Log in

Search

Latest topics

» Roger Harris revisitedby rsv1cox Today at 3:38 pm

» My N-1R build log

by GallopingGhostler Today at 3:04 pm

» Tee Dee .020 combat model

by 1/2A Nut Today at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» My latest doodle...

by batjac Yesterday at 9:47 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

Cox Engine of The Month

.049 runs good for 50% of the time then coughs and dies

Page 1 of 1

.049 runs good for 50% of the time then coughs and dies

.049 runs good for 50% of the time then coughs and dies

I have two .049. One a black the other a golden.

Good compression, reed valve etc etc.

The start run normal for let's say 50% of their expected run time then sputter and cough. I have double triple checked the O-ring to make sure no leak. What the ** can cause this. I don't see any cracks or other holes. The pickup tube is clear and tight.

I tried switching needles too and will try later today. What might be a possible cause. I use the same technic for numerous other motors and they run just fine. Why these two little ** won't?

Thought?

Thanks

Ice

Good compression, reed valve etc etc.

The start run normal for let's say 50% of their expected run time then sputter and cough. I have double triple checked the O-ring to make sure no leak. What the ** can cause this. I don't see any cracks or other holes. The pickup tube is clear and tight.

I tried switching needles too and will try later today. What might be a possible cause. I use the same technic for numerous other motors and they run just fine. Why these two little ** won't?

Thought?

Thanks

Ice

Iceberg- Gold Member

- Posts : 382

Join date : 2018-11-03

Location : Suva Fiji Islands

Re: .049 runs good for 50% of the time then coughs and dies

Re: .049 runs good for 50% of the time then coughs and dies

Ice,

You might try sealing your tank back. It sounds like it has an air leak that is covered by fuel until the tank level drops far enough to uncover. Some recommend a string pushed into the back plate slot before reinstalling the tank, but just smoothing the lip of the tank on very fine sandpaper should help.

Also check the fuel line inside the tank for splits that are very hard to see. The line is covered by fuel until the tank is run down far enough to uncover any air leaks in the pickup line.

Bill

You might try sealing your tank back. It sounds like it has an air leak that is covered by fuel until the tank level drops far enough to uncover. Some recommend a string pushed into the back plate slot before reinstalling the tank, but just smoothing the lip of the tank on very fine sandpaper should help.

Also check the fuel line inside the tank for splits that are very hard to see. The line is covered by fuel until the tank is run down far enough to uncover any air leaks in the pickup line.

Bill

smooth_bill- Gold Member

- Posts : 229

Join date : 2012-02-19

Age : 87

Location : Beaverton, OR

Re: .049 runs good for 50% of the time then coughs and dies

Re: .049 runs good for 50% of the time then coughs and dies

While this gets brought up frequently and I do know you are knowledgable, but I have to ask how the engines are mounted, upright or sideways, as well as where the fuel pick-up is located? In the bottom for standard flying, and to the 9'oclock position for control line. I have caught myself with the pickup being in the wrong orientation before....

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: .049 runs good for 50% of the time then coughs and dies

Re: .049 runs good for 50% of the time then coughs and dies

Hi The engines all mounted vertical.

I am using the aluminum tub bent as Gibeault describes. It is in the 8 pm position away from center of flying circle.

Thanks

Ice

I am using the aluminum tub bent as Gibeault describes. It is in the 8 pm position away from center of flying circle.

Thanks

Ice

Iceberg- Gold Member

- Posts : 382

Join date : 2018-11-03

Location : Suva Fiji Islands

Re: .049 runs good for 50% of the time then coughs and dies

Re: .049 runs good for 50% of the time then coughs and dies

Screw the needle valve down until it seats. Pressurize the tank with a large syringe and watch and listen for leaks. Put oil on the screw heads, tank connection, case to tank, needle valve body and needle. Double check the reed, I have seen brand new reeds fail. Flip them over and re try. If you put a 5 oz. syringe with tubing onto the venturi and your able to pull the plunger back even the slightest, the reed isn't sealing. I have even had the need to true up the reed seat in the lathe. I just took a faint pass on the center.

Ken Cook- Top Poster

- Posts : 5637

Join date : 2012-03-27

Location : pennsylvania

Re: .049 runs good for 50% of the time then coughs and dies

Re: .049 runs good for 50% of the time then coughs and dies

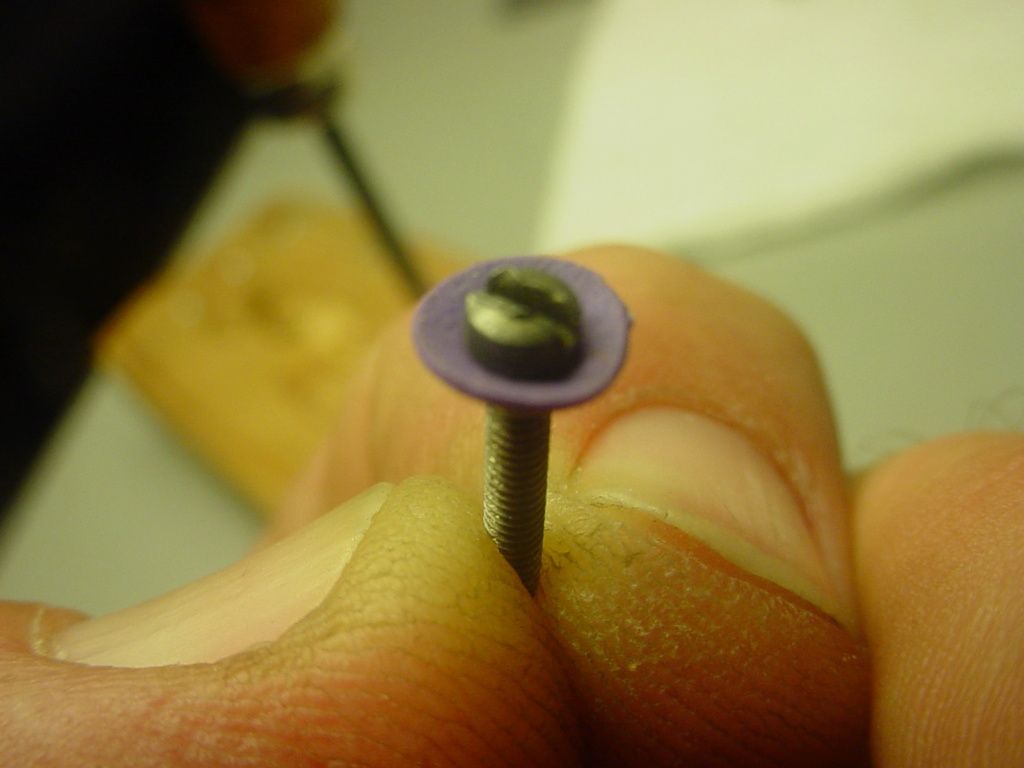

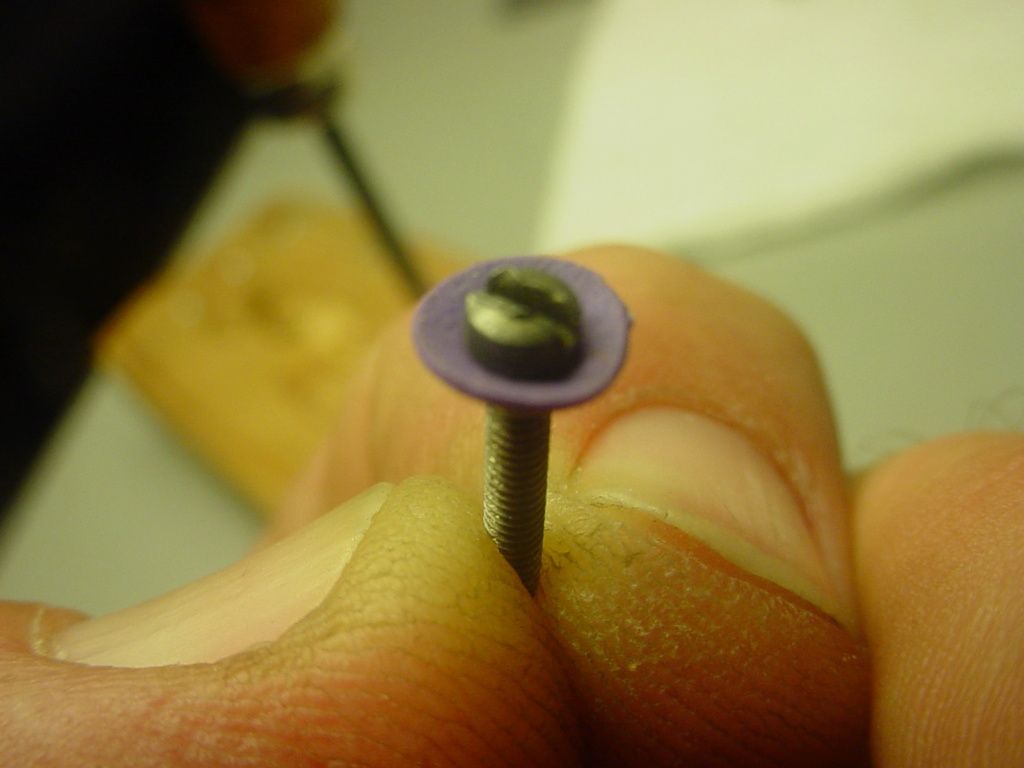

Hi Darren, There's always the possibility that the tank screws are leaking where they seat. If so; it could be because of a couple different scenarios.

The "best case scenario" would be that your crankcase(s) weren't tapped deep enough for the screw's fillister-head to tighten against the backplate. This was not uncommon.. and can be checked by measuring the thread-depth using a tank-screw.. and then the depth of the bore. You may find that there's enough difference to cut a couple additional threads; using a 2-56 (American Standard Machine-Screw size) bottoming-type tap.

Another scenario would be that the backplate has issues where these tank-screw heads seat. If any of the screws were ever over-tightened.. they could have opened-up (enlarged) the seat-area of the soft/pot-metal. Look for leaks around all four screw-heads.. and be aware of how-well or "if" all four screws are seating/sealing. You "can" make seals.. if the backplate holes aren't damaged too badly. I've made some from kitchen-gloves (Playtex rubber-type) I used a paper hole-punch to make these..

The "best case scenario" would be that your crankcase(s) weren't tapped deep enough for the screw's fillister-head to tighten against the backplate. This was not uncommon.. and can be checked by measuring the thread-depth using a tank-screw.. and then the depth of the bore. You may find that there's enough difference to cut a couple additional threads; using a 2-56 (American Standard Machine-Screw size) bottoming-type tap.

Another scenario would be that the backplate has issues where these tank-screw heads seat. If any of the screws were ever over-tightened.. they could have opened-up (enlarged) the seat-area of the soft/pot-metal. Look for leaks around all four screw-heads.. and be aware of how-well or "if" all four screws are seating/sealing. You "can" make seals.. if the backplate holes aren't damaged too badly. I've made some from kitchen-gloves (Playtex rubber-type) I used a paper hole-punch to make these..

Re: .049 runs good for 50% of the time then coughs and dies

Re: .049 runs good for 50% of the time then coughs and dies

swap back plate bet u disasemble clean 2 engine at same time and change back plate golden bee us its own desing back plate wit its extra part inside ventury look for its golden look inside if some color remain

davidll1984- Diamond Member

- Posts : 2327

Join date : 2020-02-12

Age : 39

Location : shawinigan

Re: .049 runs good for 50% of the time then coughs and dies

Re: .049 runs good for 50% of the time then coughs and dies

Thanks Roddie

Excellent suggestions. I'll put them into affect hopefully will fix the issues!

Thank you!

Excellent suggestions. I'll put them into affect hopefully will fix the issues!

Thank you!

Iceberg- Gold Member

- Posts : 382

Join date : 2018-11-03

Location : Suva Fiji Islands

Re: .049 runs good for 50% of the time then coughs and dies

Re: .049 runs good for 50% of the time then coughs and dies

roddie wrote:Hi Darren, There's always the possibility that the tank screws are leaking where they seat. If so; it could be because of a couple different scenarios.

The "best case scenario" would be that your crankcase(s) weren't tapped deep enough for the screw's fillister-head to tighten against the backplate. This was not uncommon.. and can be checked by measuring the thread-depth using a tank-screw.. and then the depth of the bore. You may find that there's enough difference to cut a couple additional threads; using a 2-56 (American Standard Machine-Screw size) bottoming-type tap.

Another scenario would be that the backplate has issues where these tank-screw heads seat. If any of the screws were ever over-tightened.. they could have opened-up (enlarged) the seat-area of the soft/pot-metal. Look for leaks around all four screw-heads.. and be aware of how-well or "if" all four screws are seating/sealing. You "can" make seals.. if the backplate holes aren't damaged too badly. I've made some from kitchen-gloves (Playtex rubber-type) I used a paper hole-punch to make these..

Roddie,

I think the plastic washers put under the backplate screw heads will be good to prevent fuel losses there. Otherwise no matter if the screw head seats are air-tight or not, because the tank communicates with the outside atmosphere through the tank vents, anyway. Sorry if I misunderstood you message.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: .049 runs good for 50% of the time then coughs and dies

Re: .049 runs good for 50% of the time then coughs and dies

Don't forget the most common ailment of the reedies, the crank to case seal. It does not take long for play to lose the seal. Pull the crank forward and try to rock the crank up and down using the prop. If you can see the piston moving up and down, that will be the culprit. Also check all the other normal leaks and the reed etc. A new case would be the fix for the case leak. Sometimes I make a bushing up, but that is too fiddly for most people, and the cases are quite cheap.

aspeed- Platinum Member

- Posts : 796

Join date : 2013-01-18

Location : Leamington Ont. Can.

Re: .049 runs good for 50% of the time then coughs and dies

Re: .049 runs good for 50% of the time then coughs and dies

Darren, I forgot to ask. After these cut-short flights; have you tried measuring the amount of fuel needed to refill the tank? If it requires an entire 7-8cc's re-fill.. then you're losing it all somewhere. aspeed (Alan) mentioned the "crank to case" fit.. and if worn; maybe there's what I'd call blow-by.. of raw-fuel out-through the front-end? You wouldn't notice this in the pit.. or maybe not-even during static testing.

EDIT: If the reed is sealing properly.. then on the down-stroke of the piston; the crankcase has positive-pressure which might blow some unburned/raw-fuel out of a worn crank-journal.

Just a bit more to think about bro.

EDIT: If the reed is sealing properly.. then on the down-stroke of the piston; the crankcase has positive-pressure which might blow some unburned/raw-fuel out of a worn crank-journal.

Just a bit more to think about bro.

Re: .049 runs good for 50% of the time then coughs and dies

Re: .049 runs good for 50% of the time then coughs and dies

Hi Roddie

Only burns half tank so not all disappeared. I keep looking and little by little knocking out possibilities.

Thanks very much!

Darren

Only burns half tank so not all disappeared. I keep looking and little by little knocking out possibilities.

Thanks very much!

Darren

Iceberg- Gold Member

- Posts : 382

Join date : 2018-11-03

Location : Suva Fiji Islands

Re: .049 runs good for 50% of the time then coughs and dies

Re: .049 runs good for 50% of the time then coughs and dies

roddie wrote:...somewhere. aspeed (Alan) mentioned the "crank to case" fit.. and if worn; maybe there's what I'd call blow-by.. of raw-fuel out-through the front-end? You wouldn't notice this in the pit.. or maybe not-even during static testing.

EDIT: If the reed is sealing properly.. then on the down-stroke of the piston; the crankcase has positive-pressure which might blow some unburned/raw-fuel out of a worn crank-journal.

Just a bit more to think about bro.

That's what took out my Golden Bee block...lots of hours over lots of years. I could see it pump raw fuel and bubbles on the test stand. I never did take the time to try other, newer cranks.

944_Jim- Diamond Member

Posts : 2022

Join date : 2017-02-08

Age : 59

Location : NE MS

Re: .049 runs good for 50% of the time then coughs and dies

Re: .049 runs good for 50% of the time then coughs and dies

I have a few anodized crankcases that are all slightly loose fit with the shaft and I always wonder if this loose fit is an advantage because of lower friction as Paul Gibault advises in his Mouse race paper, or disadvantage for weaker seal. True that their surface hardness better resists abrasion if the prop is unbalanced but somehow I still favour the oldschool old stock 049 crankcases with exact fit and no anodization. I make sure my props are always balanced though. The crankcases last a helluva long time then.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: .049 runs good for 50% of the time then coughs and dies

Re: .049 runs good for 50% of the time then coughs and dies

On my leaky cases I could see a wear spot on the bottom back of the crank hole, like when it would push the crank down when firing. I could see it and even measure to see something was oval. They are faster when loose, but at a certain point they leak, and rev up and down and generally make you mad. Of course it can be some other thing too. Maybe the nipple has a crack or some other tubing or gasket/O ring. I pressed in some bushings on the worst ones but never tested them since, as I got away from the reedies, and also I would have to press them apart to know which ones are which. Probably have a dozen, and two were rebushed IIRC.

aspeed- Platinum Member

- Posts : 796

Join date : 2013-01-18

Location : Leamington Ont. Can.

Similar topics

Similar topics» Crumby Day for Flying--Good Day for Shop Time !!!!

» The Breezy Hill Flyers' 2nd "Black Fly-Day" Event and A Good Time For All !!!

» IT Runs...IT RUNS!!!!! The Rescue Bug Comes Alive !!

» Cox .074 Queen Bee nelson plug

» Help with a Babe Bee --loses power, slowly dies

» The Breezy Hill Flyers' 2nd "Black Fly-Day" Event and A Good Time For All !!!

» IT Runs...IT RUNS!!!!! The Rescue Bug Comes Alive !!

» Cox .074 Queen Bee nelson plug

» Help with a Babe Bee --loses power, slowly dies

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules