Log in

Search

Latest topics

» Landing-gear tipsby roddie Today at 6:17 pm

» Roger Harris revisited

by TD ABUSER Today at 2:13 pm

» Tee Dee .020 combat model

by Ken Cook Today at 1:41 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Today at 1:37 pm

» Happy 77th birthday Andrew!

by getback Today at 11:52 am

» My latest doodle...

by roddie Today at 10:43 am

» My N-1R build log

by GallopingGhostler Yesterday at 3:04 pm

» Chocolate chip cookie dough.........

by roddie Yesterday at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Yesterday at 11:32 am

» Free Flight Radio Assist

by rdw777 Yesterday at 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

Cox Engine of The Month

Cox Fun Model .049 ... flight, flight and flight!!! (page 3 & 5)

Page 2 of 6

Page 2 of 6 •  1, 2, 3, 4, 5, 6

1, 2, 3, 4, 5, 6

Re: Cox Fun Model .049 ... flight, flight and flight!!! (page 3 & 5)

Re: Cox Fun Model .049 ... flight, flight and flight!!! (page 3 & 5)

Great job Mauricio! A great high-performance engine in the making!

Re: Cox Fun Model .049 ... flight, flight and flight!!! (page 3 & 5)

Re: Cox Fun Model .049 ... flight, flight and flight!!! (page 3 & 5)

Great work Mauricio. You have saved an engine! I wish I could do the same with 2 of my similar Lynx..

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Cox Fun Model .049 ... flight, flight and flight!!! (page 3 & 5)

Re: Cox Fun Model .049 ... flight, flight and flight!!! (page 3 & 5)

MauricioB wrote:Well, I have assembled my Lynx again, the throttle ring was perfect.

But there is a problem:

The hole in the crankcase is larger in diameter than the crankshaft, so the crankshaft does not have a correct adjustment.

What is wrong here?

The diameter of the crankcase?

or

The diameter of the crankshaft?.

This is not right, I will send a link to Mr. Matt to see what he can tell me.

I am attaching a video where you can see the exaggerated play between both parts, Carter and Crankshaft.

I talked about this on the forum in February 2018 but it was said to be an exception. My Black Lynx was also a new-worn out one and wouldn't run at all. I replaced the crankcase/ -shaft by another I had lying around. At least, I now had a working engine.

https://www.coxengineforum.com/t10621p50-hydro-bat-by-vic-smeed-engine-probs?highlight=smeed

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

Re: Cox Fun Model .049 ... flight, flight and flight!!! (page 3 & 5)

Re: Cox Fun Model .049 ... flight, flight and flight!!! (page 3 & 5)

OVERLORD wrote:................

I talked about this on the forum in February 2018 but it was said to be an exception. My Black Lynx was also a new-worn out one and wouldn't run at all. I replaced the crankcase/ -shaft by another I had lying around. At least, I now had a working engine.

https://www.coxengineforum.com/t10621p50-hydro-bat-by-vic-smeed-engine-probs?highlight=smeed

I doubt this was an exceptional case.

Some years ago I bought 2 black anodized crankcases and Killer Bee shafts separately. The former all had too large bore and loose fit with the shaft. The latter had an uncentered shaft end that caused the prop to wag like the dog's tail. Those shafts with the wagging end had also a hole drilled in the face of the web. Later shafts I bought did not have the drilled hole on the web nor the wagging end..I built 2 pseudo-Lynx engines from those parts with wagging ends and black anodized cases, that remained shelf queens, simply because despite the balanced props, they generate vibration and start eating the meat inside the crank nose..

Then I won a Black Lynx on the Cox Engine of the Month competition like Mauricio, that featured the same loose shaft fit...but you do not look into the mouth of a gift horse

I also bought a red anodized case and Killer Bee shaft that I combined with a No 4 cylinder and KB backplate into one of my most terrific runners, powering my Lil Roughneck, that I call TeeDeeReedie.. The shaft-to-case fit is good even after many hours (I assume near 100) of runs, as is the No 4. cylinder fit. Even the anodizing inside the nose has remained intact.

From my non-representative statistics it looks like it is the black anodized aftermarket crankcases that feature the loose fit, other anodized cases - that may come from a different maker? - seem to be OK.

BTW I have a fairly used stock Black Widow made in the 70's as well as NIB ones made in the 80's with apparently perfect case fit in all..it looks like the aftermarket black anodized cases, or those made during the Estes era, feature the more forgiving tolerances.

Anyways I understood Matt is instructing the aftermarket crankcase manufacturer of the next batch of cases to reduce the bore diameter.

No harm is meant to Bernie or Matt, and I am a bit embarrassed to write about the goods of our friends and suppliers of COX engines and parts, without whom we would not have the convenience of instant parts availability..I just hope these feedbacks from Lieven, Mauricio and myself and others will help sustain the legendary COX quality.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Cox Fun Model .049 ... flight, flight and flight!!! (page 3 & 5)

Re: Cox Fun Model .049 ... flight, flight and flight!!! (page 3 & 5)

Very good work Mauricio!

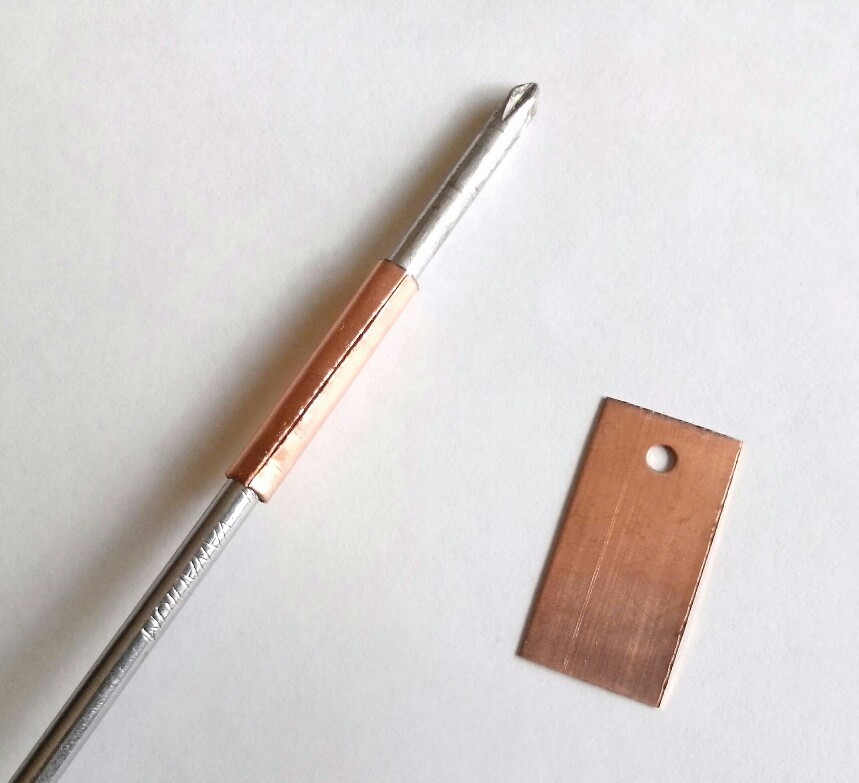

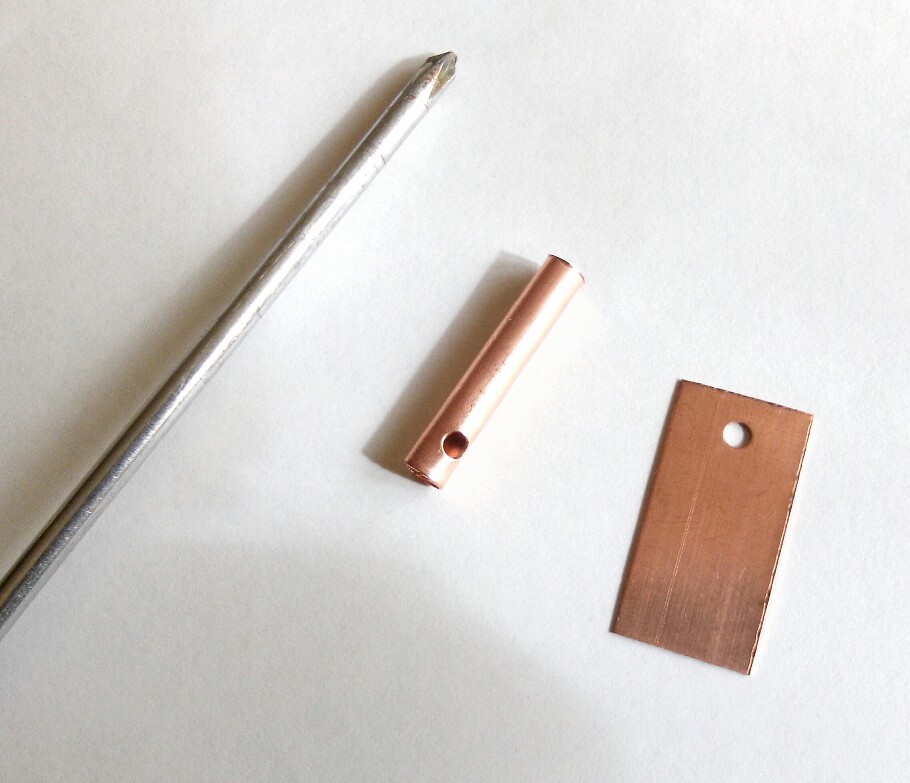

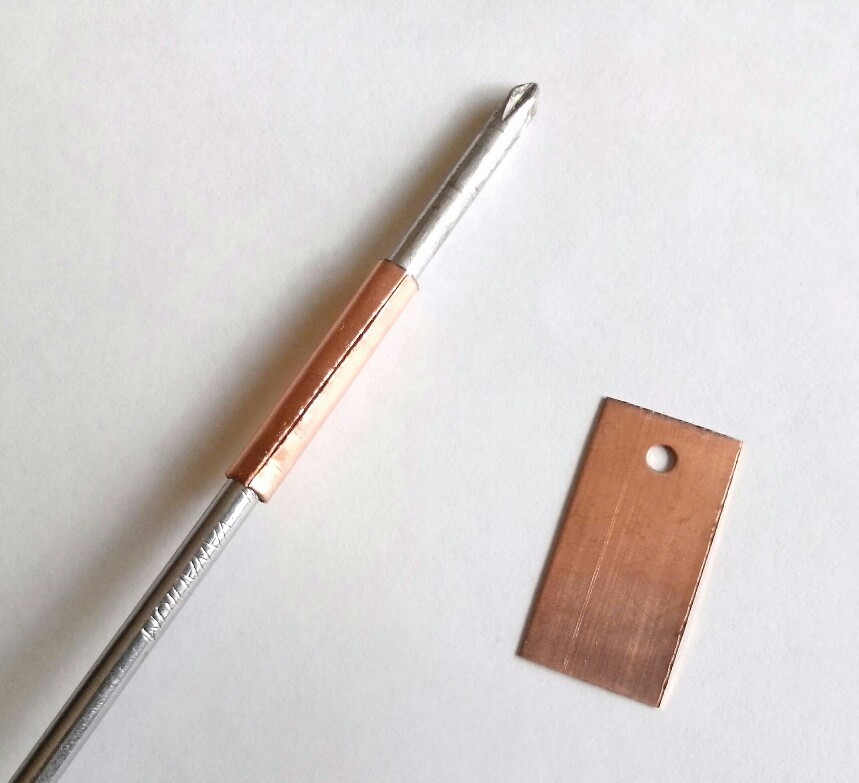

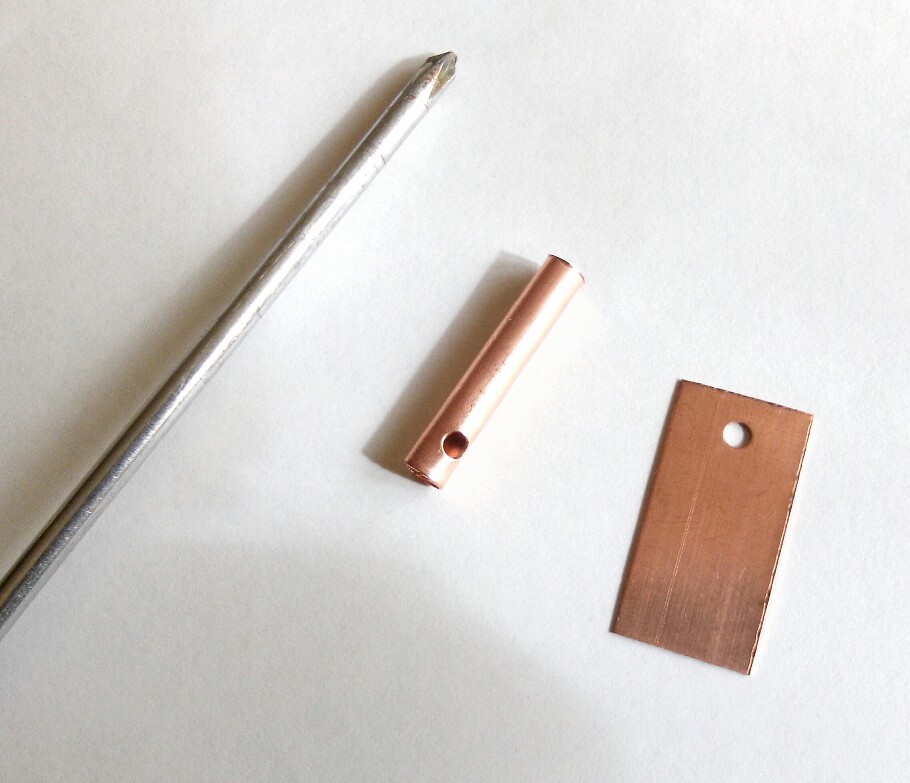

Yet I don't have a lathe, so I made a sleeve from thin copper sheet. I made this by wrapping 0.5 mm copper sheet around a screwdriver shaft. After inserting this sleeve in crankcase, it need to be lapped with same screwdriver shaft. However I don't know copper can withstand to high rpm or not. It also can be made from thin steel sheet.

Yet I don't have a lathe, so I made a sleeve from thin copper sheet. I made this by wrapping 0.5 mm copper sheet around a screwdriver shaft. After inserting this sleeve in crankcase, it need to be lapped with same screwdriver shaft. However I don't know copper can withstand to high rpm or not. It also can be made from thin steel sheet.

Last edited by Levent Suberk on Thu Oct 29, 2020 5:36 am; edited 1 time in total

Levent Suberk- Diamond Member

- Posts : 2265

Join date : 2017-12-24

Location : Türkiye

Re: Cox Fun Model .049 ... flight, flight and flight!!! (page 3 & 5)

Re: Cox Fun Model .049 ... flight, flight and flight!!! (page 3 & 5)

MauricioB wrote:roddie wrote:

You may wish to "sleeve" the crankshaft-bore.. to save the defective case; seeing that you have the capability. It's been done.. (but not by me..)

ohhh Roddie has inspired me !!!!

A special thanks to Roddie for the idea!

Mauricio,

excellent refurbishment. I tached 14-15k rpm on the bench.

Just a quick question: does the bronze bushing protrude inside the crankcase and sit on the shaft web, or the shaft web still sits on the aluminum case?

As far as I know, the case internal shoulder acts in the original COX design as a thrust bearing of sufficient face area. If the bronze bushing is long and protrudes to support the crank web, then this thrust bearing area is reduced. Sorry for the complicated explanation of my question..

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Levent Suberk- Diamond Member

- Posts : 2265

Join date : 2017-12-24

Location : Türkiye

Re: Cox Fun Model .049 ... flight, flight and flight!!! (page 3 & 5)

Re: Cox Fun Model .049 ... flight, flight and flight!!! (page 3 & 5)

I won a Black Lynx in 2016 I think. Haven’t attempted to run it, but this conversation prompted me to check the radial play on the axle. It does have quite a lot of play, I would call it ”excessive”, although it is not like the worst that I have seen in a couple of worn-out thin-nose Babe Bees. I hope the problem is the case and not the axle.

I have no equipment to make a sleeve, so I’ll just replace the case, as soon as there is a confirmation that there is a good batch of black-anodized crankcases available.

I have no equipment to make a sleeve, so I’ll just replace the case, as soon as there is a confirmation that there is a good batch of black-anodized crankcases available.

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Re: Cox Fun Model .049 ... flight, flight and flight!!! (page 3 & 5)

Re: Cox Fun Model .049 ... flight, flight and flight!!! (page 3 & 5)

I think that black anodizing is thicker than other anodizing colors, so crankcases had been manufactured a little undersized to compensate black anodizing thickness.

Levent Suberk- Diamond Member

- Posts : 2265

Join date : 2017-12-24

Location : Türkiye

Re: Cox Fun Model .049 ... flight, flight and flight!!! (page 3 & 5)

Re: Cox Fun Model .049 ... flight, flight and flight!!! (page 3 & 5)

Levent Suberk wrote:I think that black anodizing is thicker than other anodizing colors, so crankcases had been manufactured a little undersized to compensate black anodizing thickness.

I agree Levent...I have a small scratch on one of the black anodized aftermarket cases and the coating seems to be thicker than with the gold anodized 020 TeeDees or similar. It is referred to as anodization on the website of Bernie, anyway..

But on the other hand anodization is nothing else than an enhanced aluminum oxide layer in the thickness of several microns or less, only...so maybe the black layer is not an anodization of the parent metal, but some additional coating?

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Cox Fun Model .049 ... flight, flight and flight!!! (page 3 & 5)

Re: Cox Fun Model .049 ... flight, flight and flight!!! (page 3 & 5)

That’s a good point Andras. Anodizing generally does not add much to the surface. It is, as you say, a way to deliberately oxidize the parent metal in a controlled way. As we all know, aluminum oxide is much harder than bare aluminum.

The colour is just a dye that can be embedded in the oxide and the next step of the process (forgot the details ) seals the dye in the material. Skip the dye and you’ll get a ”natural” colour anodizing.

) seals the dye in the material. Skip the dye and you’ll get a ”natural” colour anodizing.

The repro cases and tanks (other colours than black) do look different compared to oem ones, I just assumed the oem’s were polished prior to anodizing and repros are not, but there could be a difference in the process itself. Maybe due to environmental/health laws or something?

The colour is just a dye that can be embedded in the oxide and the next step of the process (forgot the details

The repro cases and tanks (other colours than black) do look different compared to oem ones, I just assumed the oem’s were polished prior to anodizing and repros are not, but there could be a difference in the process itself. Maybe due to environmental/health laws or something?

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Re: Cox Fun Model .049 ... flight, flight and flight!!! (page 3 & 5)

Re: Cox Fun Model .049 ... flight, flight and flight!!! (page 3 & 5)

Mauricio has brought this thread to my attention and I would like to address the concern over the Killer Bee crankshaft.

The crankshaft specification on the 'Killer Bee' crank was designed by Cox for a looser fit. We made them according to the OEM specifications. After listening to feedback from various modelers and my own testing these will be making the new production run with tighter tolerances despite this being slightly different than the OEM specifications.

The crankcase on a Killer Bee was/is no different than your typical reed valve case with the exception of anodizing. As many know anodizing was not done 'in-house' by Cox and therefore different batches may exhibit slightly different color, finish, and thickness. This is true for the ones we anodize as well. The anodizing itself (thickness) does not contribute much to the reduction of the ID of the bearing surface (in this case the bore / hone of the reed valve case). It can create a smoother surface to reduce friction and would count this as a tangible benefit outside of the cosmetic color of the case. As an aside, the color and quality of finish is often determined on preparation of the part (i.e. polishing) prior to the anodizing process.

In regards to using an Oilite Bronze bushing/bearing, either full surface or at the two ends of the crankcase, these can work very well when done correctly. Outside of the fit, which is typically hand-lapped when doing one at a time, they need to be perfectly square. I have considered offering a production engine with this setup, but the current process if very labor intensive.

As always, if there is any part or engine purchased from us, and you are not 100% satisfied, email or call and I will be sure to make it right.

Matt

The crankshaft specification on the 'Killer Bee' crank was designed by Cox for a looser fit. We made them according to the OEM specifications. After listening to feedback from various modelers and my own testing these will be making the new production run with tighter tolerances despite this being slightly different than the OEM specifications.

The crankcase on a Killer Bee was/is no different than your typical reed valve case with the exception of anodizing. As many know anodizing was not done 'in-house' by Cox and therefore different batches may exhibit slightly different color, finish, and thickness. This is true for the ones we anodize as well. The anodizing itself (thickness) does not contribute much to the reduction of the ID of the bearing surface (in this case the bore / hone of the reed valve case). It can create a smoother surface to reduce friction and would count this as a tangible benefit outside of the cosmetic color of the case. As an aside, the color and quality of finish is often determined on preparation of the part (i.e. polishing) prior to the anodizing process.

In regards to using an Oilite Bronze bushing/bearing, either full surface or at the two ends of the crankcase, these can work very well when done correctly. Outside of the fit, which is typically hand-lapped when doing one at a time, they need to be perfectly square. I have considered offering a production engine with this setup, but the current process if very labor intensive.

As always, if there is any part or engine purchased from us, and you are not 100% satisfied, email or call and I will be sure to make it right.

Matt

Re: Cox Fun Model .049 ... flight, flight and flight!!! (page 3 & 5)

Re: Cox Fun Model .049 ... flight, flight and flight!!! (page 3 & 5)

Hi guys, thanks for your feedback.

This experience helped me to go further with Cox engines, and you can even recover some old crankcase that had natural wear due to use.

Making a custom bronze bushing can even improve engine performance, as the friction type is much smoother.

András, I answer your question about the length of the hub:

I have respected the original internal seat of the engine, so the hub is a few tenths shorter than the crankcase and therefore does not protrude from it.

Kari here I detail the type of bronze used:

Phosphor bronze generally contains 8-12% tin and 0.1-0.5% phosphorus. Las aleciones S.A.E. 64, 640 and 65 belong to this group. SAE 64 alloy (ASTM B505 937) is used, due to its antifrictional properties, as a bearing metal for medium loads and speeds.

Matt, thanks for answering:

I am very grateful for this award, and I appreciate your support for the hobby, that said, I have no claim whatsoever. My intention is that these engines and their manufacture continue for many years and therefore, I would like that anyone who acquires an engine of these, well, has no problems and does not find an engine in these conditions either.

Many of us here love Cox motors and almost always look for all kinds of solutions to make them work, but there are many fans who do not feel the same and when they find a product of these, they may discard it completely generating a negative concept for the Cox brand.

For my part I have a custom Cox Black Lynx, which looks great, so I don't need any kind of replacement.

My humble advice, just if you want to take it into account, is not to run engines with this problem, not only to avoid damaging the Cox brand with negative comments, but to avoid a possible accident. The engine in these original conditions vibrates excessively, not only can it loosen the propeller, but also the servo cables can be cut by vibration, losing control of the model, causing an accident to third parties.

Thank you once again for this GREAT FORUM OF FRIENDS!

This experience helped me to go further with Cox engines, and you can even recover some old crankcase that had natural wear due to use.

Making a custom bronze bushing can even improve engine performance, as the friction type is much smoother.

András, I answer your question about the length of the hub:

I have respected the original internal seat of the engine, so the hub is a few tenths shorter than the crankcase and therefore does not protrude from it.

Kari here I detail the type of bronze used:

Phosphor bronze generally contains 8-12% tin and 0.1-0.5% phosphorus. Las aleciones S.A.E. 64, 640 and 65 belong to this group. SAE 64 alloy (ASTM B505 937) is used, due to its antifrictional properties, as a bearing metal for medium loads and speeds.

Matt, thanks for answering:

I am very grateful for this award, and I appreciate your support for the hobby, that said, I have no claim whatsoever. My intention is that these engines and their manufacture continue for many years and therefore, I would like that anyone who acquires an engine of these, well, has no problems and does not find an engine in these conditions either.

Many of us here love Cox motors and almost always look for all kinds of solutions to make them work, but there are many fans who do not feel the same and when they find a product of these, they may discard it completely generating a negative concept for the Cox brand.

For my part I have a custom Cox Black Lynx, which looks great, so I don't need any kind of replacement.

My humble advice, just if you want to take it into account, is not to run engines with this problem, not only to avoid damaging the Cox brand with negative comments, but to avoid a possible accident. The engine in these original conditions vibrates excessively, not only can it loosen the propeller, but also the servo cables can be cut by vibration, losing control of the model, causing an accident to third parties.

Thank you once again for this GREAT FORUM OF FRIENDS!

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-16

Age : 53

Location : ARG

Re: Cox Fun Model .049 ... flight, flight and flight!!! (page 3 & 5)

Re: Cox Fun Model .049 ... flight, flight and flight!!! (page 3 & 5)

Thanks Matt for openly addressing this concern of some of us, and providing the detailed background.

So I understand the "culprit" is the KB shaft that so far has been made with loose fit based on COX OEM specs. Indeed my observations of loose fit always involved combinations of black anodized casings with KB shafts, but somehow I thought it is the case that carries too large bore. (The black case Black Widow engines have standard shafts with "normal" diameter.)

When do you think the first batches of KB shafts with slightly increased diameter will be posted on your and Bernie's webshop sites? I just bought one and it is on its way to me, but I am afraid then it is no solution to my problem of loose fit...

So I understand the "culprit" is the KB shaft that so far has been made with loose fit based on COX OEM specs. Indeed my observations of loose fit always involved combinations of black anodized casings with KB shafts, but somehow I thought it is the case that carries too large bore. (The black case Black Widow engines have standard shafts with "normal" diameter.)

When do you think the first batches of KB shafts with slightly increased diameter will be posted on your and Bernie's webshop sites? I just bought one and it is on its way to me, but I am afraid then it is no solution to my problem of loose fit...

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Cox Fun Model .049 ... flight, flight and flight!!! (page 3 & 5)

Re: Cox Fun Model .049 ... flight, flight and flight!!! (page 3 & 5)

I also had this problem but with Cox International where i purchased the CC and CS separate and had the loose no run effect , we never got it sorted even with replacements of both this was three yrs. ago ... Nice work on the upgrade Mauricio ! I must ask though did you make any kind or channel for oiling the affected area ?  Seems to run Good !!

Seems to run Good !!

Seems to run Good !!

Seems to run Good !!

getback- Top Poster

Posts : 10442

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Cox Fun Model .049 ... flight, flight and flight!!! (page 3 & 5)

Re: Cox Fun Model .049 ... flight, flight and flight!!! (page 3 & 5)

balogh wrote:Thanks Matt for openly addressing this concern of some of us, and providing the detailed background.

So I understand the "culprit" is the KB shaft that so far has been made with loose fit based on COX OEM specs. Indeed my observations of loose fit always involved combinations of black anodized casings with KB shafts, but somehow I thought it is the case that carries too large bore. (The black case Black Widow engines have standard shafts with "normal" diameter.)

When do you think the first batches of KB shafts with slightly increased diameter will be posted on your and Bernie's webshop sites? I just bought one and it is on its way to me, but I am afraid then it is no solution to my problem of loose fit...

Yes, the Killer Bee crankshaft is the part that is made with a smaller final outside diameter (OD) based on OEM specs which ultimately results in a looser fit in the case.

I cannot speak to different runs of cases that were anodized over the years. Sometimes if a part is re-anodized after being previously anodized it can result in a sloppy fit with the standard crankshaft since there is an etching process that takes place and effectively removes too much material. I've had to scrap a number of cases after I found out a prior vendor was doing this to get the finish 'better' as they described it.

There is always the possibility of a bad case that made it through the quality control (Cox or my own) and in this situation I would say reach out for a replacement.

I still have a large amount of stock of the existing Killer Bee cranks so I would not expect to see a new production run until next year. I will have the Davis Diesel crank available soon which is very similar to the Killer Bee style except it has a full bearing surface and no drilled crankpin.

Re: Cox Fun Model .049 ... flight, flight and flight!!! (page 3 & 5)

Re: Cox Fun Model .049 ... flight, flight and flight!!! (page 3 & 5)

Eric, I have applied the concept of intersection or tolerance, which applies to bushings and shafts, therefore the adjustment allows the oil to penetrate and lubricate the moving part.

There is no lubrication channel here, the tolerance between parts allows exactly the laminar flow of the lubricant.

The killer Bee crankshaft that I own is a truly high performance crankshaft, you could say: racing.

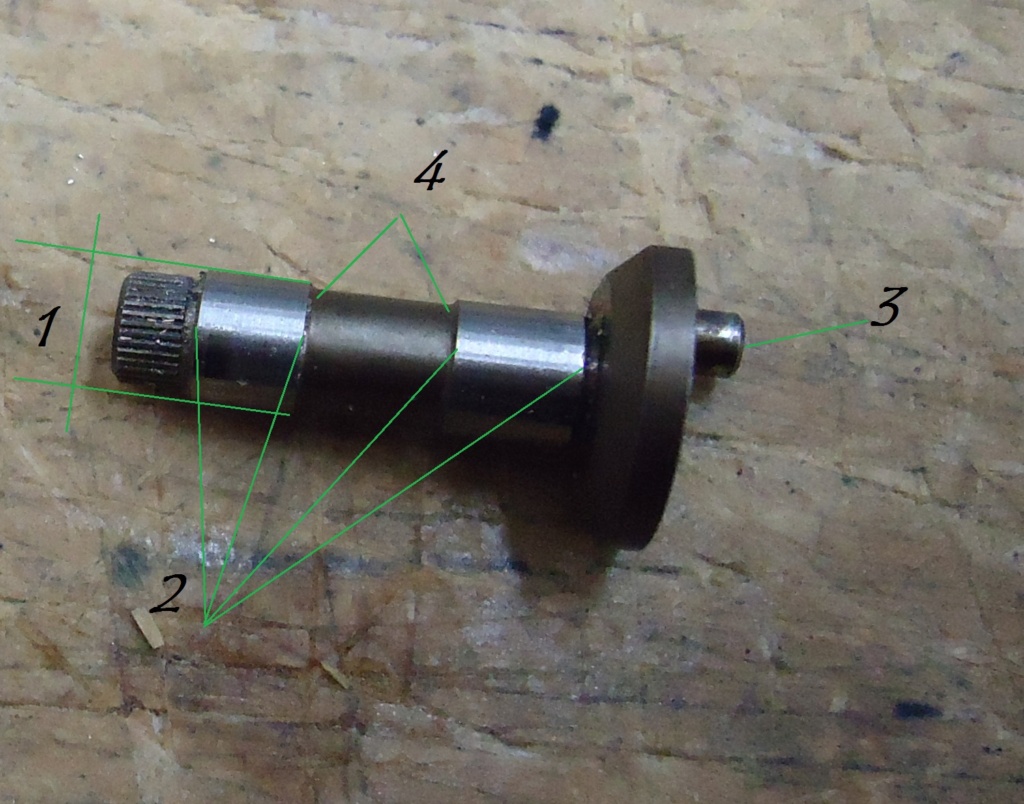

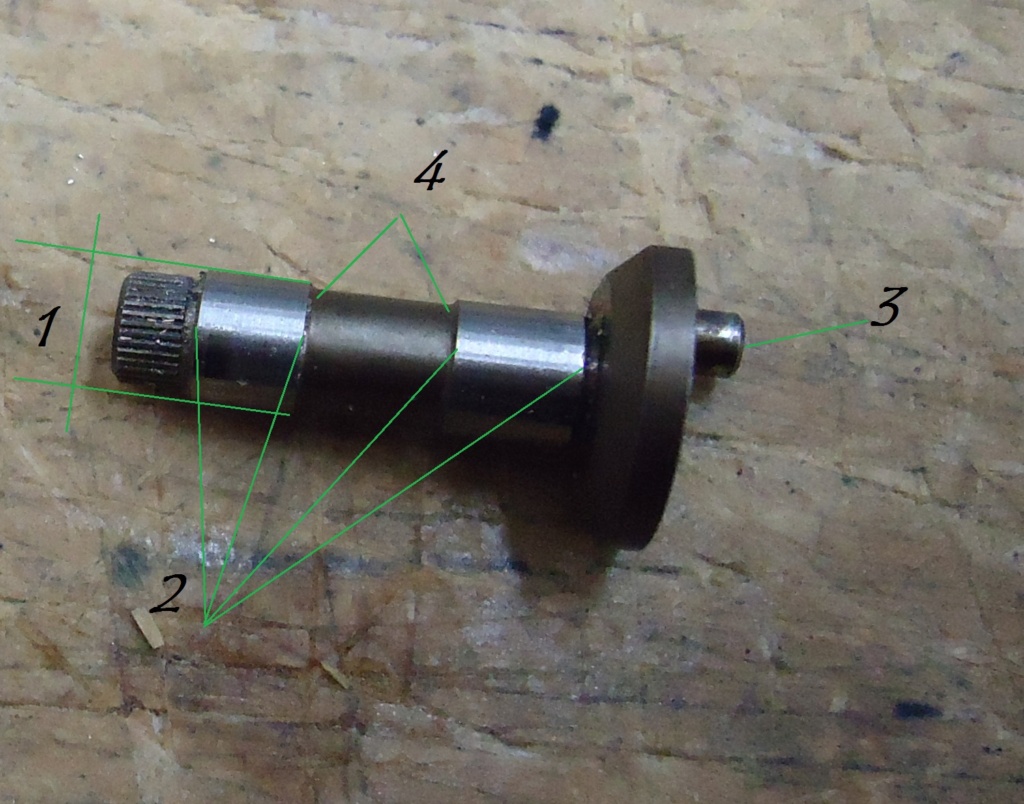

You can see there some aspects that make it really a piece where the best engine performance is sought, here I detail some aspects.

1) the diameter of the crankshaft is smaller than the standard ones, this allows less surface travel per turn and therefore less friction.

2) End support surface and not integral, the intermediate emptying of the axle, makes that surface does not rub against the crankcase and therefore reduces friction even more, achieving better rpm claims.

3) Notch or perforated connecting rod socket, that gives less weight and what is intended is to make it as light as possible, all to add to gain rpm.

4) the intermediate sector between the bearing surfaces of the crankshaft, manages to trap lubricant, which allows a constant delivery of lubrication to the entire part while it is in motion.

I believe that the crankshaft that I have is a high performance, very high performance part, only for this part, a crankcase must be manufactured with a special hole for it and not the standard type.

It is possible that at some point in the manufacture, Cox for the Killer Bee, made a special perforation for those carters.

The other is to make a bushing like the one I made, out of phosphor bronze, but I understand that it would sum up the production costs, it all also depends on what the market is willing to pay.

There is no lubrication channel here, the tolerance between parts allows exactly the laminar flow of the lubricant.

The killer Bee crankshaft that I own is a truly high performance crankshaft, you could say: racing.

You can see there some aspects that make it really a piece where the best engine performance is sought, here I detail some aspects.

1) the diameter of the crankshaft is smaller than the standard ones, this allows less surface travel per turn and therefore less friction.

2) End support surface and not integral, the intermediate emptying of the axle, makes that surface does not rub against the crankcase and therefore reduces friction even more, achieving better rpm claims.

3) Notch or perforated connecting rod socket, that gives less weight and what is intended is to make it as light as possible, all to add to gain rpm.

4) the intermediate sector between the bearing surfaces of the crankshaft, manages to trap lubricant, which allows a constant delivery of lubrication to the entire part while it is in motion.

I believe that the crankshaft that I have is a high performance, very high performance part, only for this part, a crankcase must be manufactured with a special hole for it and not the standard type.

It is possible that at some point in the manufacture, Cox for the Killer Bee, made a special perforation for those carters.

The other is to make a bushing like the one I made, out of phosphor bronze, but I understand that it would sum up the production costs, it all also depends on what the market is willing to pay.

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-16

Age : 53

Location : ARG

Re: Cox Fun Model .049 ... flight, flight and flight!!! (page 3 & 5)

Re: Cox Fun Model .049 ... flight, flight and flight!!! (page 3 & 5)

Okay, here's a full video of the Black Lynx .049 march

Ranges between: 16000 and 17000 rpm.

Surely as the parts settle into each other, the engine will achieve a few more rpm!

Ranges between: 16000 and 17000 rpm.

Surely as the parts settle into each other, the engine will achieve a few more rpm!

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-16

Age : 53

Location : ARG

Re: Cox Fun Model .049 ... flight, flight and flight!!! (page 3 & 5)

Re: Cox Fun Model .049 ... flight, flight and flight!!! (page 3 & 5)

Thank You for the espernation , I see now that with enough relief to turn and the way the CS is made to trap lucarant and actually store for use ,, the way i see it  No need for the lub. channel

No need for the lub. channel  Very good now i watch the run

Very good now i watch the run  I believe with some run time it will settle down to steady rpms .

I believe with some run time it will settle down to steady rpms .

No need for the lub. channel

No need for the lub. channel Last edited by getback on Fri Oct 30, 2020 6:22 am; edited 1 time in total (Reason for editing : add on)

getback- Top Poster

Posts : 10442

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Cox Fun Model .049 ... flight, flight and flight!!! (page 3 & 5)

Re: Cox Fun Model .049 ... flight, flight and flight!!! (page 3 & 5)

Cox Black Lynx .049

Proof:

Spacers to avoid the accumulation of oil in the suction venturi.

The engine begins to stretch its laps! We are already at 18000!

Proof:

Spacers to avoid the accumulation of oil in the suction venturi.

The engine begins to stretch its laps! We are already at 18000!

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-16

Age : 53

Location : ARG

Levent Suberk- Diamond Member

- Posts : 2265

Join date : 2017-12-24

Location : Türkiye

Re: Cox Fun Model .049 ... flight, flight and flight!!! (page 3 & 5)

Re: Cox Fun Model .049 ... flight, flight and flight!!! (page 3 & 5)

Tink engine Good To get is firs ride in sky sound Good

davidll1984- Diamond Member

- Posts : 2327

Join date : 2020-02-12

Age : 39

Location : shawinigan

Re: Cox Fun Model .049 ... flight, flight and flight!!! (page 3 & 5)

Re: Cox Fun Model .049 ... flight, flight and flight!!! (page 3 & 5)

Nice run Mauricio..what size prop did you use?

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Cox Fun Model .049 ... flight, flight and flight!!! (page 3 & 5)

Re: Cox Fun Model .049 ... flight, flight and flight!!! (page 3 & 5)

balogh wrote:Nice run Mauricio..what size prop did you use?

Thanks guys!

András, I keep the same previous conditions in order to check the evolution of the engine.

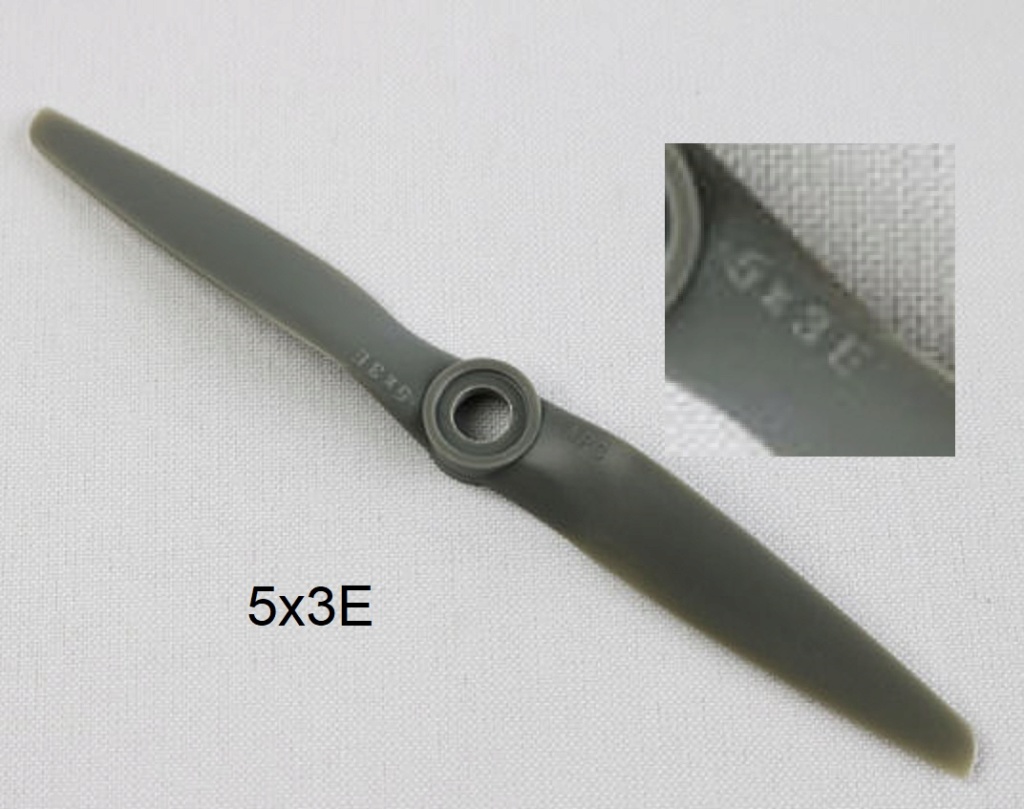

Propeller APC 5x3

Fuel: N25 / R20 / M55

RPM: 16000/17000 Now 18400/18500

Glow plug: insert type

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-16

Age : 53

Location : ARG

1/2A Nut- Top Poster

- Posts : 3538

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Page 2 of 6 •  1, 2, 3, 4, 5, 6

1, 2, 3, 4, 5, 6

Similar topics

Similar topics» New Flight: Pitts -Skelton Aerobatic model (page 9)

» Another Cox .010 converted to R/C & P-51 Mustang. (Flight page 5)

» VTO free flight model

» Charybdis-a free-flight model

» There is a Cox model airplane fan over on the Model Train Forum

» Another Cox .010 converted to R/C & P-51 Mustang. (Flight page 5)

» VTO free flight model

» Charybdis-a free-flight model

» There is a Cox model airplane fan over on the Model Train Forum

Page 2 of 6

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules