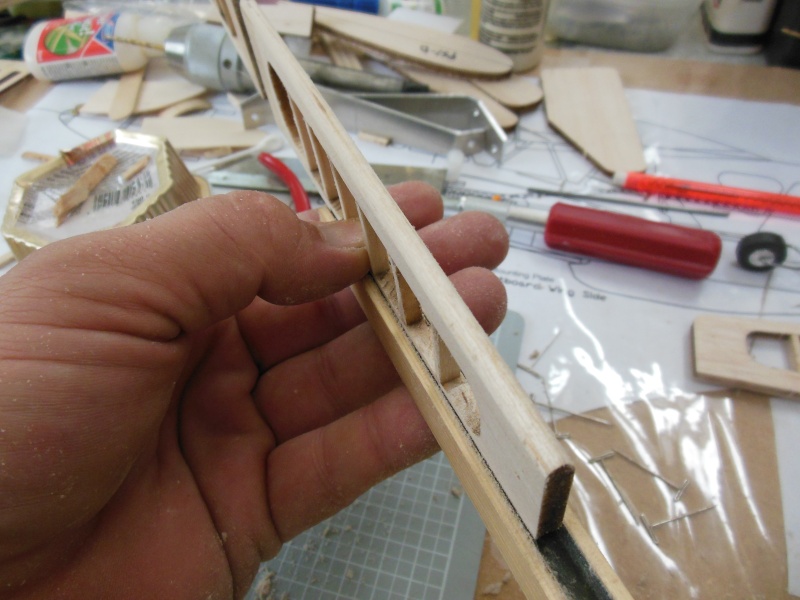

I decided to split it - the picture shows one original tip in the middle, the two outer ones split. Again the quality of the wood allowed me to do this with an xacto blade!

I then made an insert to widen it and used 1/64 ply to prevent the lead outs wearing the balsa. At this stage I also realised that the tip would bind the adjusting screw so I allowed a slot.

and made the other tip match. The wood split just as easily on the second tip. While probably not necessary - symmetry has an appeal.

The finished result

This was blended with the leading edge using the constructed sanding block

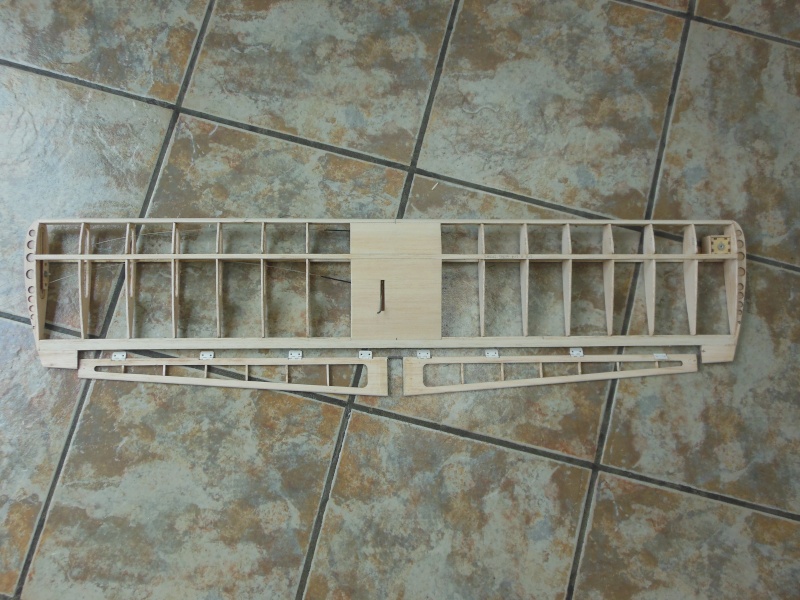

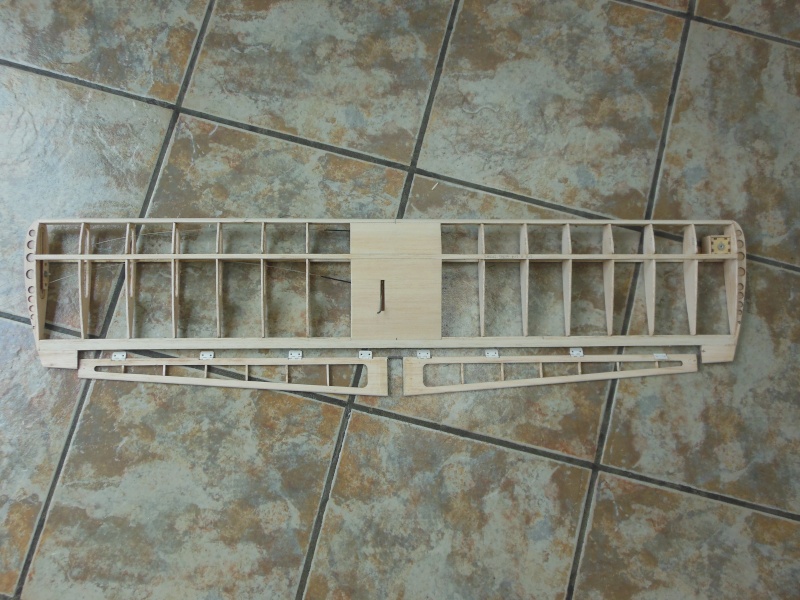

The finished wing awaiting ailerons

To be continued ....................

https://www.coxengineforum.com/t7104-leading-edge-profile-sander

I have kept a track of it and noted some of the issues I had (all minor). The first thing to note is that the materials are excellent but I had trouble following the instructions. Like most kits, I have come to the conclusion that they are often written in hindsight by skilled builders (or designers) and a degree of knowledge or aptitude is often assumed.

Pictures are worth a thousand words!

The wings were an easy build until it came to the tips. The kit was supplied with adjustable lead out. It was rectangular in shape but only just larger than the slot cut in the ribs. So I shaved off a smidgen along the length and rounded the edges.

This enabled it to fit neatly into the rib.

There was also a wing tip weight box

I didn't want it proud of the wing surface and so I trimmed it to fit the rib shape. Should allow me to cover the wing neatly just leaving the lid (I also curved the edge of this)

The bellcrank fitted neatly

Webbing and sheeting

Then I came to another tricky bit. The wing tips - all ready cut and lightened - How can you place these centrally without interfering with the lead outs?

I decided to split it - the picture shows one original tip in the middle, the two outer ones split. Again the quality of the wood allowed me to do this with an xacto blade!

I then made an insert to widen it and used 1/64 ply to prevent the lead outs wearing the balsa. At this stage I also realised that the tip would bind the adjusting screw so I allowed a slot.

and made the other tip match. The wood split just as easily on the second tip. While probably not necessary - symmetry has an appeal.

The finished result

This was blended with the leading edge using the constructed sanding block

The finished wing awaiting ailerons

To be continued ....................

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: RSM P51d build

Re: RSM P51d build

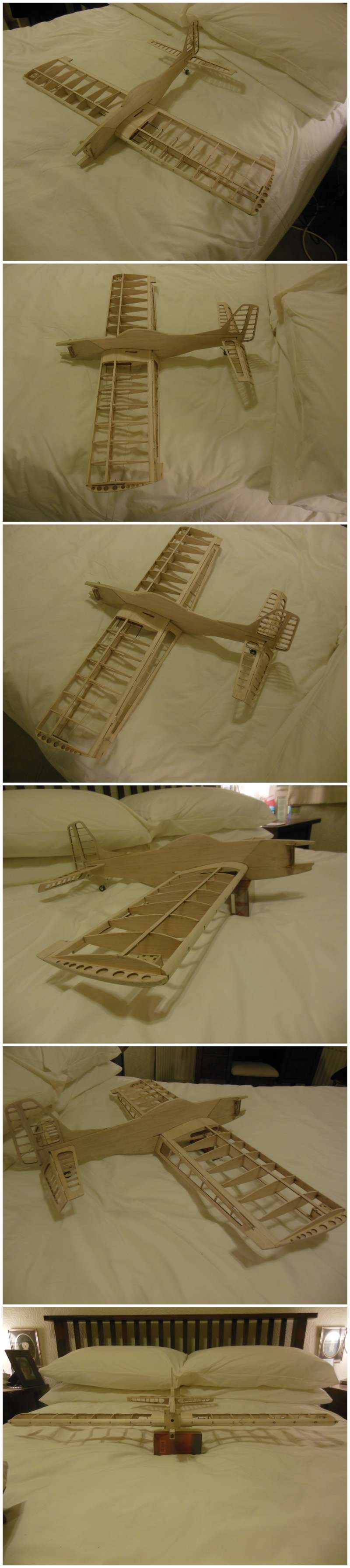

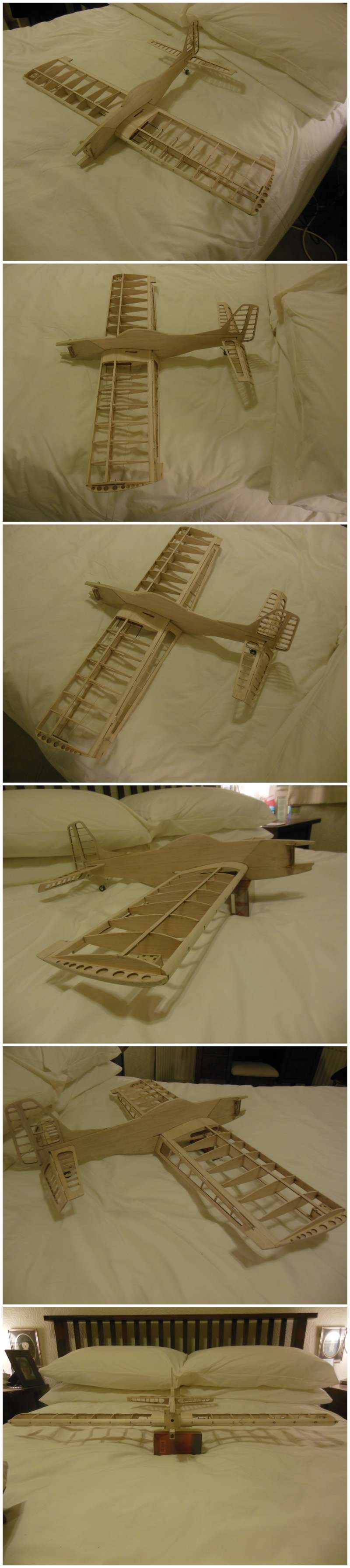

The fuselage. not much to say here - it is one of those silhouettes (but a rather nice one!)

The parts

add glue

more glue and build ailerons while waiting for set

Epoxying ply, slow setting hence clamps

The parts

add glue

more glue and build ailerons while waiting for set

Epoxying ply, slow setting hence clamps

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: RSM P51d build

Re: RSM P51d build

Generally a balsa plug is glued to the lid of a weight box with relief for the screw head. A half of a half rib can allow for sheeting the gap around the box so the box is perfectly faired in with material for covering to attach to.

Got any more clamps?

Phil

Got any more clamps?

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: RSM P51d build

Re: RSM P51d build

Very nice. Love it.

I looked it up, I guess with the inner fuse section it would be the "built-up" kit rather than the profile. I see that you use both CA and epoxy according to application. CA sure makes the build go faster and many times frees up a hand or two.

I also like the "Pentastar" that RSM offers.

Good luck with your build. What are you thinking of using as a cover/paint?

Bob

I looked it up, I guess with the inner fuse section it would be the "built-up" kit rather than the profile. I see that you use both CA and epoxy according to application. CA sure makes the build go faster and many times frees up a hand or two.

I also like the "Pentastar" that RSM offers.

Good luck with your build. What are you thinking of using as a cover/paint?

Bob

rsv1cox- Top Poster

Posts : 11250

Join date : 2014-08-18

Location : West Virginia

Re: RSM P51d build

Re: RSM P51d build

pkrankow wrote:Generally a balsa plug is glued to the lid of a weight box with relief for the screw head. A half of a half rib can allow for sheeting the gap around the box so the box is perfectly faired in with material for covering to attach to.

Got any more clamps?

Phil

Wish I had have known this before building.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: RSM P51d build

Re: RSM P51d build

rsv1cox wrote:Very nice. Love it.

What are you thinking of using as a cover/paint?

Bob

Not decided yet but it isn't going to be iron on stuff. I have amassed dope and like the smell of it. I have Silk, Starspan tissue, heavy and medium weight tissue, nylon ......as I don't have to fuel proof it - any old paint as long as it is light. I usually mess up painting and have been practising with spray gun and airbrushes.

I am not a fine wine and have not improved with age!

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: RSM P51d build

Re: RSM P51d build

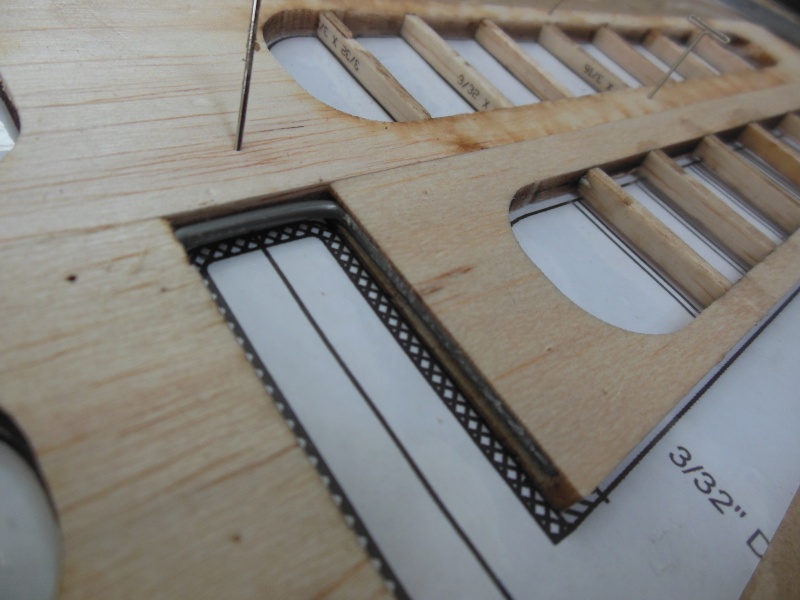

Now for the fin, rudder and tailplane.

A departure from the plan, I inset the piano wire. It was then epoxied in place with a covering of glass fibre.

I made another profiled sanding block to round the edges.

One edge done and reversed in the block

The block

It speeds things up

We are talking seconds and not minutes. Outside curves and corners not a problem. Inside curves, a bit of hand sanding is needed to finish.

A departure from the plan, I inset the piano wire. It was then epoxied in place with a covering of glass fibre.

I made another profiled sanding block to round the edges.

One edge done and reversed in the block

The block

It speeds things up

We are talking seconds and not minutes. Outside curves and corners not a problem. Inside curves, a bit of hand sanding is needed to finish.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: RSM P51d build

Re: RSM P51d build

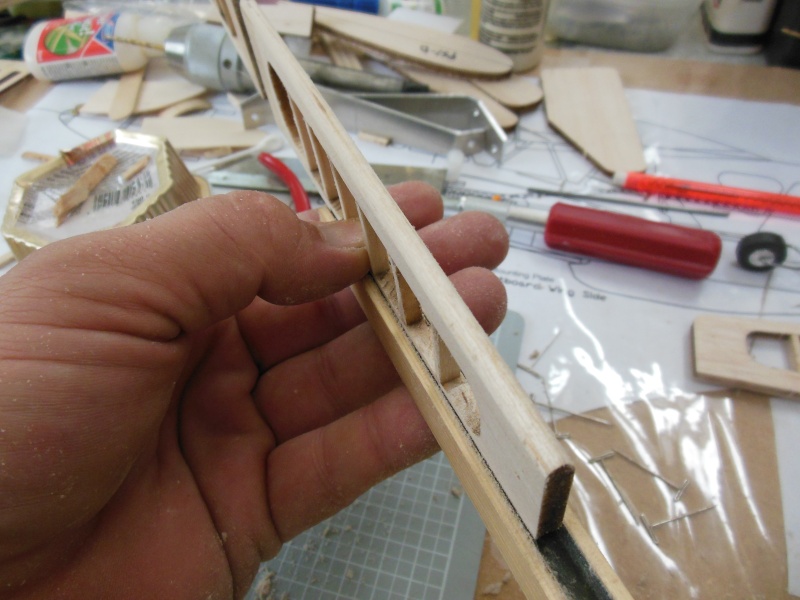

I watched the Windy videos and followed his lead on trimming hinges. Everyone has there own preference on hinges and materials but I like these.

As original, they would have been to big and protruded through the balsa.

I did the same thing for the ailerons

I also made the mistake of glueing on the fixed aileron tips more of that later. It seemed the easiest way to line everything up.

As original, they would have been to big and protruded through the balsa.

I did the same thing for the ailerons

I also made the mistake of glueing on the fixed aileron tips more of that later. It seemed the easiest way to line everything up.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: RSM P51d build

Re: RSM P51d build

That is pretty awesome looking.

Phil

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: RSM P51d build

Re: RSM P51d build

That's a full on PA stunter. Looks good Ian, not seeing how the flap tips will cause you any issues though.

Ron

Ron

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: RSM P51d build

Re: RSM P51d build

I suspect the flap tips are supposed to have "soft" metal attachments so they can be used as trim tabs. I have seen other builds use that technique, but I don't know if it was the builder or the plans.

Phil

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: RSM P51d build

Re: RSM P51d build

I've seen that as well, many times. It's always been a builder mod. Trim tabs usually are required to fix a fault in the wing. Not always though, I have seen arrow straight wings need trim tabs and I have seen wonky wings fly fine without.

If Ian requires a trim adjustment it would be easy to cut that tab off at the joint and create a tab.

Ron

If Ian requires a trim adjustment it would be easy to cut that tab off at the joint and create a tab.

Ron

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: RSM P51d build

Re: RSM P51d build

Hi Ian,

Looks great, should be a good plane for you. That fuselage reminds me of Larry Cunningham's Mo'best design, one of the best flying profiles out there.

Looks great, should be a good plane for you. That fuselage reminds me of Larry Cunningham's Mo'best design, one of the best flying profiles out there.

Re: RSM P51d build

Re: RSM P51d build

Thank you chaps. The thought of trim tabs never entered my head It was the sudden realisation that the wing would now not slide into the fuselage without further surgery.

The fuselage seems very robust and is also light.

There is a dowel at the back

for mounting a tail wheel

I am the stage of starting covering. This is it temporarily assembled.

A few hints on covering would be appreciated. I do intend to use either silk or tissue but, for example, should I cover the whole wing before attaching the fuselage?

Or glue and assemble wings etc to the fuselage first?

The fuselage seems very robust and is also light.

There is a dowel at the back

for mounting a tail wheel

I am the stage of starting covering. This is it temporarily assembled.

A few hints on covering would be appreciated. I do intend to use either silk or tissue but, for example, should I cover the whole wing before attaching the fuselage?

Or glue and assemble wings etc to the fuselage first?

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: RSM P51d build

Re: RSM P51d build

Covering before gluing the hinges in, whichever material you use, will make life easier.

Painting the sheeting with fuel proof paint, including inside the bell crank exit, is a good idea. If you cover the whole wing prior to installation, paint it anyways. I like to glue the wing in, then paint, then cover (with film), typically.

I have tried the ARF method and don't like it too much.

Phil

Painting the sheeting with fuel proof paint, including inside the bell crank exit, is a good idea. If you cover the whole wing prior to installation, paint it anyways. I like to glue the wing in, then paint, then cover (with film), typically.

I have tried the ARF method and don't like it too much.

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: RSM P51d build

Re: RSM P51d build

Ian,

I would assemble then cover. As Phil suggested do the hinge gluing after the fact.

I would assemble then cover. As Phil suggested do the hinge gluing after the fact.

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: RSM P51d build

Re: RSM P51d build

I glue the wing into the fuselage in its skeletal state. For me it allows easier alignment of the wing and the thrust line because I can get a ruler against the spar for reference and measure to the prop tip. Depending on how the wing is built, you may trust the actual LE for the reference points, but I didn't on my Osprey since I had shaped it manually with sandpaper. Use a one bladed prop so you can rotate it back and forth to measure from the tip to each reference point on the wing. I also use the same spar to align the stabilizer hinge line with the wing.

Before you glue the flap horns in place, if they are particularly hard metal you may want to anneal them so as to be able to twist a flap for flying trim without breaking the flap. I didn't know that when I built my Yak-9 and tried to adjust a flap and only succeeded in cracking the wood, giving up and adding a trim tab to the outboard wing to level it in flight.

Rusty

Before you glue the flap horns in place, if they are particularly hard metal you may want to anneal them so as to be able to twist a flap for flying trim without breaking the flap. I didn't know that when I built my Yak-9 and tried to adjust a flap and only succeeded in cracking the wood, giving up and adding a trim tab to the outboard wing to level it in flight.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: RSM P51d build

Re: RSM P51d build

RknRusty wrote:...

Before you glue the flap horns in place, if they are particularly hard metal you may want to anneal them so as to be able to twist a flap for flying trim without breaking the flap. I didn't know that when I built my Yak-9 and tried to adjust a flap and only succeeded in cracking the wood, giving up and adding a trim tab to the outboard wing to level it in flight.

Rusty

Annealing is difficult and dicey, on a small part like this it is pretty difficult. Deeply drawing the temper is more realistic, although the softest state of the metal won't be achieved. IF YOU REALLY THINK IT IS NECESSARY Heat the steel to dull red in dim light. Use wet towel on the ends if it is glued, keep the towel wet with a squirt bottle. Allow the metal to cool evenly (with the ends wet if glued in).

(to anneal the metal has to be raised above "critical" for the phase change, about 1450-1650F for most steels, then cooled over about 24 hours in dry fluffy ashes or similar insulation. Since the wire is so small a heat mass of added steel would need heated and packed at the same time.)

If you anneal wrong the metal may be harder or more brittle than before starting. If the wire is annealed drill rod deeply drawing temper will not heat the metal to "critical" and the metal will remain at the same hardness that it started at. Steel has to be hardened to temper, tempering is not hardening, but is softening.

Apologies for waxing pedantic.

Long hardwood adjusting handles can be made to fit the flaps tightly and allow tweaking of the flaps.

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: RSM P51d build

Re: RSM P51d build

Oh. Well in the words of the late great Roseannrosanadana."Nevermind."

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: RSM P51d build

Re: RSM P51d build

Ian your aeroplane is looking really swift , Thanks for the building slides , If it were me I like building the plane as complete as possible then covering I thing it make it easier to alien everthing as straight as poss. without the covering interference . Just my  Should be a good flyer from the looks . Eric

Should be a good flyer from the looks . Eric

Should be a good flyer from the looks . Eric

Should be a good flyer from the looks . Eric

getback- Top Poster

Posts : 10442

Join date : 2013-01-17

Age : 67

Location : julian , NC

Re: RSM P51d build

Re: RSM P51d build

I have decided to cover it with tissue and silk. I only have "white" examples of both and so have decided to try my hand at dyeing. If I don't like it I can always paint!

Ken warns against dyeing in another topic as he has seen many example fade over time. I suppose exposure to sunlight will definitely cause this but if you are just after a colour (and still learning to fly control line) then it seems a quicker way to "finish" a model.

I have now covered quite a few models with the iron on stuff and, while a relatively quick way to cover, the various coverings I have tried don't seem to impart much strength to the model as I remember from using silk or nylon coverings.

Maybe I'm right, maybe I'm wrong but I won't know until I try it. It may end up heavier than I expect but I'm all for trying.

Anyway. I learned that not all tissues are suitable for this process.

Here is the silk being soaked.

I then bunged in two different tissues - one called Starspan and another from my "stock" - they both appeared as strong as each other dry and weighed the same.

Here is two sheets of Starspan squeezed after rinsing.

Here is the slop left by my stock tissue.

I did wonder what would have happened covering with that when wet.

Due to the absence of SWTSMBO - not that it would make much difference - here is the tissue drying nicely

and the silk

Ken warns against dyeing in another topic as he has seen many example fade over time. I suppose exposure to sunlight will definitely cause this but if you are just after a colour (and still learning to fly control line) then it seems a quicker way to "finish" a model.

I have now covered quite a few models with the iron on stuff and, while a relatively quick way to cover, the various coverings I have tried don't seem to impart much strength to the model as I remember from using silk or nylon coverings.

Maybe I'm right, maybe I'm wrong but I won't know until I try it. It may end up heavier than I expect but I'm all for trying.

Anyway. I learned that not all tissues are suitable for this process.

Here is the silk being soaked.

I then bunged in two different tissues - one called Starspan and another from my "stock" - they both appeared as strong as each other dry and weighed the same.

Here is two sheets of Starspan squeezed after rinsing.

Here is the slop left by my stock tissue.

I did wonder what would have happened covering with that when wet.

Due to the absence of SWTSMBO - not that it would make much difference - here is the tissue drying nicely

and the silk

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: RSM P51d build

Re: RSM P51d build

Nice! It never occurred to me that silk could be dyed prior to covering. What kind of dye did you use? Wetting a piece of tissue attached to a separate frame is a "traditional" way to pre-shrink tissue to prevent warping when covering light models. Might work with dye too? Although your better tissue seems fine.

If I ever build a combat plane it's going to be tie-dyed silk

If I ever build a combat plane it's going to be tie-dyed silk

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Re: RSM P51d build

Re: RSM P51d build

The dye I used is "Dylon" from the hardware shop. the whole process takes one hour. The dye (powder) is first dissolve in warm water. Salt is then mixed into a bowl of water and the now liquid dye added to that. The soaking and stirring takes 45 minutes. The first fifteen being constant stirring.

It is not a quick dip job. The final colour depends on the amount of water, salt and dye used. The instruction recomended mixing according to the weight of material. I suppose that is OK for cottons and wools but silk and tissue weigh next to nothing and are thin.

I used a more concentrated mix than recommended. They said 6 litres of water, I uses 11/2 reduced the amount of salt but kept the dye amount the same.

It is not a quick dip job. The final colour depends on the amount of water, salt and dye used. The instruction recomended mixing according to the weight of material. I suppose that is OK for cottons and wools but silk and tissue weigh next to nothing and are thin.

I used a more concentrated mix than recommended. They said 6 litres of water, I uses 11/2 reduced the amount of salt but kept the dye amount the same.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: RSM P51d build

Re: RSM P51d build

Well that looks just Dandy never seen it done / and I have not heard of preshrinking silk for light frame construction  Is that pretty much the same as what ur doing to color the silk , soak and dry before you apply? Its always good to learn something on CEF

Is that pretty much the same as what ur doing to color the silk , soak and dry before you apply? Its always good to learn something on CEF  Eric

Eric

Eric

Eric

getback- Top Poster

Posts : 10442

Join date : 2013-01-17

Age : 67

Location : julian , NC

Re: RSM P51d build

Re: RSM P51d build

getback wrote:Well that looks just Dandy never seen it done / and I have not heard of preshrinking silk for light frame constructionIs that pretty much the same as what ur doing to color the silk , soak and dry before you apply? Its always good to learn something on CEF

Eric

I am not sure that it will be pre shrunk. This particular silk is close weave and so will not shrink much anyway. It will still need applying wet and a little stretching. Some silks shrink so much they can distort a frame. This will be all "trial and error"

Tis all new to me, although silk is expensive - it is not as expensive as it used to be. I have covered with nylon before but that wil not take a "household dye".

But if practical, I suppose preshrinking silk could be a good idea but I wouldn't know what to recommend.

I have seen wrinkled wing coverings with dope smooth out by themselves after a couple of months. I think dope takes a lot longer than often but thought to cure. It skins quickly but underneath the solvent can take some time to evaporate.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Page 1 of 2 • 1, 2

Similar topics

Similar topics» The BTC-2 build

» COX MISS AMERICA P51D .049 ENGINE

» Guillows Cessna 150 build circa 1970 (Build Log)

» Help Deciding on Kit

» look what rkflyer sent me and jack AGAIN!

» COX MISS AMERICA P51D .049 ENGINE

» Guillows Cessna 150 build circa 1970 (Build Log)

» Help Deciding on Kit

» look what rkflyer sent me and jack AGAIN!

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules