Log in

Search

Latest topics

» Tee Dee .020 combat modelby Ken Cook Today at 3:23 am

» My latest doodle...

by batjac Yesterday at 9:47 pm

» My N-1R build log

by roddie Yesterday at 8:50 pm

» Free Flight Radio Assist

by rdw777 Yesterday at 4:51 pm

» Purchased the last of any bult engines from Ken Enya

by getback Yesterday at 12:05 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

» My current avatar photo

by roddie Mon Nov 18, 2024 9:05 pm

» Brushless motors?

by rsv1cox Sun Nov 17, 2024 6:40 pm

Cox Engine of The Month

Zinc rot - Nothing to be proud of.....

Page 1 of 1

Zinc rot - Nothing to be proud of.....

Zinc rot - Nothing to be proud of.....

Not much of a problem in the model plane/car world unless you happen to collect cast early examples.

Reprinted from the Model Train Forum:

The Achilles heel of vintage locomotives.

I collect old Varney locomotives, a lot of them and about 10% suffer from some degree of "zinc rot." There is no cure. Varney eventually saw the light and went from zinc on their tender bases to plastic solving the problem, probably cheaper.. They used zinc (alloyed with tin, Varney called it Zamac)) in their cast accessories too, but I have not found it in their locomotive shells.

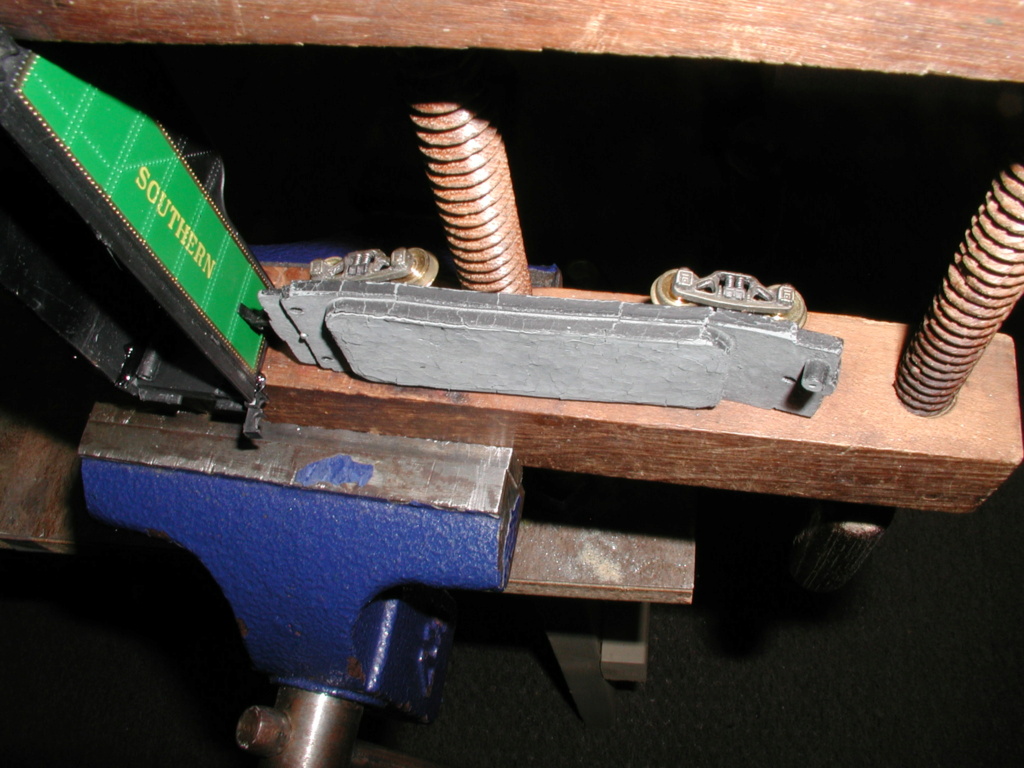

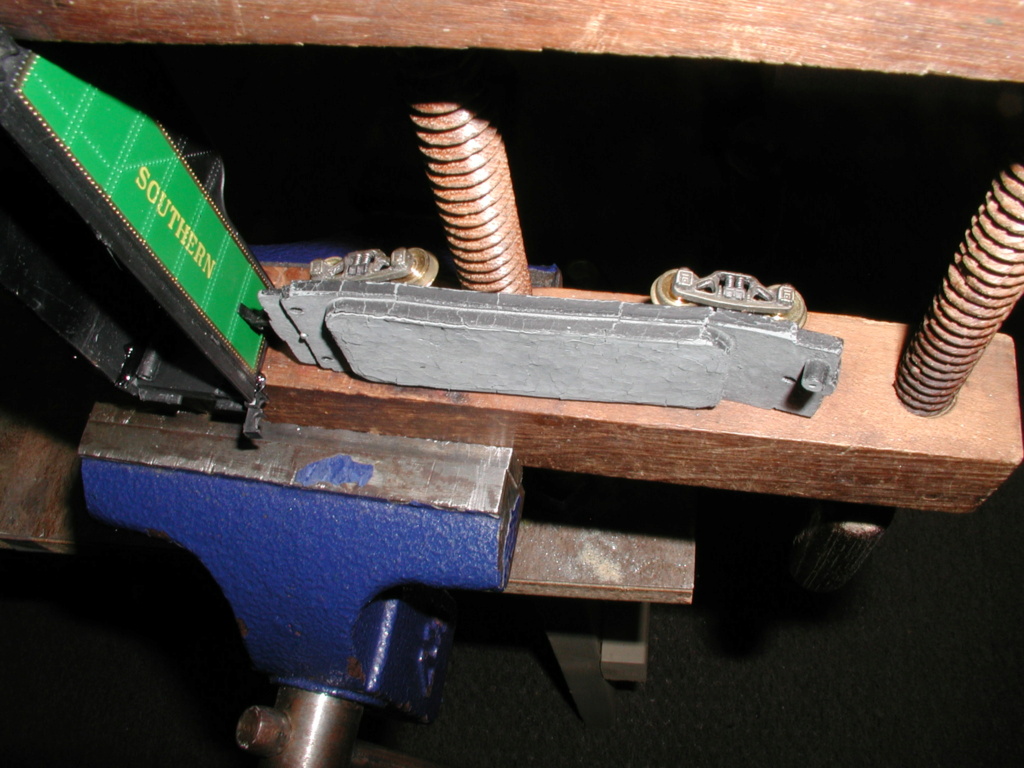

All that cracking causes expansion which has to go somewhere, in this case the tenders shell pushing it outward and cracking the edges. I just use Testors red tube plastic cement, soften the plastic lightly with a heat gun and clamp until cured with good results, then use a treated balsa base and a cut bracket drilled and tapped to accept the trucks.

A lot of effort, but it saved this $28 ebay find.

Reprinted from the Model Train Forum:

The Achilles heel of vintage locomotives.

I collect old Varney locomotives, a lot of them and about 10% suffer from some degree of "zinc rot." There is no cure. Varney eventually saw the light and went from zinc on their tender bases to plastic solving the problem, probably cheaper.. They used zinc (alloyed with tin, Varney called it Zamac)) in their cast accessories too, but I have not found it in their locomotive shells.

All that cracking causes expansion which has to go somewhere, in this case the tenders shell pushing it outward and cracking the edges. I just use Testors red tube plastic cement, soften the plastic lightly with a heat gun and clamp until cured with good results, then use a treated balsa base and a cut bracket drilled and tapped to accept the trucks.

A lot of effort, but it saved this $28 ebay find.

rsv1cox- Top Poster

Posts : 11245

Join date : 2014-08-18

Location : West Virginia

OhBee- Platinum Member

- Posts : 698

Join date : 2016-03-23

Age : 73

Location : Minnesota

Re: Zinc rot - Nothing to be proud of.....

Re: Zinc rot - Nothing to be proud of.....

The "original" Mills .75 diesels had the same problem.

That is why they were painted black to try to stop the corrosion (to no avail).

That is why they were painted black to try to stop the corrosion (to no avail).

sosam117- Diamond Member

- Posts : 1349

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

dckrsn- Diamond Member

- Posts : 2750

Join date : 2010-10-21

Age : 71

Location : Long Island, New York

Re: Zinc rot - Nothing to be proud of.....

Re: Zinc rot - Nothing to be proud of.....

Hi Bob, I bought one of those for my son years ago.

But model railroad manufacturers and buyers were looking for weight, while Cox was looking for lightness. Zinc is heavier than aluminum and I think that's just aluminum alloyed with something else and is just common corrosion. But, I'm guessing here, perhaps someone more knowledgeable will chime in.

Severe zinc rot will crumble like a cracker when handled.

But model railroad manufacturers and buyers were looking for weight, while Cox was looking for lightness. Zinc is heavier than aluminum and I think that's just aluminum alloyed with something else and is just common corrosion. But, I'm guessing here, perhaps someone more knowledgeable will chime in.

Severe zinc rot will crumble like a cracker when handled.

rsv1cox- Top Poster

Posts : 11245

Join date : 2014-08-18

Location : West Virginia

Re: Zinc rot - Nothing to be proud of.....

Re: Zinc rot - Nothing to be proud of.....

In the Galvanic Series of metals, Zinc and aluminum are considered sacrificial metals. They will sacrifice themselves when electrically connected to other metals higher on the scale like steel and iron, to protect them from corroding when placed in water (table developed from sea water). This is why you may see aluminum or zinc bars being attached to bottoms of hulls of ships.

Your water heater has a zinc or magnesium rod inserted that can be easily replaced, through a screw plug fitting usually from the top although can be in other locations. It protects the inside of the tank, usually for up to around 6 years (why water tank warranties are that long). Although the interior of the steel tank has a corrosion resistant coating on it, it is not perfect. The rod protects the surface imperfections such as pin holes by sacrificing itself over time.

http://www.eaa1000.av.org/technicl/corrosion/galvanic.htm

It was why my K&B .35 Stallion was heavily pitted on the outside, whereas the internal steel parts had only mild surface rust.

This is why usually the aluminum or base metal zinc alloys that show heavy corrosion versus the steel parts, which may only show surface rust that usually cleans up pretty good.

Your water heater has a zinc or magnesium rod inserted that can be easily replaced, through a screw plug fitting usually from the top although can be in other locations. It protects the inside of the tank, usually for up to around 6 years (why water tank warranties are that long). Although the interior of the steel tank has a corrosion resistant coating on it, it is not perfect. The rod protects the surface imperfections such as pin holes by sacrificing itself over time.

http://www.eaa1000.av.org/technicl/corrosion/galvanic.htm

It was why my K&B .35 Stallion was heavily pitted on the outside, whereas the internal steel parts had only mild surface rust.

This is why usually the aluminum or base metal zinc alloys that show heavy corrosion versus the steel parts, which may only show surface rust that usually cleans up pretty good.

GallopingGhostler- Top Poster

Posts : 5722

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Zinc rot - Nothing to be proud of.....

Re: Zinc rot - Nothing to be proud of.....

Very true George, but I have the Plummer cut off that sacrificial rod in my water heater because if left in place my well water reacts with it and smells like sulfur, partly because of that I have had to replace my water heater twice in the last 11 years.

rsv1cox- Top Poster

Posts : 11245

Join date : 2014-08-18

Location : West Virginia

Re: Zinc rot - Nothing to be proud of.....

Re: Zinc rot - Nothing to be proud of.....

My Rheem (gas) hot water heater has a mfg. date of 1994.rsv1cox wrote:Very true George, but I have the Plummer cut off that sacrificial rod in my water heater because if left in place my well water reacts with it and smells like sulfur, partly because of that I have had to replace my water heater twice in the last 11 years.

The first time removing the magnesium rod was a bear. It was really tight and I thought I wouldn't be able to remove it.

Like anything else -- heat did the job.

I've been replacing that sacrificial rod every 5 years and that Rheem tank is still being use to this date. (27 years later).

The only other thing I do is to drain the tank once a year to get the sediments out from the bottom of the tank as well.

That is where the magnesium ( from the sacrificial rod) will be when it gets eaten up by the water.

sosam117- Diamond Member

- Posts : 1349

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Re: Zinc rot - Nothing to be proud of.....

Re: Zinc rot - Nothing to be proud of.....

A little info on zinc rot, sometimes zinc pest, it is not caused by any external factors, but by an internal one, namely, lead impurities in the alloy, The lead eventually crystallizes, expands, and causes the casting to break apart. There is no stopping it, and even fairly recent zinc castings are not immune. The only good news is, if you have an old casting that isn't affected, it won't start now. And yes, I do have a some old locomotives suffering from this ailment. Plastic aircraft modelers have a similar problem, the lead weights they use for nose weight, begin to crystallize, and split their aircraft's noses apart.

trebor3170- Moderate Poster

- Posts : 26

Join date : 2018-07-13

Age : 66

Location : Eastern Shore, MD

Re: Zinc rot - Nothing to be proud of.....

Re: Zinc rot - Nothing to be proud of.....

Outboard motors also have sacrificial anodes installed in the lower units. To stave off galvanic corrosion.

OhBee- Platinum Member

- Posts : 698

Join date : 2016-03-23

Age : 73

Location : Minnesota

Re: Zinc rot - Nothing to be proud of.....

Re: Zinc rot - Nothing to be proud of.....

I've seen them on anchors and anchor chains.OhBee wrote:Outboard motors also have sacrificial anodes installed in the lower units. To stave off galvanic corrosion.

Bob

dckrsn- Diamond Member

- Posts : 2750

Join date : 2010-10-21

Age : 71

Location : Long Island, New York

Re: Zinc rot - Nothing to be proud of.....

Re: Zinc rot - Nothing to be proud of.....

This is interesting to me I don't think I have every hear of this sacrificial rod inhibitors  But I do know rot

But I do know rot

But I do know rot

But I do know rot

getback- Top Poster

Posts : 10439

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Zinc rot - Nothing to be proud of.....

Re: Zinc rot - Nothing to be proud of.....

About 15 years ago, I got certified as a NACE (National Association of Corrosion Engineers) Cathodic Technician II for work, so, although I am by no means an expert have a little understanding through training. Since retiring have let that lapse. I don't know if I'd want to be lowered into a 150,000 gallon elevated tank using a rubber lift raft to take current readings to determine if the cathodic protection system has current levels properly set.

What you have with the zinc / magnesium / aluminum anodes is basically components of a battery when including the tank / vessel and electrolyte which is the water or other medium of fluid tank / vessel is carrying. One tests various locations in the water to determine if there is sufficient current produced to protect the defects in the tank / vessel internal coating.

Usually on tanks larger than say, 5,000 - 10,000 gallons, they install a transformer rectifier set and a wired anode system. The transformer steps down the voltage to the required level, the bridge rectifier converts A.C. to D.C. There are taps off the transformer to step down the voltage to the required range, then a rheostat adjusts the current level. Readings are taken at various locations in the water to determine the current levels.

Just sosam117 indicated, properly maintaining the cathodic protection system can provide a very long life for the tank. Theoretically, those major municipal water storage tanks can have a life of a 100+ years or so I understand if the cathodic and internal coating (and exterior weather coating) are maintained. There is also exterior cathodic protection for above ground and in ground tanks, to protect their surfaces exposed to soil and water.

Anyway, it is a good field to get involved with if one wants a stable income.

What you have with the zinc / magnesium / aluminum anodes is basically components of a battery when including the tank / vessel and electrolyte which is the water or other medium of fluid tank / vessel is carrying. One tests various locations in the water to determine if there is sufficient current produced to protect the defects in the tank / vessel internal coating.

Usually on tanks larger than say, 5,000 - 10,000 gallons, they install a transformer rectifier set and a wired anode system. The transformer steps down the voltage to the required level, the bridge rectifier converts A.C. to D.C. There are taps off the transformer to step down the voltage to the required range, then a rheostat adjusts the current level. Readings are taken at various locations in the water to determine the current levels.

Just sosam117 indicated, properly maintaining the cathodic protection system can provide a very long life for the tank. Theoretically, those major municipal water storage tanks can have a life of a 100+ years or so I understand if the cathodic and internal coating (and exterior weather coating) are maintained. There is also exterior cathodic protection for above ground and in ground tanks, to protect their surfaces exposed to soil and water.

Anyway, it is a good field to get involved with if one wants a stable income.

GallopingGhostler- Top Poster

Posts : 5722

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules