Log in

Search

Latest topics

» Tee Dee .020 combat modelby roddie Today at 1:34 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» My latest doodle...

by batjac Yesterday at 9:47 pm

» My N-1R build log

by roddie Yesterday at 8:50 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

» My current avatar photo

by roddie Mon Nov 18, 2024 9:05 pm

Cox Engine of The Month

Just HOW do you test compression??

Page 1 of 1

Marleysky- Top Poster

Posts : 3618

Join date : 2014-09-28

Age : 72

Location : Grand Rapids, MI

Re: Just HOW do you test compression??

Re: Just HOW do you test compression??

I believe that's the engine I posted a picture of a short time ago. That's a very early Enya .45 6001 which has no head fins on the cylinder. Essentially a baldie, it's not a common engine as this is a plain bearing .45. The later 6001 engines are all ball bearing. Essentially a Enya .35 on steroids. Sad that the head is missing as this is more than likely unobtainable.

Ken Cook- Top Poster

- Posts : 5637

Join date : 2012-03-27

Location : pennsylvania

Re: Just HOW do you test compression??

Re: Just HOW do you test compression??

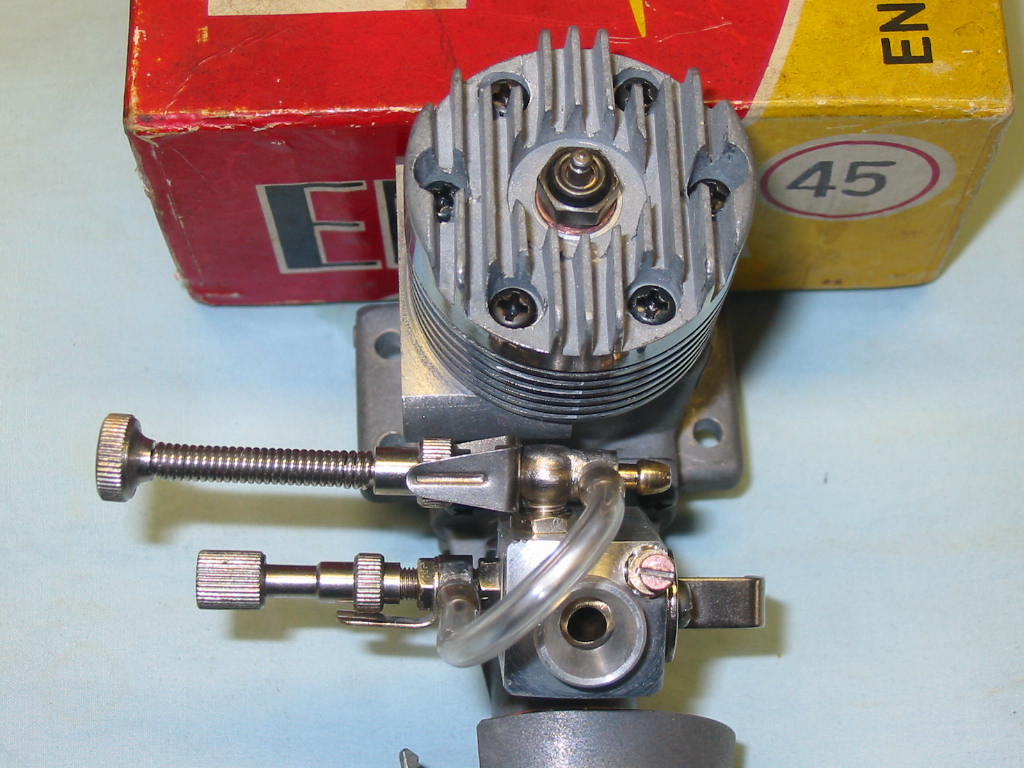

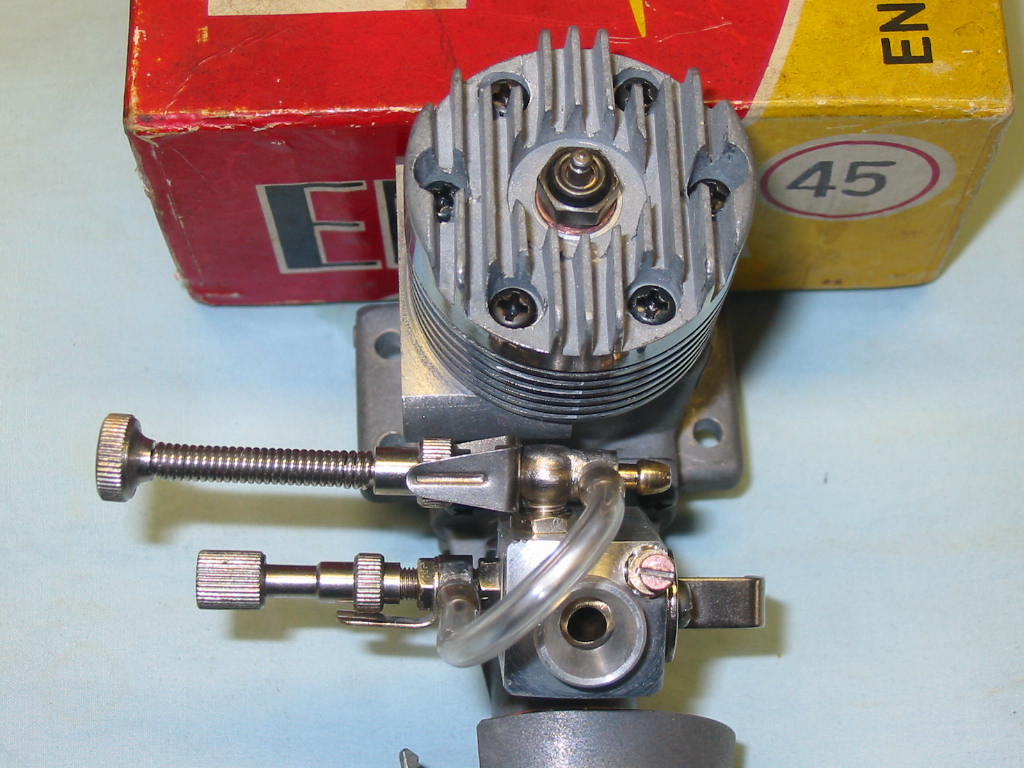

I have a Enya 45 model #6001 that was my dad's. and the spinner was included with the engine.

Dad purchased it in 1965. to use in a Sr. Falcon 3 channel plane.

I cleaned it up and refurbished it.

It has both the U-control needle valve and the R/C carburetor.

Original Enya Glo plug from back then too. ( still glows brightly)

It also has a Enya strap-on muffler (same gray color) but doesn't fit on the engine when the R/C carb is installed.

The R/C carburetor has two needle valves for adjustment

It is a plain bearing engine.

Dad purchased it in 1965. to use in a Sr. Falcon 3 channel plane.

I cleaned it up and refurbished it.

It has both the U-control needle valve and the R/C carburetor.

Original Enya Glo plug from back then too. ( still glows brightly)

It also has a Enya strap-on muffler (same gray color) but doesn't fit on the engine when the R/C carb is installed.

The R/C carburetor has two needle valves for adjustment

It is a plain bearing engine.

sosam117- Diamond Member

- Posts : 1350

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Re: Just HOW do you test compression??

Re: Just HOW do you test compression??

Getting back to the gist of the original post, I'd suggest that a firmly placed thumb over the top of the cylinder would make most engines feel like they had good compression. A little like the other ads claiming a "good pop" when turned over, but there's no prop attached. Try turning over a healthy .09 and larger engine by just twiddling the prop driver!

Last edited by Oldenginerod on Sun Sep 19, 2021 5:51 am; edited 1 time in total

Oldenginerod- Top Poster

- Posts : 4018

Join date : 2012-06-15

Age : 62

Location : Drouin, Victoria

Re: Just HOW do you test compression??

Re: Just HOW do you test compression??

Testing compression in COX engines and any other engine with its exhaust port visible is easily done by visual checking if bubbles indicate blow-by in the exhaust port when the piston moves towards top dead center. Apart from worn cylinders, it is poor head gaskets,or very rarely, a loose central electrode in COX head that may also contribute to compression losses, but these are easy to recognize with a bubble test, and mend.

I would say that if the blow-by does not develop for a few seconds while the piston is on TDC, the compression of the engine is more than adequate.

Most COX engines, if not abused, kept clean, and saved from lean runs, retain good compression for very long time..you will recall an experiment by COX proving that even after a run of 400 hours a COX engine still worked well but needed an electric starter to start.

The smaller the engine, the more the negative impact of blow-by on engine performance.

The higher the rpm of a given engine the lower the loss of power due to blow-by, as the time available for compressed gases to escape is inversely proportional with rpm.

Castor, that is not burnt with fuel, helps compression retention better than synthetic oils, and the varnish it leaves on the cylinder wall will also sit in and seal micro-scratches that otherwise would allow blow-by..

This is my experience at least..

I would say that if the blow-by does not develop for a few seconds while the piston is on TDC, the compression of the engine is more than adequate.

Most COX engines, if not abused, kept clean, and saved from lean runs, retain good compression for very long time..you will recall an experiment by COX proving that even after a run of 400 hours a COX engine still worked well but needed an electric starter to start.

The smaller the engine, the more the negative impact of blow-by on engine performance.

The higher the rpm of a given engine the lower the loss of power due to blow-by, as the time available for compressed gases to escape is inversely proportional with rpm.

Castor, that is not burnt with fuel, helps compression retention better than synthetic oils, and the varnish it leaves on the cylinder wall will also sit in and seal micro-scratches that otherwise would allow blow-by..

This is my experience at least..

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Just HOW do you test compression??

Re: Just HOW do you test compression??

I am in agreement with much of balogh posted.

Working for Caterpillar in the Fuel Systems division, when matching the plunger and barrel assemblies (similar to a piston and cylinder) the match clearance was about 0.005 microns and the matching and leak down was done in a environmentally controlled and "clean" room. Clean filtered air was forced into the room from above and duct work in the floor sucked up the dirty air.

The temperature was held between 68 and 72 degrees with the humidity held between 45 and 50%. Part of my job was every hour check on the temp and humidity gage that was recording the readings. There was also hooked up to that gage warning lights and a buzzer when either temperature or humidity was out of the controller specifications.

When the buzzer and lights would go off, matching and leak down testing was haulted until the tempature and humidity was back to operation temperatures.

Just like how jmendoza explained on his room at Cox.

https://www.coxengineforum.com/t15508-cox-tem-trol#202061

There was a vestibule(40' x 40')before you entered the match / leak down room. There you changed into you tyvek "clean" jumpsuit and before entering the room there was a automatic "bootie" machine that when you place your shoe into the machine and pull your shoe out you had this white bootie installed over your shoe.

Anyway back to the compression (leak down) testing.

The matched plunge and barrel would be assembled together, just like a piston into the cylinder.

Then with the barrel clamped face down onto the gage and the plunger set to a certain length, air was introduced.

After the air was introduced at a certain pressure, the leak down test has started.

The gage would check how much air was leaking by the match clearance in the allotted time that was allowed.

If there was to much air leakage the gage would fail that P&B assembly. If it passed, then it was trayed up and then rolled out the room on a conveyor for the next operation to be assembled into a completed injector.

That same gage was used for fuel rate flow. The plunger had a spiral cut on it that the gage turned and pulled the plunger out to set distances to check fuel rare flow. This was at 4 different lengths. If the flow was correct then it passed. If not it was rejected.

The barrel (piston) had what was considered a open/close ports. Similar to the bypass ports on a cylinder.

By the way, matching the plunger and barrels was done using air probes made by Etamic or Federal gaging equipment.

One was an air ring (for the plunger (piston) and the other was a air probe (rod) for the barrel (cylinder).

I can bet that Cox used the Federal gaging equipment to match their pistons with their cylinders.

This was my main job to keep the match gages and leak down gages accurate. Verifying the air probe and ring were accurate to the master rings (min/nom./max. - for linearity) and then verify that the matching of the ring and probe was accurate using the six min./nom./max rings and rods for linearity over the entire range and adjusting the gage accordingly to the certification of the masters to be within specifications.

One more thing. The best controlled room should be kept at 69° with 48% humidity. Reason being is that is considered the "zero" expansion/contraction of steel.

Ah, this brings back memories of my good times at Cat.

Did so well on the job, 6 months later after retiring, they asked me to come back to the job I retired from.

As a contract employee with less pay.

My replacement wasn't able to do the job as well as I did. By the way, they only filled my job after I left.

I trained no one before I left? And I did a computer program to help me calculate the match clearances between the masters.

I don't think anyone knew about that?

Sorry no photos as this is restricted. (even today with cell phones)

Retired - Quality Engineer Mike (sosam117)

Working for Caterpillar in the Fuel Systems division, when matching the plunger and barrel assemblies (similar to a piston and cylinder) the match clearance was about 0.005 microns and the matching and leak down was done in a environmentally controlled and "clean" room. Clean filtered air was forced into the room from above and duct work in the floor sucked up the dirty air.

The temperature was held between 68 and 72 degrees with the humidity held between 45 and 50%. Part of my job was every hour check on the temp and humidity gage that was recording the readings. There was also hooked up to that gage warning lights and a buzzer when either temperature or humidity was out of the controller specifications.

When the buzzer and lights would go off, matching and leak down testing was haulted until the tempature and humidity was back to operation temperatures.

Just like how jmendoza explained on his room at Cox.

https://www.coxengineforum.com/t15508-cox-tem-trol#202061

There was a vestibule(40' x 40')before you entered the match / leak down room. There you changed into you tyvek "clean" jumpsuit and before entering the room there was a automatic "bootie" machine that when you place your shoe into the machine and pull your shoe out you had this white bootie installed over your shoe.

Anyway back to the compression (leak down) testing.

The matched plunge and barrel would be assembled together, just like a piston into the cylinder.

Then with the barrel clamped face down onto the gage and the plunger set to a certain length, air was introduced.

After the air was introduced at a certain pressure, the leak down test has started.

The gage would check how much air was leaking by the match clearance in the allotted time that was allowed.

If there was to much air leakage the gage would fail that P&B assembly. If it passed, then it was trayed up and then rolled out the room on a conveyor for the next operation to be assembled into a completed injector.

That same gage was used for fuel rate flow. The plunger had a spiral cut on it that the gage turned and pulled the plunger out to set distances to check fuel rare flow. This was at 4 different lengths. If the flow was correct then it passed. If not it was rejected.

The barrel (piston) had what was considered a open/close ports. Similar to the bypass ports on a cylinder.

By the way, matching the plunger and barrels was done using air probes made by Etamic or Federal gaging equipment.

One was an air ring (for the plunger (piston) and the other was a air probe (rod) for the barrel (cylinder).

I can bet that Cox used the Federal gaging equipment to match their pistons with their cylinders.

This was my main job to keep the match gages and leak down gages accurate. Verifying the air probe and ring were accurate to the master rings (min/nom./max. - for linearity) and then verify that the matching of the ring and probe was accurate using the six min./nom./max rings and rods for linearity over the entire range and adjusting the gage accordingly to the certification of the masters to be within specifications.

One more thing. The best controlled room should be kept at 69° with 48% humidity. Reason being is that is considered the "zero" expansion/contraction of steel.

Ah, this brings back memories of my good times at Cat.

Did so well on the job, 6 months later after retiring, they asked me to come back to the job I retired from.

As a contract employee with less pay.

My replacement wasn't able to do the job as well as I did. By the way, they only filled my job after I left.

I trained no one before I left? And I did a computer program to help me calculate the match clearances between the masters.

I don't think anyone knew about that?

Sorry no photos as this is restricted. (even today with cell phones)

Retired - Quality Engineer Mike (sosam117)

Last edited by sosam117 on Sun Sep 19, 2021 8:20 am; edited 1 time in total (Reason for editing : added link to Cox tem-trol)

sosam117- Diamond Member

- Posts : 1350

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Re: Just HOW do you test compression??

Re: Just HOW do you test compression??

+1 on what The others above say. I will wet the piston and block, and then turn the assy to see if it passes the "wet test" while looking for bubbles. Then I purposely hydro-lock the engine by filling the cylinder (upside down, and through the exhaust port), and then turning to the point of significant resistance...and hold the twisted position to observe leakdown through the exhaust port, around the head/cylinder joint, and the glowplug tip.

For reedies:

Filling the crankcase crankcase from the SPI gap, then bringing the piston towards bottom dead center will pressurize the crankcase. The piston will leak/bypass until it clears (exposes/opens) the intake charge flutes, and then dump into the combustion chamber. But for that period the flutes aren't cleared/opened yet, and with enough fuel to just about hydro-lock the piston from below, the fuel will press a good reed shut...no leak-back into the venturi. The fuel will also dribble out the snout of the crank on a worn crankcase or crank.

Of course, this isn't scientific. No humidity or temp control...but it does weed out the weakest P/C combination fairly quickly. It does require a bit of finesse, and it helps if a known good engine is available for a touchie-feelie standard. It also works if you are checking one out at a flea-market. Feel free to use straight alcohol too, but expect a more fluid experience...as the thinner "cleaner" will expose leak-down areas very quickly,.and with reduced oil friction, will identify any rotational oddities/concerns.

For reedies:

Filling the crankcase crankcase from the SPI gap, then bringing the piston towards bottom dead center will pressurize the crankcase. The piston will leak/bypass until it clears (exposes/opens) the intake charge flutes, and then dump into the combustion chamber. But for that period the flutes aren't cleared/opened yet, and with enough fuel to just about hydro-lock the piston from below, the fuel will press a good reed shut...no leak-back into the venturi. The fuel will also dribble out the snout of the crank on a worn crankcase or crank.

Of course, this isn't scientific. No humidity or temp control...but it does weed out the weakest P/C combination fairly quickly. It does require a bit of finesse, and it helps if a known good engine is available for a touchie-feelie standard. It also works if you are checking one out at a flea-market. Feel free to use straight alcohol too, but expect a more fluid experience...as the thinner "cleaner" will expose leak-down areas very quickly,.and with reduced oil friction, will identify any rotational oddities/concerns.

Last edited by 944_Jim on Sun Sep 19, 2021 12:11 pm; edited 1 time in total (Reason for editing : Clarity)

_________________

Never enough time to build them all...always enough time to smash them all!

944_Jim- Diamond Member

Posts : 2022

Join date : 2017-02-08

Age : 59

Location : NE MS

Re: Just HOW do you test compression??

Re: Just HOW do you test compression??

My vocation was refrigeration/electrical…. We did leak down tests on compressors that had reed valves in the head….Valve off the outlet side of the condenser which is the coil downstream of the compressor and pump down until most of the refrigerant was in the coil…. Turn the compressor off and watch hi and lo side gauges for leak by…. You could tell valve performance and integrity of the compressor….Checked current draw during this test as well….

Jim, I like the hydro test you described…. I’ve heard of bubble test but not hydro … Might be interesting to attach a lever and a weight to the crankshaft and time the leak down and compare to a known good engine….

Jim, I like the hydro test you described…. I’ve heard of bubble test but not hydro … Might be interesting to attach a lever and a weight to the crankshaft and time the leak down and compare to a known good engine….

rdw777- Diamond Member

Posts : 1718

Join date : 2021-03-11

Location : West Texas

Re: Just HOW do you test compression??

Re: Just HOW do you test compression??

balogh: I really like your explanation of compression and testing. I never really thought much about the glazing lift behind by castor before but I bet it might help quite a bit to help with a better seal at the piston and sleeve.

Unfortunately lapped piston/sleeve engines are kind of at the mercy of the care shown my the user during the life of the engine. I suppose that's true of everything though.

Ringed engines have quite a big advantage over lapped engines in that area. Ringed engines can have their own problems too but if you get one that is designed good using the right materials it will just go and go for years with little complaint.

rdw777: OhMyGosh,,, my little Sears 2 piston air compressor needs a valve job so bad. It takes 3 times as long to fill the 12 gallon tank as it did new some 40 years ago. I think it's reed valves.

Unfortunately lapped piston/sleeve engines are kind of at the mercy of the care shown my the user during the life of the engine. I suppose that's true of everything though.

Ringed engines have quite a big advantage over lapped engines in that area. Ringed engines can have their own problems too but if you get one that is designed good using the right materials it will just go and go for years with little complaint.

rdw777: OhMyGosh,,, my little Sears 2 piston air compressor needs a valve job so bad. It takes 3 times as long to fill the 12 gallon tank as it did new some 40 years ago. I think it's reed valves.

FlipStart- Gold Member

- Posts : 161

Join date : 2018-09-05

Location : Phoenix, Arizona

Re: Just HOW do you test compression??

Re: Just HOW do you test compression??

FlipStart wrote:balogh: I really like your explanation of compression and testing. I never really thought much about the glazing lift behind by castor before but I bet it might help quite a bit to help with a better seal at the piston and sleeve.

Unfortunately lapped piston/sleeve engines are kind of at the mercy of the care shown my the user during the life of the engine. I suppose that's true of everything though.

Ringed engines have quite a big advantage over lapped engines in that area. Ringed engines can have their own problems too but if you get one that is designed good using the right materials it will just go and go for years with little complaint.

rdw777: OhMyGosh,,, my little Sears 2 piston air compressor needs a valve job so bad. It takes 3 times as long to fill the 12 gallon tank as it did new some 40 years ago. I think it's reed valves.

Thanks, Flipstart,

I can attest to the longevity of well taken-care of COX engines, with a TD051 tapered bore engine that has run near 300 hours in my planes, and while its compression is a bit impaired already, it still screams as any of my best COX engines. Only one conrod balljoint setting ever...but always 20% full castor in the fuel..

I remove varnish from my cylinders only when it really is a drag on the engine performance. You want to think of the conrod connection too, not just compression, and a piston tight in varnished cylinder will make its toll on conrod joint play, big and small ends both..big end issue cannot be doctored only by replacement, but balljoint reset is possible..

Ringed engines will last longer and retain compression better by the end of their life than ringless engines, but ringed engines will always have some blow-by between the tips of the compression ring, new or used alike, while the tapered bore ringless pistons of COX will also last so long that nobody would expect, thinking that engine wear will soon bring it to retirement.

Take a counter example of aluminum pistoned Norvel engines, that advertised in their manuals of " at least 6 hours" life expectancy...what???, would you hold my beer? Maybe the later production aluminum pistoned NV Big Mig engines with some converted aluminum skin on the piston will last a bit longer...but ringless aluminum pistons, that expand more than the steel cylinder liner, when hot, are inherently doomed to shorter life expectancy than steel piston and steel cylinder combos..either they are loose fit to prevent engine freeze-up when hot, or fit well but grind the piston that expands more than the cylinder when hot..just my 10 cents based on elementary physics..

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Just HOW do you test compression??

Re: Just HOW do you test compression??

The engines that have a good long life expectancy is the diesel engines.

Cast iron sleeve with a iron piston.

I have PAW engines that I have had for over 35 years, along with Enya .06 and .15 diesels

There are also may more diesels out there still in good used.

Problem nowadays is getting the fuel like you could years ago?

Just a small sample of my PAW engines

My Enya diesels

And my other diesels (in my collection)

Cast iron sleeve with a iron piston.

I have PAW engines that I have had for over 35 years, along with Enya .06 and .15 diesels

There are also may more diesels out there still in good used.

Problem nowadays is getting the fuel like you could years ago?

Just a small sample of my PAW engines

My Enya diesels

And my other diesels (in my collection)

sosam117- Diamond Member

- Posts : 1350

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Re: Just HOW do you test compression??

Re: Just HOW do you test compression??

balogh wrote: Maybe the later production aluminum pistoned NV Big Mig engines with some converted aluminum skin on the piston will last a bit longer...but ringless aluminum pistons, that expand more than the steel cylinder liner, when hot, are inherently doomed to shorter life expectancy than steel piston and steel cylinder combos..either they are loose fit to prevent engine freeze-up when hot, or fit well but grind the piston that expands more than the cylinder when hot..just my 10 cents based on elementary physics.....

No one is running aluminium in a steel liner (!), accept perhaps for the failed attempt by Cox, and they never put those into production, as far as I know?

What does work is a piston made from a high silicon-aluminium alloy, these are very wear resistant and have a lower expansion rate compared to regular pure aluminium. The matching cylinder is then made in a material that has a higher expansion rate than the piston alloy, such as brass or another aluminium alloy (lower in Si). The bore is then coated with a chrome layer (strong and very wear resistant, combined with low friction) and you have something that will last a very, very long time.

The design is always made such that the cylinder will expand more than the piston as the temperature goes up, anything else would be rather silly.

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Just HOW do you test compression??

Re: Just HOW do you test compression??

Thanks, Kris,

it makes it clear for me..just for curiosity, do you or anyone have experience on the life expectancy of such combos like the Revlite coated aluminum piston and chrome plated (steel??) cylinder of NV engines? I have a spare NV cylinder of the Revlite series and I assume this is made of steel..

it makes it clear for me..just for curiosity, do you or anyone have experience on the life expectancy of such combos like the Revlite coated aluminum piston and chrome plated (steel??) cylinder of NV engines? I have a spare NV cylinder of the Revlite series and I assume this is made of steel..

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Just HOW do you test compression??

Re: Just HOW do you test compression??

Enya did at one time one of their engines as AAC but later versions of the same engine was changed to ABC.

Enya 11CX --- AAC

Enya Ultra 11CX ---ABC

There has been discussions on other websites of reasons, power, displacement difference from AAC to ABC engines, and other differences of the Enya 11CX AAC engine and Enya Ultra 11CX ABC engine.

I have two of each engines --- the 11CX (AAC) and the Ultra 11CX (ABC)

Photos of exhaust ports show either the aluminum sleeve (11CX) or the brass sleeve (Ultra 11CX)

Enya 11CX --- AAC

Enya Ultra 11CX ---ABC

There has been discussions on other websites of reasons, power, displacement difference from AAC to ABC engines, and other differences of the Enya 11CX AAC engine and Enya Ultra 11CX ABC engine.

I have two of each engines --- the 11CX (AAC) and the Ultra 11CX (ABC)

Photos of exhaust ports show either the aluminum sleeve (11CX) or the brass sleeve (Ultra 11CX)

sosam117- Diamond Member

- Posts : 1350

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Fledgling

Fledgling

I just love the way CAT use a pentagon head bolt that holds the pump element on a reasonably modern mini digger.

No seperate pumping elements available, whole new pump etc. costing more or less a £grand a few years ago.

Continuously fuel leak on one element, a Twin cylinder diesel untill the leaky 3rd joined in. A small river of diesel fuel leak.

As far as I know she still runs but has the habit of "kinking" out after about an hour's hard work. Suspect rotted tank fuel pick up pipe, lots of crap/corrosion and water seen on the tank bottom. The drain was blocked and I told dai to do regular test drains for water and to keep the drain unblocked.

He may be deaf...

Great little machine...

No seperate pumping elements available, whole new pump etc. costing more or less a £grand a few years ago.

Continuously fuel leak on one element, a Twin cylinder diesel untill the leaky 3rd joined in. A small river of diesel fuel leak.

As far as I know she still runs but has the habit of "kinking" out after about an hour's hard work. Suspect rotted tank fuel pick up pipe, lots of crap/corrosion and water seen on the tank bottom. The drain was blocked and I told dai to do regular test drains for water and to keep the drain unblocked.

He may be deaf...

Great little machine...

Coxfledgling- Gold Member

- Posts : 404

Join date : 2021-01-10

Location : Near Caernarfon, Snowdonia, Wales, UK

Re: Just HOW do you test compression??

Re: Just HOW do you test compression??

balogh wrote:Thanks, Kris,

it makes it clear for me..just for curiosity, do you or anyone have experience on the life expectancy of such combos like the Revlite coated aluminum piston and chrome plated (steel??) cylinder of NV engines? I have a spare NV cylinder of the Revlite series and I assume this is made of steel..

The Revlite cylinders are made from aluminium (likely an alloy) and they have a "ceramic" coating in the cylinder bore. The piston is high silicon content aluminium, and the materials are chosen/matched such that the cylinder will expand more that the piston when the temperature goes up. In a new engine one should therefore pre-heat the cylinder in order to relieve some of the pinch at TDC before the first few starts. These engines will last a very long time when using all castor fuel, I have yet to wear out any Norvel engine and cannot say what the life expectancy is, other than long enough.

You cannot compare these to the products offered by NV, these do not have the same quality as the original Norvel engines had.

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Just HOW do you test compression??

Re: Just HOW do you test compression??

Well here it is the first one i remember seeing .. https://www.ebay.com/itm/154620275002?_trkparms=amclksrc%3DITM%26aid%3D1110006%26algo%3DHOMESPLICE.SIM%26ao%3D1%26asc%3D234519%26meid%3Dd3e75b04ba1944849dfa9908e5a2889c%26pid%3D101195%26rk%3D1%26rkt%3D12%26sd%3D185108775882%26itm%3D154620275002%26pmt%3D1%26noa%3D0%26pg%3D2047675%26algv%3DSimplAMLv9PairwiseUnbiasedWebCpr08MlcGreedyV3WithPLX%26brand%3DHobbico&_trksid=p2047675.c101195.m1851&amdata=cksum%3A154620275002d3e75b04ba1944849dfa9908e5a2889c%7Cenc%3AAQAGAAACEAKv4%252FtGLPGl99GAtApD1mp79x6PuCLGyCgQ%252BdWGCdWHYRLGlozmRzcD9XvhiHhiON1%252BuSH0PYqj9sUuInu%252FKm7tm%252FOpvL77EP3SBJ80LkDEjv18gg4KTlgmqk25uUSnmwkaKMkFjhW21TFSp9QiXNc2j7r%252BAp0ajtYqtpwFdUcV4uYnKJj4k0TyZ5FHFKmIwonQUjmpcxB0XeOXbryXHv2EW75qgFaS9vfro%252FxPPR9NIbJ5%252FNXC0bwFum8I6oGFJnBPJyoL14WmKp1fJoBak83N%252FFtuq772ptB3ZIpztjEmn9Wok1OS4uLznrpL4DY%252FlGupz12EkhNML3mPFeia%252F8k0qBgBecCUBWDFXfkEVd1TW98cjjUMk%252F81v%252FcEaVdAI1fnqCXirN%252BUm82ezZBVEinY8uakFA67RI50Ooby1g11CfoIot9RgZTrYwmlA4nFIo0y3pG6HChGuQIMAbTBLsZsYFUH6OKZrUMrZd2DmCURJ04c18Mm4zTOWkUlmV4o0YmrheLmKOlptpOYCr%252FUcmrcuJIECupJEblrjvG6Bs7UurGrqb4ZWFlRVq90PnDppnWUkPkNvR%252BdHn2ksT7tUjxhn1U9h1sBQVFg1ne2yyqWBS%252Frgu7qsuhNi0%252FSeSqwQm6VI54KoKyM2PZKsWGlURFxP2ylhdZPhWbafZepcBGwns3khbWZlXXy6e%252Figmpx%252BA%253D%253D%7Campid%3APL_CLK%7Cclp%3A2047675

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

Similar topics

Similar topics» Compression

» New Pee Wee with low compression?

» Restoring a rusty engine

» bad compression.. how to fix it

» Is hotter fuel harder to needle?

» New Pee Wee with low compression?

» Restoring a rusty engine

» bad compression.. how to fix it

» Is hotter fuel harder to needle?

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules