Log in

Search

Latest topics

» My N-1R build logby roddie Today at 12:32 am

» Happy 77th birthday Andrew!

by akjgardner Today at 12:27 am

» TEE DEE Having issues

by TD ABUSER Yesterday at 9:43 pm

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» Roger Harris revisited

by TD ABUSER Yesterday at 2:13 pm

» Tee Dee .020 combat model

by Ken Cook Yesterday at 1:41 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Yesterday at 1:37 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Fri Nov 22, 2024 11:32 am

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

Cox Engine of The Month

Bulk-sanding balsa

Page 1 of 1

Bulk-sanding balsa

Bulk-sanding balsa

Has anyone ever had the need to sand rough-cut balsa into thickness? I have access to a "Time-Saver" sanding machine... but I'm not sure how well it will work.

A previous employer used large laminated "planks" of balsa (1.75" thickness x 24"W. x 84"L.) to make an "X-shaped" design for signage. Grain-type/weight is random... The 1.75" thick laminations were 6"W. and butt-jointed (x4 to make the 24" plank width) and 28"L. (x3) with x2 precision "finger-joints" (to make the 84" plank-length)

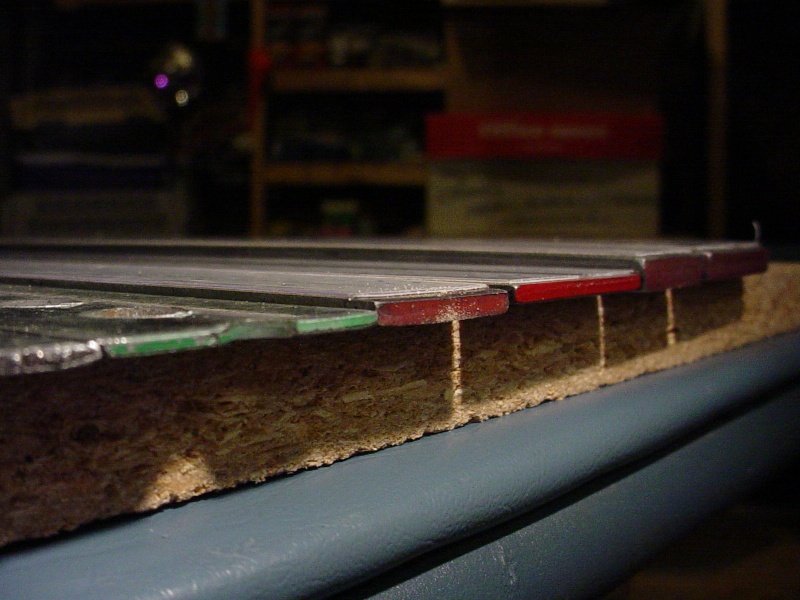

Notice the diff. grain-types on this jointed piece...

Large amounts of scrap were thrown away. I saved some of it by ripping "strips" on a panel saw to "rough" thicknesses of 1/8"+ and 1/4"+ in varied lengths between 18" to 48"... and all pieces are 1.75"W. (plank thickness)

I have 2 boxes full, but this one was easily accessible for the photo.

I'd like to sand "all" the strips into thickness... so I can box them by grain-type/weight, and have a more "useable" stock to work with.

A previous employer used large laminated "planks" of balsa (1.75" thickness x 24"W. x 84"L.) to make an "X-shaped" design for signage. Grain-type/weight is random... The 1.75" thick laminations were 6"W. and butt-jointed (x4 to make the 24" plank width) and 28"L. (x3) with x2 precision "finger-joints" (to make the 84" plank-length)

Notice the diff. grain-types on this jointed piece...

Large amounts of scrap were thrown away. I saved some of it by ripping "strips" on a panel saw to "rough" thicknesses of 1/8"+ and 1/4"+ in varied lengths between 18" to 48"... and all pieces are 1.75"W. (plank thickness)

I have 2 boxes full, but this one was easily accessible for the photo.

I'd like to sand "all" the strips into thickness... so I can box them by grain-type/weight, and have a more "useable" stock to work with.

Bulk Balsa

Bulk Balsa

Roddie,

Why don't you buy/beg/borrow/steal an inexpensive bandsaw and rip those balsa boards to your desired thickness? With a good fence and balsa being such a light wood, there shouldn't be much drift on the cuts (at least consistent enough for model work).

Just a thought.

Why don't you buy/beg/borrow/steal an inexpensive bandsaw and rip those balsa boards to your desired thickness? With a good fence and balsa being such a light wood, there shouldn't be much drift on the cuts (at least consistent enough for model work).

Just a thought.

VUgearhead- Gold Member

- Posts : 155

Join date : 2013-07-02

Age : 57

Location : Boynton Beach, FL

Re: Bulk-sanding balsa

Re: Bulk-sanding balsa

The boxes are full of strips 1-3/4" wide and varied-lengths, which I already "rough-ripped" to thicknesses of 1/8"+ to 1/4"+... (see comment between photos) What I need to do, is "micro-sand" the strips to "finish-grade". The 1/8" stock is roughly .150" thick and the 1/4" stock is roughly .280" thick. I rough-ripped the pcs. on a panel saw, with the intent of finish-sanding them into size later.VUgearhead wrote:Roddie,

Why don't you buy/beg/borrow/steal an inexpensive bandsaw and rip those balsa boards to your desired thickness? With a good fence and balsa being such a light wood, there shouldn't be much drift on the cuts (at least consistent enough for model work).

Just a thought.

Re: Bulk-sanding balsa

Re: Bulk-sanding balsa

Annoying at best idea here...Get some channel iron, some iron pipe, a good stack of FLAT thin plywood or particle board, a stout table, and some sandpaper.

...Make a sanding rig that can control the thickness.

Phil

...Make a sanding rig that can control the thickness.

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: Bulk-sanding balsa

Re: Bulk-sanding balsa

That sounds interesting (maybe because I'm annoying)... would you care to "expand" on this method? I'm trying to visualize a rig using the mat'ls. you mentioned...pkrankow wrote:Annoying at best idea here...Get some channel iron, some iron pipe, a good stack of FLAT thin plywood or particle board, a stout table, and some sandpaper.

...Make a sanding rig that can control the thickness.

Phil

Actually; you helped me think outside the box here... My balsa stock is ALL exactly 1-3/4" wide... and between 2 to 3 ft. long strips. If I obtain pairs of 1" wide steel strips in the thicknesses I need... by 3-4 ft. long, I could mount them "flush" 1-3/4" apart w/counter-sunk flathead screws, to my workbench. This would make a slot to hold the balsa strips, and a gage to sand down to; using a sanding block or palm-sander. I'd still have to sand one pc. at a time... but at least it would be quick and accurate.

This would make a handy tool for anyone working with balsa sheet, needing a thickness "less than" what they have on hand. For example; obtain pairs of steel gage-strips 1" wide, in thicknesses of 1/16", 1/8", 3/16", 1/4" etc. and you'll always be able to precision-sand your own stock, without having to make a trip to the hobby shop.

Re: Bulk-sanding balsa

Re: Bulk-sanding balsa

OK, you found a different idea. I am glad I DIDN'T elaborate. I think your idea is more useful.

If you are going to mount single strip sanding gauges to the table, get a razor plane and mount the plane to the table with a stack of thin shims under it. Pass all the pieces under the plane till they don't cut anymore at each shim level, alternating sides as you remove shims. If you can spring mount the plane it might work too without changing so many shims.

Heck, you could simply mount the gauges to the plane if your table is flat and smooth enough.

Just make sure the blade is fresh and keen.

Phil

(My original idea was to take the angle iron, and a smaller piece of stout, flat plywood. Mount the plywood in the center of 2 pieces of angle iron so you can glue the paper to the plywood with spray glue. Use the pipe of suitable diameter to sanding block, and stack the shims underneath to raise the work to the sandpaper. Run the angle iron perpendicular to the pipe to gauge thickness. The idea is with a little tacky spray under the balsa you can do a large number of pieces in one go.)

If you are going to mount single strip sanding gauges to the table, get a razor plane and mount the plane to the table with a stack of thin shims under it. Pass all the pieces under the plane till they don't cut anymore at each shim level, alternating sides as you remove shims. If you can spring mount the plane it might work too without changing so many shims.

Heck, you could simply mount the gauges to the plane if your table is flat and smooth enough.

Just make sure the blade is fresh and keen.

Phil

(My original idea was to take the angle iron, and a smaller piece of stout, flat plywood. Mount the plywood in the center of 2 pieces of angle iron so you can glue the paper to the plywood with spray glue. Use the pipe of suitable diameter to sanding block, and stack the shims underneath to raise the work to the sandpaper. Run the angle iron perpendicular to the pipe to gauge thickness. The idea is with a little tacky spray under the balsa you can do a large number of pieces in one go.)

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: Bulk-sanding balsa

Re: Bulk-sanding balsa

It took me a few minutes... but I understand your method now, and it should work reasonably well for "bulk"... as I stated in my topic subject.pkrankow wrote:OK, you found a different idea. I am glad I DIDN'T elaborate. I think your idea is more useful.

If you are going to mount single strip sanding gauges to the table, get a razor plane and mount the plane to the table with a stack of thin shims under it. Pass all the pieces under the plane till they don't cut anymore at each shim level, alternating sides as you remove shims. If you can spring mount the plane it might work too without changing so many shims.

Heck, you could simply mount the gauges to the plane if your table is flat and smooth enough.

Just make sure the blade is fresh and keen.

Phil

(My original idea was to take the angle iron, and a smaller piece of stout, flat plywood. Mount the plywood in the center of 2 pieces of angle iron so you can glue the paper to the plywood with spray glue. Use the pipe of suitable diameter to sanding block, and stack the shims underneath to raise the work to the sandpaper. Run the angle iron perpendicular to the pipe to gauge thickness. The idea is with a little tacky spray under the balsa you can do a large number of pieces in one go.)

Either way; the situation with my 1.75" W. strips, is both faces are saw-cut (need sanding)... so I'll have to shim the "guides" up .010" for the 1st side... and then shim the "slot" up .010" for the 2nd side... which should work fine, seeing that I rough-ripped it .020"/.030" over finish thicknesses.

This may seem a little extreme, but so is the $$$ of balsa... These are the strips needing sanding, along with some plank-pieces they were cut from. The large plank is "A" grain... and is less than half the weight of the smaller piece behind it. Grades range from very light to very hard.

Re: Bulk-sanding balsa

Re: Bulk-sanding balsa

What do you plan to do with these pieces?

1/4 x 1 3/4 inch is not a terribly useful size in bulk. Stripping it into spars would make a lot of spars.

An option would be to edge glue to make up 1/4 x 3 1/2 inch prior to taking the material down to thickness. Since you have a large quantity of pieces chances of finding good fitting edges without excess straightening is pretty good. Planing and sanding are two ways to improve fit.

Taking the pieces significantly thinner would be a lot of effort and making a lot of wood into sawdust...unless you can resaw again. On a fine bandsaw it is possible to get two 3/32 out of 1/4 inch, but it would be careful work.

Phil

1/4 x 1 3/4 inch is not a terribly useful size in bulk. Stripping it into spars would make a lot of spars.

An option would be to edge glue to make up 1/4 x 3 1/2 inch prior to taking the material down to thickness. Since you have a large quantity of pieces chances of finding good fitting edges without excess straightening is pretty good. Planing and sanding are two ways to improve fit.

Taking the pieces significantly thinner would be a lot of effort and making a lot of wood into sawdust...unless you can resaw again. On a fine bandsaw it is possible to get two 3/32 out of 1/4 inch, but it would be careful work.

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: Bulk-sanding balsa

Re: Bulk-sanding balsa

Phil, You are correct on all your points. My focus over my modeling years, has been self-designing C/L 1/2A "Profile/Slab-wing" airplanes, in the "Skyray"/"Stuntman"/"Ambush" class. for "Reedies".pkrankow wrote:What do you plan to do with these pieces?

1/4 x 1 3/4 inch is not a terribly useful size in bulk. Stripping it into spars would make a lot of spars.

An option would be to edge glue to make up 1/4 x 3 1/2 inch prior to taking the material down to thickness. Since you have a large quantity of pieces chances of finding good fitting edges without excess straightening is pretty good. Planing and sanding are two ways to improve fit.

Taking the pieces significantly thinner would be a lot of effort and making a lot of wood into sawdust...unless you can resaw again. On a fine bandsaw it is possible to get two 3/32 out of 1/4 inch, but it would be careful work.

Phil

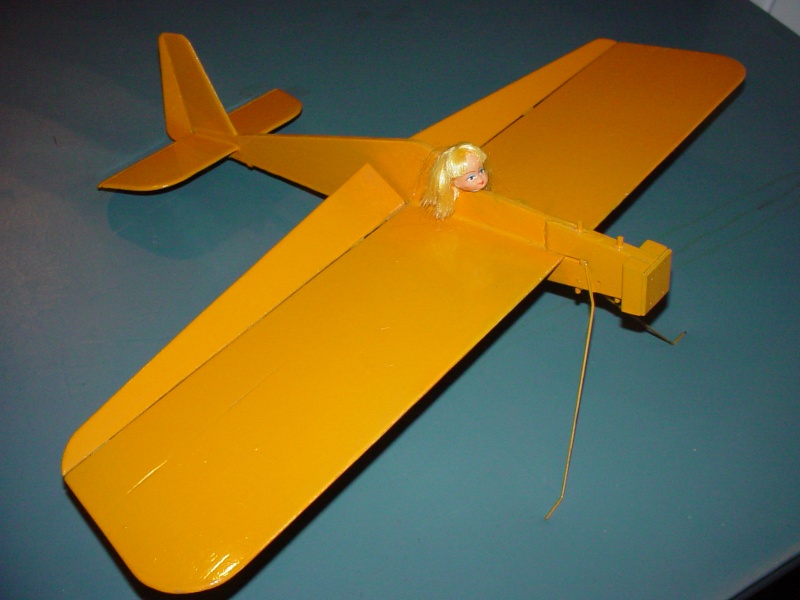

The "Barbie" plane has flaps... (1st plane I ever flew inverted)

I designed it 20 years ago; for my Daughter when she was little... as you said; regarding your Speed Contest entry choice... your Daughter would "approve". A Father doesn't know that feeling, if he doesn't have a Daughter.

One thing I seldom do, is design a 1/8" 1/2A "slab-wing" in one piece... I "edge-glue" max. span-length pieces to meet the max.chord spec... then cut the outline afterward. The 1/4" stock @ 1.75" W. is generally a perfect size for a 1/2A "Profile" fuse... and if not; any desired "wider" top/bottom contours may be edge-glued in place, in the same way. I haven't had any issues with warped "sheet-wings"... possibly due to their being multiple edge-glued panels.

I think of all the balsa that I "had" purchased over the years... and it has mostly been 1/8" and 1/4"thicknesses x3"W. x 36"L... Just yesterday I was at a craft store... and a "Midwest" 1/8" x 3" x 36" sheet was $2.99... which makes me want to hurl. (where's the emoticon?)

I made balsa strippers for cutting sticks... so, for the most part; this 1.75" width "surplus" I have; will be very useful. I look at what I have in balsa... as stock for "several dozen" airplanes of this class... It would be interesting to assemble "scratch-build kits" for this class, and sell them. I could never use this much balsa myself... and there would be 100% profit on the balsa alone.

What would you pay for a scratch-build kit? Let's include balsa for 1/8" sheet-wing/fin/stab/elev. (200 sq. total)... 1/4" x 1.75"W. x 24"L. balsa for fuse, a 1/16" plywood engine plate, some 1/64" ply for upper/lower bell-crank mount (approx. 3/4" x 1.5"), bell-crank/horn, .015" and .062" music-wire x36" lengths (x1 ea.) and a pair of hat/safety-pin lead-out guides?

I made-up a scratch-build kit for a C/L club Christmas party "Yankee-swap" gift once. It also included wheels/collars, Sig Easy-Hinges, and CA glue... just add labor, engine and paint.

Re: Bulk-sanding balsa

Re: Bulk-sanding balsa

Revisiting this thread while sitting here in my basement workshop. Winter is setting in.. and I MUST get some kind of organization to my shop. I have "project stock" of all types stacked, piled, standing.. plus an overflow of other household items.. that just don't fit in our small home.. and either can't be put in cold-storage, or they're used too frequently to put outdoors in the shed (which is also over-loaded). It pains me to know that I have a few large models and a couple bare foam-ribbed wing prototypes hangar'd out there.. and other people who live here, are "ham-fisted" when it's time to find a lawn rake. (did they not witness the crunch and the resulting pieces of balsa/foam falling to the floor?)  I usually find out when I see a broken piece. It's amazing that I can avoid breaking anything, when putting the pool ladder away (up in the loft.. by myself..

I usually find out when I see a broken piece. It's amazing that I can avoid breaking anything, when putting the pool ladder away (up in the loft.. by myself..  ) for the winter.

) for the winter.

Anyway.. the balsa has been on my mind lately, for a lot of reasons. #1.. I have a lot of it.. and #2.. there have been so many wicked builds and plans posted recently.. along with some awesome contributions/info. from new members!. I'll need to get this balsa sanded and graded.. so I can build airplanes this winter.

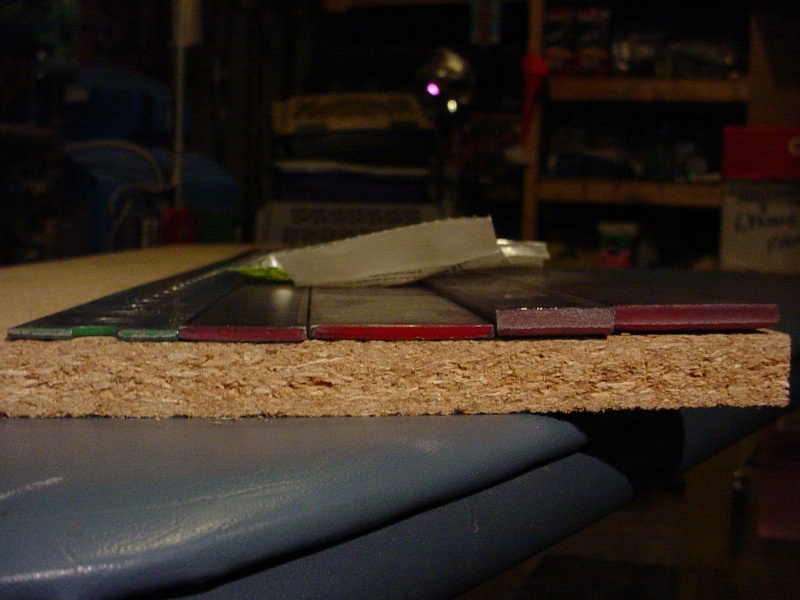

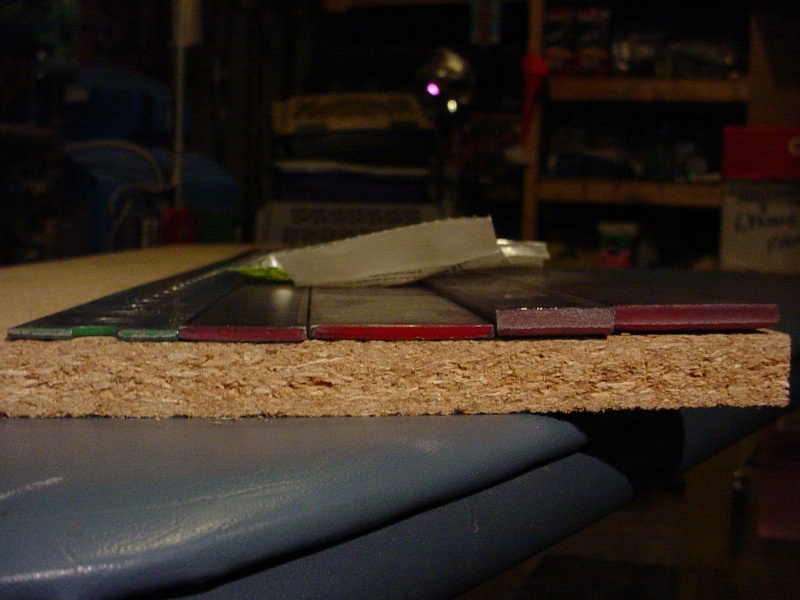

Setting-up a sanding fixture as previously discussed is the plan.. and I'm going to the local home-center today, to buy materials for the fixture. The base will be a thick piece of melamine shelving.. and the gage-rails will be pairs of 1"W. strap steel.. 36"L. in thickness of 1/4", 1/8" and 1/16". This will allow me to custom-sand 4 common sheet thicknesses. (1/16", 1/8", 3/16" and 1/4") using a table-top design that will store easily. I'm thinking that it could be c-clamped to a bench or sturdy table. We'll see how much it will cost for the fixture parts.. I'm off to the home center.

I usually find out when I see a broken piece. It's amazing that I can avoid breaking anything, when putting the pool ladder away (up in the loft.. by myself..

I usually find out when I see a broken piece. It's amazing that I can avoid breaking anything, when putting the pool ladder away (up in the loft.. by myself.. Anyway.. the balsa has been on my mind lately, for a lot of reasons. #1.. I have a lot of it.. and #2.. there have been so many wicked builds and plans posted recently.. along with some awesome contributions/info. from new members!. I'll need to get this balsa sanded and graded.. so I can build airplanes this winter.

Setting-up a sanding fixture as previously discussed is the plan.. and I'm going to the local home-center today, to buy materials for the fixture. The base will be a thick piece of melamine shelving.. and the gage-rails will be pairs of 1"W. strap steel.. 36"L. in thickness of 1/4", 1/8" and 1/16". This will allow me to custom-sand 4 common sheet thicknesses. (1/16", 1/8", 3/16" and 1/4") using a table-top design that will store easily. I'm thinking that it could be c-clamped to a bench or sturdy table. We'll see how much it will cost for the fixture parts.. I'm off to the home center.

Re: Bulk-sanding balsa

Re: Bulk-sanding balsa

Got the stuff.. less than $50 for the steels and the particle board base. (gig $$ from last night is how I justified the expense..  ) Both the 1/8" and 1/4" steels are slightly "under" thickness (by exactly the same amount.. which is .015") and the only steel I could find close to 1/16" is thicker by .008". I can gage up/down by facing the thinner steels with film tape on the bottoms.. and the thicker steel, by using a .008" shim-strip under the balsa. I might as well try to gage accurately if I can.. and this will be easier to understand as I proceed. I will take pictures during the process.

) Both the 1/8" and 1/4" steels are slightly "under" thickness (by exactly the same amount.. which is .015") and the only steel I could find close to 1/16" is thicker by .008". I can gage up/down by facing the thinner steels with film tape on the bottoms.. and the thicker steel, by using a .008" shim-strip under the balsa. I might as well try to gage accurately if I can.. and this will be easier to understand as I proceed. I will take pictures during the process.

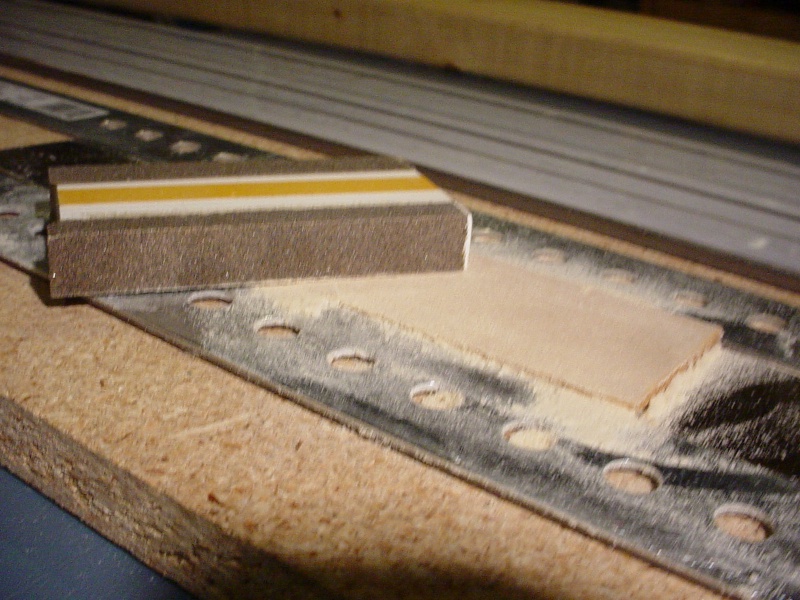

Here's the stock.. I don't think I'll screw the steels down to the base though.. there will be "pins" driven into the base, which will simplify changing steels.. and also prevent the steels from "bowing".

More to come.. stay tuned

Here's the stock.. I don't think I'll screw the steels down to the base though.. there will be "pins" driven into the base, which will simplify changing steels.. and also prevent the steels from "bowing".

More to come.. stay tuned

Re: Bulk-sanding balsa

Re: Bulk-sanding balsa

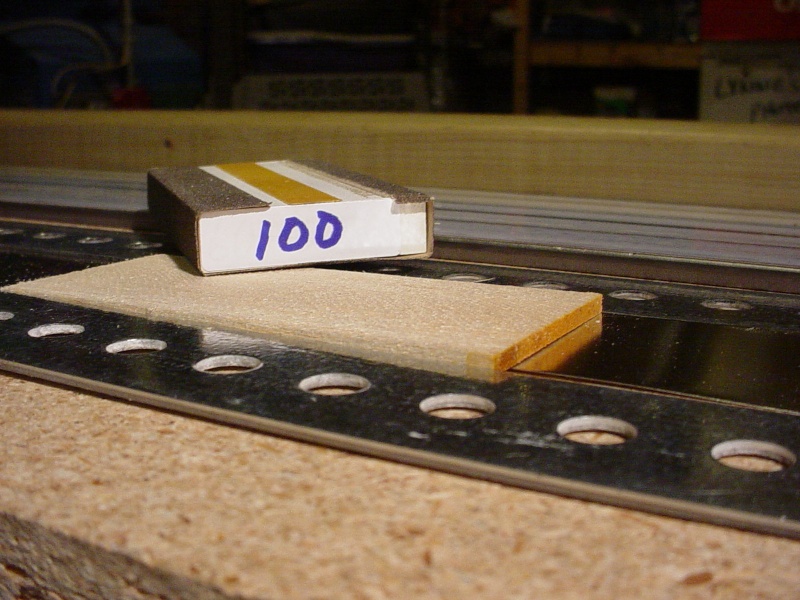

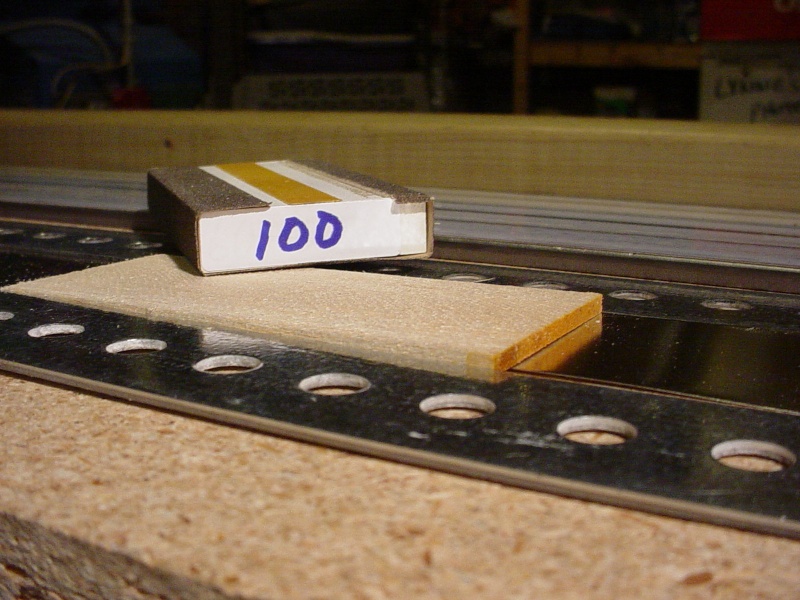

Steels are now faced with the .010" polycarbonate sheet with .005" double-sided film-tape. They are now +/- .002" from 1/8" and 1/4". I am satisfied with that.

There are "pairs" of steel gage-rails for straddling a balsa sheet. One will serve as a fence (stationary) while the other will "block-up" against the balsa and be held by hand. This will allow for varying width sheets.. and also easy periodic dust removal. A small sanding block is all that's needed. Cutting down to the steel will be fast with 100-150 grit paper.

There are "pairs" of steel gage-rails for straddling a balsa sheet. One will serve as a fence (stationary) while the other will "block-up" against the balsa and be held by hand. This will allow for varying width sheets.. and also easy periodic dust removal. A small sanding block is all that's needed. Cutting down to the steel will be fast with 100-150 grit paper.

Re: Bulk-sanding balsa

Re: Bulk-sanding balsa

Resuming work on the fixture today. My "bulk" balsa as previously mentioned, is all 1.75"W strips in various lengths between 22" to 30+" that I ripped-down from plank-scrap years ago. I have two large boxes full.

To make 1/16" sheet stock.. I need to make a .008" shim at 1.75"W and the length of the pc. to be sanded.. because the steels are .070" thick. Shimming the balsa .008" higher will sand-out to .062" or at least "close" to it. The only .008" stock I have, is a 4" x 10" sheet of Tin-plate. The 1/16" sanding-jig will be harder to make work. The shim.. along with a steel will have to be mounted rigidly.. or else the shim could slide under the steel while sanding.. which would create a high-spot in the sheet. Maybe the answer is to use the double sided tape to anchor both. This will require facing the bottom of the other (free-moving) steel, with the same tape though.. or the gaging is offset. The tape also has a liner that gets removed. This exposes the 2nd side's adhesive.. and also accounts for .002" of thickness.. so it has to come off. A quick and neat remedy for neutralizing tape-type adhesive.. is to sprinkle it with talcum powder. Believe me.. it becomes and stays un-sticky. The tape I use is permanent.. and has a core-liner of thin .004" plastic. After the tape is stuck-down, the exposed adhesive on the other side can be removed with a solvent.. leaving the bare white colored and smooth plastic surface. The free-moving steel will have it's bottom faced with the tape.. and the exposed adhesive removed.

My goal is to sand the 3 different thickness samples today. The nice thing is.. I'm already an hour ahead!

EDIT: it was asked earlier in the thread; what I would do with 1 3/4" wide balsa? Actually.. you can make wing-ribs of substantial airfoil thickness.. for one use. As I mentioned previously.. I edge-glue panels together with thick CA on a smooth level surface over wax paper.. and the joints have always been strong. Bulkheads, formers, sheet-tail surfaces, "sticks"... There are a multitude of uses. When building a little slab-wing, I feel that it also makes it more warp resistant. Whereas I build a fair amount of small slab-wing models; 3 pieces of this stock finish-sanded to 1/8" and edge-glued.. produces a 5.25" wing chord. Cut them to 20-22" long.. and you've got 100-115sq. to work with.

To make 1/16" sheet stock.. I need to make a .008" shim at 1.75"W and the length of the pc. to be sanded.. because the steels are .070" thick. Shimming the balsa .008" higher will sand-out to .062" or at least "close" to it. The only .008" stock I have, is a 4" x 10" sheet of Tin-plate. The 1/16" sanding-jig will be harder to make work. The shim.. along with a steel will have to be mounted rigidly.. or else the shim could slide under the steel while sanding.. which would create a high-spot in the sheet. Maybe the answer is to use the double sided tape to anchor both. This will require facing the bottom of the other (free-moving) steel, with the same tape though.. or the gaging is offset. The tape also has a liner that gets removed. This exposes the 2nd side's adhesive.. and also accounts for .002" of thickness.. so it has to come off. A quick and neat remedy for neutralizing tape-type adhesive.. is to sprinkle it with talcum powder. Believe me.. it becomes and stays un-sticky. The tape I use is permanent.. and has a core-liner of thin .004" plastic. After the tape is stuck-down, the exposed adhesive on the other side can be removed with a solvent.. leaving the bare white colored and smooth plastic surface. The free-moving steel will have it's bottom faced with the tape.. and the exposed adhesive removed.

My goal is to sand the 3 different thickness samples today. The nice thing is.. I'm already an hour ahead!

EDIT: it was asked earlier in the thread; what I would do with 1 3/4" wide balsa? Actually.. you can make wing-ribs of substantial airfoil thickness.. for one use. As I mentioned previously.. I edge-glue panels together with thick CA on a smooth level surface over wax paper.. and the joints have always been strong. Bulkheads, formers, sheet-tail surfaces, "sticks"... There are a multitude of uses. When building a little slab-wing, I feel that it also makes it more warp resistant. Whereas I build a fair amount of small slab-wing models; 3 pieces of this stock finish-sanded to 1/8" and edge-glued.. produces a 5.25" wing chord. Cut them to 20-22" long.. and you've got 100-115sq. to work with.

Re: Bulk-sanding balsa

Re: Bulk-sanding balsa

That's a nice pile of FREE balsa there man , its good you are going to be able to get a lot of uses out of and we plan to see some more fine looking models coming from it  . Have you figured out what the first project will bee ? Have you thought off maybe hollowing out a log of that thick stuff for a full fuse plane ? / I really like the full fuse but they can be a pain to repair and sooner or later if you fly its going to happen / sometimes you don't have to fly I have had to fix several planes from getting knocked around as you were also saying

. Have you figured out what the first project will bee ? Have you thought off maybe hollowing out a log of that thick stuff for a full fuse plane ? / I really like the full fuse but they can be a pain to repair and sooner or later if you fly its going to happen / sometimes you don't have to fly I have had to fix several planes from getting knocked around as you were also saying

Eric

Eric

Eric

Eric

getback- Top Poster

Posts : 10442

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Bulk-sanding balsa

Re: Bulk-sanding balsa

getback wrote:That's a nice pile of FREE balsa there man , its good you are going to be able to get a lot of uses out of and we plan to see some more fine looking models coming from it. Have you figured out what the first project will bee ? Have you thought off maybe hollowing out a log of that thick stuff for a full fuse plane ? / I really like the full fuse but they can be a pain to repair and sooner or later if you fly its going to happen / sometimes you don't have to fly I have had to fix several planes from getting knocked around as you were also saying

Eric

Thanks for the interest Eric. Yes.. it's hard to describe just how much wood there is in the two boxes that's ripped down into strips. The boxes are 6" x 6" x 36".. and 8" x 8" x 48".. The balsa strips vary in length as I said.. but there's probably 2 cu. ft. of rough-cut wood there. I also have a large cardboard tube 6ft. long x 6"dia. that has 4+ft. stock in it. Some is the same width balsa.. only there's longer pieces. I also have leading-edge stock in that tube that's 3/8" x 4+ft. that I made with the CNC router at work.. just to see if I could do it.

Here's a pic of that tubes contents. everything is 4+ft. in length.

This leading-edge stock is 60"L. I used a 1/4-round router bit with "step-over" passes which formed the 1/2 the radius of two pieces in one pass. IE: 5 passes with the tool would produce 4 pieces of leading edge stock.

The "plank" pieces I have, would indeed provide for several hollow-log fuses. I really like the way they look.. but I dread carving one out!

I haven't done a lot of whittling..

I haven't done a lot of whittling.. Hoping to build "some" models this winter. It will definitely help if I have decent balsa to work with. Depending on the "effort" needed to finish-sand my sheets.. will dictate whether I only make stock for a single plan... or whether I do a production-run.. and "grade" the stock for weight/grain-type. I already know that the weight/grain-type vary greatly between the pieces.. as the balsa was originally and "randomly" jointed.. and then laminated into "planks" which were run through a planer. This provides me with a great variety of wood... much of which is very lightweight. These pieces will obviously sand the quickest.

Re: Bulk-sanding balsa

Re: Bulk-sanding balsa

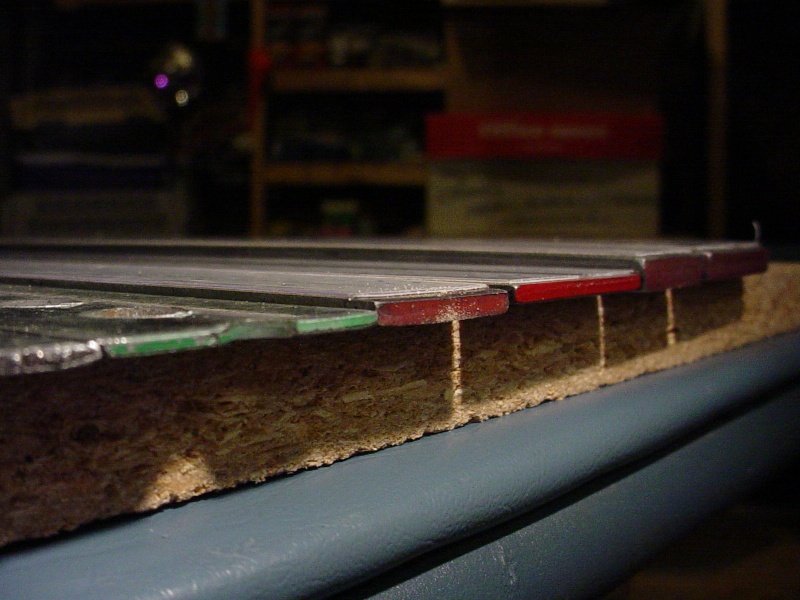

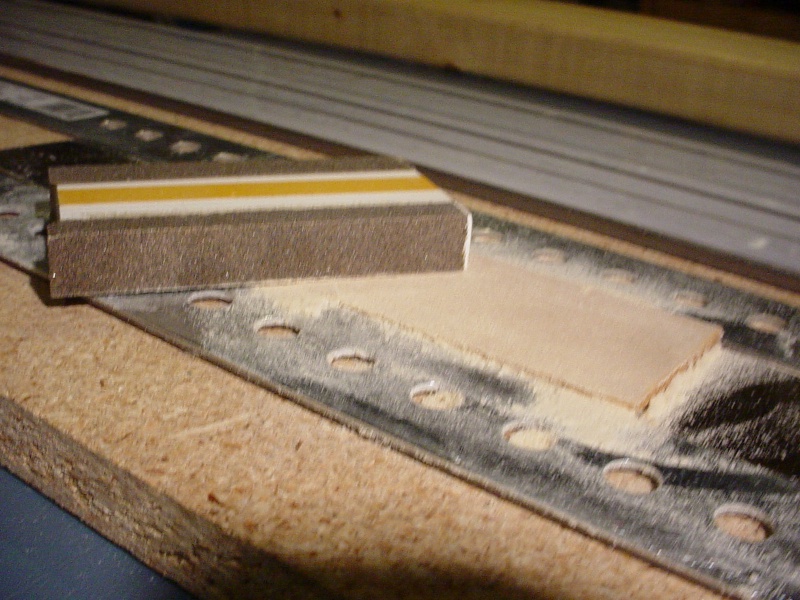

Well.. I managed to get the more difficult fixture for 1/16" gage set up. Sample-work will have to wait til' tomorrow.. but here's the layout. The upper (or rear) rail is fixed. The .008" Tin-shims I decided to cut 1/8" narrower than my stock.. and they haven't been taped down yet. This jig is only 18" long.. where the 1/8" and 1/4" jigs are 36".

Here's how a loaded piece of stock looks when ready to start sanding. This is one of my "tall" (roughed) 1/8" sheets.

I may need to initially cut faster with a coarser grit.. when producing 1/16" sheet from 1/8".. but I'll only make this thickness for specific projects. The 1/8" and 1/4" fixtures will produce a finished sheet from the rough-ripped stock in seconds. The beauty in using steel.. is that you can sand "to it".. without it being affected. It gives you the feedback through the block, when your down to your thickness.

Here's how a loaded piece of stock looks when ready to start sanding. This is one of my "tall" (roughed) 1/8" sheets.

I may need to initially cut faster with a coarser grit.. when producing 1/16" sheet from 1/8".. but I'll only make this thickness for specific projects. The 1/8" and 1/4" fixtures will produce a finished sheet from the rough-ripped stock in seconds. The beauty in using steel.. is that you can sand "to it".. without it being affected. It gives you the feedback through the block, when your down to your thickness.

Re: Bulk-sanding balsa

Re: Bulk-sanding balsa

Tonight we have a 4" sample sheet.. sanded down from "twice" it's thickness.. to 1/16". This was a high-effort production.. due to the thickness of the material to be removed... and the abrasive papers I chose to start with. This is to show.. that you "can" custom-sand your balsa sheets to any gage you desire.

I am pleased with this 1/16" fixture layout.

Cutting through this sheet was laborious.. so I made an 80-grit block.. 60.. or even 40 grit would take 1/8" down to 1/16" in short-order.. When you start to "feel the steel"... back-off to a fine grit.

When you can consistently "feel the steel" through your block.. you'll know that your sheet is gaged-down to it's thickness.

Here's my sample of 1/16"... sanded-down from 1/8"+ thickness.

I am pleased with this 1/16" fixture layout.

Cutting through this sheet was laborious.. so I made an 80-grit block.. 60.. or even 40 grit would take 1/8" down to 1/16" in short-order.. When you start to "feel the steel"... back-off to a fine grit.

When you can consistently "feel the steel" through your block.. you'll know that your sheet is gaged-down to it's thickness.

Here's my sample of 1/16"... sanded-down from 1/8"+ thickness.

Re: Bulk-sanding balsa

Re: Bulk-sanding balsa

I started building a Woodstock 13 meter wooden glider years ago. I purchased a desk top planer to use on the glider spruce and tried planning balsa on it once. It worked just fine down to about 3/32 thick but that was about a thin as I could shut down the throat. I never tried it but you could have placed a second sheet under the balsa to be plained and that should have worked. Nicest thing was it had a powered roller that fed the sheet through the cutters.

faif2d- Bronze Member

- Posts : 30

Join date : 2014-09-08

Location : texas

Re: Bulk-sanding balsa

Re: Bulk-sanding balsa

faif2d wrote:I started building a Woodstock 13 meter wooden glider years ago. I purchased a desk top planer to use on the glider spruce and tried planning balsa on it once. It worked just fine down to about 3/32 thick but that was about a thin as I could shut down the throat. I never tried it but you could have placed a second sheet under the balsa to be plained and that should have worked. Nicest thing was it had a powered roller that fed the sheet through the cutters.

Yes.. probably a piece of smooth 1/4" MDF would work nicely. Set the planer at just over 5/16" thickness and finish-sand a few thousandths off afterward. Sanding 3/32" sheet down to 1/16" using my system, takes very little effort. I wouldn't want to have to make too much 1/16" stock from 1/8" though.. especially hard balsa. I had to use an aggressive grit to remove most of the stock.. then finish with fine paper. It can be done though.. and with micro accuracy.

What became of the glider?

Re: Bulk-sanding balsa

Re: Bulk-sanding balsa

I quit smoking and gained a bunch of weight. I became to heavy for the glider so sold the plans. I visited lone star balsa several years ago and their sander used 80 or 100 grit belts. I was surprised how rough it was.

faif2d- Bronze Member

- Posts : 30

Join date : 2014-09-08

Location : texas

Re: Bulk-sanding balsa

Re: Bulk-sanding balsa

faif2d wrote:I quit smoking and gained a bunch of weight. I became to heavy for the glider so sold the plans. I visited lone star balsa several years ago and their sander used 80 or 100 grit belts. I was surprised how rough it was.

Yea.. I hear ya.. I gained 60lbs. when I quit smoking during my last attempt which was 5 years ago. I made it 2 years without a cigarette.. then stupidly started again. I only lost 20 of those 60lbs I'd gained.

I'm guessing that Lonestar probably uses that grit abrasive because of balsa being so soft. The dust would quickly fill/clog a finer grit paper (especially with machine sanding) and might heat up and glaze/burnish the sheet. The dust generated from stock-removal probably fills the voids between a "coarser" abrasive grit.. and makes it less aggressive than hand-sanding would.. with the same grit. That's my theory anyway.

Re: Bulk-sanding balsa

Re: Bulk-sanding balsa

After I had stopped my tobacco use for about 6 months I asked a friend of my wife, who had quit years ago, How long it took for the craving to go away. She answered that she had not gotten to that point yet. I quit about 25 years ago and I still want a hit now and then. I have heard that when discussing tobacco addiction with heroin addicts that they all said that it was harder to quit cigarettes than heroin!

faif2d- Bronze Member

- Posts : 30

Join date : 2014-09-08

Location : texas

Re: Bulk-sanding balsa

Re: Bulk-sanding balsa

faif2d wrote:After I had stopped my tobacco use for about 6 months I asked a friend of my wife, who had quit years ago, How long it took for the craving to go away. She answered that she had not gotten to that point yet. I quit about 25 years ago and I still want a hit now and then. I have heard that when discussing tobacco addiction with heroin addicts that they all said that it was harder to quit cigarettes than heroin!

Sad but true.

Similar topics

Similar topics» "Rodd-O-Gyro"

» "Molding Balsa"...NOT to be confused with "Moldy Balsa"!!!!! M.A.N 12-64

» Another proposed design by Roddie

» A Sanding Tip

» Sanding ideas..add yours too please

» "Molding Balsa"...NOT to be confused with "Moldy Balsa"!!!!! M.A.N 12-64

» Another proposed design by Roddie

» A Sanding Tip

» Sanding ideas..add yours too please

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules