Log in

Search

Latest topics

» My latest doodle...by batjac Yesterday at 10:05 pm

» Retail price mark-up.. how much is enough?

by gkamysz Yesterday at 9:29 pm

» Happy 77th birthday Andrew!

by roddie Yesterday at 9:22 pm

» Roger Harris revisited

by rsv1cox Yesterday at 3:38 pm

» My N-1R build log

by GallopingGhostler Yesterday at 3:04 pm

» Tee Dee .020 combat model

by 1/2A Nut Yesterday at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Yesterday at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Yesterday at 11:32 am

» Free Flight Radio Assist

by rdw777 Yesterday at 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

Cox Engine of The Month

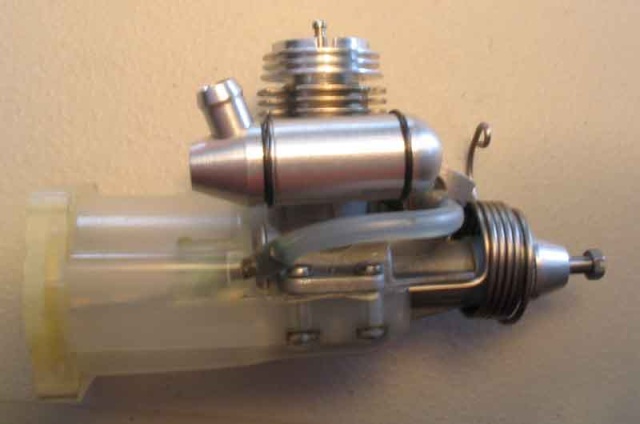

Cranking and running Norvel engines

Page 4 of 10

Page 4 of 10 •  1, 2, 3, 4, 5, 6, 7, 8, 9, 10

1, 2, 3, 4, 5, 6, 7, 8, 9, 10

Re: Cranking and running Norvel engines

Re: Cranking and running Norvel engines

Also, I have a hot Nelson plug in the box. Is that the one without the grooves on the corners of the hex nut? I have both. Maybe I'll give that one a spin.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Cranking and running Norvel engines

Re: Cranking and running Norvel engines

I almost never start an engine anymore rotating the prop forward. A flooded engine will start and clear the flood as well if you back flip it. But, everyone has their own techniques and what works for one doesn't work for others. You certainly can flip forward if you choose as this is the way the spring starter is designed. I would try both methods until the engine is up and running. The engine is timed to run one way. It will only run backwards if it it flooded. It usually runs backwards for a few seconds, pops and instantly runs forward. Rusty, Henry Nelson made a few different plugs. The hot plug has a large element hole surrounding the element compared to the notched hex plug the HD plug. There's also the NLO2 plug which is essentially the HD plug. There is no difference between the two. There was yet another Nelson which was the earlier NLO2 but it had a different post which looked like a Glo Bee post with a ceramic epoxy around the post. These were older and you probably won't see these unless someone has old stock as they're not made anymore. I don't feel the plug is the issue here.

I recommend the HD plug as it has a better heat range for these engines and handles a variety of nitro percentages. You'll be surprised about how cool these engine run which is why you need to get heat into them initially providing short burst of rpm's. After you've painstakingly spent the past few days doing and taking in all the info that everyone suggested, the engine in my opinion should be up and running now.

The pinch in these engines are amazingly tight. This is the most problematic step which is getting over the hump and heat cycling the piston cylinder to alleviate this initial problem. I thought I even heard you say the pinch isn't readily as noticeable as it was prior. The engine should be locking to the point you can't turn it during this stage. This is why the heat gun can be your best friend. The all castor could be masking that at this stage and the additional head gaskets are doing the same. At this point, I feel the all castor fuel is certainly boosting your compression which is only enhancing the problem.

After the engine gets a bit of time on it and you want to run all castor, so be it. I don't feel it's necessary as some do and I'm not disputing what works for others. I'm merely suggesting to try the 20% 50/50 fuel and see. Ken

I recommend the HD plug as it has a better heat range for these engines and handles a variety of nitro percentages. You'll be surprised about how cool these engine run which is why you need to get heat into them initially providing short burst of rpm's. After you've painstakingly spent the past few days doing and taking in all the info that everyone suggested, the engine in my opinion should be up and running now.

The pinch in these engines are amazingly tight. This is the most problematic step which is getting over the hump and heat cycling the piston cylinder to alleviate this initial problem. I thought I even heard you say the pinch isn't readily as noticeable as it was prior. The engine should be locking to the point you can't turn it during this stage. This is why the heat gun can be your best friend. The all castor could be masking that at this stage and the additional head gaskets are doing the same. At this point, I feel the all castor fuel is certainly boosting your compression which is only enhancing the problem.

After the engine gets a bit of time on it and you want to run all castor, so be it. I don't feel it's necessary as some do and I'm not disputing what works for others. I'm merely suggesting to try the 20% 50/50 fuel and see. Ken

Ken Cook- Top Poster

- Posts : 5637

Join date : 2012-03-27

Location : pennsylvania

Re: Cranking and running Norvel engines

Re: Cranking and running Norvel engines

Surfer_kris wrote: There are also two different glow heads out there for these engines. You'll want to have the hotter version which is recognizable on its rounded tip where the glow driver goes. There is a colder glow head that has a more squared off pin and a little smaller diameter where the clamp goes.

OK to avoid confusion, here is a pic. The top plug is the "Freedom" plug. Note how it had room inside the adapter to insert a booster whereas the lower (earlier) plug does not.

Also note that the NORVEL wrench has a small hex at the bottom. This was to fit the prop screw. You could use the screwdriver end or the hex nut to tighten the prop. I assume this screw was discarded as a cost reduction.

George

gcb- Platinum Member

- Posts : 908

Join date : 2011-08-11

Location : Port Ewen, NY

Re: Cranking and running Norvel engines

Re: Cranking and running Norvel engines

I'd have to go back out to the shop and look at it to check the head, but I got it running.

I just came in from running about 4 ounces of fuel through it. I started with the usual insanity, doing the same things I have been trying with the same results. One more shim(6), a 5" prop, a broken wire, another set of batteries, and a Babe Bee head later, she cranked. I finally got it to act like i expected... burn off a prime with the fuel pinched, increase the needle from zero and increment it an 8th of a turn braapping it until at 1.6 turns she lit off and never looked back. I let it peak and backed off rich and let it peak, staying on the peaks longer than the rich times. I tached it starting out at 15.5K and by the end of the run it was doing 17.5K... with 6 shims and a Bee head. I'm sure with more compression and the right head she will run faster.

I have to lay off now for a few days. I wish I could continue, but I have other pressing business. I made sure the piston was at BDC while it cooled, and there she sits, with a plier marked 35 year old Cox head. I'll set it back up closer to normal and run it in when I get back to it. The shop is a smoky mess so I had to evacuate.

Thanks everyone for your patience and tons of information and advice.

See you in the funny papers. :

:

Actually I'll be logged in tonight.

I just came in from running about 4 ounces of fuel through it. I started with the usual insanity, doing the same things I have been trying with the same results. One more shim(6), a 5" prop, a broken wire, another set of batteries, and a Babe Bee head later, she cranked. I finally got it to act like i expected... burn off a prime with the fuel pinched, increase the needle from zero and increment it an 8th of a turn braapping it until at 1.6 turns she lit off and never looked back. I let it peak and backed off rich and let it peak, staying on the peaks longer than the rich times. I tached it starting out at 15.5K and by the end of the run it was doing 17.5K... with 6 shims and a Bee head. I'm sure with more compression and the right head she will run faster.

I have to lay off now for a few days. I wish I could continue, but I have other pressing business. I made sure the piston was at BDC while it cooled, and there she sits, with a plier marked 35 year old Cox head. I'll set it back up closer to normal and run it in when I get back to it. The shop is a smoky mess so I had to evacuate.

Thanks everyone for your patience and tons of information and advice.

See you in the funny papers.

Actually I'll be logged in tonight.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Cranking and running Norvel engines

Re: Cranking and running Norvel engines

... Of course I made a video. And I will delete the other one when I post it.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Cranking and running Norvel engines

Re: Cranking and running Norvel engines

After a few milliseconds long "brrapps" in the video there, it was time for a preheat again. That short burst cools down the inside of that liner REALLY quick.

With you bad shoulder and such Rusty, we might have to get you worked into a electric starter. Much less painfull, all the way around.

They are a bugger to break in, but once you get past that, They are a rpm motor for sure.

https://www.youtube.com/watch?v=9IfyBCGv-As

a Little run up of my R/C .061. Alot more throttle responsive with the port work and polishing I did. It waivers just a bit as fuel droplets go thru, but it returns to the set rpm on the carb body.

With you bad shoulder and such Rusty, we might have to get you worked into a electric starter. Much less painfull, all the way around.

They are a bugger to break in, but once you get past that, They are a rpm motor for sure.

https://www.youtube.com/watch?v=9IfyBCGv-As

a Little run up of my R/C .061. Alot more throttle responsive with the port work and polishing I did. It waivers just a bit as fuel droplets go thru, but it returns to the set rpm on the carb body.

PV Pilot- High Tech Balsa Basher

- Posts : 1854

Join date : 2011-08-11

Age : 57

Location : The ragged end of the Universe.

Re: Cranking and running Norvel engines

Re: Cranking and running Norvel engines

All that time flipping this morning and it turned out there was a Norvel starter spring in the mailbox.

I'm just glad to have it running. I was afraid I was going to damage it by flooding it so many times. Once it took off it really sounded happy. And so did I.

I'm just glad to have it running. I was afraid I was going to damage it by flooding it so many times. Once it took off it really sounded happy. And so did I.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Cranking and running Norvel engines

Re: Cranking and running Norvel engines

Glad you got it running, once they are run-in they get easier to start too.

I can't find my notes for the cox 5x3 props, but here are some other numbers on 10% nitro ( and with the RC carb);

Graupner 6x3; 18200 rpm

Cox 5x4; 20500 rpm

APC 5x3; 23000 rpm

I think these engines really come live at +20000rpm, and the 5x4 works very well in the air too.

I can't find my notes for the cox 5x3 props, but here are some other numbers on 10% nitro ( and with the RC carb);

Graupner 6x3; 18200 rpm

Cox 5x4; 20500 rpm

APC 5x3; 23000 rpm

I think these engines really come live at +20000rpm, and the 5x4 works very well in the air too.

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Cranking and running Norvel engines

Re: Cranking and running Norvel engines

My youtube vid above was with a very used motor, with a Cox 5x3 and sig 25/20 it was 19,800. which is more than enough to pull my little creations around.

Nice number with the Graup 6x3,,still pulls well there. I put a 7x4 on there just for fun and it was a low 17K-ish.

Nice number with the Graup 6x3,,still pulls well there. I put a 7x4 on there just for fun and it was a low 17K-ish.

PV Pilot- High Tech Balsa Basher

- Posts : 1854

Join date : 2011-08-11

Age : 57

Location : The ragged end of the Universe.

Re: Cranking and running Norvel engines

Re: Cranking and running Norvel engines

Sounds good. With my Baby F Streak and its .051, I was already planning to go up to 40' lines from 35'. When I put the Norvel on it I may have to add some more. Maybe time to find a bigger field if I have to go up to 45 or 50. I now have a fine thread NVA too, so I can switch right over without doing anything except maybe removing a little of my added nose weight.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Cranking and running Norvel engines

Re: Cranking and running Norvel engines

RknRusty wrote:All that time flipping this morning and it turned out there was a Norvel starter spring in the mailbox.

I'm just glad to have it running. I was afraid I was going to damage it by flooding it so many times. Once it took off it really sounded happy. And so did I.

Glad you got it running. Gives you quite a feeling of accomplishment doesn't it.

How did the Norvel Starter spring work out? All of mine are old ones that fit in a groove in the Norvel Startup tanks are are anchored in a hole in the left (facing it) engine mounting lug. Here's a pic. Note the hole between the mounting bolts.

George

gcb- Platinum Member

- Posts : 908

Join date : 2011-08-11

Location : Port Ewen, NY

Re: Cranking and running Norvel engines

Re: Cranking and running Norvel engines

AWESOME!!! I'm glad to hear you got it running before you had to leave it be for a while. I can't wait to see the vid. I hope the surgery goes quickly and well. Heal quickly so you can get that engine in the air.

Congratulations,

Bob

Congratulations,

Bob

fit90- Diamond Member

- Posts : 1341

Join date : 2011-08-11

Location : Naples, Florida

Re: Cranking and running Norvel engines

Re: Cranking and running Norvel engines

hhaven't mounted the spring yet. Maybe in a couple of days Ican get to it. I saw the hole between the screws.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Cranking and running Norvel engines

Re: Cranking and running Norvel engines

Glad you got it running!

I am sure it will be a good engine for you. Just don't forget your roots

I am sure it will be a good engine for you. Just don't forget your roots

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Cranking and running Norvel engines

Re: Cranking and running Norvel engines

How did your surgery go Rusty? everything ok?

PV Pilot- High Tech Balsa Basher

- Posts : 1854

Join date : 2011-08-11

Age : 57

Location : The ragged end of the Universe.

Re: Cranking and running Norvel engines

Re: Cranking and running Norvel engines

Hurts like hell, but that's how you can tell you're still alive.  Everything went well. I should slowly start to regain the feeling in my hand. The other one which I had done in May is beginning to wake up. Feeling makes modeling a lot easier... among other things.

Everything went well. I should slowly start to regain the feeling in my hand. The other one which I had done in May is beginning to wake up. Feeling makes modeling a lot easier... among other things.

I have my Norvel engine run uploading to the tube now. Looks like it'll take a few hours.

See y'all this afternoon, USA eastern time.

I have my Norvel engine run uploading to the tube now. Looks like it'll take a few hours.

See y'all this afternoon, USA eastern time.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Cranking and running Norvel engines

Re: Cranking and running Norvel engines

Rusty, I wish you well. I've never experienced that but my wife does. She sleeps with her hands in wrist braces doesn't look like fun. Glass drinking glasses are not in our household. Good luck and speedy recovery. Ken

Ken Cook- Top Poster

- Posts : 5637

Join date : 2012-03-27

Location : pennsylvania

Re: Cranking and running Norvel engines

Re: Cranking and running Norvel engines

RknRusty wrote:Hurts like hell, but that's how you can tell you're still alive.Everything went well. I should slowly start to regain the feeling in my hand. The other one which I had done in May is beginning to wake up. Feeling makes modeling a lot easier... among other things.

Glad things went well and wishing you a speedy recovery.

I lost the feeling and had extensive paralysis in my right hand due to nerve compression from a long cycling trip. Fully recovered now, but it did make things difficult for a while.

Re: Cranking and running Norvel engines

Re: Cranking and running Norvel engines

Just from gripping a commercial truck steering wheel, and going thru the motions of using one for the past 20+ years,,my wrists start to go numb after a 12 hr day. Eventually i imagine i will have issues.

PV Pilot- High Tech Balsa Basher

- Posts : 1854

Join date : 2011-08-11

Age : 57

Location : The ragged end of the Universe.

Re: Cranking and running Norvel engines

Re: Cranking and running Norvel engines

You are at the stage where it can be cured completely. The longer you wait, the less nerve function can be regained. There's a ligament that crosses your wrist. When it gets inflamed it compresses the nerve trunk that passes under it. The surgery takes 10 minutes to clip the ligament and release the pressure. Watch out for atrophy of the muscles at the base of your thumbs, top and bottom. If they seem to be shrinking, it's getting late. Resting your wrists on the wheel or anything else(the table in front of a mouse) puts similar pressure. That's why they used to think repetitive keyboarding movements caused it. But they know it's not repetitive motions now, just pressure on that nerve trunk and ligament.PV Pilot wrote:Just from gripping a commercial truck steering wheel, and going thru the motions of using one for the past 20+ years,,my wrists start to go numb after a 12 hr day. Eventually i imagine i will have issues.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Cranking and running Norvel engines

Re: Cranking and running Norvel engines

Where'd my movie go??? I must have forgotten to click Submit. DOH! Or I posted it somewhere else, who knows... pain killers, ya know.

Anyway, it's not terribly exciting, just an engine running, but since I spent so much time getting it going, here it is.

It turns out the needle likes to be at just over 1.5 turns. I had the 6 shims and Cox Bee bead and finally got her going. It only peaked at 17.5 K with a Cox 5x3 prop, but with the right compression and head she ought to perk right up. I no longer feel a hard pinch at TDC, even cold. I can still feel the double bump of the con rod. I have a spring on it now, so I think it should be no problem to crank any more.

I just alternated between lean and rich, letting it stay lean longer than rich, unlike a Cox break-in.

Anyway, it's not terribly exciting, just an engine running, but since I spent so much time getting it going, here it is.

It turns out the needle likes to be at just over 1.5 turns. I had the 6 shims and Cox Bee bead and finally got her going. It only peaked at 17.5 K with a Cox 5x3 prop, but with the right compression and head she ought to perk right up. I no longer feel a hard pinch at TDC, even cold. I can still feel the double bump of the con rod. I have a spring on it now, so I think it should be no problem to crank any more.

I just alternated between lean and rich, letting it stay lean longer than rich, unlike a Cox break-in.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Cranking and running Norvel engines

Re: Cranking and running Norvel engines

Glad everything went well. Have a speedy recovery.

George

George

gcb- Platinum Member

- Posts : 908

Join date : 2011-08-11

Location : Port Ewen, NY

Re: Cranking and running Norvel engines

Re: Cranking and running Norvel engines

Good job Mister,,you got it!.

Just a FYI for all. I use these little 1/2oz needle dropper bottles from Brownell's for a single drop prime in the venturi. You get 3 to a package so I use the other two for after run oil and CA accelerator. I bought some of the 1oz ones they sell for other uses.

http://www.brownells.com/.aspx/pid=44434/Product/NEEDLE-OILER-BOTTLES

And the reason why I posted that is it probably could have benefited from a single drop prime after you preheated and then started in with the chicken stick. That way you are not whacking away to get it to go. a little faster start up is all we hope for once you get it preheated.

I use a piece of cardboard or hobby plywood to block the heat gun flow from hitting the fuel tank, as I usualy have all that hooked up and the fuel line then pinched with the hemostats.

Not bashing anything you did there, just posting what I do. Your over the break in hump for the most part now, Congrats!

Just a FYI for all. I use these little 1/2oz needle dropper bottles from Brownell's for a single drop prime in the venturi. You get 3 to a package so I use the other two for after run oil and CA accelerator. I bought some of the 1oz ones they sell for other uses.

http://www.brownells.com/.aspx/pid=44434/Product/NEEDLE-OILER-BOTTLES

And the reason why I posted that is it probably could have benefited from a single drop prime after you preheated and then started in with the chicken stick. That way you are not whacking away to get it to go. a little faster start up is all we hope for once you get it preheated.

I use a piece of cardboard or hobby plywood to block the heat gun flow from hitting the fuel tank, as I usualy have all that hooked up and the fuel line then pinched with the hemostats.

Not bashing anything you did there, just posting what I do. Your over the break in hump for the most part now, Congrats!

PV Pilot- High Tech Balsa Basher

- Posts : 1854

Join date : 2011-08-11

Age : 57

Location : The ragged end of the Universe.

Re: Cranking and running Norvel engines

Re: Cranking and running Norvel engines

Thanks, PV. Now I'm itching to play with it, but I gotta wait a few days.

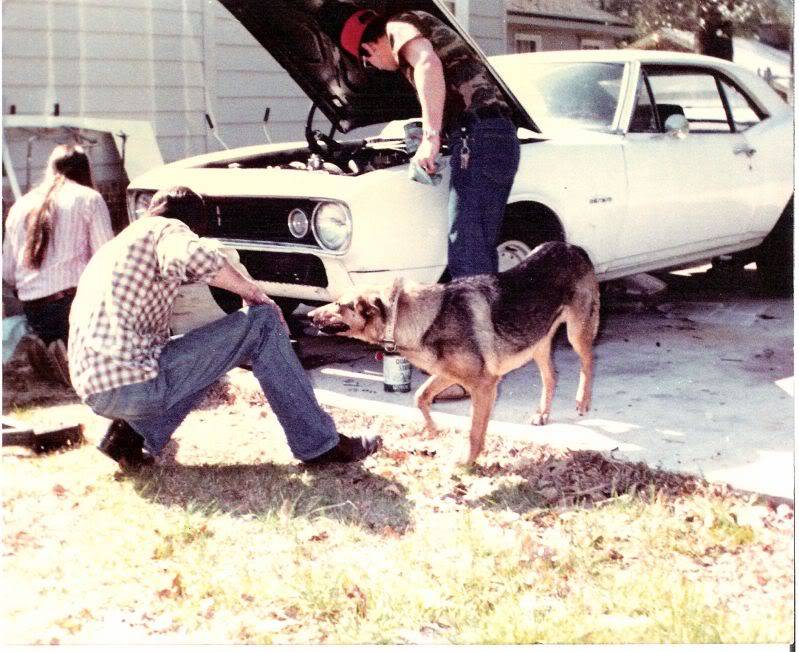

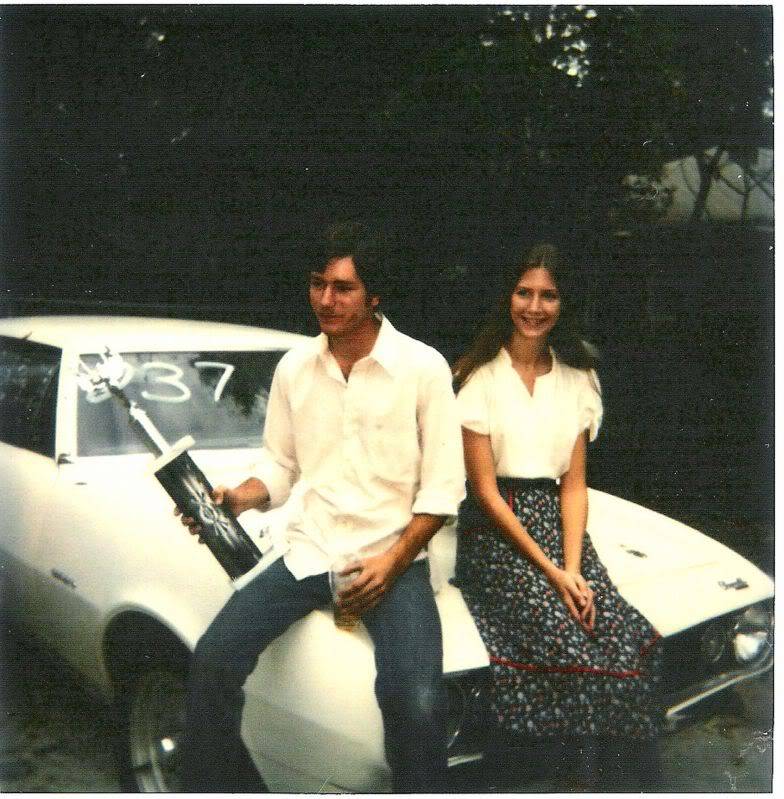

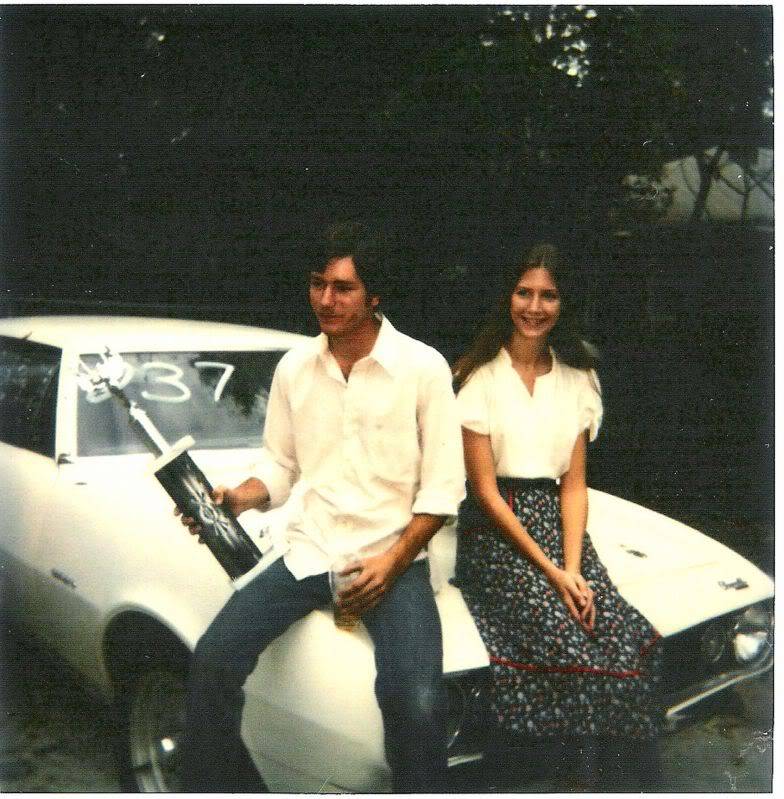

Hey, I saw your Camaro at the drag strip. I used to race a Camaro too, strictly a shade tree production. I wouldn't want to look over and see yours in the other lane.

Hey, I saw your Camaro at the drag strip. I used to race a Camaro too, strictly a shade tree production. I wouldn't want to look over and see yours in the other lane.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Cranking and running Norvel engines

Re: Cranking and running Norvel engines

Lookit that young man holding the trophy,,lol! Nice car Rusty!

A win last weekend with my brothers new Car. 70.5 camaro body, full tube frame, 780 inch Gene Fulton nitrous dedicated motor (1200 hp naturally aspirated, a tick over 2700 on nitrous) $10,000 cash and a nice trophy. 1/8 mile racing. 4.51 @ 172 mph. a drop in the bucket as far as winnings/overall cost, but the prestige is there,,and the fun.

A win last weekend with my brothers new Car. 70.5 camaro body, full tube frame, 780 inch Gene Fulton nitrous dedicated motor (1200 hp naturally aspirated, a tick over 2700 on nitrous) $10,000 cash and a nice trophy. 1/8 mile racing. 4.51 @ 172 mph. a drop in the bucket as far as winnings/overall cost, but the prestige is there,,and the fun.

Last edited by PV Pilot on Sat Aug 04, 2012 1:19 pm; edited 1 time in total (Reason for editing : dumb reason)

PV Pilot- High Tech Balsa Basher

- Posts : 1854

Join date : 2011-08-11

Age : 57

Location : The ragged end of the Universe.

Page 4 of 10 •  1, 2, 3, 4, 5, 6, 7, 8, 9, 10

1, 2, 3, 4, 5, 6, 7, 8, 9, 10

Similar topics

Similar topics» Got my Norvel 049 running

» Older Norvel AME 061 running trouble

» Norvel pre-revlite, bench running numbers

» Running some O&R engines

» Running some marine engines: OS MAX-S 30 RC

» Older Norvel AME 061 running trouble

» Norvel pre-revlite, bench running numbers

» Running some O&R engines

» Running some marine engines: OS MAX-S 30 RC

Page 4 of 10

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules