Log in

Search

Latest topics

» My N-1R build logby KariFS Today at 1:56 pm

» New Model Build

by bsadonkill Today at 11:31 am

» Project Cox .049 r/c & Citabrian Champion

by MauricioB Today at 10:49 am

» Octura engines?

by UncleLumpy Today at 8:16 am

» Tatone EM-7

by sosam117 Today at 7:50 am

» Honoring All Who Served

by roddie Yesterday at 8:59 pm

» Cox NaBOO - Just in time for Halloween

by rsv1cox Yesterday at 3:30 pm

» Free Flight Radio Assist

by TD ABUSER Yesterday at 1:41 pm

» Cox 020 PeeWee rebuild questions

by balogh Yesterday at 1:36 pm

» K&B .09 Torpedo Engine

by LooseSpinner99 Yesterday at 12:01 pm

» 3D printing of parts?

by UncleLumpy Yesterday at 9:08 am

» L4 Grasshopper

by bottomgun Yesterday at 7:58 am

Cox Engine of The Month

English Diesel Engine.

Page 1 of 1

English Diesel Engine.

English Diesel Engine.

I acquired this engine a long time ago and I am interested in starting it up and learning how it works, so:

Friends, I would appreciate anyone who can give me information about this English engine.

It is a diesel engine, which in appearance and compared to a Cox Medallion .09 engine, it could be a similar displacement.

I would also appreciate anyone who can tell me the mixture of components for your ideal fuel that should be made.

In addition, I will also appreciate the high needle regulation parameters and cylinder cover adjustment using its screw.

Thank you so much!

Friends, I would appreciate anyone who can give me information about this English engine.

It is a diesel engine, which in appearance and compared to a Cox Medallion .09 engine, it could be a similar displacement.

I would also appreciate anyone who can tell me the mixture of components for your ideal fuel that should be made.

In addition, I will also appreciate the high needle regulation parameters and cylinder cover adjustment using its screw.

Thank you so much!

MauricioB- Top Poster

- Posts : 3709

Join date : 2016-02-16

Age : 53

Location : ARG

Re: English Diesel Engine.

Re: English Diesel Engine.

The attached article says that the ED Bee is 1cc capacity.

https://modelenginenews.org/cardfile/edb.html

https://modelenginenews.org/cardfile/edb.html

Oldenginerod- Top Poster

- Posts : 4017

Join date : 2012-06-15

Age : 62

Location : Drouin, Victoria

Re: English Diesel Engine.

Re: English Diesel Engine.

Your diesel is an ED Bee Mk2- of 1 cc capacity (0.06 cu ins) produced anywhere from 1955 to 1963. The original model (the mk1) appeared in 1949 and had a different appearance-though still rear disc induction. Your engine should have a serial number, the last digit of which is usually the year of manufacture-though if it is a late production one, that is 1960-63, the last 'digit' will be in fact a letter, 'A' being 1960, 'B' being 1961, C 1962 and 'D' 1963. Yours appears to have been made in 1959 going by the last digit barely visible on the serial number. the initial 'X' designates it as a Bee, the 'M' is the production batch-in this case December, and the remaining numbers excluding the last digit, the engine's number within that batch. i cannot make out the second digit in your photo but the number seems to be 4?8 so four hundred and something eight-this is entirely consistent with ED's practice as the December batch as it would have been the largest one of the year to meet Xmas orders...sometimes there was even an 'N' batch if they had orders for more than 1000

They were produced in vast numbers-some 300,000 examples-(Mk1 and Mk2)-so by no means rare. Yours is missing the fuel tank which mounts on the rear-and through which the intake tube- along with NVA- passes. These are good sport engines with no bad habits-but not especially powerful-and run out of steam above about 11,000rpm. Best props are 8x4, 8x3 or 7x4 for FF and R/c and 7x5 or 7x6 for C/L.

I very much doubt you'll be able to find pre mixed fuel in Argentina, so you will have to mix your own-given that its a plain bearing, ferrous metallurgy engine do not use synthetic oils in it. Assuming the engine has been run previously and is run in, a suitable fuel would be 25% oil, 35% diethyl ether, and 38-39% kerosene, to which you could add if available- 1-2% of EHN diesel ignition smoother. Such as that sold by Amsoil for full size automotive diesel use. If you can't find EHN don't panic the engine will still run on an ether-kero-oil mix, just not quite as smoothly.

If you cannot source ether-then I'm sorry-you have an ornament-there is NO, repeat NO alternative to diethyl ether in model diesel engines. The ether SOURCE may vary-from industrial or research chemical solvents, or car engine cold start spray can, but you cannot operate without it. As regards the latter, John Deere is the preferred brand, as it is normally over 80% ether content.

Now for the bad news-I-nor anyone else cannot tell you where your compression screw setting should be-it varies from engine to engine, and you can only find it by running the engine and adjusting it-and in turn it depends slightly on fuel-but far more greatly on prop load. The compression setting for a 8x4 prop will be quite different to a 6x6 for example. If the engine is-as I assume second hand, then there is no reason to think that the compression is still in the correct position, as people love to fiddle with comp screws-especially people without a clue of what they're doing.

One way of finding an APPROXIMATE setting, is to fit a prop, and turn the engine over slowly, then advance the compression bit by bit-say 1/4 of a turn at a time-turning the engine over after each 1/4 turn adjustment of the screw. EVENTUALLY you will reach a point where you can no longer turn the engine over-and you will feel the piston hit the contrapiston as it tries to pass over TDC. Don't try and force it!! Stop-and back the compression screw off (counter clockwise) ONE FULL TURN-then turn over the engine again-hopefully the contra piston will pop back to the new lower compression setting and you will hear a 'click' as the top of the contra contacts the tip of the compression screw. That setting will usually-with most commonly used compression screw thread pitches-in this case 2BA (many European diesels are M5 thread-which is not dissimilar..31.4 tpi for 2BA, 32 tpi for M5) get you close to the starting setting. It is normal practice to start on a slightly lower compression setting, given the rich mixture and priming needed for cold starts-once fully warmed up, some engines-not all (!) will start at their running settings. When the engine starts it will be running 'rough' and mis firing-and you advance the compression to smooth out firing until the engine runs smoothly. You can go too far though-'overcompressed' and the engine will labour, sound unhappy and have a 'hard' exhaust note. Overdo it-and the engine will labour to a halt, getting very hot in the process.

The first thing you need to understand is the compression adjustment sets the ignition timing-in this respect it functions EXACTLY like the advance-retard arm on a spark ignition petrol motor from the 40s-you start with the ignition timing retarded (ie low compression) and advance the timing (ie increase compression) until the engine runs smoothly. This is where diesels differ markedly from glow engines-the compression setting, NOT the needle setting is the primary means of speed adjustment-the needle is less important-providing it is open far enough to provide sufficient fuel. you can still lean the needle until the engine quits, but it is quite possible to run a diesel quite rich without this being obvious in the revs it produces.

I would suggest-assuming you can come up with a working fuel mix that you bench mount it, fit a 9x4 prop (temporarily-it will run happily on this-but be down on power) to give plenty of flywheel action, leave the needle valve closed and just try an exhaust prime before flicking-if you can get the engine to fire and run out the prime several times, then you can be confident that you're in the right ballpark, compression setting wise...if not then carry out the procedure I've outlined above to establish a starting position and repeat the process. Once you can get the engine to reliably run out an exhaust prime-it will only fire and run for perhaps a second or so, then fill the tank, and open the needle say 2-1/2 turns-place your finger over the intake and turn the prop over one full turn-that should be sufficient choking. You may need to repeat the exhaust prime-but hopefully if the needle is open far enough, the engine should start and run-albeit quite rich and misfiring-you then slowly advance the compression-and you will hear the engine revs both increase and the misfiring disappear to an even exhaust note. That might take anywhere from 1/4 of a turn to half a turn advance on the compression. Once running smoothly, by all means tweak the needle carefully to find the best running position-you will note that until you get to a 'too lean' point, the engine note and revs will not alter that much. Likewise you can experiment and once running smoothly, start reducing the compression bit by bit-and you will find the revs dropping as you do, and the misfiring return...you can throttle the engine quite effectively by this means....eventually if you back off too much- the engine will misfire to the point where it stops running.

The two things you need to keep foremost in your mind when unfamiliar with diesel operation are: the danger of flooding both the crankcase and cylinder-from over enthusiastic choking in the former and too much priming in the latter-and coupled with this the risk of hydraulic lock-diesels are running at compression ratios of 18:1 or higher-and the gap between the piston crown and the underside of the contrapiston may be as little as 0.005" at some running settings-that's a very small volume-and if it is filled by liquid rather than gas-by flooding-then you can easily find yourself with a hydraulic lock-in that case attempting to turn the engine over will either break the gudgeon pin, break the crankpin or bend the conrod-or if you're really unlucky.... all three!

Don't persist with a flooded engine-close the needle valve, back off the compression at least half a turn and blow into the cylinder to clear it, then resume flicking....if the crankcase is flooded you may well end up with the same problem as liquid fuel is carried up into the upper cylinder-in which case keep blowing out till you have cleared the case. One relatively rare-but not unknown phenonemon can occur with a partly flooded motor where the engine oscillates over TDC-the prop moving perhaps through a 45 degree arc backwards and forwards-and the engine seems to be running on its own-but making an odd noise-this is due to a really rich-but still combustible mixture and too much compression-the engine partly fires but bounces off compression, but there is enough unburnt mixture getting into the cylinder to keep this process going-it is possible to run an entire tank out-very slowly-in this condition. The answer is to back off compression, blow out the cylinder, reset compression and continue flicking until it starts.

Good luck-diesels have their own learning curve-and previous glow operating experience is not a great help when you are new to diesels.

ChrisM

'ffkiwi'

They were produced in vast numbers-some 300,000 examples-(Mk1 and Mk2)-so by no means rare. Yours is missing the fuel tank which mounts on the rear-and through which the intake tube- along with NVA- passes. These are good sport engines with no bad habits-but not especially powerful-and run out of steam above about 11,000rpm. Best props are 8x4, 8x3 or 7x4 for FF and R/c and 7x5 or 7x6 for C/L.

I very much doubt you'll be able to find pre mixed fuel in Argentina, so you will have to mix your own-given that its a plain bearing, ferrous metallurgy engine do not use synthetic oils in it. Assuming the engine has been run previously and is run in, a suitable fuel would be 25% oil, 35% diethyl ether, and 38-39% kerosene, to which you could add if available- 1-2% of EHN diesel ignition smoother. Such as that sold by Amsoil for full size automotive diesel use. If you can't find EHN don't panic the engine will still run on an ether-kero-oil mix, just not quite as smoothly.

If you cannot source ether-then I'm sorry-you have an ornament-there is NO, repeat NO alternative to diethyl ether in model diesel engines. The ether SOURCE may vary-from industrial or research chemical solvents, or car engine cold start spray can, but you cannot operate without it. As regards the latter, John Deere is the preferred brand, as it is normally over 80% ether content.

Now for the bad news-I-nor anyone else cannot tell you where your compression screw setting should be-it varies from engine to engine, and you can only find it by running the engine and adjusting it-and in turn it depends slightly on fuel-but far more greatly on prop load. The compression setting for a 8x4 prop will be quite different to a 6x6 for example. If the engine is-as I assume second hand, then there is no reason to think that the compression is still in the correct position, as people love to fiddle with comp screws-especially people without a clue of what they're doing.

One way of finding an APPROXIMATE setting, is to fit a prop, and turn the engine over slowly, then advance the compression bit by bit-say 1/4 of a turn at a time-turning the engine over after each 1/4 turn adjustment of the screw. EVENTUALLY you will reach a point where you can no longer turn the engine over-and you will feel the piston hit the contrapiston as it tries to pass over TDC. Don't try and force it!! Stop-and back the compression screw off (counter clockwise) ONE FULL TURN-then turn over the engine again-hopefully the contra piston will pop back to the new lower compression setting and you will hear a 'click' as the top of the contra contacts the tip of the compression screw. That setting will usually-with most commonly used compression screw thread pitches-in this case 2BA (many European diesels are M5 thread-which is not dissimilar..31.4 tpi for 2BA, 32 tpi for M5) get you close to the starting setting. It is normal practice to start on a slightly lower compression setting, given the rich mixture and priming needed for cold starts-once fully warmed up, some engines-not all (!) will start at their running settings. When the engine starts it will be running 'rough' and mis firing-and you advance the compression to smooth out firing until the engine runs smoothly. You can go too far though-'overcompressed' and the engine will labour, sound unhappy and have a 'hard' exhaust note. Overdo it-and the engine will labour to a halt, getting very hot in the process.

The first thing you need to understand is the compression adjustment sets the ignition timing-in this respect it functions EXACTLY like the advance-retard arm on a spark ignition petrol motor from the 40s-you start with the ignition timing retarded (ie low compression) and advance the timing (ie increase compression) until the engine runs smoothly. This is where diesels differ markedly from glow engines-the compression setting, NOT the needle setting is the primary means of speed adjustment-the needle is less important-providing it is open far enough to provide sufficient fuel. you can still lean the needle until the engine quits, but it is quite possible to run a diesel quite rich without this being obvious in the revs it produces.

I would suggest-assuming you can come up with a working fuel mix that you bench mount it, fit a 9x4 prop (temporarily-it will run happily on this-but be down on power) to give plenty of flywheel action, leave the needle valve closed and just try an exhaust prime before flicking-if you can get the engine to fire and run out the prime several times, then you can be confident that you're in the right ballpark, compression setting wise...if not then carry out the procedure I've outlined above to establish a starting position and repeat the process. Once you can get the engine to reliably run out an exhaust prime-it will only fire and run for perhaps a second or so, then fill the tank, and open the needle say 2-1/2 turns-place your finger over the intake and turn the prop over one full turn-that should be sufficient choking. You may need to repeat the exhaust prime-but hopefully if the needle is open far enough, the engine should start and run-albeit quite rich and misfiring-you then slowly advance the compression-and you will hear the engine revs both increase and the misfiring disappear to an even exhaust note. That might take anywhere from 1/4 of a turn to half a turn advance on the compression. Once running smoothly, by all means tweak the needle carefully to find the best running position-you will note that until you get to a 'too lean' point, the engine note and revs will not alter that much. Likewise you can experiment and once running smoothly, start reducing the compression bit by bit-and you will find the revs dropping as you do, and the misfiring return...you can throttle the engine quite effectively by this means....eventually if you back off too much- the engine will misfire to the point where it stops running.

The two things you need to keep foremost in your mind when unfamiliar with diesel operation are: the danger of flooding both the crankcase and cylinder-from over enthusiastic choking in the former and too much priming in the latter-and coupled with this the risk of hydraulic lock-diesels are running at compression ratios of 18:1 or higher-and the gap between the piston crown and the underside of the contrapiston may be as little as 0.005" at some running settings-that's a very small volume-and if it is filled by liquid rather than gas-by flooding-then you can easily find yourself with a hydraulic lock-in that case attempting to turn the engine over will either break the gudgeon pin, break the crankpin or bend the conrod-or if you're really unlucky.... all three!

Don't persist with a flooded engine-close the needle valve, back off the compression at least half a turn and blow into the cylinder to clear it, then resume flicking....if the crankcase is flooded you may well end up with the same problem as liquid fuel is carried up into the upper cylinder-in which case keep blowing out till you have cleared the case. One relatively rare-but not unknown phenonemon can occur with a partly flooded motor where the engine oscillates over TDC-the prop moving perhaps through a 45 degree arc backwards and forwards-and the engine seems to be running on its own-but making an odd noise-this is due to a really rich-but still combustible mixture and too much compression-the engine partly fires but bounces off compression, but there is enough unburnt mixture getting into the cylinder to keep this process going-it is possible to run an entire tank out-very slowly-in this condition. The answer is to back off compression, blow out the cylinder, reset compression and continue flicking until it starts.

Good luck-diesels have their own learning curve-and previous glow operating experience is not a great help when you are new to diesels.

ChrisM

'ffkiwi'

ffkiwi- Gold Member

- Posts : 398

Join date : 2018-07-10

Location : Wellington, NZ

Re: English Diesel Engine.

Re: English Diesel Engine.

Here for your further education, the relevant engine tests:

https://sceptreflight.com/Model%20Engine%20Tests/ED%20Bee%20Mk%201.html

https://sceptreflight.com/Model%20Engine%20Tests/ED%20Bee%20Mk%201%20%282%29.html

https://sceptreflight.com/Model%20Engine%20Tests/ED%20Bee%20Mk%20II.html

https://sceptreflight.com/Model%20Engine%20Tests/ED%20Bee%20MkII%20%282%29.html

https://sceptreflight.com/Model%20Engine%20Tests/ED%20Bee%20Series%201960-61.html

Note that the last one is of the 'souped up' version, developed by the late Gordon Cornell when he was chief designer at ED's around 1958-60-and a few porting changes and a shorter piston turned the previously pedestrian ED Bee into a very solid performer for a 1cc diesel. Unfortunately-this sub model-which can be identified to a 'V' serial number prefix rather than the 'X', seems to have been produced in fairly small numbers.....and are not often found.

Two other useful links:

https://www.ebay.com/itm/115938080712?hash=item1afe72b7c8:g:SQcAAOSwHxZfjdHu&amdata=enc%3AAQAIAAAA0MOcMZspnekXm1gebAOAvJXfAXsJF02ti%2Fp7BfsR7uSRwCNySNgXP59GizsJtuYnjeHjtP%2BUXEt5VdCjKEGUjFcD8wurk69OOlQ1iJ7KPnSdaHwMPC3%2B3

https://www.ebay.com/itm/115922664477?hash=item1afd877c1d:g:gCQAAOSw8ENgWcGc&amdata=enc%3AAQAIAAAAsBiPKWc8qGUL0hVocRmW6i9%2FR%2FRUTOCKUSJya%2Fyg1mOrRF4lANIDvjHZ4A87O4U%2BoQcVdXhHEtnn7CI3LdNe2aAzKj40mkqZ50XtO%2FzTCstm

https://www.ebay.com/itm/295838099861?hash=item44e1532995:g:1w8AAOSw3uxfiZAL

'popular1956' is Mike Crisp who offers a range of replica NVAs and other parts for a wide range of classic British diesel and glow engines-plus a few other, while 'greyfish54' offers a range of replica fuel tanks for the EDs, Allbons, AMs and Mills diesels. Note if ordering that the Mk1 Bee and Mk2 Bee tanks-including the repros-are not interchangable-make sure you order the correct one!

ChrisM

'ffkiwi'

https://sceptreflight.com/Model%20Engine%20Tests/ED%20Bee%20Mk%201.html

https://sceptreflight.com/Model%20Engine%20Tests/ED%20Bee%20Mk%201%20%282%29.html

https://sceptreflight.com/Model%20Engine%20Tests/ED%20Bee%20Mk%20II.html

https://sceptreflight.com/Model%20Engine%20Tests/ED%20Bee%20MkII%20%282%29.html

https://sceptreflight.com/Model%20Engine%20Tests/ED%20Bee%20Series%201960-61.html

Note that the last one is of the 'souped up' version, developed by the late Gordon Cornell when he was chief designer at ED's around 1958-60-and a few porting changes and a shorter piston turned the previously pedestrian ED Bee into a very solid performer for a 1cc diesel. Unfortunately-this sub model-which can be identified to a 'V' serial number prefix rather than the 'X', seems to have been produced in fairly small numbers.....and are not often found.

Two other useful links:

https://www.ebay.com/itm/115938080712?hash=item1afe72b7c8:g:SQcAAOSwHxZfjdHu&amdata=enc%3AAQAIAAAA0MOcMZspnekXm1gebAOAvJXfAXsJF02ti%2Fp7BfsR7uSRwCNySNgXP59GizsJtuYnjeHjtP%2BUXEt5VdCjKEGUjFcD8wurk69OOlQ1iJ7KPnSdaHwMPC3%2B3

https://www.ebay.com/itm/115922664477?hash=item1afd877c1d:g:gCQAAOSw8ENgWcGc&amdata=enc%3AAQAIAAAAsBiPKWc8qGUL0hVocRmW6i9%2FR%2FRUTOCKUSJya%2Fyg1mOrRF4lANIDvjHZ4A87O4U%2BoQcVdXhHEtnn7CI3LdNe2aAzKj40mkqZ50XtO%2FzTCstm

https://www.ebay.com/itm/295838099861?hash=item44e1532995:g:1w8AAOSw3uxfiZAL

'popular1956' is Mike Crisp who offers a range of replica NVAs and other parts for a wide range of classic British diesel and glow engines-plus a few other, while 'greyfish54' offers a range of replica fuel tanks for the EDs, Allbons, AMs and Mills diesels. Note if ordering that the Mk1 Bee and Mk2 Bee tanks-including the repros-are not interchangable-make sure you order the correct one!

ChrisM

'ffkiwi'

ffkiwi- Gold Member

- Posts : 398

Join date : 2018-07-10

Location : Wellington, NZ

Re: English Diesel Engine.

Re: English Diesel Engine.

I thought it quite interesting that it produced the same BHP as the Golden Bee,ffkiwi wrote:Your diesel is an ED Bee Mk2- of 1 cc capacity (0.06 cu ins) produced anywhere from 1955 to 1963. The original model (the mk1) appeared in 1949 and had a different appearance-though still rear disc induction. Your engine should have a serial number, the last digit of which is usually the year of manufacture-though if it is a late production one, that is 1960-63, the last 'digit' will be in fact a letter, 'A' being 1960, 'B' being 1961, C 1962 and 'D' 1963. Yours appears to have been made in 1959 going by the last digit barely visible on the serial number. the initial 'X' designates it as a Bee, the 'M' is the production batch-in this case December, and the remaining numbers excluding the last digit, the engine's number within that batch.

[...]

Here for your further education, the relevant engine tests:

Sceptre Flight Model Engine Tests: ED Bee Mk 1, Oct. 1949 Aeromodeller

Sceptre Flight Model Engine Tests: Cox Babe Bee & Golden Bee, May 1961 Aeromodeller

0.062 BHP, but the ED Bee Mk 1 peaked at 10,500 RPM versus the Golden Bee at 14,000 RPM. This would explain why the ED Bee would be popular for larger, lightweight free flight aircraft, recommended prop was 8x4 for F/F and 7x6 for C/L, whereas the Golden Bee optimum prop would be a 6x3 for F/F and a 5x4 for C/L. (YMMV - you mileage may vary

The gasser, .60 Brown Jr. was only 0.25 BHP, but it could haul an 8 foot wingspan F/F because it could swing 14+ inch props, whereas your cross scavenge .15 glow engines same HP swung typically 8 or a low pitch 9 inch prop. Similar power sport Schneurle .09-.10's typically used a 7 inch prop or maybe a low pitch 8". The Brown Jr. put the wind past the fuselage cross section.

So, I would understand why the ED Bee was so popular.

GallopingGhostler- Top Poster

Posts : 5700

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: English Diesel Engine.

Re: English Diesel Engine.

...GallopingGhostler wrote:

So, I would understand why the ED Bee was so popular

There are several reasons-firstly ED were big...as big-relative to the UK and Commonwealth market as Cox (and before them, Ohlsson & Rice) were in the US in terms of production. Secondly when the Bee was introduced in 1949 there was not a lot of domestic competition in the 1cc market in the UK..only the Frog 100....which a bit fragile and certainly finicky to operate.....so a self contained engine that was lightweight, compact and reasonably durable was well received by the market...and one that was capable-admittedly only just-of flying a simple C/L model-which smaller engines were not-and there were not a lot of smaller engines to pick from in any case-only low production ones like the Kemp .2 and Kalper .32, or the Ace 0.5...which while useful for small FF sport models, were not up to C/L use-unless you were intending to fly a 3 oz model on 15 foot cotton lines....

But what about those old standby the Mills 75 and Amco .87...of which people wax lyrical....well yes they were on the market-but produced less power-and the last-but key point-they were expensive....you could buy an ED Bee, a decent FF or CL kit and a bottle of fuel for the cost of a Mills 75.....so a combination of affordability and availability was the secret to the ED Bee's success. ED also were quite clever in introducing the 1.5cc Hornet in 1952-which although somewhat different in appearance-used the same mounting footprint and an identical induction system...this meant it was a straight drop-in replacement for the ED Bee when you wanted more power....in the case of the Hornet around 50% more than the Bee....which again makes sense-it had 50% more displacement... Unfortunately though, the Hornet's design meant you got a lot of variation from engine to engine, and it sold nowhere near as well as the Bee, even though remaining in production for around 10 years.

ChrisM

'ffkiwi

ffkiwi- Gold Member

- Posts : 398

Join date : 2018-07-10

Location : Wellington, NZ

Re: English Diesel Engine.

Re: English Diesel Engine.

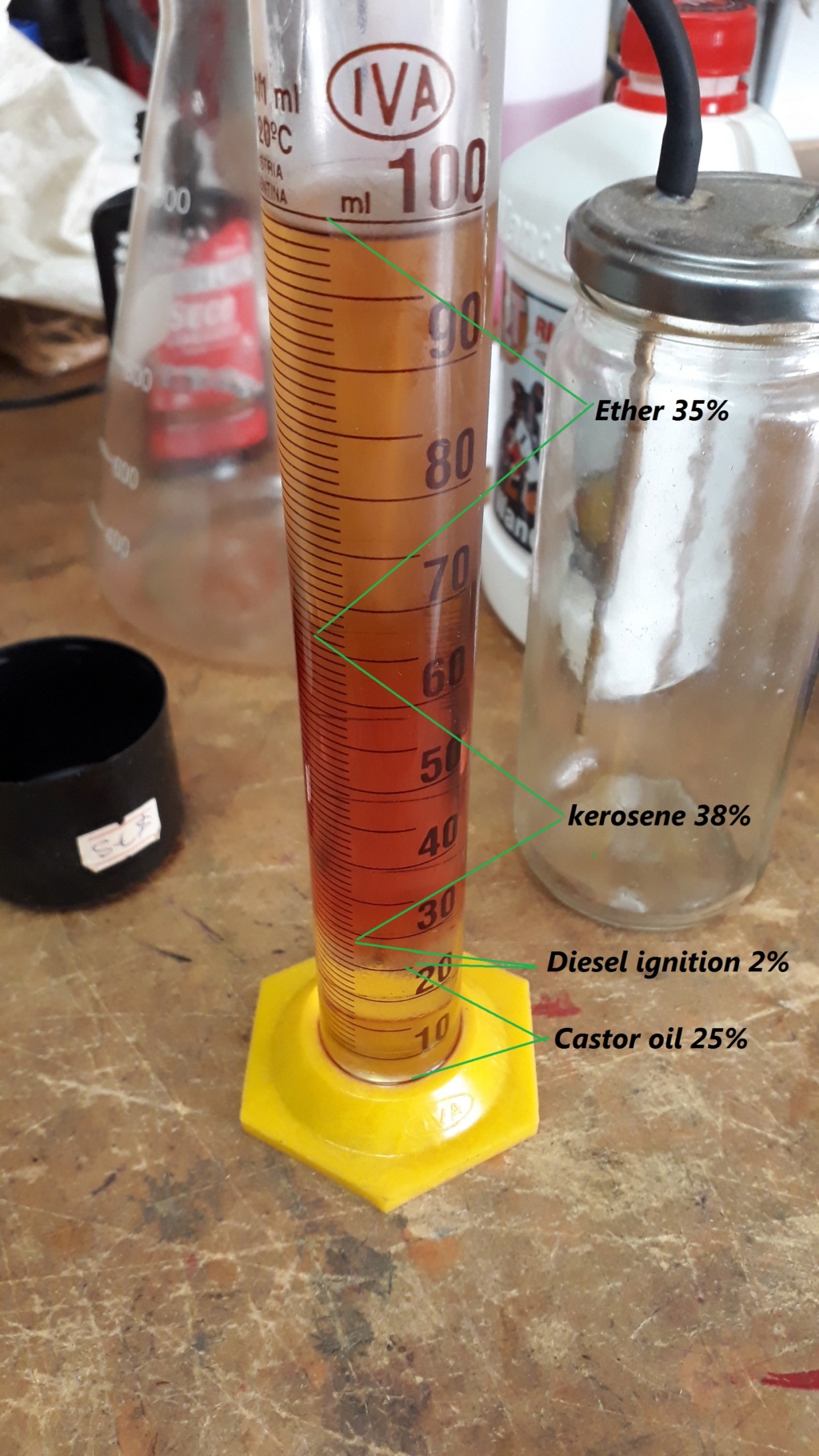

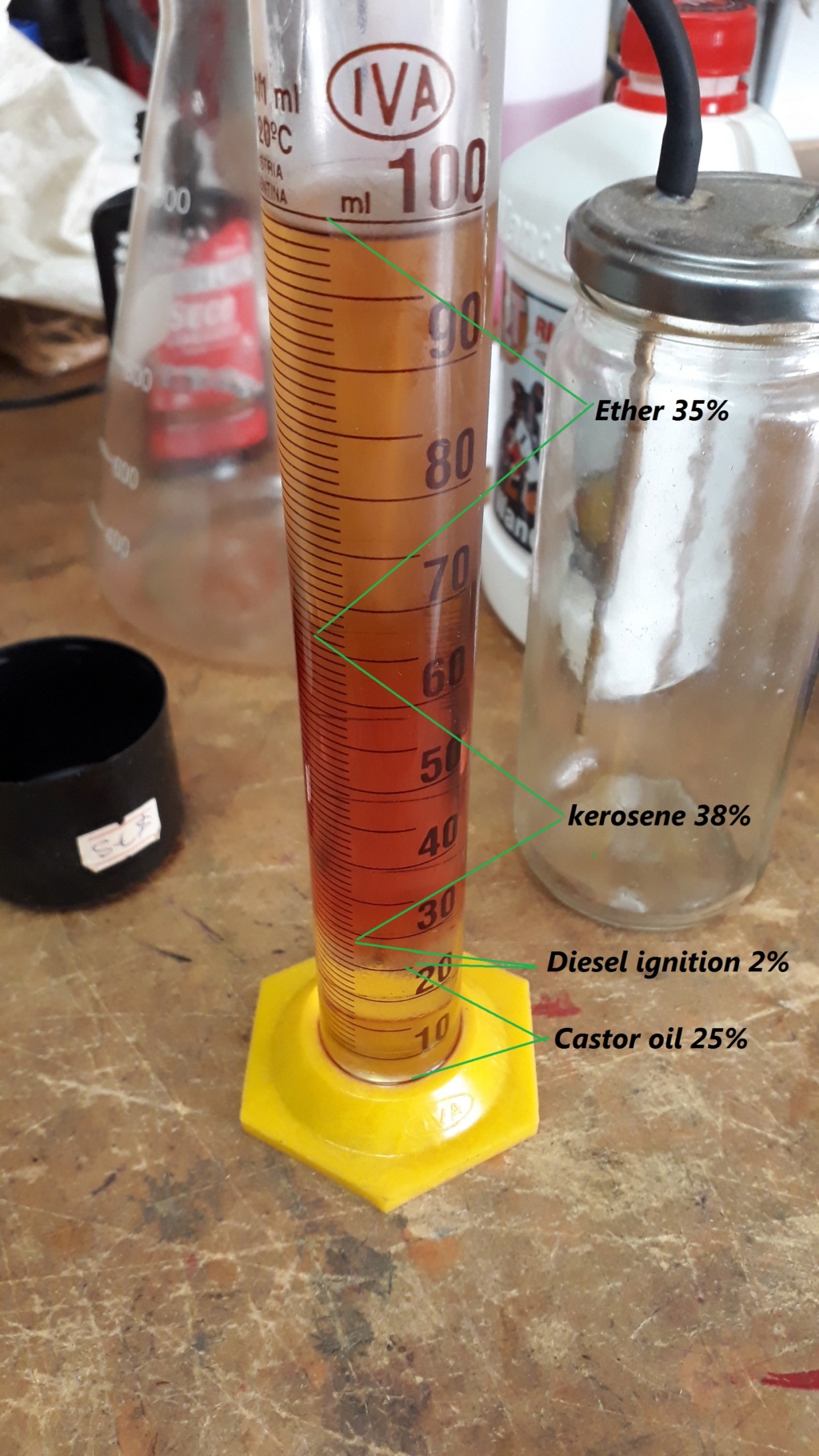

Dear friends, thank you very much for all the information, for giving me your time and I want you to know that it was not in vain. I value your time and I am grateful. The way to repay you for this beautiful gesture on your part is to show you my first test, which bore fruit.

I made the mixture according to ChrisM's instructions and also followed his instructions.

You can see the photo of the total mixture of 100 cc before beating and mixing.

I made the adjustments manually by shoveling by hand or by finger, whatever they call it instead, it made a couple of explosions but it couldn't start, then I gave it a touch with the electric starter and that's it! It goes very well.

The propeller is a Master 8 x 4

I understand that adjustments may be missing, but the optimal result would also be with high quality fuel.

The ether I use here is milked from an aerosol of "engine starters", so it is not 100% ether.

Finally, having the engine running is quite an achievement. I don't know its history, I don't know exactly its origin and how it arrived in the country.

My deepest thanks to all of you. I am proud to belong to the Cox Engines Forum.

Engine number: XM 4 2366 (1959)

Fuel:

Castor oil 25%

Ether 35%

kerosene 38%

Diesel ignition 2%

Action!:

I made the mixture according to ChrisM's instructions and also followed his instructions.

You can see the photo of the total mixture of 100 cc before beating and mixing.

I made the adjustments manually by shoveling by hand or by finger, whatever they call it instead, it made a couple of explosions but it couldn't start, then I gave it a touch with the electric starter and that's it! It goes very well.

The propeller is a Master 8 x 4

I understand that adjustments may be missing, but the optimal result would also be with high quality fuel.

The ether I use here is milked from an aerosol of "engine starters", so it is not 100% ether.

Finally, having the engine running is quite an achievement. I don't know its history, I don't know exactly its origin and how it arrived in the country.

My deepest thanks to all of you. I am proud to belong to the Cox Engines Forum.

Engine number: XM 4 2366 (1959)

Fuel:

Castor oil 25%

Ether 35%

kerosene 38%

Diesel ignition 2%

Action!:

MauricioB- Top Poster

- Posts : 3709

Join date : 2016-02-16

Age : 53

Location : ARG

Re: English Diesel Engine.

Re: English Diesel Engine.

Well done Mauricio....the only comment I'll make regarding the fuel is-if using 'engine start' as your ether source, it is important to know what the ether content is-if not written on the can you can normally find it in the MSDS leaflet-either as part of the overall product packaging or on line...often on the manufacturer's website. The important thing here to note is that you should treat the 'non ether' portion as part of the kerosene portion of the fuel when determining mixing volumes. For example -and don't get fixated on these exact figures, understand the methodology-suppose you wanted to make 1-litre of 1/3:1/3;1/3 fuel....the old standby diesel mix since Adam was still in short trousers-[its a bit high in lubricant but easy to make up]-and your ether source was John Deere engine start at 80% ether....if you were using pure ether (and I'm talking in a very general rather than a chemist's definition of pure here) you would mix 333ml of ether, 333ml of kerosene and 333 mls of the oil of choice, be it castor or something else to give you your 1-litre of 1/3/1/3/13 fuel mix...BUT your ether is only 80% more-so to get 33% ether in the final mix you will have to add more than 333 mls-in fact you would need to add 333x 100/80...or 1.25x your original calculated volume of ether-or for the purposes of the example....416.25mls....or an extra 83.25 mls to get a final % of 33% ether, because you are adding a liquid that is only 80% ether. BUT you have now also added the residual other hydrocarbons-`~20% that were mixed in with the ether, so you would add less kerosene-to the tune of 333ml minus 83.25 mls or 249.75 mls of kerosene. Of course if using another similar product, your conversion ratio would be whatever the stated % of ether in the product was-it might be 50%, 60% 70% or whatever the stated contents on the can or MSDS said. [John Deere product is stated to be 80%...and this seems to be the highest % ether level found in this type of product] Ether is an expensive product-so manufacturers will use the lowest level they think they can get away with to keep costs down...]

In practice it doesn't matter what your actual %s are in the fuel mix as long as you compensate for the ether being less than 100% pure [there are limits-for example some Australian 'tropical' engine start mixes are only 25% ether...and no matter what you do you can never get a reasonable fuel mix using these-the starting ether % content is too low-and you will be diluting it even lower in the final fuel mix. In practical terms, your ether content should never be factored as less than 30% of the final fuel mix-and for some engines can be a lot higher-Webra used to recommend a 45% ether content for their small 0.8cc Webra Piccolo....and very small diesels often benefit from a higher ether content fuel.

It is also quite common practice to add the 'dope'-the DII ignition improver, 2-EHN, amyl nitrate , isopropyl nitrate or whatever ignition smoother additive compound you can get your hands on after the fuel is mixed...which means that you theoretically may have 101.5% or 102% fuel mix....but since you're only going to be adding 1-2% of these additives, in practice we don't get too worried about it, since the extra volume is going to amount to only a few millilitres extra volume-and this isn't going to have any significant effect on your overall proportions.....unless you plan to fly FAI team race at international level....and you certainly won't be doing THAT with an ED Bee!

Finally, some more words of wisdom: ALWAYS use a good quality screw capped bottle to store your mixed fuel in...and make sure it is on tight, and

NEVER store diesel in a plastic container-the ether -(an excellent solvent as I stated in a previous reply) will dissolve plasticisers out of the plastic the bottle is made from-and these will 'deaden' the fuel very quickly. Keep your diesel in either glass bottles or metal cans for storage.

ChrisM

'ffkiwi'

PS Having watched the video-well done-you've now experienced some of the things I mentioned about mis firing, running smoothly etc...very good results for your first effort

In practice it doesn't matter what your actual %s are in the fuel mix as long as you compensate for the ether being less than 100% pure [there are limits-for example some Australian 'tropical' engine start mixes are only 25% ether...and no matter what you do you can never get a reasonable fuel mix using these-the starting ether % content is too low-and you will be diluting it even lower in the final fuel mix. In practical terms, your ether content should never be factored as less than 30% of the final fuel mix-and for some engines can be a lot higher-Webra used to recommend a 45% ether content for their small 0.8cc Webra Piccolo....and very small diesels often benefit from a higher ether content fuel.

It is also quite common practice to add the 'dope'-the DII ignition improver, 2-EHN, amyl nitrate , isopropyl nitrate or whatever ignition smoother additive compound you can get your hands on after the fuel is mixed...which means that you theoretically may have 101.5% or 102% fuel mix....but since you're only going to be adding 1-2% of these additives, in practice we don't get too worried about it, since the extra volume is going to amount to only a few millilitres extra volume-and this isn't going to have any significant effect on your overall proportions.....unless you plan to fly FAI team race at international level....and you certainly won't be doing THAT with an ED Bee!

Finally, some more words of wisdom: ALWAYS use a good quality screw capped bottle to store your mixed fuel in...and make sure it is on tight, and

NEVER store diesel in a plastic container-the ether -(an excellent solvent as I stated in a previous reply) will dissolve plasticisers out of the plastic the bottle is made from-and these will 'deaden' the fuel very quickly. Keep your diesel in either glass bottles or metal cans for storage.

ChrisM

'ffkiwi'

PS Having watched the video-well done-you've now experienced some of the things I mentioned about mis firing, running smoothly etc...very good results for your first effort

ffkiwi- Gold Member

- Posts : 398

Join date : 2018-07-10

Location : Wellington, NZ

Re: English Diesel Engine.

Re: English Diesel Engine.

Chris. Your info on the less-than-100% Ether is the way I do it. Yes, generally Aussie starting fluids don't have enough. Best I can find is 50%, so I count the residual liquid as kerosene and don't have to add any more kero. For the 1/3 1/3 1/3 mix I just consider the contant of the can as 66% and the rest is oil and DII. (DII is another story. The stuff I use is "watered down" so need to add more to get the % up. That means that the other components in the DII ( Naphtha/Kero) has to be taken into consideration as well.

Rod.

Rod.

Oldenginerod- Top Poster

- Posts : 4017

Join date : 2012-06-15

Age : 62

Location : Drouin, Victoria

MauricioB- Top Poster

- Posts : 3709

Join date : 2016-02-16

Age : 53

Location : ARG

Re: English Diesel Engine.

Re: English Diesel Engine.

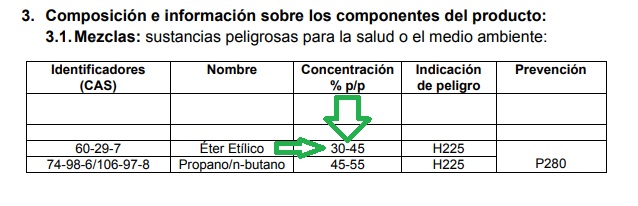

I also have this "aerosol engine starter", but I can't figure out the percentage of Ether it contains, here is its technical data sheet:

https://www.bardahl.com.ar/wp-content/uploads/2011/06/FDS-AMI.pdf

https://www.bardahl.com.ar/wp-content/uploads/2011/06/FDS-AMI.pdf

MauricioB- Top Poster

- Posts : 3709

Join date : 2016-02-16

Age : 53

Location : ARG

Re: English Diesel Engine.

Re: English Diesel Engine.

Mauricio-your engine start product is a little unusual to my eyes-I've never seen one with such a large volume % of propellant-45-55% of propane and n-butane...which are of course gases-and flammable in their own right. Normally the figure you see if 5-10%-with various other hydrocarbons such as hexane, heptane etc making up the remaining difference between the ether content % and the propellant %. In your case it is possible that by careful spraying of the contents into a suitable container, and allowing time for the mixture to 'gas off' what remains should be largely all ether-or as near to 100% ether as you need for our purposes. If I've misread the spanish, and what they're referring to is not propane or butane GAS, but the respective alcohols then your comment would hold-and you would have to apply a factor of 3.33X (for a 30% content) or 2.22X for a 45% content [this is one of the reasons I DON'T like using these products as an ether source-it is extremely rare to find one stating the EXACT ether % in the contents-they almost always state a range such as your 30-45% -and short of a chemical analysis, there is no accurate way of determining the true ether content, unlike 'pure' ether ['pure' being used in a very relative sense, since reagent grade or solvent grade ether might well contain quite a lot of impurities-but it will still be at least 97% or better..]

This means you'll never be entirely sure how much ether is in your fuel-and of course getting repeatability between fuel batches is virtually impossible-unless you were to buy an entire case of engine start product, where it would be reasonable to expect that every can in the case would have a similar ether content, regardless of the exact %. Still -if you can't source straight ether, then engine start is your only option, unless you have friends in the petroleum/petrochemical industry...

As for your second candidate-the bardahl product-I can't find anything in the data sheet about the ether content either-so it would be a lottery to use it. Its likely it contains SOME ether-but without knowing how many other components are in there-and what they are, you couldn't even begin to roughly estimate the amount even by evaporation techniques. Of course if you have friends at a university chemistry department or a commercial analytical lab, then a gas chromatography analysis will give you the true result in very short order. I would guess that the ether content would fall somewhere between a low of 25% and a high of 80%....and the higher the ether content, the higher the product price....so price alone might give you some idea of the likely ether content

ChrisM

'ffkiwi'

This means you'll never be entirely sure how much ether is in your fuel-and of course getting repeatability between fuel batches is virtually impossible-unless you were to buy an entire case of engine start product, where it would be reasonable to expect that every can in the case would have a similar ether content, regardless of the exact %. Still -if you can't source straight ether, then engine start is your only option, unless you have friends in the petroleum/petrochemical industry...

As for your second candidate-the bardahl product-I can't find anything in the data sheet about the ether content either-so it would be a lottery to use it. Its likely it contains SOME ether-but without knowing how many other components are in there-and what they are, you couldn't even begin to roughly estimate the amount even by evaporation techniques. Of course if you have friends at a university chemistry department or a commercial analytical lab, then a gas chromatography analysis will give you the true result in very short order. I would guess that the ether content would fall somewhere between a low of 25% and a high of 80%....and the higher the ether content, the higher the product price....so price alone might give you some idea of the likely ether content

ChrisM

'ffkiwi'

ffkiwi- Gold Member

- Posts : 398

Join date : 2018-07-10

Location : Wellington, NZ

Ed

Ed

Scpectreflight may give engine info, model technics may give a fuel formula...

See PAW site for fuel formula also. PAW say Weston's model diesel fuel is suitable these days as well for their latest engines....ed was defo a castor engine...

See PAW site for fuel formula also. PAW say Weston's model diesel fuel is suitable these days as well for their latest engines....ed was defo a castor engine...

Coxfledgling- Gold Member

- Posts : 404

Join date : 2021-01-10

Location : Near Caernarfon, Snowdonia, Wales, UK

Re: English Diesel Engine.

Re: English Diesel Engine.

Congratulations on getting your ED to run , sounds good too ! I am more confused on the mixing now than before because of the content beeing more or less % of ether ... I have john deere starting fluid at 80% ether 7 ozs. spray , if I get 4 ozs. out of it how much castor and kerosene would I add to it / I don't have diesel ignition to put in it . I have a .75 Mills i was trying to run .

getback- Top Poster

Posts : 10428

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: English Diesel Engine.

Re: English Diesel Engine.

Has anyone priced a Cox glowhead lately? I did...so I consider this a timely exercise in "options." Somewhere this evening I saw a site that indicated a decent .15 "squish-banger" and 34" Sig AkroMaster might be a good combination.

I enjoyed hearing Maricio's recent diesel engine running video. It didn't scream my ears apart.

Add the non-butyrate dope finish and more fuel efficient power...Call me intrigued by diesel. I'm really scratching my chin with this...hmmm.

I enjoyed hearing Maricio's recent diesel engine running video. It didn't scream my ears apart.

Add the non-butyrate dope finish and more fuel efficient power...Call me intrigued by diesel. I'm really scratching my chin with this...hmmm.

Last edited by 944_Jim on Sun Nov 19, 2023 8:11 pm; edited 1 time in total (Reason for editing : Clarity regarding dope)

_________________

Never enough time to build them all...always enough time to smash them all!

944_Jim- Diamond Member

Posts : 2021

Join date : 2017-02-08

Age : 59

Location : NE MS

Re: English Diesel Engine.

Re: English Diesel Engine.

getback wrote:Congratulations on getting your ED to run , sounds good too ! I am more confused on the mixing now than before because of the content beeing more or less % of ether ... I have john deere starting fluid at 80% ether 7 ozs. spray , if I get 4 ozs. out of it how much castor and kerosene would I add to it / I don't have diesel ignition to put in it . I have a .75 Mills i was trying to run .

Oh-lets take this bit by bit-before you can decide how much of the other ingredients to add to your john deere liquid, you have first to decide WHAT fuel mix you want to make-there are a variety-just like glow fuels, and likewise, more or less optimised for different uses. The EASIEST is the good old 1:1:1 blend-simply because its equal amounts of all three ingredients-this is safe-no engine has ever died from it-and it is a very good mix to use on a brand new engine when running it in-the downside is that its a bit generous on the lubricant proportion-so a bit messier in terms of exhaust than it needs to be. That is a good time to review the fuel itself-glowplug engines burn methanol (not nitro-I grind my teeth every time someone refers to a 'nitro' engine...)-our model diesels burn kerosene....simple as that-the 'fuel' is kerosene, not ether-the ether is there solely to provide the ignition aspect, whilst the role of the oil should be self evident. Ether has quite a low calorific value, unlike kerosene-so the combustion of the ether contributes very little to the power output of the engine. The important thing to note here is that the more ether (and oil) the less kerosene you have in the mix-and that automatically limits the power available-the ideal fuel would have the minimum amount of ether, the minimum amount of oil, and the maximum amount of kerosene.

Note that there is NOTHING you can add to diesel fuel that will raise power in a way that adding nitromethane to glow fuel does-there is no compound that does this for diesels. The so called 'dope' or additives are there to eliminate missing-smooth combustion and also allow you to operate at a slightly lower compression setting for the same prop load. In practice they are used only at levels around 2% of the volume-and too much results in hard running and overheating.

So-the aim of the game is to use as much kerosene as possible-but this is limited by the need to use adequate amounts of the other two components as well-in practice, the lowest ether proportion in the fuel bottoms out at ~30%-as once you go below this starting becomes unreliable and a bit of a lottery-and of course every time you open the bottle, a tiny amount of ether escapes to the atmosphere....so most fuels are formulated with bit more-say around 35%-now that leaves you 65% remaining to cover both the kerosene and oil component-so you want to use as little oil as possible to maximise the amount of kerosene....but still have some margin of safety.....and THAT depends very much on both the metallurgy and the engine design....in practice, plain bearing engines use about 25% oil, ball bearing ones 20%....so if you have a ball bearing engine, using our sample figures, you can get away with 45% kero in the mix, but only 40% if its a plain bearing engine because you need that extra 5% oil. That's basically how diesel fuel formulas are derived -the ultimate 'classic' diesel era mix was 'Oliver Tiger' brew-30% ether, 50% kerosene, 20% oil plus 2% amyl nitrate.....that adds up to 102% by the way-but that's how people usually do it-add the nitrate or ignition improver to the final mix. And that brings us to 'additives' 'dopes' 'ignition improvers etc-these are all alkyl nitrates-that is nitrate esters of aliphatic short chain hydrocarbons-and they all seem to work fine, regardless of how long the chain length is. Traditionally amyl nitrate was the dope of choice in the 50s and 60s, then isopropyl nitrate in the 70s and early 80s, then in the later 80s DII became available-largely due to the massive increase in diesel engined automobiles-where it was found useful to smooth running-and produced by the railcar tankerload. Some enterprising modellers found that it worked in our engines-and voila, almost overnight it became the ignition improver of choice, because it was a) available and b) relatively cheap-neither of which applied to the earlier compounds which were both expensive and hard to find.

Now returning to your Mills-you could simply mix up 1:1;1 mix-and as you don't have any DII or equivalent we can leave that out-it just means the engine won't run quite as smoothly, but it will certainly run-and run quite well [I have some modeller acquaintances who claim Mills run better with NO dope in the fuel, anyway...in my case i've never seen enough difference to worry-plus I don't mix my fuel for use in a single engine type, so I always include some ignition improver, regardless.

Your Mills is plain bearing so that means at least 25% oil, and I'd stick with 35% ether to make life easy, as small diesels tend to handle a bit better with a bit more ether in the fuel-that amounts to 60% of your final mix so far...so the remainder-40% of the final volume- has to be kerosene (or whatever local equivalent you're going to use-'paraffin' 'lamp oil' 'coleman fuel' 'jet A-1' 'av-tur'......remember 'kerosene' isn't a chemical compound-it's a 'cut' from the petroleum refining process-so a mixture of short(6C) to medium (20C) carbon chain hydrocarbons....and will in fact vary from place to place depending on where they source their product from (in terms of the refinery) and also where that refinery sets its own limits on the fractional 'cut'. There will also be a proportion of aromatics (closed ring structure not chain) in the mix as well. [Bear this in mind when we start talking about the ether fraction]

Now we come to the source of your confusion-the John Deere ether-which as we know is 80% ether not 100%-that means when you add the 'ether' component-you're not in fact adding enough-you're adding only 80% of the added volume of the 'ether proportion'-so if we use our 1:1:1 mix as an example, instead of 33-1/3% in your fuel mix, you will in fact have only 80% of this or 26.66%-which is under the 30% minimum limit we generally work to-AND you've added 20% of miscellaneous hydrocarbons-depending what john deere uses in that remaining 20%. The only way of dealing with this is to treat that extra 20% hydrocarbon fraction as if it was kerosene-which means you now have too much 'kerosene' in the mix-and you will have to reduce the amount of actual kerosene added to keep the proportions right-but you still need to get the ether right-so to get 33-1/3% in the final mix, you have to increase the John deere component by 100/80-or 1.25X to get your correct amount. To keep things simple we'll pretend you want to make 1-litre of 1:1:1 mix-if the john deere was 100% ether you'd mix 333mls of each component, give it a good shake, put ther lid back on and go for a beer or a nice cup of tea.....but since it is only 80% ether and you still want 1:1:1 mix-you will have to add 333x1.25 mls-or 416.66mls of john deere ether...but if you add this plus 333mls of the other two components-you end up with 1083.3 mls of mixture-not 1000. So you need to reduce the kerosene component by the amount of 'extra' you added ALONG with the ether-or 83.33mls....so your kerosene component becomes 333.33-83.33=250mls (a nice round volume to measure BTW).....your oil remains as calculated as 333.33mls....and there you have 1 litre of 1:1:1 fuel

Now John Deere is as good as it gets when it comes to ether content in 'engine start' type products-others have quite a lot less ether-but the principle remains the same-you MUST establish the ether content as a %-either from the technical info or the MSDS-and factor this into your volume calculations-If it is only 50% you'd multiply by 100/50 or 2x to get your required ether volume. Once the product gets down to 25% ether, then its a complete waste of time-you can never blend anything-even with only 20% oil and no added kerosene-better than 20% ether-and that rarely works at all-though you might get the engine to fire occasionally on it. The other problem I have with these type of products is they rarely-if ever state an actual accurate ether %-it seems to be always given as a range-eg diethyl ether 45-60% (or whatever your particular brand says)-that's a 25% possibly variance right there-and that's before you start calculating! It make fuel mixing a bit of a guessing game-since your fuel mix can end up varying wildly in ether content depending on what part of the stated range your particular can of engine start actually contains.

Hopefully this explains some of the pitfalls....

ChrisM

'ffkiwi'

PS sorry if you're struggling-I'm a trained chemist and biochemist so can do this stuff in my sleep-plus I have the background and equipment to do it accurately-it becomes second nature in my profession

ffkiwi- Gold Member

- Posts : 398

Join date : 2018-07-10

Location : Wellington, NZ

Re: English Diesel Engine.

Re: English Diesel Engine.

I've invested in aftermarket glow plug heads for my Cox .09 Medallion and and .15 Sportsman, plus have a couple Cox .049 glow plug heads just in case these become harder to find.944_Jim wrote:Has anyone priced a Cox glowhead lately? I did...so I consider this a timely exercise in "options." Somewhere this evening I saw a site that indicated a decent .15 "squish-banger" and 34" Sig AkroMaster might be a good combination.

For the larger engines, depending on how they were machined, I don't envision as great of an RPM loss as I would for the .049's, since their combustion chambers are larger.

The fact the diesel .06 peaks out at a lower RPM of 10,500, means it can turn larger props with ease.944_Jim wrote:I enjoyed hearing Maricio's recent diesel engine running video. It didn't scream my ears apart. Add the non-dope finish and more fuel efficient power...Call me intrigued by diesel. I'm really scratching my chin with this...hmmm.

It sort of reminds me of my Enya's. The humble .09-III TV can easily turn a 7x6 or 8x4 to its in flight max HP, stump pulling power. Those who have disappointed themselves by propping them like the Schneurles with smaller diameter props, just didn't understand you can't do that. Those engines peak out at a higher RPM, hence to get them there need smaller props.

But, I certainly enjoyed hearing that diesel run, can understand why they were so popular, Chris M. pointed out the factors making the engine popular, pricing point plus reliable running being key. It was those points that also caused Cox engines to outpace the others.

GallopingGhostler- Top Poster

Posts : 5700

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: English Diesel Engine.

Re: English Diesel Engine.

Thanks Chris , that does help a lot i understand that the percentage is more depended on how strong the ether is and not just how much comes out of the can . Maybe if I can get some time before it gets to cold here to ty and run the Mills again with your help here i think i can make it happen

getback- Top Poster

Posts : 10428

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: English Diesel Engine.

Re: English Diesel Engine.

Nice engine Mauricio and congratulations on quickly understanding it and putting together a fuel for it to get a run…. The video demonstrates its abilities well ….Do you have plans to put together an airplane for it?

Also enjoyed Chris’s detailed explanation of history and fuel formulation…. I’ve never owned or operated a diesel but they’re interesting to read…

Also enjoyed Chris’s detailed explanation of history and fuel formulation…. I’ve never owned or operated a diesel but they’re interesting to read…

rdw777- Diamond Member

Posts : 1688

Join date : 2021-03-11

Location : West Texas

Re: English Diesel Engine.

Re: English Diesel Engine.

getback wrote:Thanks Chris , that does help a lot i understand that the percentage is more depended on how strong the ether is and not just how much comes out of the can . Maybe if I can get some time before it gets to cold here to ty and run the Mills again with your help here i think i can make it happen

Once you get some fuel made up, you shouldn't have too much trouble...Mills 75s were always among the easiest starting of diesels...and were ideal beginners' engines-but as I noted earlier -not the most affordable for their size class.

If you haven't much diesel experience then fit an 8x4 or an 8x3. The flywheel effect of an 8" prop will help-and still develop plenty of thrust-though max power is delivered on a 7x4 or 7x3. Do NOT try to run one on a glow 049 sized prop! (you'll be nursing bruised fingers-they'll bite you on a 5 or 6" prop)

Try just an exhaust prime and the needle valve fully closed to start with-as I advised Mauricio earlier-just to get the starting compression right (it may be close to correct, or way off-you never know till you try) be careful not to hydraulic lock it by over generous priming. Once you can get it firing and running off the prime, then open the needle two full turns from fully closed, which should be plenty, choke the intake and turn it through compression ONCE....then proceed as before-you might still need a small exhaust prime when starting from cold [when warm, a single choked flick to prime, then you should get a first or second flick start every time!] Be careful not to overchoke-Millses have extremely good venturi suction, and it is very easy to flood then with over enthusiastic choking-and then they become a bugger to clear the flood.

Make sure the cooling fins are tight-as if they loosen the cylinder can rotate slightly-and chew out the flanks of the conrod-which is only alloy. You can usually spot if there is a problem as the exhaust ports in the liner and the crankcase are the same size-so any axial misalignment between the liner and the case is obvious when you look through the ports-which will not line up properly-when they should match exactly if everything is lined up as it should be. The reason for mentioning this is that the mills is a VERY long stroke engine-and so not surprisingly has a very long liner....so long in fact that there has to be a cutout on either side at the bottom end to allow the conrod clearance.....this cutout is just big enough to clear the rod shank-so if any misalignment occurs, the rod rubs against the edges of this cutout....and since the rod is alloy and the liner hardened nitrided steel, the rod is the one that loses the argument! Not pretty!

The problem was cleverly solved with the Doonside Mills replicas-made in the early 70s, by fitting a locating pin to a slot in the cylinder flange, preventing any rotation of the liner-but the problem still occurs with the UK originals and the Indian reproductions.

Once you've got it running, play around with the comp setting a bit-you'll soon discover what happens if you advance the compression too far-the engine will run 'hard' and sound laboured and eventually labour to a halt.....go the other way and you'll discover the true delight of the Mills in particular....you can throttle them back to almost a tick over by backing off the compression....which is a marvellous help during trimming and very useful in scale models.

Not all diesels are this tractable however, and its their handling-plus the build quality-that gained Mills engines their enduring reputation amongst small diesels. They're good....but by no means perfect...the tank retaining method is a nonsense, the crankshaft is fragile-and will often snap just in front of the prop driver flats in a heavy crash...and the prop driver retention system is a bad joke.....but despite all that, we like them...and some of their bad points have been corrected in later replicas...eg the Irvine one-which has a screw in fuel tank bowl and a taper fit prop driver, or the Russian Mk2 Doonside which has a replacable screw in prop stud....all of which are a better engineering solution than the originals.

ChrisM

'ffkiwi'

ffkiwi- Gold Member

- Posts : 398

Join date : 2018-07-10

Location : Wellington, NZ

Re: English Diesel Engine.

Re: English Diesel Engine.

Thank you very much Roberto for your words.....sincerely when installing this very old engine for me, I am attracted by its own unknown history, its origin and its era.

When I start it and see that it really works very well, I feel admiration for its quality. Also the smell that comes out after combustion and the oil and gasket that it partly creates, form an incredible airplane model atmosphere, it even reminds me of my mechanic grandfather (I wish I could share this example of an engine with him).

You ask me if I plan to make any model airplanes, in fact I have made so many airplane models lately that my mind is going faster than my hands and I want to make more and more, but at the same time I also want to really enjoy the ones that I have already made and are there. on the shelf waiting for me.

This engine pushes me to build a UC model airplane, so the idea of something with control lines began to float around my head (incredible!)...I have to think of some model for it, the flat fuselage or plank and wings in ribs or veneered styrofoam would perhaps be interesting, (if you have any plans to recommend, I would gladly study it and place it on the manufacturing waiting line haha)...

I don't know exactly what size model airplane should go for the 1cc ED Bee?

Chris, You have turned out to be an open book on all these questions, I renew my gratitude for your time and for sharing your experience and wisdom with us, thank you very much!

When I start it and see that it really works very well, I feel admiration for its quality. Also the smell that comes out after combustion and the oil and gasket that it partly creates, form an incredible airplane model atmosphere, it even reminds me of my mechanic grandfather (I wish I could share this example of an engine with him).

You ask me if I plan to make any model airplanes, in fact I have made so many airplane models lately that my mind is going faster than my hands and I want to make more and more, but at the same time I also want to really enjoy the ones that I have already made and are there. on the shelf waiting for me.

This engine pushes me to build a UC model airplane, so the idea of something with control lines began to float around my head (incredible!)...I have to think of some model for it, the flat fuselage or plank and wings in ribs or veneered styrofoam would perhaps be interesting, (if you have any plans to recommend, I would gladly study it and place it on the manufacturing waiting line haha)...

I don't know exactly what size model airplane should go for the 1cc ED Bee?

Chris, You have turned out to be an open book on all these questions, I renew my gratitude for your time and for sharing your experience and wisdom with us, thank you very much!

MauricioB- Top Poster

- Posts : 3709

Join date : 2016-02-16

Age : 53

Location : ARG

Re: English Diesel Engine.

Re: English Diesel Engine.

Thanks again Chris , This helps a bunch and thanks for taking the time to putting the info to me . Mine is the original Mills that the liner will turn if not kept tight , i seen and have the article on how to affix a pin in it to remedy this but don't know if its something I can do without messing up the cly/liner .. I will save this for reference .

getback- Top Poster

Posts : 10428

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: English Diesel Engine.

Re: English Diesel Engine.

The book could be based on some earlier works. But being substantially rewritten be considered a new work in its own right. Many of the earlier authors I grew up with have passed on.  The greats, Walt Musciano, Ken Willard, Bill Northrop, Sid Axlerod, Robert Peck, Jack Headley, Paul Del Gatto, Lee Renaud, William "Bill" Winter, Don McGovern, Carl Goldberg, Keith Laumer, they all were alive when I grew up.

The greats, Walt Musciano, Ken Willard, Bill Northrop, Sid Axlerod, Robert Peck, Jack Headley, Paul Del Gatto, Lee Renaud, William "Bill" Winter, Don McGovern, Carl Goldberg, Keith Laumer, they all were alive when I grew up.

Regarding the cover photo, there are many excellent rubber plans from the early 1950's that one could post on the front and be just as appropriate.

Many of the sources I grew up with are no longer available. Even green soap and glycerin are no longer used as rubber motor lubricant. Dope and cellulose glues are now harder to obtain and expensive.

A shift in building materials, finishes, and lessons learned make a fresh rewrite appropriate.

Regarding the cover photo, there are many excellent rubber plans from the early 1950's that one could post on the front and be just as appropriate.

Many of the sources I grew up with are no longer available. Even green soap and glycerin are no longer used as rubber motor lubricant. Dope and cellulose glues are now harder to obtain and expensive.

A shift in building materials, finishes, and lessons learned make a fresh rewrite appropriate.

GallopingGhostler- Top Poster

Posts : 5700

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: English Diesel Engine.

Re: English Diesel Engine.

This engine pushes me to build a UC model airplane, so the idea of something with control lines began to float around my head (incredible!)...I have to think of some model for it, the flat fuselage or plank and wings in ribs or veneered styrofoam would perhaps be interesting, (if you have any plans to recommend, I would gladly study it and place it on the manufacturing waiting line haha)...

I admire that Mauricio , The desire to try something different…. Keeps things fresh!!….Others than me will be better to recommend a suitable plane for it….. If I were to choose it would probably be something from its country of origin that was popular around the same time period as the engine…

I get it about having too many model planes…. I’m trying to keep my count low and just keep experimenting with the ones I have….

Roberto

I admire that Mauricio , The desire to try something different…. Keeps things fresh!!….Others than me will be better to recommend a suitable plane for it….. If I were to choose it would probably be something from its country of origin that was popular around the same time period as the engine…

I get it about having too many model planes…. I’m trying to keep my count low and just keep experimenting with the ones I have….

Roberto

rdw777- Diamond Member

Posts : 1688

Join date : 2021-03-11

Location : West Texas

Similar topics

Similar topics» Last of the Enya Diesel engines purchased off of Enya's website.

» Need help identifying diesel engine

» AM15 1.5cc Diesel Engine

» P.A.W. Diesel Engine

» Cox .049 RC Diesel Engine

» Need help identifying diesel engine

» AM15 1.5cc Diesel Engine

» P.A.W. Diesel Engine

» Cox .049 RC Diesel Engine

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules