Log in

Search

Latest topics

» Roger Harris revisitedby rsv1cox Today at 3:38 pm

» My N-1R build log

by GallopingGhostler Today at 3:04 pm

» Tee Dee .020 combat model

by 1/2A Nut Today at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» My latest doodle...

by batjac Yesterday at 9:47 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

Cox Engine of The Month

Cleaning old Cox .049ers

Page 1 of 1

Cleaning old Cox .049ers

Cleaning old Cox .049ers

Hey there Cox aficionados.....getting back into the hobby after a 19 year pause and have come across many of my old .049s.

Got many up and running even using old fuel. Wow! Love hearing that sound and smelling that smell.

My query is this......what are you folks using and doing to clean up the old engines? Is there a certain grease-off or magic potion to get them ready for the Cox Ball?

Any intel would be much appreciated.

I'll post some pix of them and even a video after my 7 day new-boy break-in period.

Thankee.

Shug

Got many up and running even using old fuel. Wow! Love hearing that sound and smelling that smell.

My query is this......what are you folks using and doing to clean up the old engines? Is there a certain grease-off or magic potion to get them ready for the Cox Ball?

Any intel would be much appreciated.

I'll post some pix of them and even a video after my 7 day new-boy break-in period.

Thankee.

Shug

ShugEmery- Moderate Poster

- Posts : 10

Join date : 2014-04-04

Age : 66

Location : Roseville, Minnesota

Re: Cleaning old Cox .049ers

Re: Cleaning old Cox .049ers

to the forum! If you're mainly after a general cleaning to get them running well, soaking the parts overnight in fuel or Isopropyl alcohol should help loosen the gummy castor. If you are looking for a deeper cleaning, Hoppes #9 gun cleaner should help remove the more baked on castor oil residue. Others have also used brake fluid however the parts shouldn't be soaked more than a few hours. If you want to make them look like new, polishing the parts with Mothers Mag & Aluminum Polish and refinishing with fine sandpaper or a sctochbrite pad will give them that machined look.

to the forum! If you're mainly after a general cleaning to get them running well, soaking the parts overnight in fuel or Isopropyl alcohol should help loosen the gummy castor. If you are looking for a deeper cleaning, Hoppes #9 gun cleaner should help remove the more baked on castor oil residue. Others have also used brake fluid however the parts shouldn't be soaked more than a few hours. If you want to make them look like new, polishing the parts with Mothers Mag & Aluminum Polish and refinishing with fine sandpaper or a sctochbrite pad will give them that machined look.There's guys on here who will go into much greater detail.

By the way, have you been up to Hub Hobby lately (I see you're in the local area).

Re: Cleaning old Cox .049ers

Re: Cleaning old Cox .049ers

You mean in detail like this?

First off avoid rotating the crank at at any time during disassembly because it

is likely that there is dirt or debris inside the engine and you don't want it to damage

anything, especially the piston and cylinder.

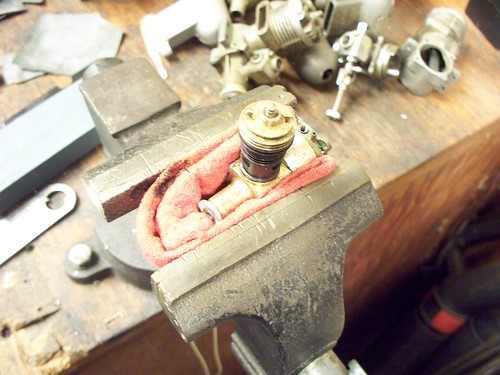

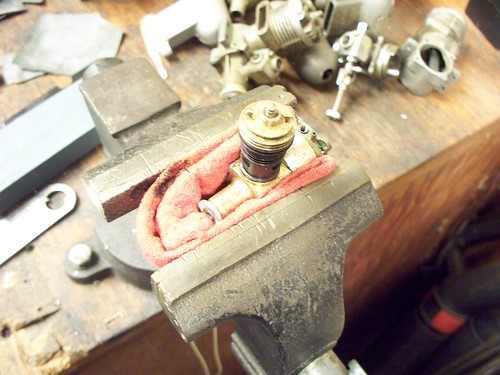

To get started, fold up a rag so it is several layers thick and cover the engines case

with it so the engine can be LIGHTLY clamped (cradled is a better word) in a vise without getting scratched up.

Situate the engine in the vise in such a way that wrenches can be put on the cylinder

and the glow head. [at this time try to loosen the glow head. If it loosens remove it,

if it is stuck go to next step.]

Now it is time to heat the engine. I like using a propane torch but

a heat gun works too, it just takes longer. Take care not to set your rag on fire! Get the

engine pretty hot, to the point you can't touch it for more than a second. Heating is

something you kind of have to get used to doing.

Quickly, before the engine cools to much, put a wrench on the glow head and break it

loose. If the glow head breaks loose from the cylinder then quickly go ahead and put a

wrench on the cylinder and break it loose from the case. If the cylinder broke loose along

with the glow head then just quickly move on to the next step. Move fast so the engine

does not cool off.

With the engine still wrapped in the rag take it out of the vise and and break loose the

fuel tank screws. If it is a Tee Dee or Medallion then rotate the engine in the vise [be

sure to keep the rag in place and only snug the vise up] so you can put a wrench on the

rear cover and break it loose.

Now go ahead and remove the fuel tank or rear cover. If the cylinder broke loose with

the glow head wait until it is warm to the touch and with a cylinder exhaust slot wrench

and a glow head wrench the head should now loosen up without any trouble. [I heavily

edited this paragraph, read on to see why]

Now put a 5-40 screw in the end of the crank until it bottoms out. Stand the case up on

a piece of hard wood on a solid surface. Hit the screw head with a small hammer and

drive the crank shaft off of the prop driver. It should only take a few fairly light blows

to get it off. The engine is now completely disassembled and ready to clean.

I like using 90% or better isopropyl alcohol (rubbing alcohol) for cleaning parts.

A 10 to 15 minute soak followed up by a good going over with a stiff bristle brush

usually gets off most all residue. An assortment of brushes is essential to a good

cleaning. Be aware that the alcohol can alter the color of delrin parts, gives them

a whitish faded look. For really baked on residue I'll use Dawn Power Disolver. It

is a cleaner available at most grocery stores in the household cleaner section. Don't

soak parts it it for longer than an hour or so. It can ruin the finish on aluminum parts.

If any dirt or residue remains after soaking and brushing I may try another round.

If it comes out clean with just a few stubborn spots I will pick what remains off very

carefully with a pin. I use a T-pin, cut off the "t" and clamp it in a finger drill or pin

vise as some call them. Takes a bit of care and practice to do it without causing scratches.

With this method I can disassemble and clean every part of the nastiest, grimmest, Babe Bee

you've ever seen in 30 - 40 minutes.

First off avoid rotating the crank at at any time during disassembly because it

is likely that there is dirt or debris inside the engine and you don't want it to damage

anything, especially the piston and cylinder.

To get started, fold up a rag so it is several layers thick and cover the engines case

with it so the engine can be LIGHTLY clamped (cradled is a better word) in a vise without getting scratched up.

Situate the engine in the vise in such a way that wrenches can be put on the cylinder

and the glow head. [at this time try to loosen the glow head. If it loosens remove it,

if it is stuck go to next step.]

Now it is time to heat the engine. I like using a propane torch but

a heat gun works too, it just takes longer. Take care not to set your rag on fire! Get the

engine pretty hot, to the point you can't touch it for more than a second. Heating is

something you kind of have to get used to doing.

Quickly, before the engine cools to much, put a wrench on the glow head and break it

loose. If the glow head breaks loose from the cylinder then quickly go ahead and put a

wrench on the cylinder and break it loose from the case. If the cylinder broke loose along

with the glow head then just quickly move on to the next step. Move fast so the engine

does not cool off.

With the engine still wrapped in the rag take it out of the vise and and break loose the

fuel tank screws. If it is a Tee Dee or Medallion then rotate the engine in the vise [be

sure to keep the rag in place and only snug the vise up] so you can put a wrench on the

rear cover and break it loose.

Now go ahead and remove the fuel tank or rear cover. If the cylinder broke loose with

the glow head wait until it is warm to the touch and with a cylinder exhaust slot wrench

and a glow head wrench the head should now loosen up without any trouble. [I heavily

edited this paragraph, read on to see why]

Now put a 5-40 screw in the end of the crank until it bottoms out. Stand the case up on

a piece of hard wood on a solid surface. Hit the screw head with a small hammer and

drive the crank shaft off of the prop driver. It should only take a few fairly light blows

to get it off. The engine is now completely disassembled and ready to clean.

I like using 90% or better isopropyl alcohol (rubbing alcohol) for cleaning parts.

A 10 to 15 minute soak followed up by a good going over with a stiff bristle brush

usually gets off most all residue. An assortment of brushes is essential to a good

cleaning. Be aware that the alcohol can alter the color of delrin parts, gives them

a whitish faded look. For really baked on residue I'll use Dawn Power Disolver. It

is a cleaner available at most grocery stores in the household cleaner section. Don't

soak parts it it for longer than an hour or so. It can ruin the finish on aluminum parts.

If any dirt or residue remains after soaking and brushing I may try another round.

If it comes out clean with just a few stubborn spots I will pick what remains off very

carefully with a pin. I use a T-pin, cut off the "t" and clamp it in a finger drill or pin

vise as some call them. Takes a bit of care and practice to do it without causing scratches.

With this method I can disassemble and clean every part of the nastiest, grimmest, Babe Bee

you've ever seen in 30 - 40 minutes.

Last edited by iamplanecrazy2 on Tue Apr 08, 2014 10:54 am; edited 2 times in total

iamplanecrazy2- Silver Member

- Posts : 92

Join date : 2011-07-03

Location : Waxahachie Texas

Re: Cleaning old Cox .049ers

Re: Cleaning old Cox .049ers

I agree with everything above with the exception of heating the glow head to remove it.

Aluminum and iron expand at different rates so heating the head may cause it to bind as it will have expanded more/faster than the iron cylinder. I believe the Cox manual tells you never remove a head while the engine is hot as it will cause damage.

If anything I would heat the cylinder and then try and remove the head. Enough heat should have transfered from the cylinder to release the castor bond.

Just my thoughts and I surely don't want to contradict or offend anyone.

Ron

Aluminum and iron expand at different rates so heating the head may cause it to bind as it will have expanded more/faster than the iron cylinder. I believe the Cox manual tells you never remove a head while the engine is hot as it will cause damage.

If anything I would heat the cylinder and then try and remove the head. Enough heat should have transfered from the cylinder to release the castor bond.

Just my thoughts and I surely don't want to contradict or offend anyone.

Ron

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Cleaning old Cox .049ers

Re: Cleaning old Cox .049ers

I just use a heavy leather glove to hold the engine while heating with either a monokote heat gun or on the stubborn ones heat using a butane mini torch. Never clamp in the vice unless you like squashed crankcases. I have a few engines I got in engine lots that were junk because of being clamped in a vice.

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: Cleaning old Cox .049ers

Re: Cleaning old Cox .049ers

Thanks for all the info fellers.....appreciated.

I really was talking about cleaning up the outside of the engine. Got the insides loosened with a heat gun. Went with the isopropyl alcohol dip and a stiff brush. Thanks.

They look a lot better. Now.....what am I gonna put them on. That is the fun part.

I really was talking about cleaning up the outside of the engine. Got the insides loosened with a heat gun. Went with the isopropyl alcohol dip and a stiff brush. Thanks.

They look a lot better. Now.....what am I gonna put them on. That is the fun part.

ShugEmery- Moderate Poster

- Posts : 10

Join date : 2014-04-04

Age : 66

Location : Roseville, Minnesota

Re: Cleaning old Cox .049ers

Re: Cleaning old Cox .049ers

Admin wrote:to the forum! If you're mainly after a general cleaning to get them running well, soaking the parts overnight in fuel or Isopropyl alcohol should help loosen the gummy castor. If you are looking for a deeper cleaning, Hoppes #9 gun cleaner should help remove the more baked on castor oil residue. Others have also used brake fluid however the parts shouldn't be soaked more than a few hours. If you want to make them look like new, polishing the parts with Mothers Mag & Aluminum Polish and refinishing with fine sandpaper or a sctochbrite pad will give them that machined look.

There's guys on here who will go into much greater detail.

By the way, have you been up to Hub Hobby lately (I see you're in the local area).

Yessir....always Christmas shop at Hub and lately have been up there buying new bits and bobs as I am getting pulled back into the hobby. Some electric park flyers. Bought a P-51 Park Zone plane a few weeks ago and some control line stuff. Love R/C and Control Line,

See you up there.

ShugEmery- Moderate Poster

- Posts : 10

Join date : 2014-04-04

Age : 66

Location : Roseville, Minnesota

Re: Cleaning old Cox .049ers

Re: Cleaning old Cox .049ers

Whooooo Buddy....amazing in depth answer. Thankee.

iamplanecrazy2 wrote:You mean in detail like this?

First off avoid rotating the crank at at any time during disassembly because it

is likely that there is dirt or debris inside the engine and you don't want it to damage

anything, especially the piston and cylinder.

To get started, fold up a rag so it is several layers thick and cover the engines case

with it so the engine can be LIGHTLY clamped in a vise without getting scratched up.

Situate the engine in the vise in such a way that wrenches can be put on the cylinder

and the glow head.

Now it is time to heat the engine. I like using a propane torch but

a heat gun works too, it just takes longer. Take care not to set your rag on fire! Get the

engine pretty hot, to the point you can't touch it for more than a second. Heating is

something you kind of have to get used to doing.

Quickly, before the engine cools to much, put a wrench on the glow head and break it

loose. If the glow head breaks loose from the cylinder then quickly go ahead and put a

wrench on the cylinder and break it loose from the case. If the cylinder broke loose along

with the glow head then just quickly move on to the next step. Move fast so the engine

does not cool off.

With the engine still wrapped in the rag take it out of the vise and and break loose the

fuel tank screws. If it is a Tee Dee or Medallion then rotate the engine in the vise so you

can put a wrench on the rear cover and break it loose.

Now go ahead and remove the fuel tank or rear cover. If the cylinder broke loose with

the glow head put a cylinder slot wrench in the vise and slide the cylinder onto it. It will

likely have cooled to much by now so heat the glow head up with the torch and remove

it from the cylinder. If the glow head won't break loose from the cylinder fairly easily

then heat again. Be especially careful with thin wall cylinders. Sometimes the head and

cylinder can be pretty stubborn coming apart. Stuck parts are something else that requires

some trial and error to master.

Now put a 5-40 screw in the end of the crank until it bottoms out. Stand the case up on

a piece of hard wood on a solid surface. Hit the screw head with a small hammer and

drive the crank shaft off of the prop driver. It should only take a few fairly light blows

to get it off. The engine is now completely disassembled and ready to clean.

I like using 90% or better isopropyl alcohol (rubbing alcohol) for cleaning parts.

A 10 to 15 minute soak followed up by a good going over with a stiff bristle brush

usually gets off most all residue. An assortment of brushes is essential to a good

cleaning. Be aware that the alcohol can alter the color of delrin parts, gives them

a whitish faded look. For really baked on residue I'll use Dawn Power Disolver. It

is a cleaner available at most grocery stores in the household cleaner section. Don't

soak parts it it for longer than an hour or so. It can ruin the finish on aluminum parts.

If any dirt or residue remains after soaking and brushing I may try another round.

If it comes out clean with just a few stubborn spots I will pick what remains off very

carefully with a pin. I use a T-pin, cut off the "t" and clamp it in a finger drill or pin

vise as some call them. Takes a bit of care and practice to do it without causing scratches.

With this method I can disassemble and clean every part of the nastiest, grimmest, Babe Bee

you've ever seen in 30 - 40 minutes.

ShugEmery- Moderate Poster

- Posts : 10

Join date : 2014-04-04

Age : 66

Location : Roseville, Minnesota

Re: Cleaning old Cox .049ers

Re: Cleaning old Cox .049ers

Shug,

There is a lot of info on this subject buried within the forum. Do a search when you have some time. There are a few on here that do remarkable restorations.

I like to clean mine then get them really dirty

Ron

There is a lot of info on this subject buried within the forum. Do a search when you have some time. There are a few on here that do remarkable restorations.

I like to clean mine then get them really dirty

Ron

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Cleaning old Cox .049ers

Re: Cleaning old Cox .049ers

So I shall. Search on))))))Cribbs74 wrote:Shug,

There is a lot of info on this subject buried within the forum. Do a search when you have some time. There are a few on here that do remarkable restorations.

I like to clean mine then get them really dirty

Ron

ShugEmery- Moderate Poster

- Posts : 10

Join date : 2014-04-04

Age : 66

Location : Roseville, Minnesota

Re: Cleaning old Cox .049ers

Re: Cleaning old Cox .049ers

Oh come on now! I all capt LIGHTLY and even said to wrap the engine in a rag before putting it in a vise!

I know there are some people out there that will still turn the handle until the case is distorted but

here is how I put the engine in a vise, the jaws are snugged up just enough to cradle the engine nicely.

It keeps me from having to wear a glove and saves my slightly arthritic hands some discomfort.

Ron! I had an epiphany moment reading your response about heating the head.

Looking back I know the vast majority of the time when I would heat the engine

and try to loosen the glow head it invariably took the cylinder with it. Many times

I have said to myself, "why do people have to put those heads on so damn tight?"

All the while I think it was just the heat binding that head up in the cylinder. Wow!

I don't always eat crow.

But when I do,

I eat a very large portion.

I'm gonna go out to the shop, lay my finger on the work bench, and hit it with a hammer.

I'm gonna go out to the shop, lay my finger on the work bench, and hit it with a hammer.

No, seriously what I actually did was went out the the shop and experimented with glow head removal.

I had plenty of gummed up engines to work with.

Experimentation did prove that it is definitely true that the heat can bind the head up in the cylinder.

It also taught me that the first thing to do is try to loosen the glow head without any heat. I did that

to every engine in that jar and all but a dozen loosened up easily.

So I had 12 engines with glow heads that were stuck tight to experiment with. I heated them up one at

a time and tried to loosen the glow head. All of them remained stuck to the cylinder and the cylinder

loosened from the case. So I went ahead and removed the cylinders from the engine.

I put one of the cylinders on an exhaust slot wrench (noticing it was still warm), put a wrench on the

glow head and it loosened right up. The other 11 glow heads also loosened right up with some variation

in the amount of torque required to break them loose. Probably because some of the heads were initially

torqued down harder that others.

I then snugged the heads back down and one at a time I heated them up and tried to remove the head

when it was hot. Each one was stuck too tight to get off. After waiting for one to cool down to the point

that it just felt warm, the head would loosen right up.

Conclusion, to get a stuck glow head loose from the cylinder heat it up good and hot then let cool until

just warm to the touch and it should loosen right up.

I know there are some people out there that will still turn the handle until the case is distorted but

here is how I put the engine in a vise, the jaws are snugged up just enough to cradle the engine nicely.

It keeps me from having to wear a glove and saves my slightly arthritic hands some discomfort.

Ron! I had an epiphany moment reading your response about heating the head.

Looking back I know the vast majority of the time when I would heat the engine

and try to loosen the glow head it invariably took the cylinder with it. Many times

I have said to myself, "why do people have to put those heads on so damn tight?"

All the while I think it was just the heat binding that head up in the cylinder. Wow!

I don't always eat crow.

But when I do,

I eat a very large portion.

I'm gonna go out to the shop, lay my finger on the work bench, and hit it with a hammer.

I'm gonna go out to the shop, lay my finger on the work bench, and hit it with a hammer.No, seriously what I actually did was went out the the shop and experimented with glow head removal.

I had plenty of gummed up engines to work with.

Experimentation did prove that it is definitely true that the heat can bind the head up in the cylinder.

It also taught me that the first thing to do is try to loosen the glow head without any heat. I did that

to every engine in that jar and all but a dozen loosened up easily.

So I had 12 engines with glow heads that were stuck tight to experiment with. I heated them up one at

a time and tried to loosen the glow head. All of them remained stuck to the cylinder and the cylinder

loosened from the case. So I went ahead and removed the cylinders from the engine.

I put one of the cylinders on an exhaust slot wrench (noticing it was still warm), put a wrench on the

glow head and it loosened right up. The other 11 glow heads also loosened right up with some variation

in the amount of torque required to break them loose. Probably because some of the heads were initially

torqued down harder that others.

I then snugged the heads back down and one at a time I heated them up and tried to remove the head

when it was hot. Each one was stuck too tight to get off. After waiting for one to cool down to the point

that it just felt warm, the head would loosen right up.

Conclusion, to get a stuck glow head loose from the cylinder heat it up good and hot then let cool until

just warm to the touch and it should loosen right up.

Last edited by iamplanecrazy2 on Tue Apr 08, 2014 2:34 pm; edited 1 time in total

iamplanecrazy2- Silver Member

- Posts : 92

Join date : 2011-07-03

Location : Waxahachie Texas

Re: Cleaning old Cox .049'rs

Re: Cleaning old Cox .049'rs

Correct me if I'm wrong, but didn't the Cox user's manual say to squirt some glo fuel over the head before removing it?

I would think that little bit of advice would be to contract the glow head, relative to the still hot cylinder. This would serve to help loosen the threaded connection.

Added: MAN! I want a cookie jar like that!

I would think that little bit of advice would be to contract the glow head, relative to the still hot cylinder. This would serve to help loosen the threaded connection.

Added: MAN! I want a cookie jar like that!

VUgearhead- Gold Member

- Posts : 155

Join date : 2013-07-02

Age : 57

Location : Boynton Beach, FL

Re: Cleaning old Cox .049ers

Re: Cleaning old Cox .049ers

VUgearhead wrote:

MAN! I want a cookie jar like that!

I was thinking the same thing!!

I was thinking the same thing!!  I saw that photo and had a "kid in a candy shop" moment!

I saw that photo and had a "kid in a candy shop" moment! Re: Cleaning old Cox .049ers

Re: Cleaning old Cox .049ers

Ha Ha! I stole that idea from my buddy Steve Bennett. He filled an old penny gum ball machine up

with a mix of 1/2a engines like Cox, Wen Mac, Atwood, Anderson ect. Its really a neat idea but I

didn't have a gum ball machine so used the jar. A gallon pickle jar would be cool too.

My stash is a result of years of snatching up every bargain (some not) priced Cox engine I could

lay my hands on.

with a mix of 1/2a engines like Cox, Wen Mac, Atwood, Anderson ect. Its really a neat idea but I

didn't have a gum ball machine so used the jar. A gallon pickle jar would be cool too.

My stash is a result of years of snatching up every bargain (some not) priced Cox engine I could

lay my hands on.

iamplanecrazy2- Silver Member

- Posts : 92

Join date : 2011-07-03

Location : Waxahachie Texas

Re: Cleaning old Cox .049ers

Re: Cleaning old Cox .049ers

Yes, but that would be referring to an engine that hadn't been sitting and congealing for a long time. To cool it immediately after a run if you want to remove it to adjust your shims or some such reason.VUgearhead wrote:Correct me if I'm wrong, but didn't the Cox user's manual say to squirt some glo fuel over the head before removing it?

I would think that little bit of advice would be to contract the glow head, relative to the still hot cylinder. This would serve to help loosen the threaded connection.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Cleaning old Cox .049ers

Re: Cleaning old Cox .049ers

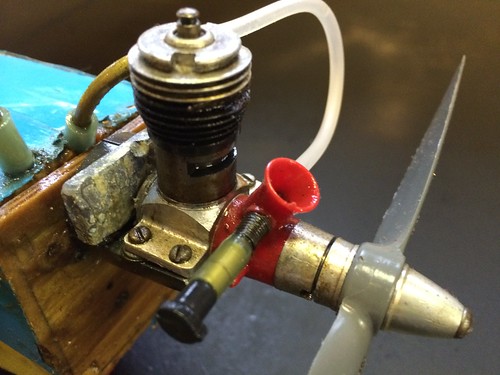

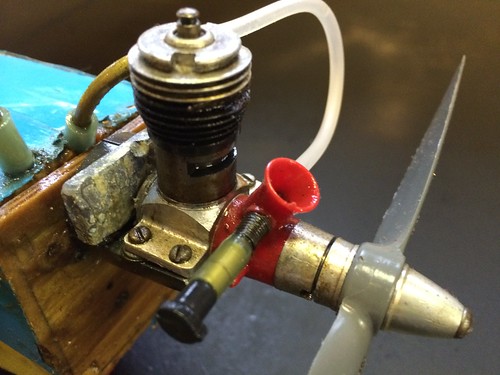

Here are some pictures and videos of my old resurrected Cox engines. They shall fly again))))))

Took the muffler off the Black Widow and put it on the QZ.

Shug

Took the muffler off the Black Widow and put it on the QZ.

Shug

ShugEmery- Moderate Poster

- Posts : 10

Join date : 2014-04-04

Age : 66

Location : Roseville, Minnesota

Re: Cleaning old Cox .049ers

Re: Cleaning old Cox .049ers

"Engine cleaning" has been covered MANY times in the "search" function.

Check there for lots of good answers.

(Most importantly DON"T use common pilers and screwdrivers but only Cox tools designed to suit the intended purpose.)

Why permanently damage a perfectly good engine by poor use of tools?

SD

Check there for lots of good answers.

(Most importantly DON"T use common pilers and screwdrivers but only Cox tools designed to suit the intended purpose.)

Why permanently damage a perfectly good engine by poor use of tools?

SD

SuperDave- Rest In Peace

- Posts : 3552

Join date : 2011-08-13

Location : Washington (state)

Re: Cleaning old Cox .049ers

Re: Cleaning old Cox .049ers

SuperDave wrote:"Engine cleaning" has been covered MANY times in the "search" function.

Check there for lots of good answers.

(Most importantly DON"T use common pilers and screwdrivers but only Cox tools designed to suit the intended purpose.)

Why permanently damage a perfectly good engine by poor use of tools?

SD

Got the old tools. These engines will fly again soon.........

ShugEmery- Moderate Poster

- Posts : 10

Join date : 2014-04-04

Age : 66

Location : Roseville, Minnesota

Re: Cleaning old Cox .049ers

Re: Cleaning old Cox .049ers

That's the spirt we like to see Shug!

Be patient and seek advice when needed.

SD

Be patient and seek advice when needed.

SD

SuperDave- Rest In Peace

- Posts : 3552

Join date : 2011-08-13

Location : Washington (state)

Similar topics

Similar topics» RTF models

» after run cleaning?

» Bore cleaning .049's

» How to clean old cox models? I appreciatte sugestions.

» Engine cleaning

» after run cleaning?

» Bore cleaning .049's

» How to clean old cox models? I appreciatte sugestions.

» Engine cleaning

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules