Log in

Search

Latest topics

» My N-1R build logby roddie Today at 12:32 am

» Happy 77th birthday Andrew!

by akjgardner Today at 12:27 am

» TEE DEE Having issues

by TD ABUSER Yesterday at 9:43 pm

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» Roger Harris revisited

by TD ABUSER Yesterday at 2:13 pm

» Tee Dee .020 combat model

by Ken Cook Yesterday at 1:41 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Yesterday at 1:37 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Fri Nov 22, 2024 11:32 am

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

Cox Engine of The Month

Making airfoils

Page 1 of 1

Making airfoils

Making airfoils

This is new territory for me. Anyone have a good method to sand an airfoil into a slab wing? My comcern is making it even across the span.

Ron

Ron

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Making airfoils

Re: Making airfoils

Draw a line span wise at the high spot. Draw lines halfway through the thickness of the leading and trailing edges. Use the lines as sanding guides, taper the leading and trailing edges to the high spot leaving the line intact:

JPvelo- Diamond Member

- Posts : 1972

Join date : 2011-12-02

Age : 57

Location : Colorado

Re: Making airfoils

Re: Making airfoils

Thanks Jim,

Sounds easy enough. We shall see...

Ron

Sounds easy enough. We shall see...

Ron

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Making airfoils

Re: Making airfoils

That's the easiest way, I also drew a line before I started sanding. I sanded the 2 half wings separately. To be sure they are symmetrical, you can hold them with the" intrados" against each other and compare the shape.

I then glued both halves together with the necessary dihedral.

Lieven

I then glued both halves together with the necessary dihedral.

Lieven

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

Re: Making airfoils

Re: Making airfoils

Lieven,

Just came back in. Everything looks good. My plane called for 3/32 balsa wings so it wasn't much to work with. I'm happy with it though.

Ron

Just came back in. Everything looks good. My plane called for 3/32 balsa wings so it wasn't much to work with. I'm happy with it though.

Ron

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Making airfoils

Re: Making airfoils

Cribbs74 wrote:This is new territory for me. Anyone have a good method to sand an airfoil into a slab wing? My comcern is making it even across the span.

Ron

Ron:

I recommend using a sanding bar like the ones from Great Planes. I have them in three different lengths.

SD

SuperDave- Rest In Peace

- Posts : 3552

Join date : 2011-08-13

Location : Washington (state)

Re: Making airfoils

Re: Making airfoils

Thanks Dave,

Good suggestion. I really don't have the time though and the chances of me making anything other than a built up after this point is slim.

Ron

Good suggestion. I really don't have the time though and the chances of me making anything other than a built up after this point is slim.

Ron

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Making airfoils

Re: Making airfoils

A good piece of 1"x2" cut 10"-12" us a piece of glass to make sure it straight, 3M 77 spray and your done, coarse on one side med/fine on other.

Re: Making airfoils

Re: Making airfoils

I use Home Depot paint stir sticks to make my own sanding boards.Mark Boesen wrote:A good piece of 1"x2" cut 10"-12" us a piece of glass to make sure it straight, 3M 77 spray and your done, coarse on one side med/fine on other.

Jim

JPvelo- Diamond Member

- Posts : 1972

Join date : 2011-12-02

Age : 57

Location : Colorado

Re: Making airfoils

Re: Making airfoils

yep, I've done that too! Years ago I picked up a couple rolls of adhesive backed sandpaper, still use it, works great.

Re: Making airfoils

Re: Making airfoils

Yeah those look nice. It's on my list of tools I want to get.SuperDave wrote:I recommend using a sanding bar like the ones from Great Planes. I have them in three different lengths.

SD

I have some ideas on how to make bars that fit specific LE shapes.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Making airfoils

Re: Making airfoils

I used a palm sander on a flat table. Did a little by hand to clean it up.

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Making airfoils

Re: Making airfoils

I started with a pre-cut airfoil, but I had to shorten the root chord by 1/2" and sweep the TE forward out to the narrow tips, which totally threw the shape out of whack. I taped a 4" x 14" strip of sandpaper to my glass and am working it back into shape on that. I'm sure the NACA shape is ruined, so I'm just trying to keep the high point parallel with the LE.

Ruminating: I think the area of maximum lift is a in a pocket starting right behind the high point? Seems like that's where the vacuum would begin to develop. So it really needs to be straight. I think if the high point is too far back toward the center it might act like it's tail heavy, but not. I'm sort of thinking as I type, since like Ron stated, this is new territory for me too. Forgot to take a pic, but I'll get one later.

Rusty

Ruminating: I think the area of maximum lift is a in a pocket starting right behind the high point? Seems like that's where the vacuum would begin to develop. So it really needs to be straight. I think if the high point is too far back toward the center it might act like it's tail heavy, but not. I'm sort of thinking as I type, since like Ron stated, this is new territory for me too. Forgot to take a pic, but I'll get one later.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Making airfoils

Re: Making airfoils

Another option is using 1" aluminum angle stock for a nice flat sanding beam. A 4 foot piece could be cut into three 16" lengths for coarse/med./fine grits. The angle serves as a handle.

To stay "on-topic"... you can use the music-wire trick by forming the wire over hardwood airfoil-shaped templates placed at the root and tip chords.. leaving clearance for your music-wire's thickness. Clamp the wire's down over the templates on a board, and use a sanding-beam about 6" longer than your span.. and sand "span-wise".. down to the wire guides. You'll have exactly the airfoil you want.. even if it's a tapered-wing. You could use sheet-metal strips as root/tip guides instead of music wire if you wanted.

It's always worthwhile (great rainy-day project) to make yourself some sanding tools of as many types as you can think up. (you "will" use them if you have them!) Short hardwood dowel cut-offs.. as well as square Spruce "sticks" of different sizes/lengths, work great. A board.. faced with a couple full-sheets 100-150 grit paper; makes a good non-skid base for sanding parts too... (better than holding with your fingers alone)

Another option for attaching sandpaper to a block/tool is to use 2-sided tape.

To stay "on-topic"... you can use the music-wire trick by forming the wire over hardwood airfoil-shaped templates placed at the root and tip chords.. leaving clearance for your music-wire's thickness. Clamp the wire's down over the templates on a board, and use a sanding-beam about 6" longer than your span.. and sand "span-wise".. down to the wire guides. You'll have exactly the airfoil you want.. even if it's a tapered-wing. You could use sheet-metal strips as root/tip guides instead of music wire if you wanted.

It's always worthwhile (great rainy-day project) to make yourself some sanding tools of as many types as you can think up. (you "will" use them if you have them!) Short hardwood dowel cut-offs.. as well as square Spruce "sticks" of different sizes/lengths, work great. A board.. faced with a couple full-sheets 100-150 grit paper; makes a good non-skid base for sanding parts too... (better than holding with your fingers alone)

Another option for attaching sandpaper to a block/tool is to use 2-sided tape.

Re: Making airfoils

Re: Making airfoils

I was thinking of getting some aluminum channel( [ ) shaped beam. Then mix some Sugru and pack it into the c-bar, then smush it over the LE of your choice to shape it and let it harden and line it with adhesive backed paper. It'll be off by the thickness of the paper, but close. Do the same with some different LE sticks and label them, even look up the NACA numbers, so you pick the one you need for whatever plane you're building.

For today's project though, it's shaping the surface of the air foil and I don't know of any way to make a sanding block for that, because the rolloff after the high point changes along the length of a wing with a forward swept TE.

Rusty

For today's project though, it's shaping the surface of the air foil and I don't know of any way to make a sanding block for that, because the rolloff after the high point changes along the length of a wing with a forward swept TE.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Making airfoils

Re: Making airfoils

How about trying a flat-plank wing with light-weight balsa "false spar-strips" top/bottom (root to tip) to form your desired tapered airfoil... and covering it with econo-kote?  ??

??

EDIT: "Don't shoot me.. I'm only the piano player"!!!

??

??EDIT: "Don't shoot me.. I'm only the piano player"!!!

Re: Making airfoils

Re: Making airfoils

Or the "forgot the name" raised block along the LE gives lift. Now don't get the wrong idea, I'm just ruminating, as I said, but I'm specifically talking about trying to keep the NACA specs pretty much intact. For the Reed Speed build, I'm not obsessing over it, just roughing it out as closely as I can reasonably get. It's just that this thread and looking at other members' foils has just given me too much to think about on a day that's too nasty to fool with anything in the shop.roddie wrote:How about trying a flat-plank wing with light-weight balsa "false spar-strips" top/bottom (root to tip) to form your desired tapered airfoil... and covering it with econo-kote???...

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Making airfoils

Re: Making airfoils

RknRusty wrote:

Or the "forgot the name" raised block along the LE gives lift.

Rusty

I believe the name you're searching for is turbulator strip. Here's a link to Martin Hepperle's page explaining their usage:

http://www.mh-aerotools.de/airfoils/turbulat.htm

They don't need to be large -- I've seen carpet thread stretched across the upper wing being used.

As an aside, I use the Great Planes sanding bars in various lengths on all of my builds. I find them ideal for trueing up edges and ensuring that airfoils remain uniform over the span of the wing.

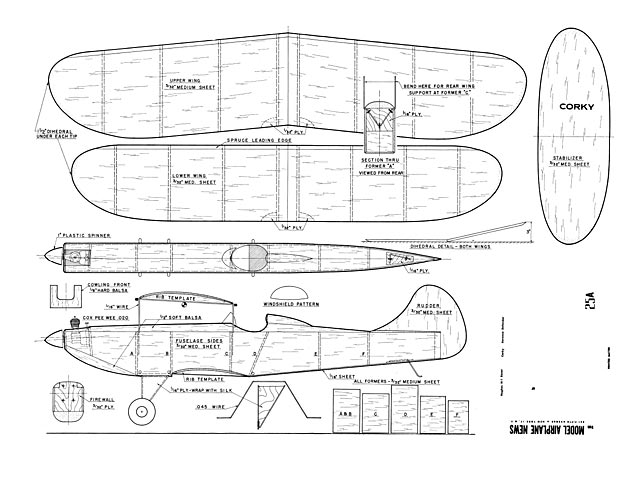

Another option for adding an airfoil to a sheet wing is shown here --- I built this plane while still in high school. The bottom is open, but the shape is maintained by the underlying ribs. It's long since gone, but I'm really tempted to build another and use the ultra light R/C gear in it.

Re: Making airfoils

Re: Making airfoils

http://flyinglines.org/kb.speedwing.html

JPvelo- Diamond Member

- Posts : 1972

Join date : 2011-12-02

Age : 57

Location : Colorado

Kline-Fogleman

Kline-Fogleman

Hey folks.. I've had a radical design for a small sheet-wing C/L model on my mind for a few months now. The scope of the model would be for simple Cox reed-valve power (.020-.049 engine displacement) simple profile-type model.. with minimal time to build.. or "modify"...

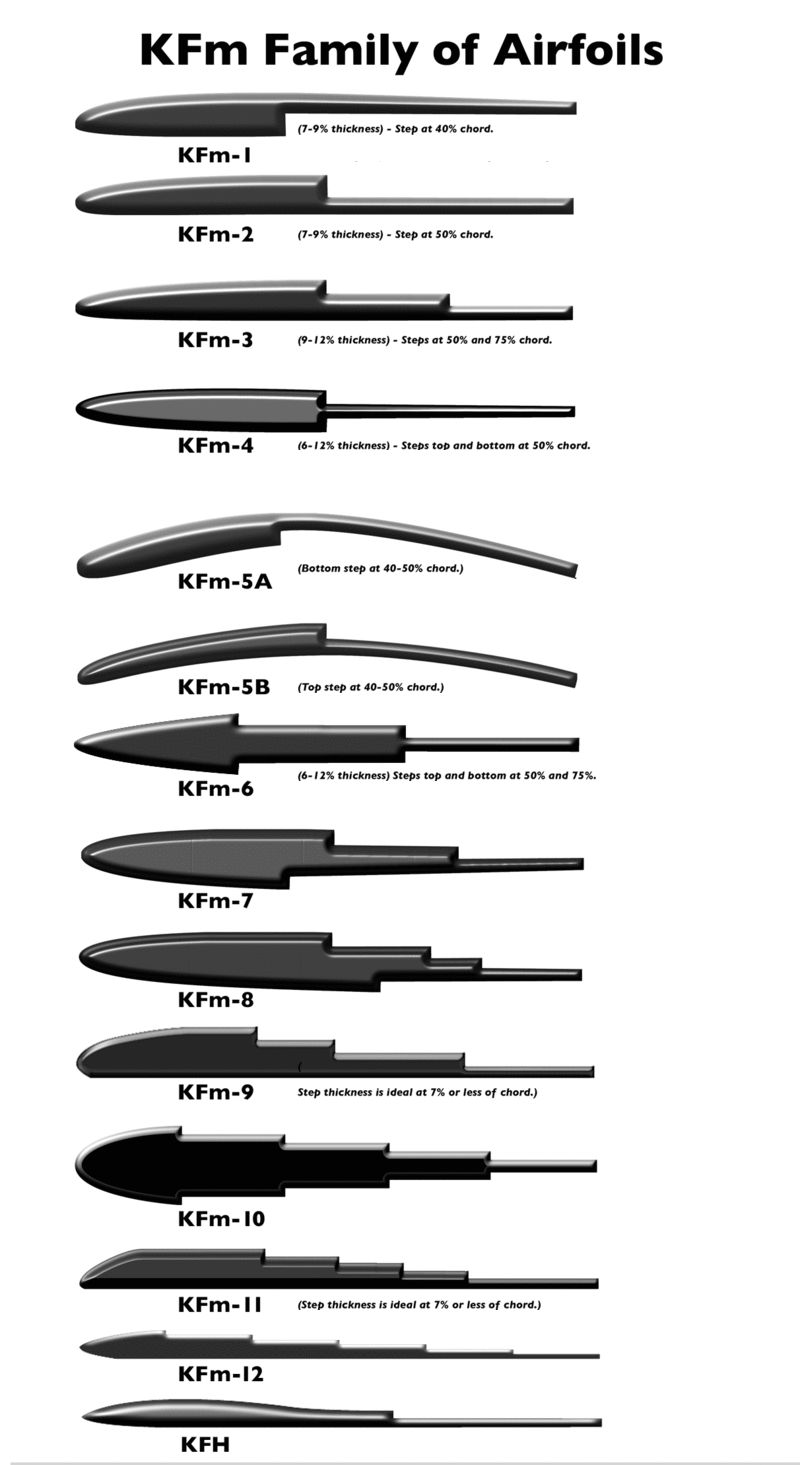

The difference is in an "air-foiled" leading-edge-strip on the wing. See these KFm airfoils for reference..

Note the symmetrical KFm-4, 6 and 10 air-foils in particular. These all employ an air-foiled leading-edge.. tapering-down symmetrically.. to a flat trailing-edge.

We know that a very few, totally-flat/slab-wing designs perform well, when subject to acrobatic flight-input from the handle.

What if.. the L/E had strips of air-foil stock glued-on? Consider a 1/8" slab-wing.. with a blunt (square) L/E... having a "simple" piece of 3/8" L/E stock glued "to it? (1/8" above.. and 1/8" below..) This would basically establish the "Kline-Fogelman" airfoil concept for the #'s that I referenced.

My thoughts are; that this single L/E strip (without any other strips rearward..) might enable the wing to "grab some air".. rather than merely slicing through it. It might also help to slow a "fast-flying" model down a little bit..

I'm not sure if I've conveyed this concept in the way that I conceive it... but it might be a worthwhile mod to try.. on one of your little birds, hanging in the shadows. Two strips of 3/8" L/E stock would add virtually no weight to a model.. and it would be forward of the cg....

The difference is in an "air-foiled" leading-edge-strip on the wing. See these KFm airfoils for reference..

Note the symmetrical KFm-4, 6 and 10 air-foils in particular. These all employ an air-foiled leading-edge.. tapering-down symmetrically.. to a flat trailing-edge.

We know that a very few, totally-flat/slab-wing designs perform well, when subject to acrobatic flight-input from the handle.

What if.. the L/E had strips of air-foil stock glued-on? Consider a 1/8" slab-wing.. with a blunt (square) L/E... having a "simple" piece of 3/8" L/E stock glued "to it? (1/8" above.. and 1/8" below..) This would basically establish the "Kline-Fogelman" airfoil concept for the #'s that I referenced.

My thoughts are; that this single L/E strip (without any other strips rearward..) might enable the wing to "grab some air".. rather than merely slicing through it. It might also help to slow a "fast-flying" model down a little bit..

I'm not sure if I've conveyed this concept in the way that I conceive it... but it might be a worthwhile mod to try.. on one of your little birds, hanging in the shadows. Two strips of 3/8" L/E stock would add virtually no weight to a model.. and it would be forward of the cg....

Similar topics

Similar topics» SIG's airfoils

» making thin washers

» building a Guillows kit P 40

» TD .09 Making some noise!

» making-up control lines

» making thin washers

» building a Guillows kit P 40

» TD .09 Making some noise!

» making-up control lines

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules