Log in

Search

Latest topics

» Tee Dee .020 combat modelby Ken Cook Today at 3:23 am

» My latest doodle...

by batjac Yesterday at 9:47 pm

» My N-1R build log

by roddie Yesterday at 8:50 pm

» Free Flight Radio Assist

by rdw777 Yesterday at 4:51 pm

» Purchased the last of any bult engines from Ken Enya

by getback Yesterday at 12:05 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

» My current avatar photo

by roddie Mon Nov 18, 2024 9:05 pm

» Brushless motors?

by rsv1cox Sun Nov 17, 2024 6:40 pm

Cox Engine of The Month

a small clunk (fuel pick-up)

Page 1 of 1

a small clunk (fuel pick-up)

a small clunk (fuel pick-up)

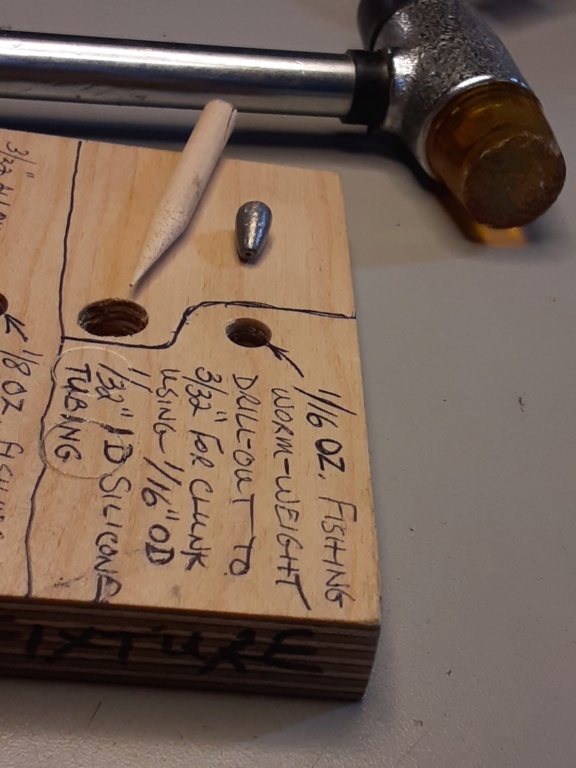

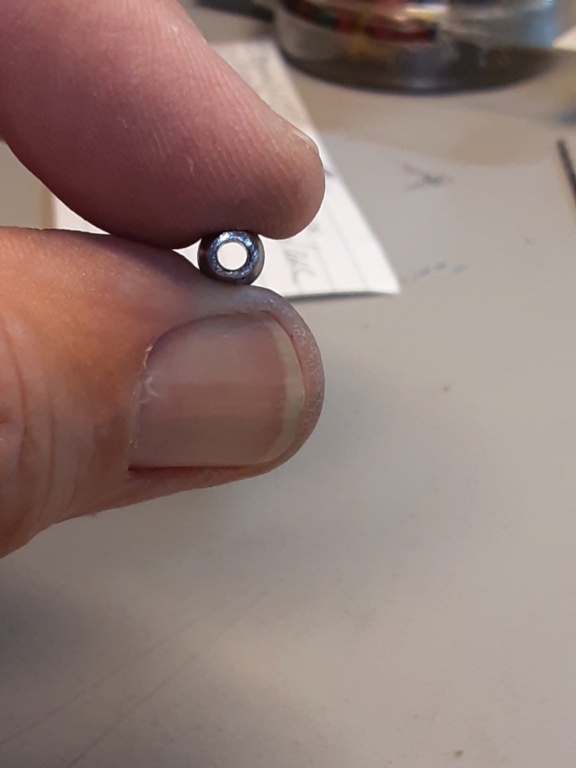

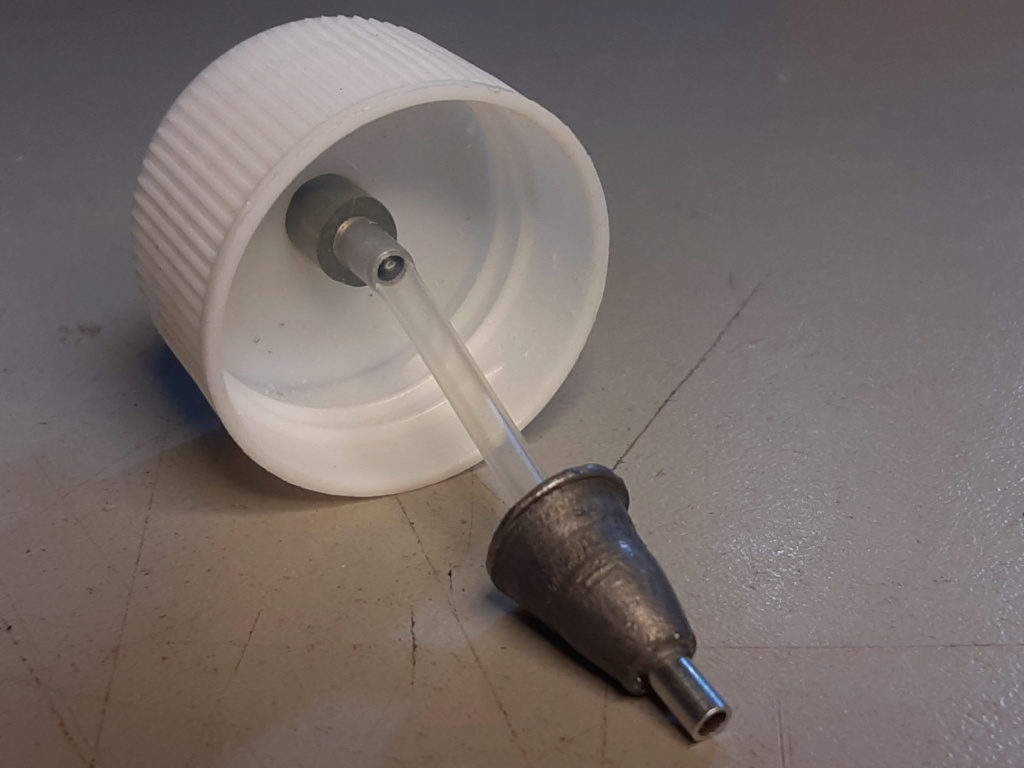

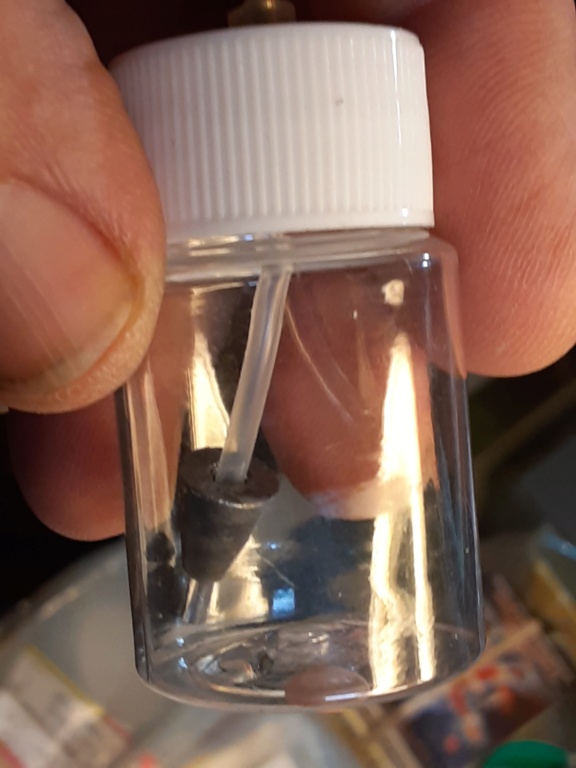

I made this little fuel cell clunk from some small (3/32" OD X 1/16" ID) Silicone tubing that I sourced from Amazon.com, a 1/8 oz. "worm weight" (fishing item) drilled-out.. and a short piece (5/16"L.) of 3/32" dia. alloy tubing. This forms a "compression-fit" when assembled.

The "final" drill used is a 7/64" (I needed to start with a 1/16" and increase in succession)

The "final" drill used is a 7/64" (I needed to start with a 1/16" and increase in succession)

Re: a small clunk (fuel pick-up)

Re: a small clunk (fuel pick-up)

Nicely done!!

I'll confess that I'm much more lazy making clunks. Start with good flexible silicon tubing with a brass tube inserted in the end; add 1 or 2 wheel collars over the brass tubing leaving a little tubing extended to suck up the last drop.

I'll confess that I'm much more lazy making clunks. Start with good flexible silicon tubing with a brass tube inserted in the end; add 1 or 2 wheel collars over the brass tubing leaving a little tubing extended to suck up the last drop.

Re: a small clunk (fuel pick-up)

Re: a small clunk (fuel pick-up)

Roddie,

Care to share the vendor and manufacturer/part number? You may have nailed a new fuel line source for our small planes.

Thanks in advance!

Care to share the vendor and manufacturer/part number? You may have nailed a new fuel line source for our small planes.

Thanks in advance!

_________________

Never enough time to build them all...always enough time to smash them all!

944_Jim- Diamond Member

Posts : 2022

Join date : 2017-02-08

Age : 59

Location : NE MS

Re: a small clunk (fuel pick-up)

Re: a small clunk (fuel pick-up)

944_Jim wrote:Roddie,

Care to share the vendor and manufacturer/part number? You may have nailed a new fuel line source for our small planes.

Thanks in advance!

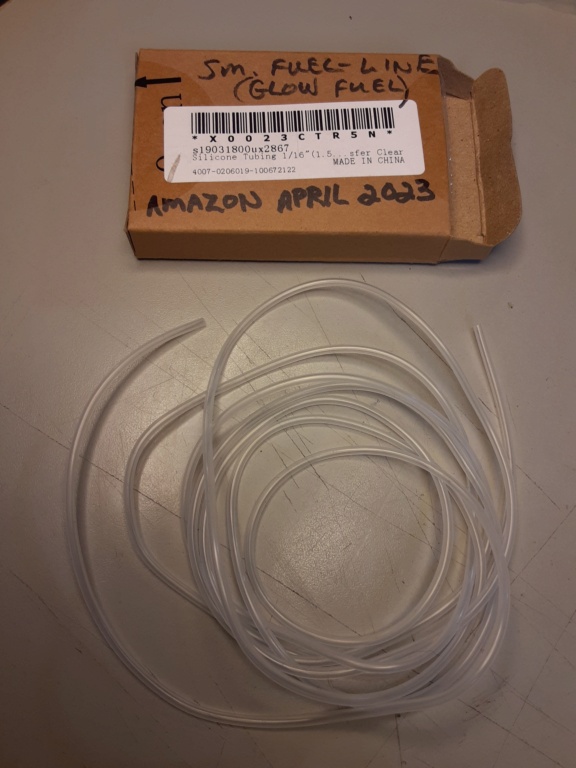

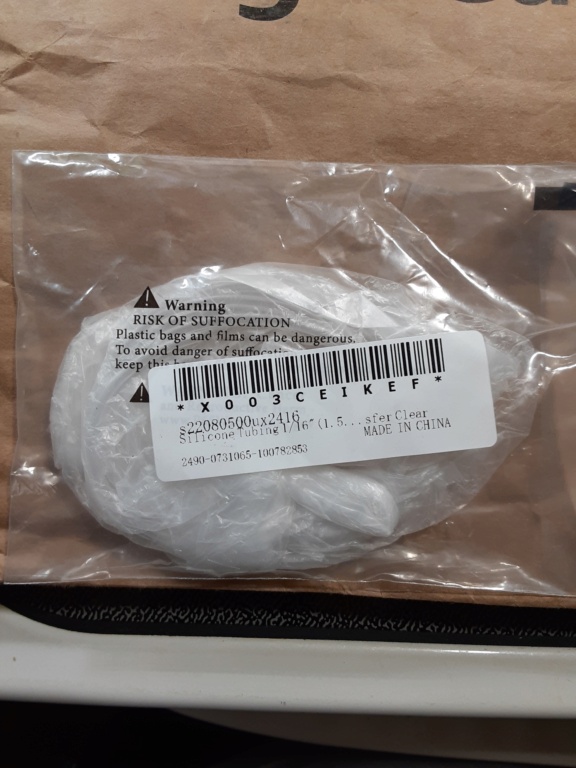

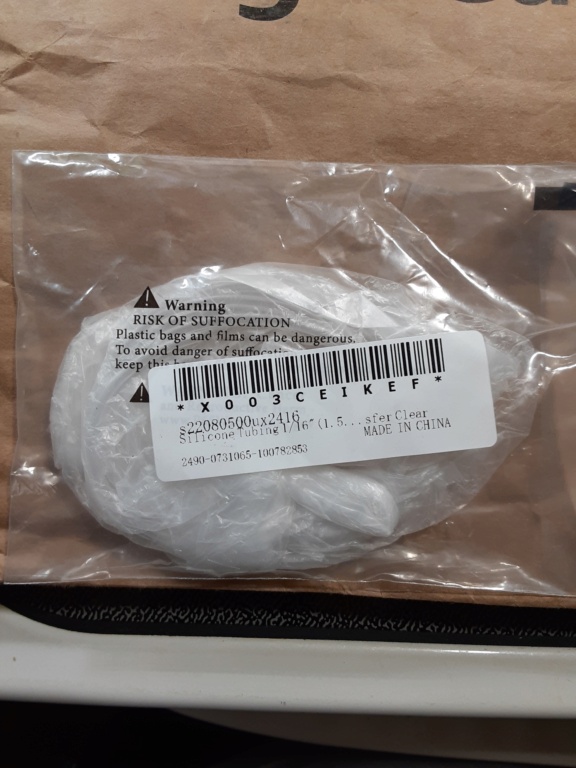

Hi Jim, The brand is "Uxcell". I found this small size by accident. I was searching for 5/16" to plumb a little solar-powered water-pump for a hummingbird fountain/bath.

Price back in March 2023 was $6.49 for a 6.6 ft. length. Unchanged as of today.

Amazon web-link

and packaging..

This stuff is like al dente' thin spaghetti.. and I mean that in a good way.

Re: a small clunk (fuel pick-up)

Re: a small clunk (fuel pick-up)

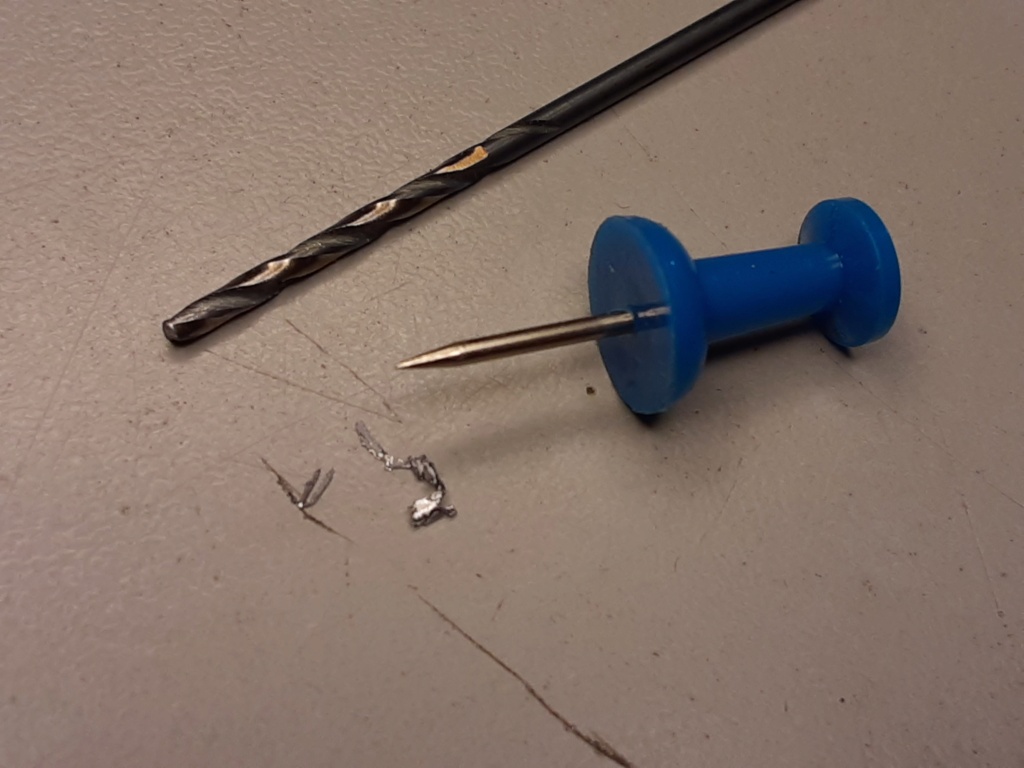

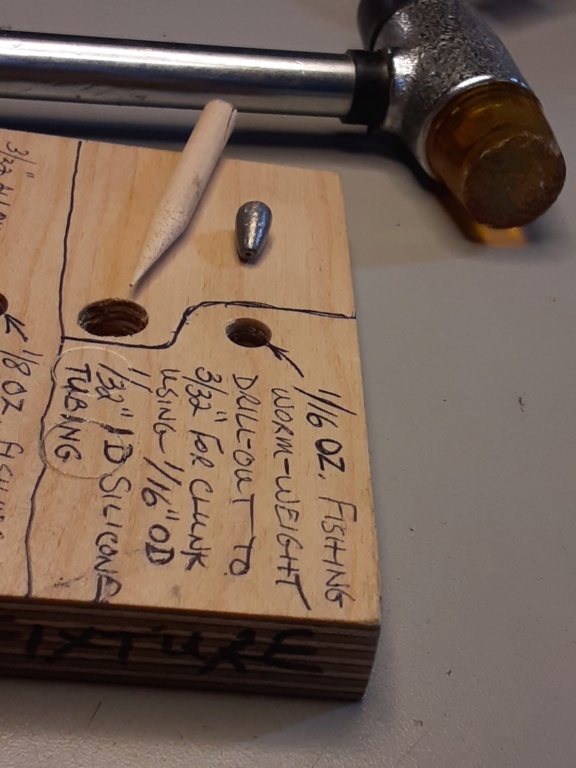

I ended up making a fixture to drill-out the weights using my drill-press. It's a small block/pad of 15mm baltic ply into which I drilled a 1/4" thru-hole. I then tapered the top-side slightly for the 1/8 oz. worm-weight to fit into. The weight is then "tapped-in" squarely using a small hammer. This keeps the weight from spinning-out while drilling. The weight material (antimony?) is soft and sticky. This is why I needed to use four drills.

To remove the weight, I use an awl inserted from the underside of the block/fixture.. and give it a light tap.

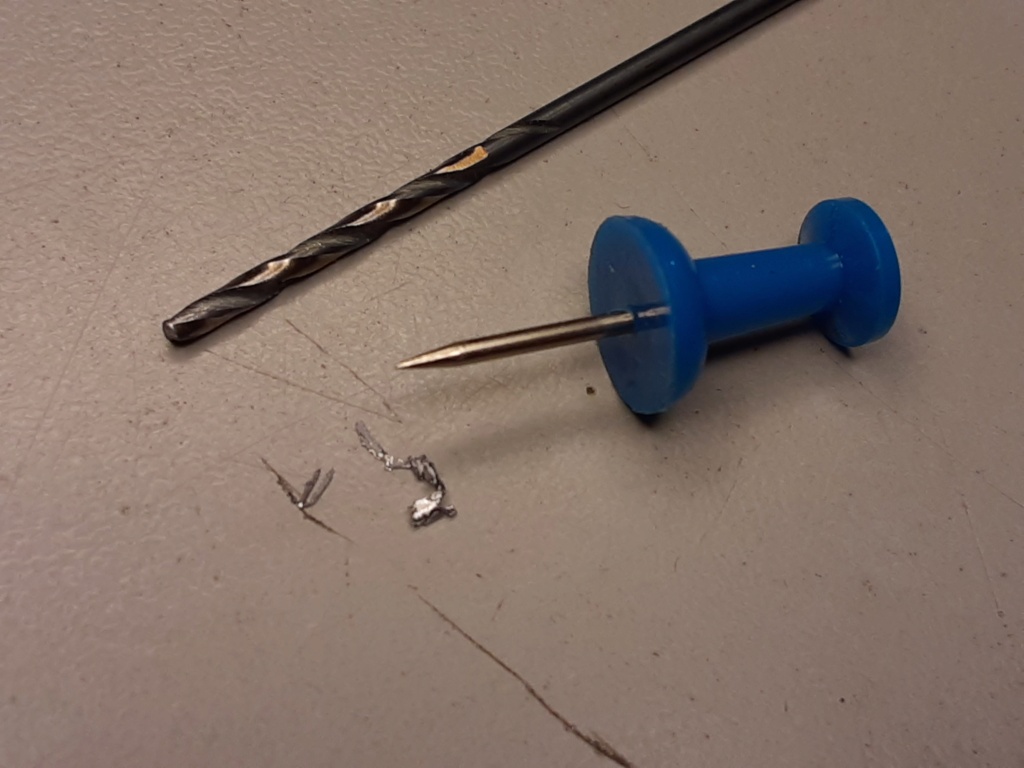

The drills "load-up" with the sticky chips even if performing pecking-strokes. This 1/16" drill is tool #1.. followed by a 5/64" then a 3/32" and finishing with the 7/64". The push-pin works great for cleaning chips from the drill flutes.

The tapered "tip" of the weight is thin where the final (7/64") drill breaks-through.. and as a result; can become jagged. This is why an awl works well for removal from the fixture. I've been using an 80grit sanding-block to cut the tip back into thicker material for when the 3/32" alloy tube/pick-up is inserted with silicone tubing attached (doesn't need much.. maybe between 1/8" and 3/16"). The pick-up assembly gets pressed-into the weight from the TAPERED-SIDE.. and is a tight fit.

To remove the weight, I use an awl inserted from the underside of the block/fixture.. and give it a light tap.

The drills "load-up" with the sticky chips even if performing pecking-strokes. This 1/16" drill is tool #1.. followed by a 5/64" then a 3/32" and finishing with the 7/64". The push-pin works great for cleaning chips from the drill flutes.

The tapered "tip" of the weight is thin where the final (7/64") drill breaks-through.. and as a result; can become jagged. This is why an awl works well for removal from the fixture. I've been using an 80grit sanding-block to cut the tip back into thicker material for when the 3/32" alloy tube/pick-up is inserted with silicone tubing attached (doesn't need much.. maybe between 1/8" and 3/16"). The pick-up assembly gets pressed-into the weight from the TAPERED-SIDE.. and is a tight fit.

Re: a small clunk (fuel pick-up)

Re: a small clunk (fuel pick-up)

Here's my latest clunk with a 3/32" (OD) aluminum pick-up tube. It seems that a 3/8" length is plenty.. with approx. 1/8" length of silicone tubing attached.

I drilled a 3/32 hole in the side of my fixture.. to aid in cutting an alloy tube to the correct length with a dremel/cut-off wheel.

Pulling the silicone tubing through the nose of the weight from the backside.. stretches its diameter slightly smaller around the pickup assy. making it easier to press it into the weight.

Just an FYI.. Fabricating a 1/2oz. clunk-tank would yield a 14.7cc capacity..

I drilled a 3/32 hole in the side of my fixture.. to aid in cutting an alloy tube to the correct length with a dremel/cut-off wheel.

Pulling the silicone tubing through the nose of the weight from the backside.. stretches its diameter slightly smaller around the pickup assy. making it easier to press it into the weight.

Just an FYI.. Fabricating a 1/2oz. clunk-tank would yield a 14.7cc capacity..

Re: a small clunk (fuel pick-up)

Re: a small clunk (fuel pick-up)

That's a neat little set-up Andrew. I'll have to remember that. Another thing that I like about this Uxcell brand 1/16" tubing is that it will flow more liquid than some tubes with 3X the wall-thickness. Dubro sm. (#221) for example; has an OD of .150" and an ID of .042" giving it a wall-thickness of .054". The Uxcell's OD is .093" with an ID of .062" giving it a wall-thickness of .0155". It stretches-on nice and tight to a 3/32" hard-tube.. and won't pull-off. Removal requires a rolling/peeling action with a thumbnail.

Re: a small clunk (fuel pick-up)

Re: a small clunk (fuel pick-up)

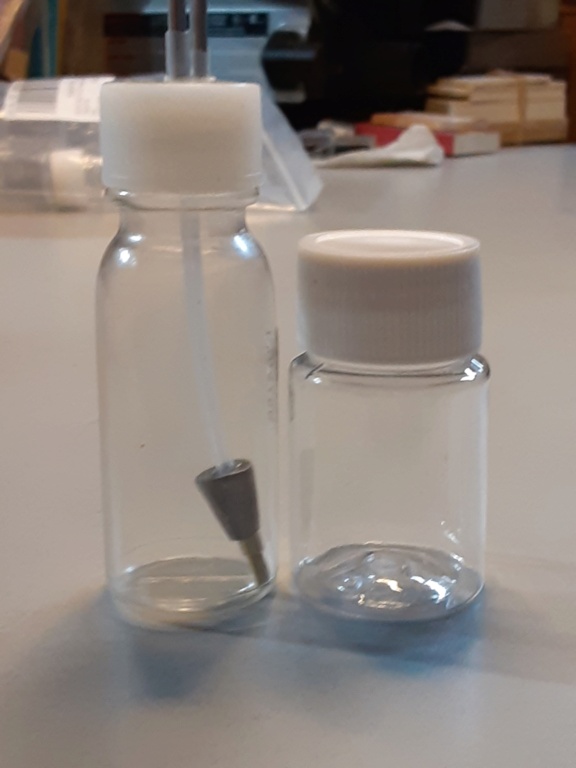

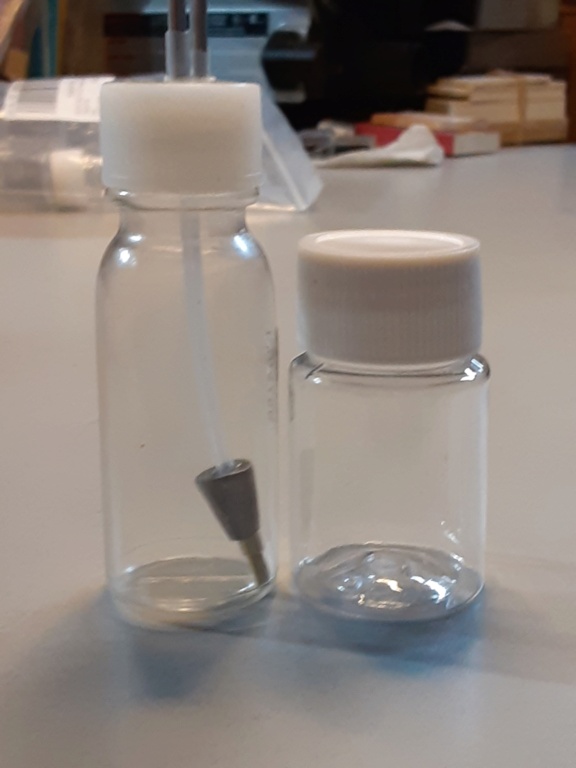

Here's a prototype/proof of concept mock-up clunk-tank using the above-referenced components..

I have some squatty-versions (see photo below..) of similar plastic bottles on order which are .5 oz. capacity.

I'm eager to test/fit these little bottles.. to see if my design can deliver positive results.

I have some squatty-versions (see photo below..) of similar plastic bottles on order which are .5 oz. capacity.

I'm eager to test/fit these little bottles.. to see if my design can deliver positive results.

Re: a small clunk (fuel pick-up)

Re: a small clunk (fuel pick-up)

Well, isn't that ever neat. Great job and idea roddie! But I wonder if teh lead, or metal from the weight may play games with our glow fuel?

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: a small clunk (fuel pick-up)

Re: a small clunk (fuel pick-up)

NEW222 wrote:Well, isn't that ever neat. Great job and idea roddie! But I wonder if teh lead, or metal from the weight may play games with our glow fuel?

Hi Chancey, The weights are lead apparently. I was under the impression that lead weights/sinkers had been prohibited for angling (fishing) use because of lead's toxicity. It doesn't say "lead" anywhere on the package.. but does have a P65warningCA.. (like what's listed on many things that we touch/handle).

I'll be more aware to wash my hands after handling the weights.. especially before snacking or smoking cigarettes. I'll be 6 years off the cigarettes as of this Winter.

I know that lead was good for gasoline..

Re: a small clunk (fuel pick-up)

Re: a small clunk (fuel pick-up)

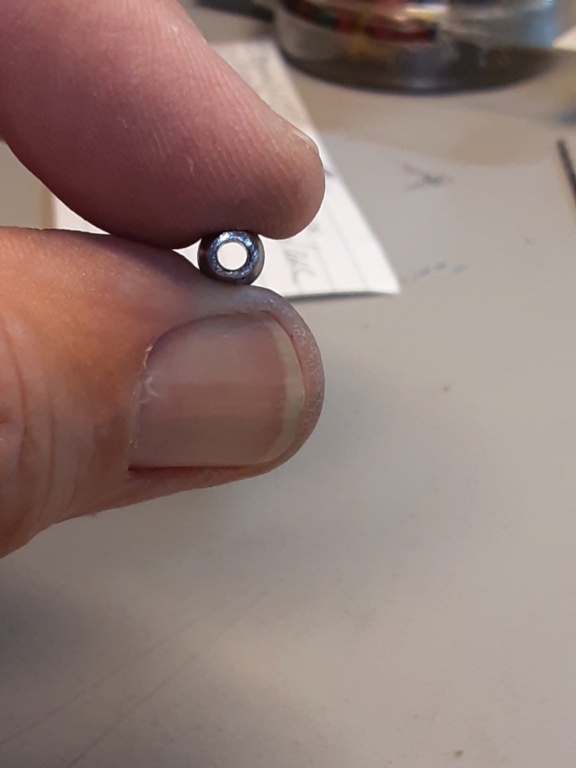

I messed-around with smaller weights today. I bought a pkg. of 1/16 oz. worm weights when I bought the 1/8 oz. ones. I learned a bit about how to drill-thru them.. by trial and error. These smaller weights are for some even smaller tubing that I found on Amazon.

These 1/16th oz. weights are much smaller. I expected them to be harder to drill-thru.. but I made a tool from a 1/4" dia. hardwood dowel that I "pencil-sharpened" which prevents deformation when tapping the weight "down" into the fixture for drilling.. and also for extraction through the bottom of the fixture.

I still need to use a sanding-block to shape the tapered-end.. but they're looking better.

I'm hoping to come up with a tiny clunk-tank that works.. I'll probably reach out here; for some "beta-testers".. as soon as I get some .5 oz. tanks built.

These 1/16th oz. weights are much smaller. I expected them to be harder to drill-thru.. but I made a tool from a 1/4" dia. hardwood dowel that I "pencil-sharpened" which prevents deformation when tapping the weight "down" into the fixture for drilling.. and also for extraction through the bottom of the fixture.

I still need to use a sanding-block to shape the tapered-end.. but they're looking better.

I'm hoping to come up with a tiny clunk-tank that works.. I'll probably reach out here; for some "beta-testers".. as soon as I get some .5 oz. tanks built.

15cc clear plastic bottles w/caps

15cc clear plastic bottles w/caps

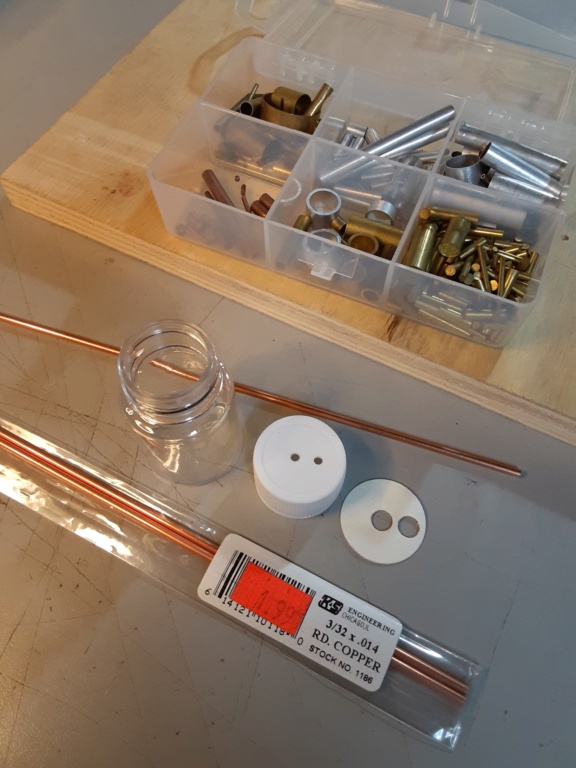

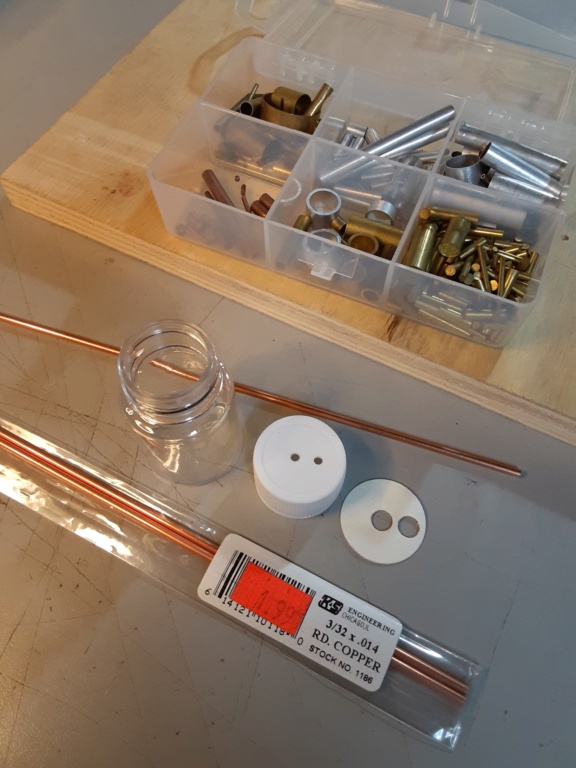

The one dozen 15cc clear plastic bottles w/caps arrived early today (Amazon Prime) along with another package of the 3/32" X 1/16" silicone tubing.

Just a reminder.. that this silicone tubing's ID is .059" (sold as 1/16") which is significantly larger than the Dubro sm. size that I've been using for decades. This latest stuff I found is more fragile.. due to its wall-thickness. Some smaller tubing will be coming in a day or so. I want to see what works with these new bottles..

The new 15cc (.5 oz.) is the stubby on the right..

the above photo is deceiving.. when compared with a bottom view of the same bottles;

The cap comes with an insert/seal.

Just a reminder.. that this silicone tubing's ID is .059" (sold as 1/16") which is significantly larger than the Dubro sm. size that I've been using for decades. This latest stuff I found is more fragile.. due to its wall-thickness. Some smaller tubing will be coming in a day or so. I want to see what works with these new bottles..

The new 15cc (.5 oz.) is the stubby on the right..

the above photo is deceiving.. when compared with a bottom view of the same bottles;

The cap comes with an insert/seal.

Re: a small clunk (fuel pick-up)

Re: a small clunk (fuel pick-up)

I'm digging your solution, Roddie. The working jig is wonderful!

The "fuel line" is in my wife's Amazon cart awaiting her selections. I hope you leave some for the rest of us.

Thanks for sharing the idea and materials list.

The "fuel line" is in my wife's Amazon cart awaiting her selections. I hope you leave some for the rest of us.

Thanks for sharing the idea and materials list.

_________________

Never enough time to build them all...always enough time to smash them all!

944_Jim- Diamond Member

Posts : 2022

Join date : 2017-02-08

Age : 59

Location : NE MS

small stuff..

small stuff..

944_Jim wrote:I'm digging your solution, Roddie. The working jig is wonderful!

The "fuel line" is in my wife's Amazon cart awaiting her selections. I hope you leave some for the rest of us.

Thanks for sharing the idea and materials list.

Jim! This is fun.. as well as challenging. It's just another example of my fascination with miniature stuff.

Some fabrication done.. but plenty more to do..

Forget about drilling holes in the cap.. I used a pc. of brass tubing as a punch with a block of Pine wood. Small hammers are good to have for small stuff.

The hole could have been cleaner because I'd already attempted to drill a hole. A standard twist-drill acts like a sheet-metal screw.. and actually twists a radial slot into the thin plastic.. rather than a clean hole. So I find a piece of tubing for a punch and proceed to "tap smartly" over the attempted drill-hole. Not bad. The "cap-seal" is foil-faced paper.

Feed-line is on-center through the cap using an expansion/compression type of seal. There will be a vent and a fill-tube done in a similar way.. except I'm planning using smaller tubes.

The clunk seems to work pretty well.. Note the position(s) of the orange sticker on the bottom of the bottle.

final assembly

final assembly

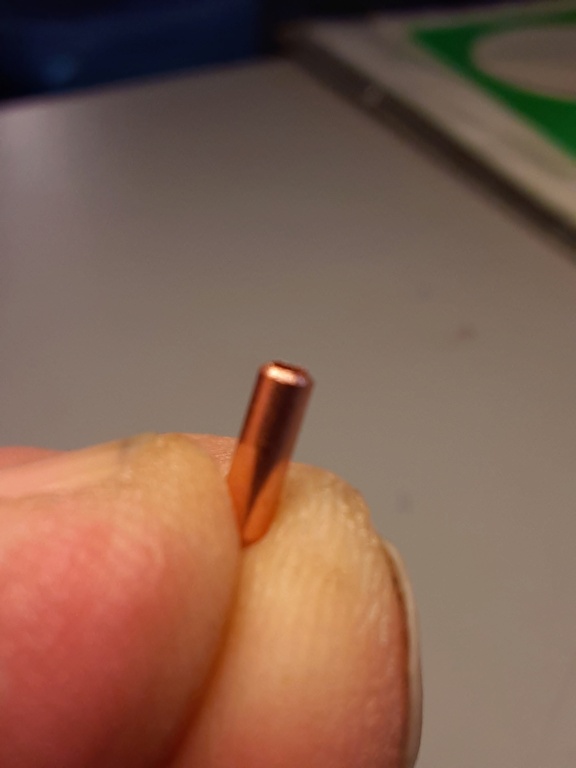

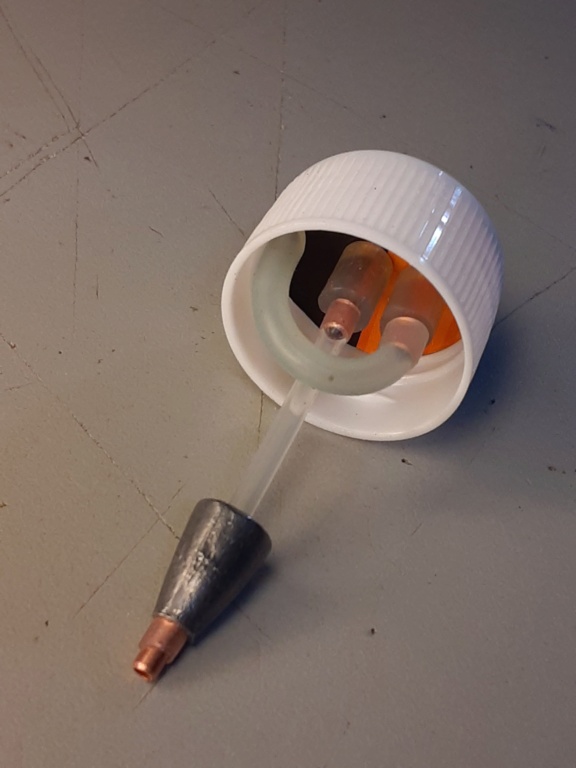

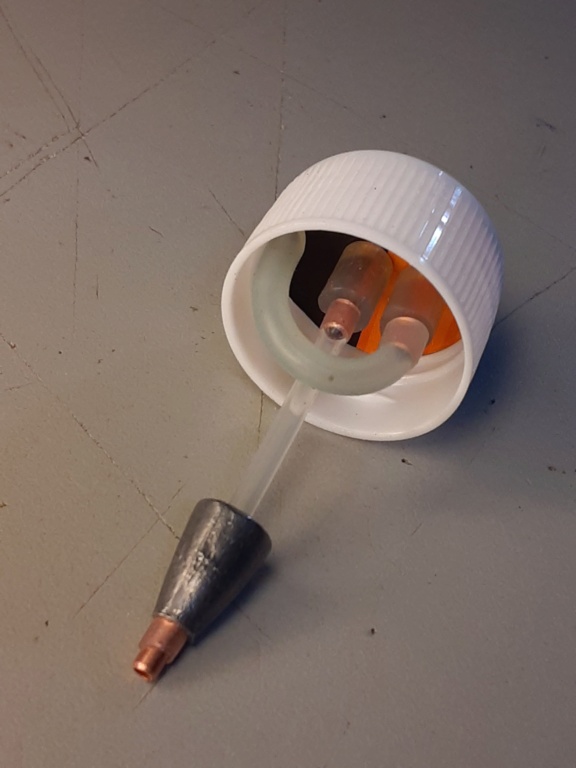

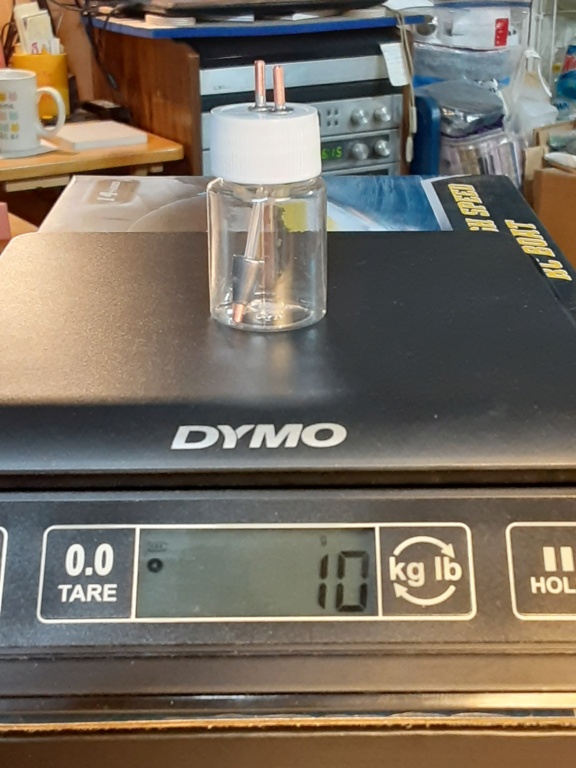

This has been a learning experience. The hard-tubes (all) are 3/32" copper. I used a short piece (.750") of 3/32" Aluminum tube and a pointed-tip on my soldering iron to melt holes through the cap.. which worked very well.

The cap-seal got a re-make for the use of my 1/8" hole-punch. I used the same thickness coated-paper (.020") from Duracell battery packaging. and used a 15/16" circle-template to trace a new cap-seal.

OCD... I cut the copper feed and vent tubes.. and soldered flat-washers on them which will bear-on the outside of the cap.

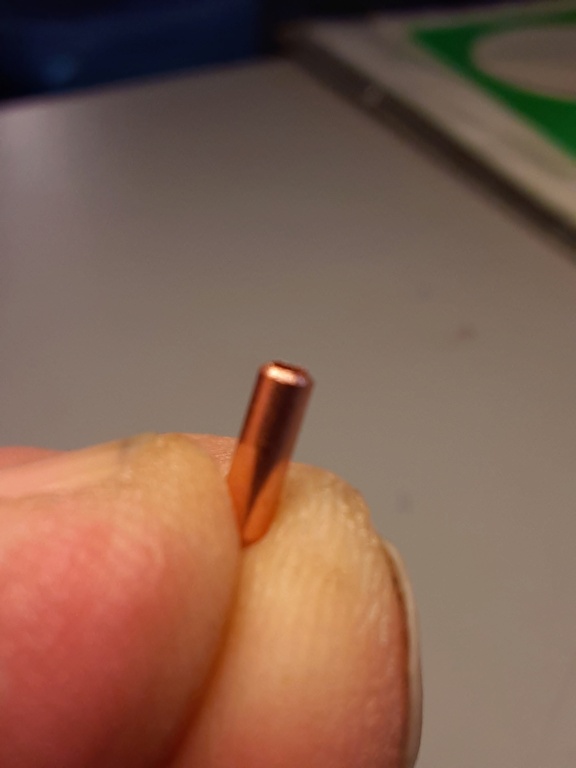

I was reading Brad's (1/2Anut) comments in one of his fuel tank threads, mentioning how he dresses the ends of his hard-tubes to prevent premature wear in the silicone tubing. It was a good reminder for me.. especially with this small stuff.

The pick-up "tip" (below) is only about 5/16" long.

Here's the final-assembly with cap off to show the inner detail.

and cap on.. showing the soldered-washers on the feed and vent-tubes.

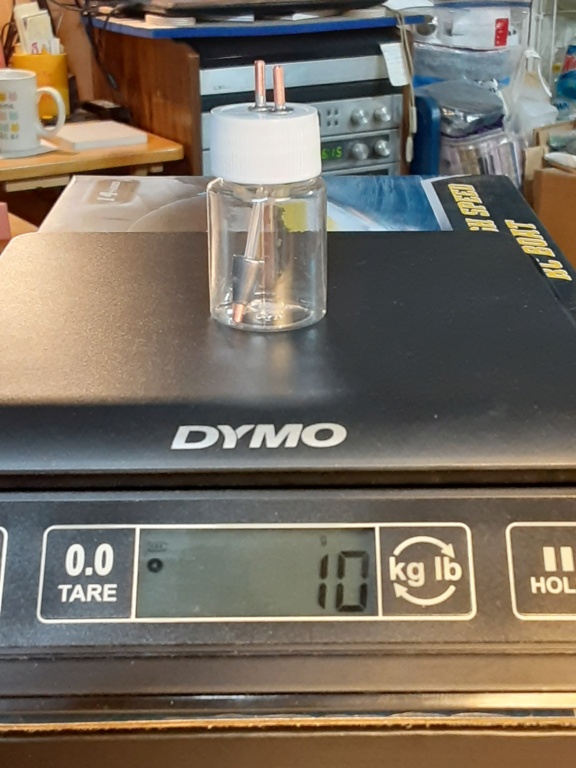

Weight empty is 10gr.

Now that there's a method created; building subsequent tanks would go quickly. This one took a lot of time.. but there was a good amount of trial and error to account for that. I need to leak-test the design though.. before I make any more.

The cap-seal got a re-make for the use of my 1/8" hole-punch. I used the same thickness coated-paper (.020") from Duracell battery packaging. and used a 15/16" circle-template to trace a new cap-seal.

OCD... I cut the copper feed and vent tubes.. and soldered flat-washers on them which will bear-on the outside of the cap.

I was reading Brad's (1/2Anut) comments in one of his fuel tank threads, mentioning how he dresses the ends of his hard-tubes to prevent premature wear in the silicone tubing. It was a good reminder for me.. especially with this small stuff.

The pick-up "tip" (below) is only about 5/16" long.

Here's the final-assembly with cap off to show the inner detail.

and cap on.. showing the soldered-washers on the feed and vent-tubes.

Weight empty is 10gr.

Now that there's a method created; building subsequent tanks would go quickly. This one took a lot of time.. but there was a good amount of trial and error to account for that. I need to leak-test the design though.. before I make any more.

Re: a small clunk (fuel pick-up)

Re: a small clunk (fuel pick-up)

Nice work on the tank Roddie….. Each step carefully thought thru and precisely worked out….I kinda like working on small finicky stuff too…. I bet the tank will serve well… Good job sir

Robert

Robert

rdw777- Diamond Member

Posts : 1716

Join date : 2021-03-11

Location : West Texas

Re: a small clunk (fuel pick-up)

Re: a small clunk (fuel pick-up)

rdw777 wrote:Nice work on the tank Roddie….. Each step carefully thought thru and precisely worked out….I kinda like working on small finicky stuff too…. I bet the tank will serve well… Good job sir

Robert

Thank You Robert!

I'm curious to see how my "vent" works out. I was scratching my head wondering how to configure it.....

I'm curious to see how my "vent" works out. I was scratching my head wondering how to configure it.....  So... the current arrangement features an internal "U" bend of Dubro sm. #221.. a 180 degree "tuck" into the cap-wall. It stays-put once the cap and bottle are assembled.. which can be verified via the clear PET bottle.

So... the current arrangement features an internal "U" bend of Dubro sm. #221.. a 180 degree "tuck" into the cap-wall. It stays-put once the cap and bottle are assembled.. which can be verified via the clear PET bottle.I'm not really that precise... but I do try to be careful..

passes 1st leak-test

passes 1st leak-test

Today I "got around to" doing a leak-test on this little 15cc (.5oz.) bottle and screw-cap arrangement. I grabbed a 10ml (cc) syringe from my glow-fuel related box; chock full of glow-fuel-related stuff.. proceeded to fit some silicone tubing and brought it; along with the little bottle-tank, upstairs to the kitchen sink.

Here's a photo of how I connected the two..

I connected the syringe to the "feed-line" tube to fill (tap water) and to also evacuate the water from the tank. It took 1.5 syringefuls of water to fill the bottle.

When disconnecting from the bottle; I was mindful to support the hard-tube by putting my thumb on the soldered-washer.. before pulling-off the syringe-tubing. This safeguards against pulling the hard-tube out of the bottle-cap. It's the way I set it up.. so I'm familiar with the limitations.

With my thumb over the bottles' feed-tube; I rotate it.. in an attempt to simulate abrupt, violent aerobatic maneuvers..

There was no evidence of leakage.. however; this would not be a real-life scenario. A real-life scenario would be to fill through the vent.. and the feed-line would already be connected directly to the engines' NVA/carb.

If I were to alternately fill through the vent-tube.. I may have experienced some back-flow leakage following disconnection of the syringe. Shouldn't this condition reverse if there's a vacuum present in the venturi? The fill-tube is the only tube open to the atmosphere in this app.

Here's a thought; try opening your needle-valve fully (very rich)... before fueling an external tank. If the tank has a 3rd tube (vent)... plug-it while introducing the fuel. Any air in the tank will purge through the feed-line and carb. When there's no more air; you'll "see" fuel start to flow through the feed-line and to the NVA/engine. At that point.. you should pinch-off and remove your fueling-bulb or syringe.. then reset your needle to where it should be for optimal running. The engine won't have to draw from the external tank.. because the feed-line from it will be fuel-purged..

Oh yea... when I evacuated the water, I just "drew-back" on the syringe.. which sucked-out about 2/3 of the tank. I disconnect and drain the syringe and reconnect. Drawing-back again empties the bottle.. and I mean emptied. I was surprised. The clunk works very nicely.

My little brain works so hard on these things.... but it's fun for me.

but it's fun for me.

Here's a photo of how I connected the two..

I connected the syringe to the "feed-line" tube to fill (tap water) and to also evacuate the water from the tank. It took 1.5 syringefuls of water to fill the bottle.

When disconnecting from the bottle; I was mindful to support the hard-tube by putting my thumb on the soldered-washer.. before pulling-off the syringe-tubing. This safeguards against pulling the hard-tube out of the bottle-cap. It's the way I set it up.. so I'm familiar with the limitations.

With my thumb over the bottles' feed-tube; I rotate it.. in an attempt to simulate abrupt, violent aerobatic maneuvers..

There was no evidence of leakage.. however; this would not be a real-life scenario. A real-life scenario would be to fill through the vent.. and the feed-line would already be connected directly to the engines' NVA/carb.

If I were to alternately fill through the vent-tube.. I may have experienced some back-flow leakage following disconnection of the syringe. Shouldn't this condition reverse if there's a vacuum present in the venturi? The fill-tube is the only tube open to the atmosphere in this app.

Here's a thought; try opening your needle-valve fully (very rich)... before fueling an external tank. If the tank has a 3rd tube (vent)... plug-it while introducing the fuel. Any air in the tank will purge through the feed-line and carb. When there's no more air; you'll "see" fuel start to flow through the feed-line and to the NVA/engine. At that point.. you should pinch-off and remove your fueling-bulb or syringe.. then reset your needle to where it should be for optimal running. The engine won't have to draw from the external tank.. because the feed-line from it will be fuel-purged..

Oh yea... when I evacuated the water, I just "drew-back" on the syringe.. which sucked-out about 2/3 of the tank. I disconnect and drain the syringe and reconnect. Drawing-back again empties the bottle.. and I mean emptied. I was surprised. The clunk works very nicely.

My little brain works so hard on these things....

Re: a small clunk (fuel pick-up)

Re: a small clunk (fuel pick-up)

Fast-forward 10 months....  I ran this little clunk-tank on a "bench-run" fixture a few times this past Summer..

I ran this little clunk-tank on a "bench-run" fixture a few times this past Summer..

So... my little clunk-tank design worked pretty good on bench-runs... but the balloon-style (non-pressure) fuel-cell has been gaining popularity with 1/2A and sub-1/2A applications.

This makes a micro-clunk design a tough-sell with modelers.... but I actually like the mechanics of it.

I was "straightening-out" around the shop tonight.. and saw the bench-test fixture with the little empty bottle.. and thought; "I need to flush that out with detergent... to keep it nice.." so I removed it from its mount, then found a 20ML syringe and fitted a short length of silicone fuel-line into its nozzle to connect to the tank's feed-line fitting.

I filled a small cup with DW detergent and warm-water to facilitate the flush.. and proceeded to draw-it into the syringe and connect it to the tank.

There were no signs of deterioration from the Sig "Champion 25" (% nitro) glow-fuel.. in any of the little clunk-tank's components.

It felt good to have made a "micro-clunk" tank that fed my bench-test engines flawlessly.. and hasn't shown any ill-effects from not being flushed since the beginning of the Summer.

So... my little clunk-tank design worked pretty good on bench-runs... but the balloon-style (non-pressure) fuel-cell has been gaining popularity with 1/2A and sub-1/2A applications.

This makes a micro-clunk design a tough-sell with modelers.... but I actually like the mechanics of it.

I was "straightening-out" around the shop tonight.. and saw the bench-test fixture with the little empty bottle.. and thought; "I need to flush that out with detergent... to keep it nice.." so I removed it from its mount, then found a 20ML syringe and fitted a short length of silicone fuel-line into its nozzle to connect to the tank's feed-line fitting.

I filled a small cup with DW detergent and warm-water to facilitate the flush.. and proceeded to draw-it into the syringe and connect it to the tank.

There were no signs of deterioration from the Sig "Champion 25" (% nitro) glow-fuel.. in any of the little clunk-tank's components.

It felt good to have made a "micro-clunk" tank that fed my bench-test engines flawlessly.. and hasn't shown any ill-effects from not being flushed since the beginning of the Summer.

Similar topics

Similar topics» Fuel clunk modify

» Large fuel-line/small nipple

» HYDROMAT fuel pick-up

» small fuel filters for 1/2A

» Pump to fuel small tanks

» Large fuel-line/small nipple

» HYDROMAT fuel pick-up

» small fuel filters for 1/2A

» Pump to fuel small tanks

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules