Log in

Search

Latest topics

» Tee Dee .020 combat modelby roddie Today at 1:34 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» My latest doodle...

by batjac Yesterday at 9:47 pm

» My N-1R build log

by roddie Yesterday at 8:50 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

» My current avatar photo

by roddie Mon Nov 18, 2024 9:05 pm

Cox Engine of The Month

Crankcase upgrade/repair

Page 1 of 1

Crankcase upgrade/repair

Crankcase upgrade/repair

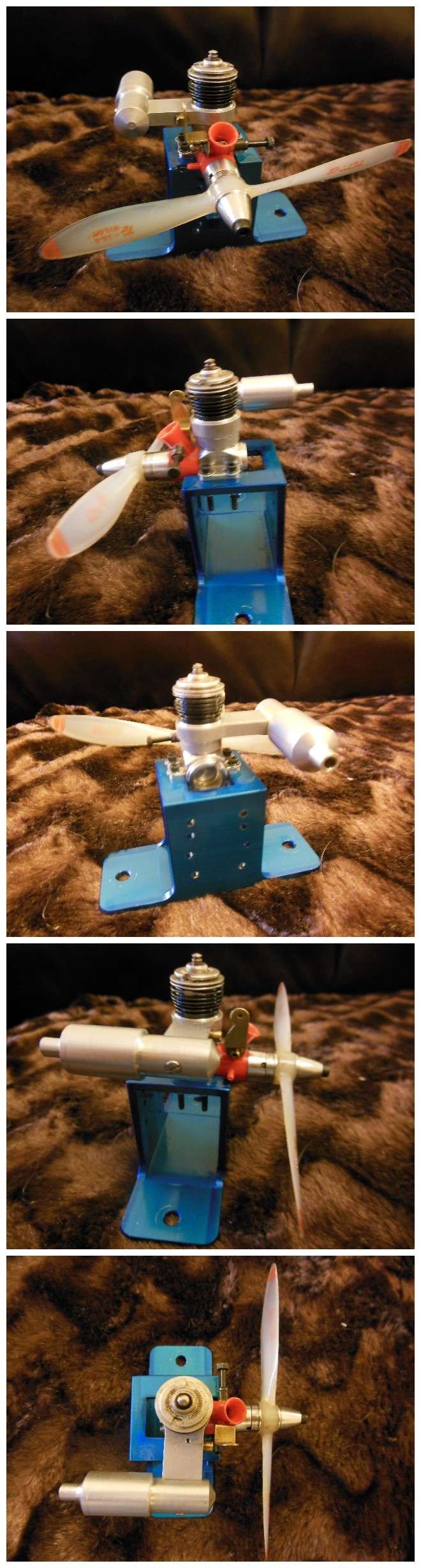

There I was starting to prepare for the Cox flight contest and deciding which engine I could use. Difficult decision in my case - too many options.

Anyway, it had to be beam mounted for the aeroplane I have chosen (this has arrived but I am still waiting for balsa cement and dope - no longer can I walk to the local model shop! - everything has to be mail order.

It also has to be quiet and so needs a good silencer (muffler) and a bit of throttle control. Matt had supplied me with a Hiscott muffley thingy and so I selected one of my restored Medallions to go with it.

It looks the boy but was not to be a runner at the first attempt!

I was prepared for a lot of messing about with heads as the Hiscott system raises the cylinder and reduces the compression. Messing about turned into two and a half hours of flick - flick - flicking!

It started a couple of times, ran for a couple of minutes and then stopped abruptly. It would not restart while hot.

I thought it was compression and I had not chosen the right head, number of gaskets and so on.................

However. when it ran - the silencer was superb and the throttle control was excellent - along with idling.

After a while I notice fuel spewing from between the prop driver and the crankcase. Further examination showed that the crankshaft was a sloppy fit to say the least!

So ...... not being one to scrap anything - it was time to strip the thing a let it visit the workshop. Where it was.........

drilled and reamed

a suitable piece of brass selected

I made a mistake and turned it too small and so worked further on it for a Bee crankcase

anyway - back to the Medallion

off to the mill!

Reassembly ready for testing. Too late to test tonight but fingers crossed for tomorrow. What am I saying? Better not cross my fingers while flicking the thing!

Anyway, it had to be beam mounted for the aeroplane I have chosen (this has arrived but I am still waiting for balsa cement and dope - no longer can I walk to the local model shop! - everything has to be mail order.

It also has to be quiet and so needs a good silencer (muffler) and a bit of throttle control. Matt had supplied me with a Hiscott muffley thingy and so I selected one of my restored Medallions to go with it.

It looks the boy but was not to be a runner at the first attempt!

I was prepared for a lot of messing about with heads as the Hiscott system raises the cylinder and reduces the compression. Messing about turned into two and a half hours of flick - flick - flicking!

It started a couple of times, ran for a couple of minutes and then stopped abruptly. It would not restart while hot.

I thought it was compression and I had not chosen the right head, number of gaskets and so on.................

However. when it ran - the silencer was superb and the throttle control was excellent - along with idling.

After a while I notice fuel spewing from between the prop driver and the crankcase. Further examination showed that the crankshaft was a sloppy fit to say the least!

So ...... not being one to scrap anything - it was time to strip the thing a let it visit the workshop. Where it was.........

drilled and reamed

a suitable piece of brass selected

I made a mistake and turned it too small and so worked further on it for a Bee crankcase

anyway - back to the Medallion

off to the mill!

Reassembly ready for testing. Too late to test tonight but fingers crossed for tomorrow. What am I saying? Better not cross my fingers while flicking the thing!

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Crankcase upgrade/repair

Re: Crankcase upgrade/repair

Impressive....... I would love to bush some of mine.

Ron

Ron

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Crankcase upgrade/repair

Re: Crankcase upgrade/repair

Me too, nice work, Ian. Do you cut an oil groove in the bushing? I don't remember if the TeeDallion crankcase has one. Is brass as good as bronze?

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Crankcase upgrade/repair

Re: Crankcase upgrade/repair

Nice work! Did you add an oil groove to the bushing or is it not needed? What material did you use. I need to get a collet system for my lathe

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: Crankcase upgrade/repair

Re: Crankcase upgrade/repair

Bronze - phosphor bronze - is better than brass by far. It is easy to machine but very difficult to drill. The material "grabs" drills and it is difficult to get a straight and clean bore. Drills will wander off line. It also heats up quite quickly when drilling. It has to be done slowly with modified drill bits.

The Medallions and Tee Dees don't need a groove but the Bee might. I will run it without and see what happens!

The Medallions and Tee Dees don't need a groove but the Bee might. I will run it without and see what happens!

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Crankcase upgrade/repair

Re: Crankcase upgrade/repair

I got it running but it needs a bit more patience setting the head and gasketing.

A bit boring but the engine is quiet!

A bit boring but the engine is quiet!

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Crankcase upgrade/repair

Re: Crankcase upgrade/repair

Nice muffler may work good on a cox car...do you have the site that sells them?

THANKS

THANKS

reptile- Gold Member

- Posts : 149

Join date : 2013-05-22

Re: Crankcase upgrade/repair

Re: Crankcase upgrade/repair

I am afraid they are no longer easily obtainable.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Crankcase upgrade/repair

Re: Crankcase upgrade/repair

I was thinking the same thing, looks like a great car muffler!

MeerschaumSteve- Gold Member

- Posts : 121

Join date : 2012-10-21

Location : Oklahoma

Re: Crankcase upgrade/repair

Re: Crankcase upgrade/repair

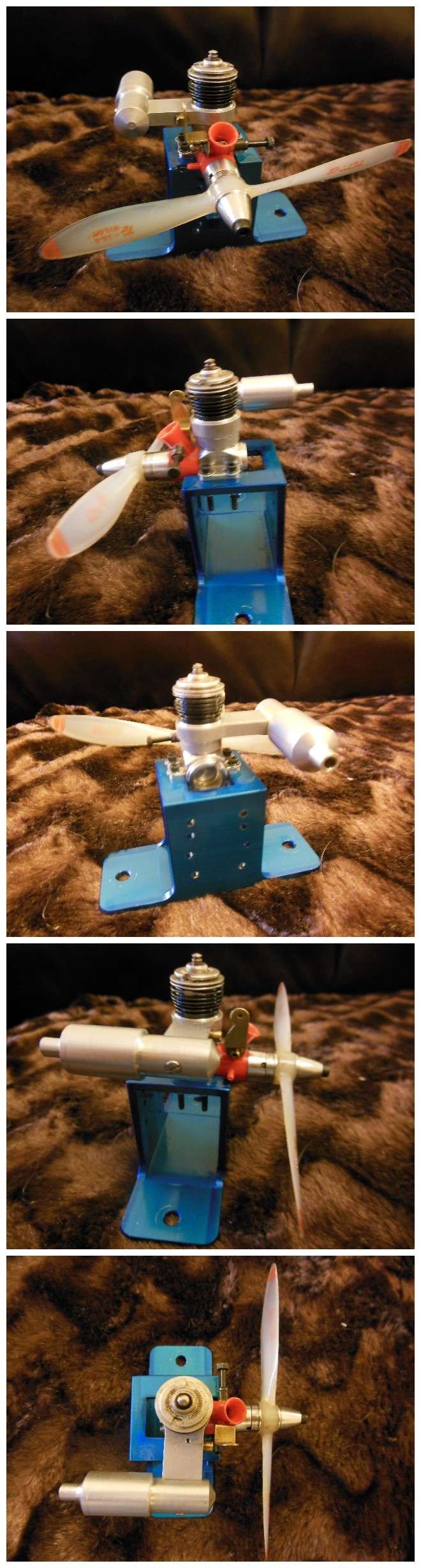

I finally got around to building up the Bee. Thought it strange watching the fuel dancing in the filler tube!

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Crankcase upgrade/repair

Re: Crankcase upgrade/repair

Nice and steady, that's as smooth as they get. Sounds ready yo fly.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Crankcase upgrade/repair

Re: Crankcase upgrade/repair

Excellent work Ian! And thanks for the videos as well.

Shawn

Shawn

sdjjadk- Platinum Member

- Posts : 640

Join date : 2012-04-07

Location : Southern Maryland

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules