Log in

Search

Latest topics

» My N-1R build logby KariFS Today at 9:56 pm

» New Model Build

by bsadonkill Today at 7:31 pm

» Project Cox .049 r/c & Citabrian Champion

by MauricioB Today at 6:49 pm

» Octura engines?

by UncleLumpy Today at 4:16 pm

» Tatone EM-7

by sosam117 Today at 3:50 pm

» Honoring All Who Served

by roddie Today at 4:59 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Yesterday at 11:30 pm

» Free Flight Radio Assist

by TD ABUSER Yesterday at 9:41 pm

» Cox 020 PeeWee rebuild questions

by balogh Yesterday at 9:36 pm

» K&B .09 Torpedo Engine

by LooseSpinner99 Yesterday at 8:01 pm

» 3D printing of parts?

by UncleLumpy Yesterday at 5:08 pm

» L4 Grasshopper

by bottomgun Yesterday at 3:58 pm

Cox Engine of The Month

So, I've got this engine problem

Page 1 of 1

So, I've got this engine problem

So, I've got this engine problem

I have never had one beat me before, but this one is testing me, and it's an important engine that I want to save.

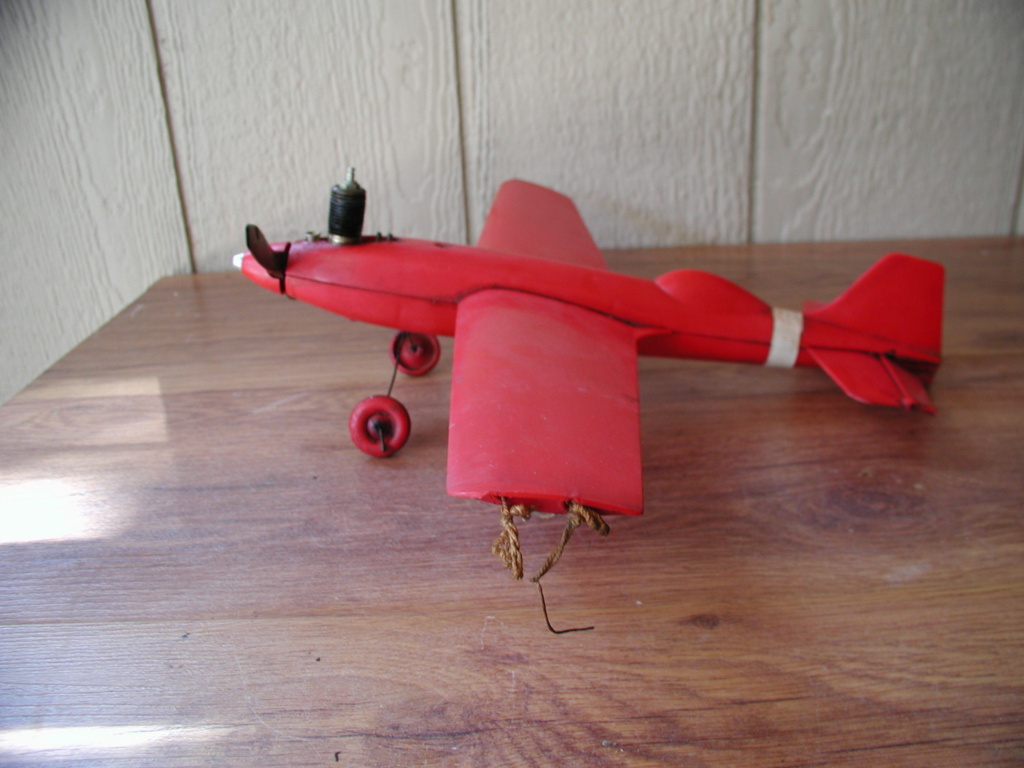

First, totally locked up Spitzy Spitfire. Berryman's soak, needle and glow plug out, heated to smoking with a heat gun (I hate doing that, but) and I'm getting about five degrees of motion either side of center up against a dead and I'm talking a dead stop no castor goo give at all.

I can't unscrew the backplate to check the crank and I'm not unscrewing the cylinder until I know what is going on. I'm thinking the motion is the crank taking up connecting rod slop as the piston is not moving at all. My last resort is an A/F boil but that reduces the anodizing and I don't want to do that.

Right now it's sitting in 91% overnight, but that is not going to help. I'm thinking a broken connecting rod.

Any ideas?

Strange these Spitzy's. No spray bar with a center hole, just two screw in pieces with a nozzle.

Oh yes, I have an identical spare, but it's not as nice and it's missing the NVA which I will have to swap.

First, totally locked up Spitzy Spitfire. Berryman's soak, needle and glow plug out, heated to smoking with a heat gun (I hate doing that, but) and I'm getting about five degrees of motion either side of center up against a dead and I'm talking a dead stop no castor goo give at all.

I can't unscrew the backplate to check the crank and I'm not unscrewing the cylinder until I know what is going on. I'm thinking the motion is the crank taking up connecting rod slop as the piston is not moving at all. My last resort is an A/F boil but that reduces the anodizing and I don't want to do that.

Right now it's sitting in 91% overnight, but that is not going to help. I'm thinking a broken connecting rod.

Any ideas?

Strange these Spitzy's. No spray bar with a center hole, just two screw in pieces with a nozzle.

Oh yes, I have an identical spare, but it's not as nice and it's missing the NVA which I will have to swap.

rsv1cox- Top Poster

Posts : 11214

Join date : 2014-08-18

Location : West Virginia

Re: So, I've got this engine problem

Re: So, I've got this engine problem

Several piece spray bar arrangement with separate ends is the same as on my A.C. Gilberts. You probably could substitute a standard spray bar arrangement for small engines on it. However, if you have internal damage as it sounds, may be another parts engine.

GallopingGhostler- Top Poster

Posts : 5700

Join date : 2013-07-14

Age : 70

Location : Clovis NM or NFL KC Chiefs

Fledgling

Fledgling

If it where mine, I would remove all heat damageable plastic parts etc. And heat in car engine oil and see if that tree's of stuck stuff any.

I have used this method many times to free off stuck stuff before, not only model engines but mechanical components for cars, bikes, marine engines etc. etc.

This " whole unit heating" will help in castor goooo softening and removal and help in c/case rear cover removal I think.

Some crank rotation is good, so maybe piston is stuck, hope con rod is not broken.

Have you ever heard this engine running at all ?

Hope it didn't sieze solid whilst running !

I also find that modern UK petrol is good at cleaning castor gooo'd up engines, but the baked on gum from some non castor fuels is really difficult to remove. Really difficult to remove.

Take your time, steady as you go, a a few " please God" 's.....

I have used this method many times to free off stuck stuff before, not only model engines but mechanical components for cars, bikes, marine engines etc. etc.

This " whole unit heating" will help in castor goooo softening and removal and help in c/case rear cover removal I think.

Some crank rotation is good, so maybe piston is stuck, hope con rod is not broken.

Have you ever heard this engine running at all ?

Hope it didn't sieze solid whilst running !

I also find that modern UK petrol is good at cleaning castor gooo'd up engines, but the baked on gum from some non castor fuels is really difficult to remove. Really difficult to remove.

Take your time, steady as you go, a a few " please God" 's.....

Coxfledgling- Gold Member

- Posts : 404

Join date : 2021-01-10

Location : Near Caernarfon, Snowdonia, Wales, UK

Re: So, I've got this engine problem

Re: So, I've got this engine problem

IF you have soaked the whole engine in Berrymans and heated it to smoking and haven't got any piston movement...that's a tough old bird. I've had similar stuck Testors engines. Injected PB Parts Blaster in the top and let sit a day, turnover and fill the bottom of the crankcase with PB flip it over so the penetrating fliud gets in the bypass port alongside the piston.Let it set overnight. With the glowhead removed I used a hardwood dowel sized to fit the center of the piston and gently tapped until the piston broke free. In your case with the Spitzy if you can't get the anodized head off maybe try a bamboo chopstick thru the glowplug hole.

EDIT: For future reference. The Piston at Bottom. bamboo stick reads .75" to top of head. Just so ya don't try tapping it down any further if it's stuck!!

Glad to see you went ahead hard on that castor goo!

EDIT: For future reference. The Piston at Bottom. bamboo stick reads .75" to top of head. Just so ya don't try tapping it down any further if it's stuck!!

Glad to see you went ahead hard on that castor goo!

Last edited by Marleysky on Fri Aug 26, 2022 6:56 pm; edited 1 time in total

Marleysky- Top Poster

Posts : 3618

Join date : 2014-09-29

Age : 72

Location : Grand Rapids, MI

Re: So, I've got this engine problem

Re: So, I've got this engine problem

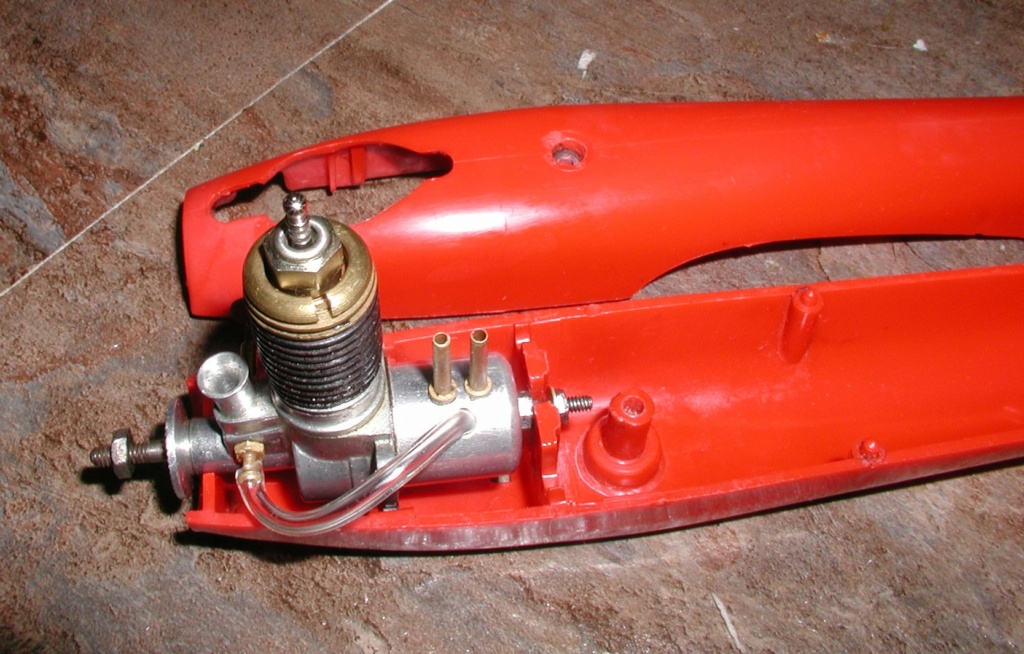

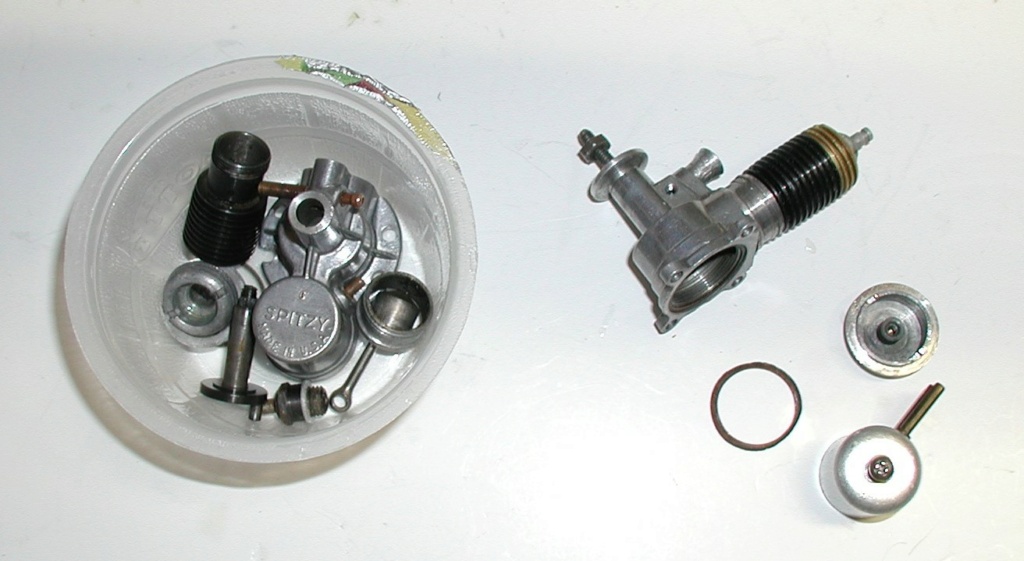

Well I got the backplate off. Caveman style, when all else fails, last resort.........torch it.

You can't cloth buffer it in the vice, torch would ignite. Wood blocks, forget it! Vice it up vertical best position, Cox wrench in the slots, max heat and downward force, and hope. Thankfully, no damage, not even a scratch.

It's not the connecting rod, or the crank which spins 360 degrees. Burned fingers and hands I got upward movement of the piston, but just a little, enough to cover the exhaust ports and full stop. This cylinder is max goo. I filled the bottom end with light oil, let is soak and cool then try the torch again.

Rather than putting a strain on the con rod, I think I will heat the cylinder and using a wooden dowel tap the piston down and remove it from the bottom, then more Berrymans soak and a bore brush. Less intrusive measures first.

Stay tuned.........

Ah, Rene we were typing at the same time. We read each others mind. Scary right...........

BTW, either this is a domed piston or there is a bunch of castor buildup on one side (viewed through the exhaust ports) on the top of the piston.

You can't cloth buffer it in the vice, torch would ignite. Wood blocks, forget it! Vice it up vertical best position, Cox wrench in the slots, max heat and downward force, and hope. Thankfully, no damage, not even a scratch.

It's not the connecting rod, or the crank which spins 360 degrees. Burned fingers and hands I got upward movement of the piston, but just a little, enough to cover the exhaust ports and full stop. This cylinder is max goo. I filled the bottom end with light oil, let is soak and cool then try the torch again.

Rather than putting a strain on the con rod, I think I will heat the cylinder and using a wooden dowel tap the piston down and remove it from the bottom, then more Berrymans soak and a bore brush. Less intrusive measures first.

Stay tuned.........

Ah, Rene we were typing at the same time. We read each others mind. Scary right...........

BTW, either this is a domed piston or there is a bunch of castor buildup on one side (viewed through the exhaust ports) on the top of the piston.

Last edited by rsv1cox on Fri Aug 26, 2022 9:59 pm; edited 1 time in total

rsv1cox- Top Poster

Posts : 11214

Join date : 2014-08-18

Location : West Virginia

Re: So, I've got this engine problem

Re: So, I've got this engine problem

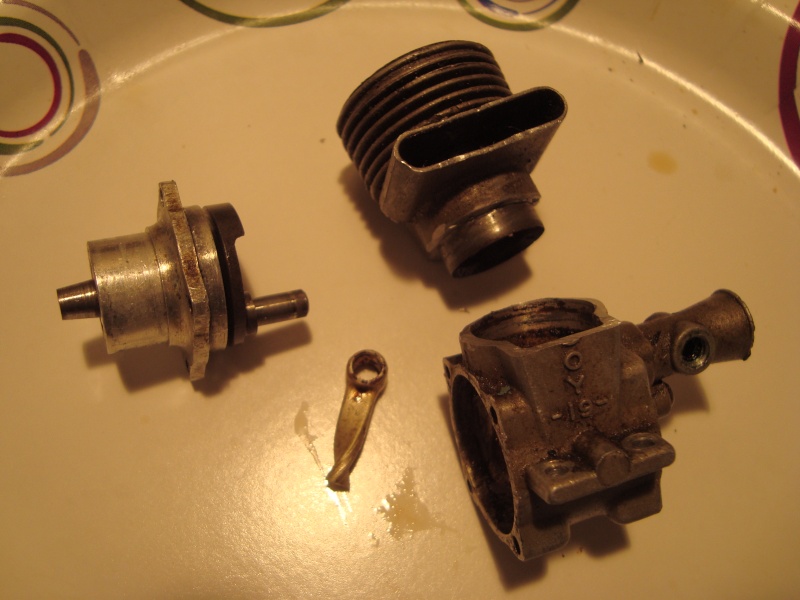

Isn't that the con. rod there in soak? That is a tough one must have been running on pure castor mix ? I had about 19 of them at one time and Had to get rid of most of them  hate it now and then too . O well

hate it now and then too . O well

getback- Top Poster

Posts : 10428

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: So, I've got this engine problem

Re: So, I've got this engine problem

getback wrote:Isn't that the con. rod there in soak? That is a tough one must have been running on pure castor mix ? I had about 19 of them at one time and Had to get rid of most of themhate it now and then too . O well

19 of them Eric..............

You're going all rsv on me.

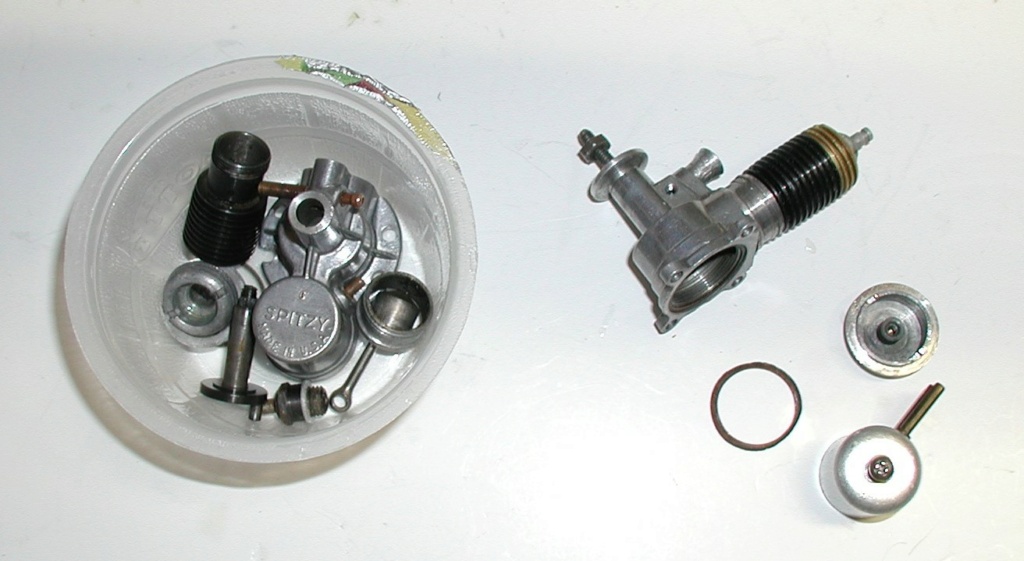

You're going all rsv on me. It is a domed piston and the cylinder is full of castor goo. I'm going to have to remove the crank and tap it out the bottom. But right now all those parts are soaking in Berrymans.

I heated and removed the anodized head, short soak for that. If your careful the torch works better than a heat gun, you can direct the heat right where you want it, and you don't get the smoke that you get with the gun. Five second torch application vice 30 seconds + with the gun.

Best friends.

rsv1cox- Top Poster

Posts : 11214

Join date : 2014-08-18

Location : West Virginia

Re: So, I've got this engine problem

Re: So, I've got this engine problem

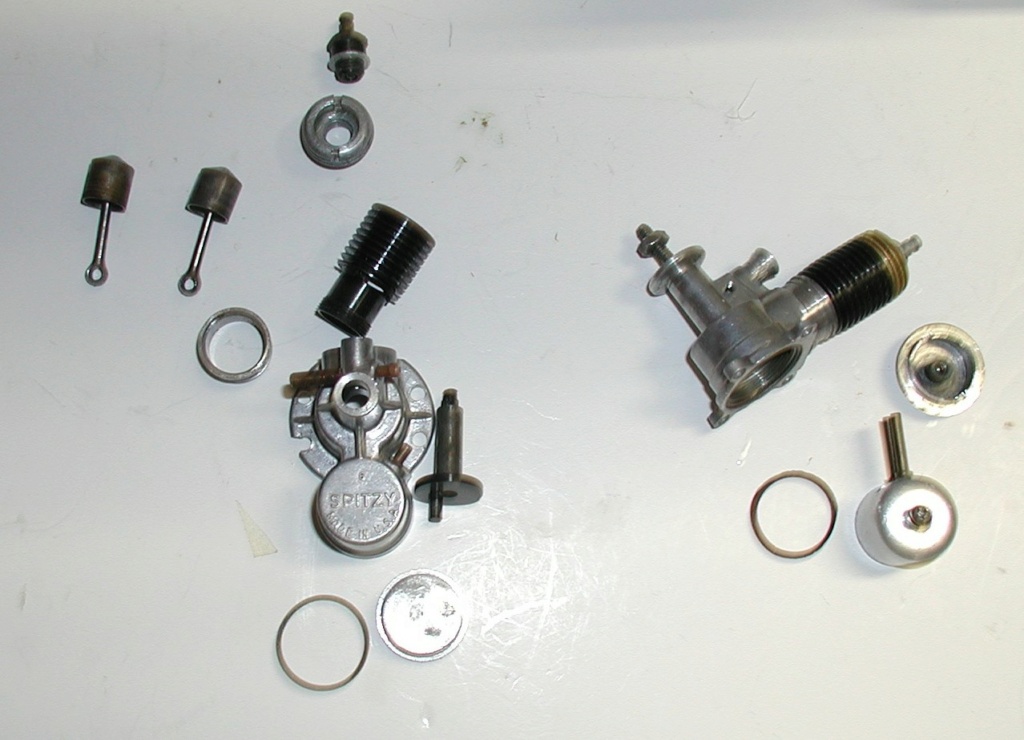

When you stop being careful, good things happen.

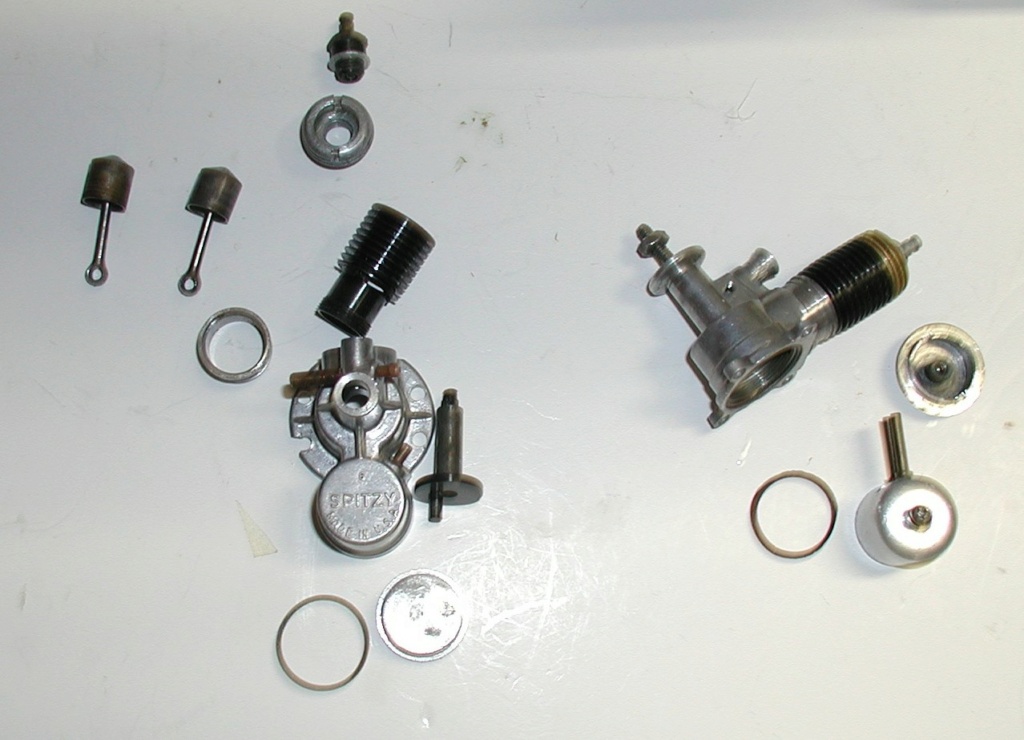

After the Berryman's soak I just muscled it apart. Badly scored piston. I was hoping that I could reset the connecting rod but it's keeper is too far gone. I have a couple of parts Spitzy's that will contribute.

I could have removed the crankshaft, but that was the only proper working part of the engine so I left it. Heat gun and a dowel removed the piston through the bottom but it wasn't easy. Oiled bore brush cleaned up the cylinder to very good. Saveable.

After the Berryman's soak I just muscled it apart. Badly scored piston. I was hoping that I could reset the connecting rod but it's keeper is too far gone. I have a couple of parts Spitzy's that will contribute.

I could have removed the crankshaft, but that was the only proper working part of the engine so I left it. Heat gun and a dowel removed the piston through the bottom but it wasn't easy. Oiled bore brush cleaned up the cylinder to very good. Saveable.

rsv1cox- Top Poster

Posts : 11214

Join date : 2014-08-18

Location : West Virginia

crankbndr- Top Poster

- Posts : 3109

Join date : 2011-12-10

Location : Homestead FL

Re: So, I've got this engine problem

Re: So, I've got this engine problem

crankbndr wrote:You are kinder and gentler that I am. The last one that gave trouble got hack sawed!!

What round for McCoy .19?

How about a "Mc" Knight 52 cal muzzle loader.

Goodness CB, a hacksaw! You even twisted that poor little con-rod.

Got a little help coming for the pistonless Baby Spit. Hopefully the piston is ok. Parts engine. Might not have to use one of my good ones.

There is an anodized version on ebay now for $175.00. Dreamer. Nice engine, but...........

From Kazakhstan

rsv1cox- Top Poster

Posts : 11214

Join date : 2014-08-18

Location : West Virginia

Re: So, I've got this engine problem

Re: So, I've got this engine problem

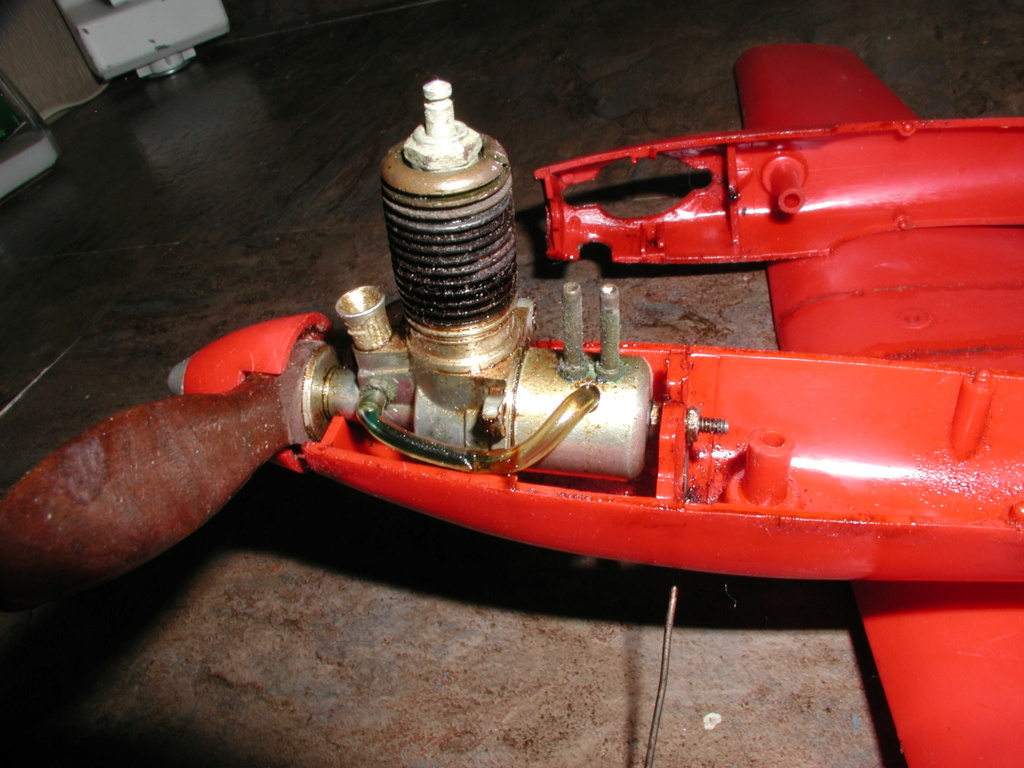

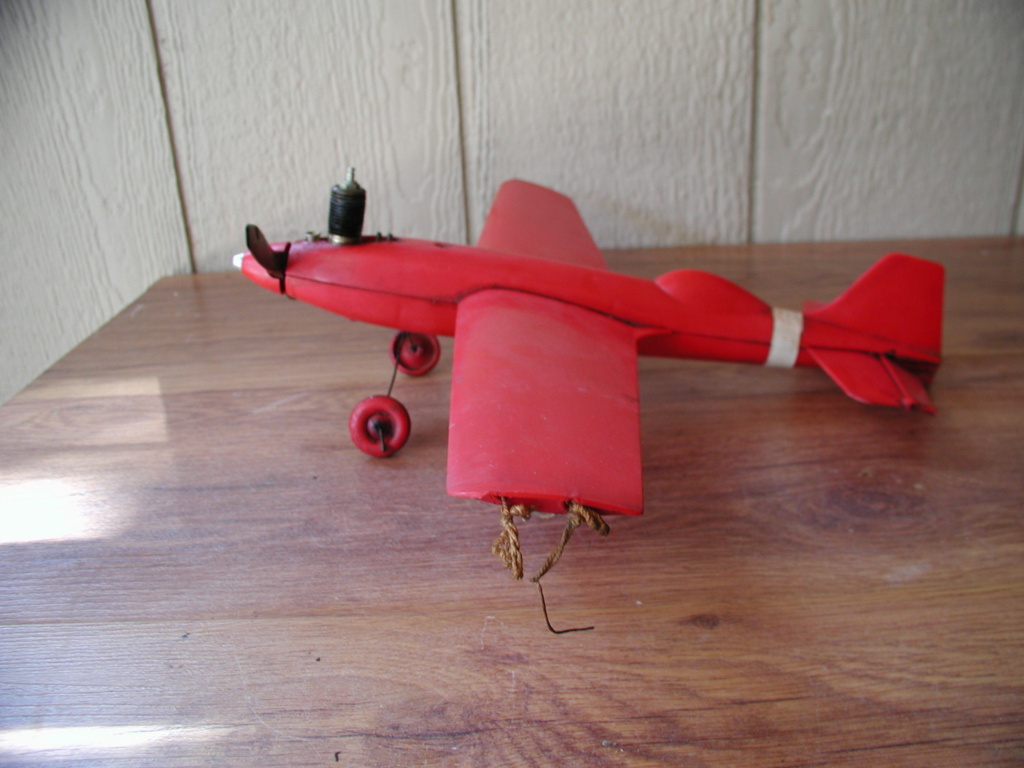

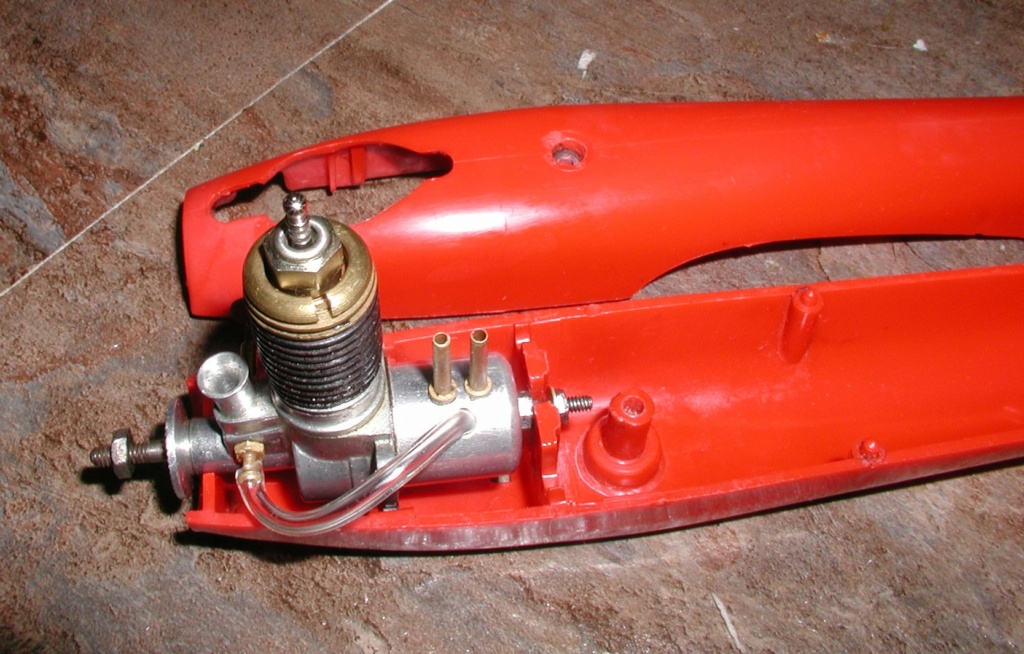

Simple temporary solution, just swap parts. When I get the parts engine in and replace the damaged piston/con rod I will just swap them back.

Done for now and flyable. Wierd prop nut #4 but thread is not forty. Infant prop stays on for now but it will find it's way to a K&B Infant and be replaced by a W/M prop. No need for the PO's adhesive medical tape. The broken tail stud is fixed.

Done for now and flyable. Wierd prop nut #4 but thread is not forty. Infant prop stays on for now but it will find it's way to a K&B Infant and be replaced by a W/M prop. No need for the PO's adhesive medical tape. The broken tail stud is fixed.

rsv1cox- Top Poster

Posts : 11214

Join date : 2014-08-18

Location : West Virginia

Re: So, I've got this engine problem

Re: So, I've got this engine problem

That cleaned up nicely, Bob.

GallopingGhostler- Top Poster

Posts : 5700

Join date : 2013-07-14

Age : 70

Location : Clovis NM or NFL KC Chiefs

rsv1cox- Top Poster

Posts : 11214

Join date : 2014-08-18

Location : West Virginia

Re: So, I've got this engine problem

Re: So, I've got this engine problem

Somehow.....

Last edited by rsv1cox on Mon Sep 05, 2022 6:49 pm; edited 1 time in total

rsv1cox- Top Poster

Posts : 11214

Join date : 2014-08-18

Location : West Virginia

Re: So, I've got this engine problem

Re: So, I've got this engine problem

Finally got the parts Spitzy in but no wrench to remove the negative hex head case back plate. Points were worn on the hex, somebody tried to get in there before. Nothing to lose I used a 5/16" bolt with jam nuts, heated the case and it unscrewed pretty easy. Big improvement over the notched head covers.

Looks like a good conrod/piston too. Might save the original gold head engine yet.

I have never seen a Spitzy/Royal Spitfire wrench yet. Maybe they intended you to use the 5/16 but on tank equipped engines you would have to drill a hole in the head.

Looks like a good conrod/piston too. Might save the original gold head engine yet.

I have never seen a Spitzy/Royal Spitfire wrench yet. Maybe they intended you to use the 5/16 but on tank equipped engines you would have to drill a hole in the head.

rsv1cox- Top Poster

Posts : 11214

Join date : 2014-08-18

Location : West Virginia

Re: So, I've got this engine problem

Re: So, I've got this engine problem

Bob here is some good info if you have not seen before >> http://www.modelenginecollectors.org/PDF/tinyengines.pdf Still don't see a wrench for the back plate i was thinking a threaded coupler would work with the one that have a screw mount .

getback- Top Poster

Posts : 10428

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: So, I've got this engine problem

Re: So, I've got this engine problem

Bob, excuse me for questioning your knowledge of these engines, but I don't believe that the head is anodised gold, but is actually solid brass. I had my suspicions, but the link Eric gave us has confirmed that they, at least some, have brass heads. Maybe a bit of unnecessary care taken in the clean-up when trying to avoid damaging the anodising.

Rod

Rod

Oldenginerod- Top Poster

- Posts : 4017

Join date : 2012-06-16

Age : 62

Location : Drouin, Victoria

Re: So, I've got this engine problem

Re: So, I've got this engine problem

Thanks Eric, I have that site logged in my favorite places. It's an excellent referance.

and Rod yes. I'm afraid these mental lapses are going to creep into my posts as I get older. I'm finding that 85 isn't 75 or even 80.

I made the piston/con rod swap. Fit fine. Flipped it over a couple of times. Put the back cover on flipped it some more and it hung up. Ok, so the connecting rod came off the pin. Took it apart again and found the other half of the broken keeper jamming up the works. (end of magnet)

Fine now with good compression. Now I have to press out and swap the NVA.

and Rod yes. I'm afraid these mental lapses are going to creep into my posts as I get older. I'm finding that 85 isn't 75 or even 80.

I made the piston/con rod swap. Fit fine. Flipped it over a couple of times. Put the back cover on flipped it some more and it hung up. Ok, so the connecting rod came off the pin. Took it apart again and found the other half of the broken keeper jamming up the works. (end of magnet)

Fine now with good compression. Now I have to press out and swap the NVA.

rsv1cox- Top Poster

Posts : 11214

Join date : 2014-08-18

Location : West Virginia

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules