Log in

Search

Latest topics

» My latest doodle...by batjac Yesterday at 10:05 pm

» Retail price mark-up.. how much is enough?

by gkamysz Yesterday at 9:29 pm

» Happy 77th birthday Andrew!

by roddie Yesterday at 9:22 pm

» Roger Harris revisited

by rsv1cox Yesterday at 3:38 pm

» My N-1R build log

by GallopingGhostler Yesterday at 3:04 pm

» Tee Dee .020 combat model

by 1/2A Nut Yesterday at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Yesterday at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Yesterday at 11:32 am

» Free Flight Radio Assist

by rdw777 Yesterday at 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

Cox Engine of The Month

Cox .074 Queen Bee nelson plug

Page 1 of 4

Page 1 of 4 • 1, 2, 3, 4

Cox .074 Queen Bee nelson plug

Cox .074 Queen Bee nelson plug

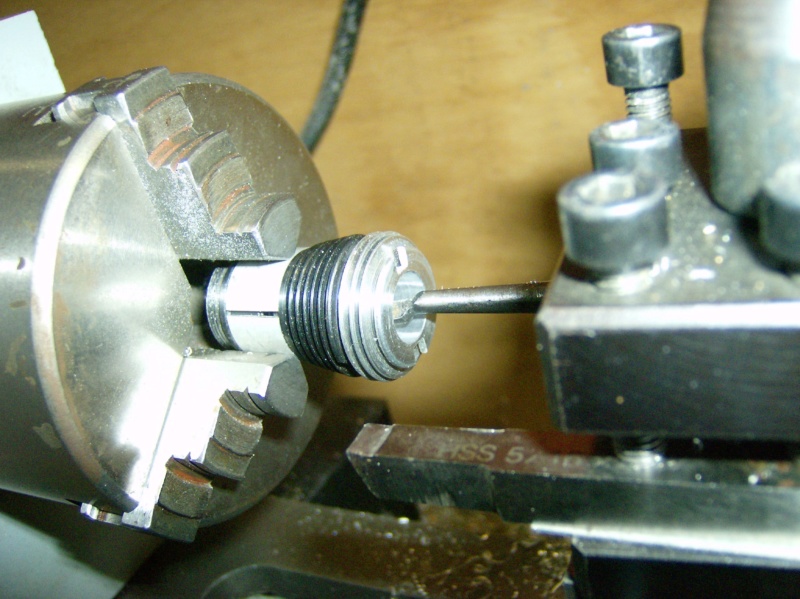

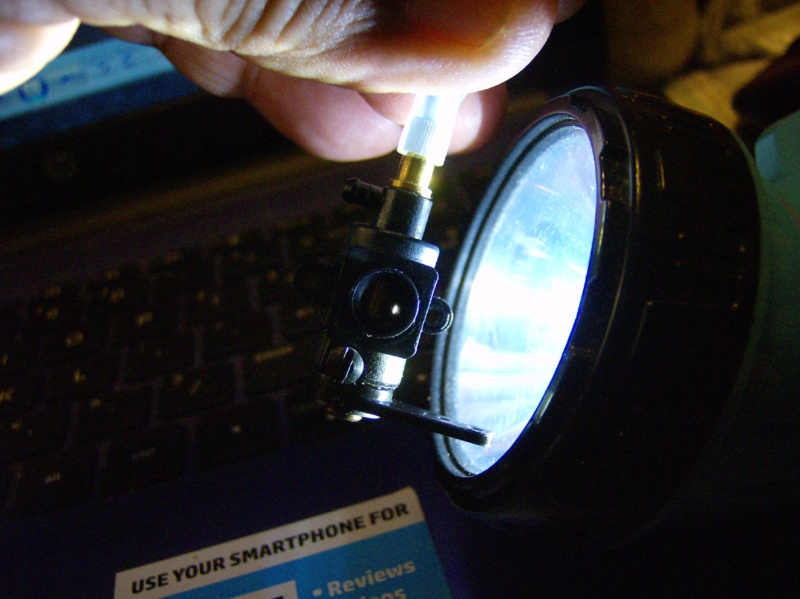

I could not find a used head to modify for my Queen Bee .074 so I went ahead and used the one I had. I made a Nelson plug button but since the plug had to be far into the head to get the combustion chamber I wanted. I noticed that I would not be able to tighten the glow plug on the engine. I made a clamp to tighten the nelson plug outside the engine. I had to bore out the cox head but before that mounting the stock glow plug on the head I used to mount it on my sherline lathe and doing light cuts I removed .060 of the bottom then I mounted the head on the cylinder and placing it on my lathe using an aluminum sleeve I bored the head to go over the plug and tighten the button. You can`t tighten the jaws on the lathe too hard as the cylinder might be damaged, I also did light cuts while boring the head. I also made the inlet to the muffler square increasing its size and turned down the back portion of the muffler to lighten it.here are some pics.

Juan

Juan

F4D Phantom II- Gold Member

- Posts : 245

Join date : 2019-04-08

Re: Cox .074 Queen Bee nelson plug

Re: Cox .074 Queen Bee nelson plug

Nice machine work

Have you had a chance to test it yet if so what was the before and after rpm increase?

Have you had a chance to test it yet if so what was the before and after rpm increase?

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .074 Queen Bee nelson plug

Re: Cox .074 Queen Bee nelson plug

Hello Nut

I ran it previously with a 6 x 3 cox grey propeller wit 5/22 fuel with the stock head and no muffler a while back and I think it hit 16,800rpm. I had wanted to run it with 10% fuel but I didn`t have any. I stopped working on it when I was not able to get a spare head to modify. Initially I was planing on using a turbo plug but I found a piece of round aluminum that I had already started to do a nelson button for an OS.40 FP and decided to use it. I will be running the engine in a few days to see how it does but still have to make a couple of head gaskets to play with compression.

Juan

I ran it previously with a 6 x 3 cox grey propeller wit 5/22 fuel with the stock head and no muffler a while back and I think it hit 16,800rpm. I had wanted to run it with 10% fuel but I didn`t have any. I stopped working on it when I was not able to get a spare head to modify. Initially I was planing on using a turbo plug but I found a piece of round aluminum that I had already started to do a nelson button for an OS.40 FP and decided to use it. I will be running the engine in a few days to see how it does but still have to make a couple of head gaskets to play with compression.

Juan

F4D Phantom II- Gold Member

- Posts : 245

Join date : 2019-04-08

Re: Cox .074 Queen Bee nelson plug

Re: Cox .074 Queen Bee nelson plug

Good you have a base line to go by.

Open exhaust 5% - 22% oil / 6D x 3P:

16.8k / .132hp - 98.47w / 48 mph pitch speed / 16.3 oz thrust

Open exhaust 5% - 22% oil / 6D x 3P:

16.8k / .132hp - 98.47w / 48 mph pitch speed / 16.3 oz thrust

Last edited by 1/2A Nut on Mon May 27, 2019 1:28 pm; edited 1 time in total

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .074 Queen Bee nelson plug

Re: Cox .074 Queen Bee nelson plug

You should probably find another 1000rpm or so with the better head.

Mine would do around 17900rpm on a 6x3 prop and a Turbo plug. It had a nice scream to it then but I would have like to use a 6x4 prop instead. It throttled much nicer on that prop I think but it wouldn't quite hold at the top end, seemed to get a little too hot.

Mine would do around 17900rpm on a 6x3 prop and a Turbo plug. It had a nice scream to it then but I would have like to use a 6x4 prop instead. It throttled much nicer on that prop I think but it wouldn't quite hold at the top end, seemed to get a little too hot.

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Cox .074 Queen Bee nelson plug

Re: Cox .074 Queen Bee nelson plug

I have owned 3 Queen Bee's two on a boat 1 of those also flew with a plane they will scream as I found

with an outrigger hydro so there is hope for the reed valve rear inducted engine. Perhaps the forward

speed of the boat help to shove in some air and allow a bit more rpm. Around 26k loaded with a surface

prop any jumps out of the water the engine would momentarily peak around 30k ish. Impressive for a

reed engine. I liked them for the throttle and the robust front end when fitted with a flywheel. Was getting

around 22 - 24 mph with the small 18" rigger.

Today I have the 3rd one mint for aero use I would like to work with it at some point.

I have a Valentine turbo head for it yet to test. I think the HQ carbon blend 5x4.5 may bring it to life.

Perhaps 30% nitro 24% castor to keep it cool. I need at least 80 mph static to get any use out of it.

Also may try another carb on it, I have some spars with low end needles that will help make it purr.

with an outrigger hydro so there is hope for the reed valve rear inducted engine. Perhaps the forward

speed of the boat help to shove in some air and allow a bit more rpm. Around 26k loaded with a surface

prop any jumps out of the water the engine would momentarily peak around 30k ish. Impressive for a

reed engine. I liked them for the throttle and the robust front end when fitted with a flywheel. Was getting

around 22 - 24 mph with the small 18" rigger.

Today I have the 3rd one mint for aero use I would like to work with it at some point.

I have a Valentine turbo head for it yet to test. I think the HQ carbon blend 5x4.5 may bring it to life.

Perhaps 30% nitro 24% castor to keep it cool. I need at least 80 mph static to get any use out of it.

Also may try another carb on it, I have some spars with low end needles that will help make it purr.

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .074 Queen Bee nelson plug

Re: Cox .074 Queen Bee nelson plug

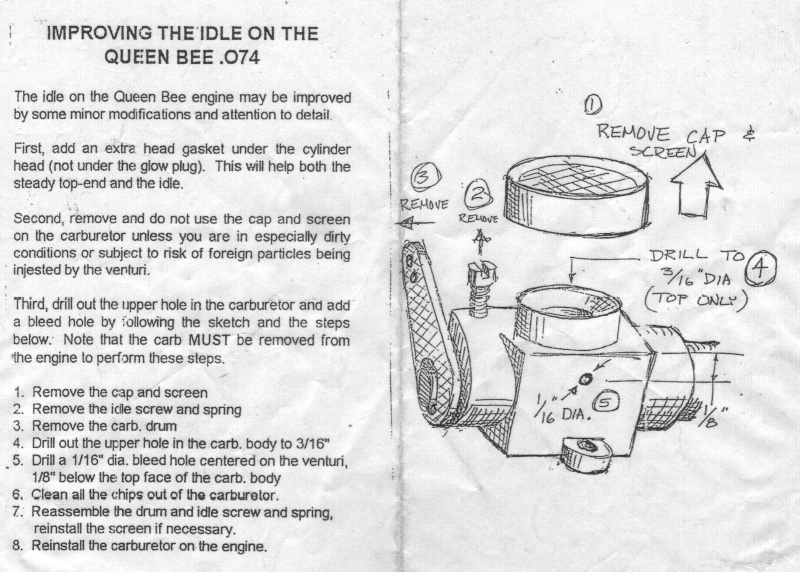

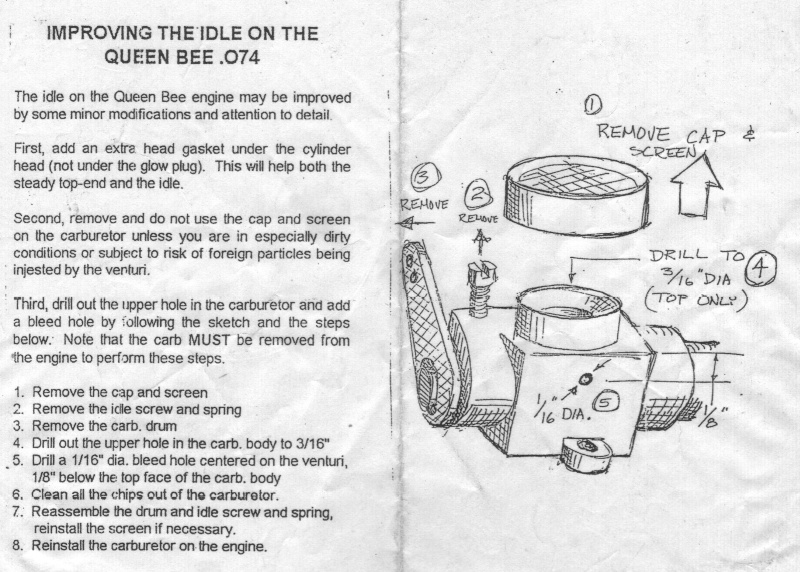

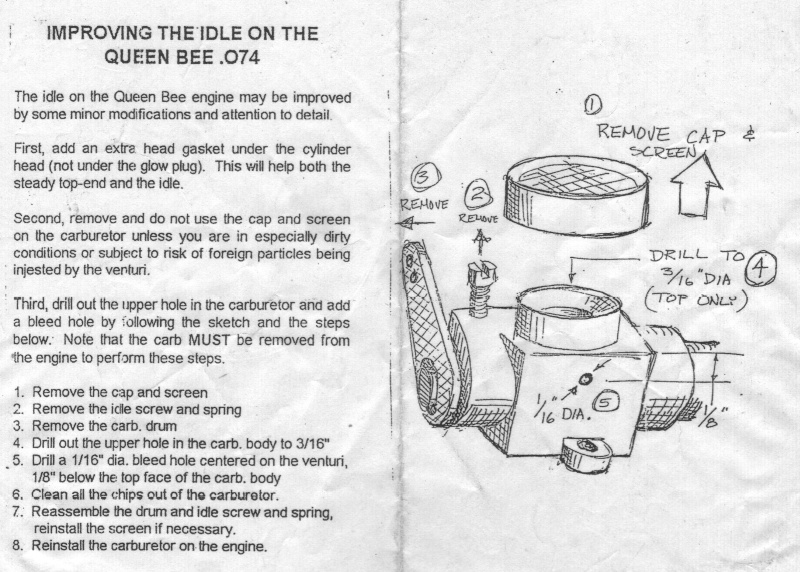

The carb has a few design errors but it can be fixed quite easily, I think I wrote about that in the thread about running it with an RJL diesel head. It should also be in the cox international news letter article that I wrote in 2016 (in the autumn I think, don't remember the number now).

The ideas for the carb mods are outline below, and one can also make it with an adjustable airbleed:

The ideas for the carb mods are outline below, and one can also make it with an adjustable airbleed:

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Cox .074 Queen Bee nelson plug

Re: Cox .074 Queen Bee nelson plug

Found the newsletter (Nov. 2016): Cox engines Quarterly

(I made the adjustable airbleed later)

(I made the adjustable airbleed later)

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Cox .074 Queen Bee nelson plug

Re: Cox .074 Queen Bee nelson plug

Hello Surfer Kriss and Nut

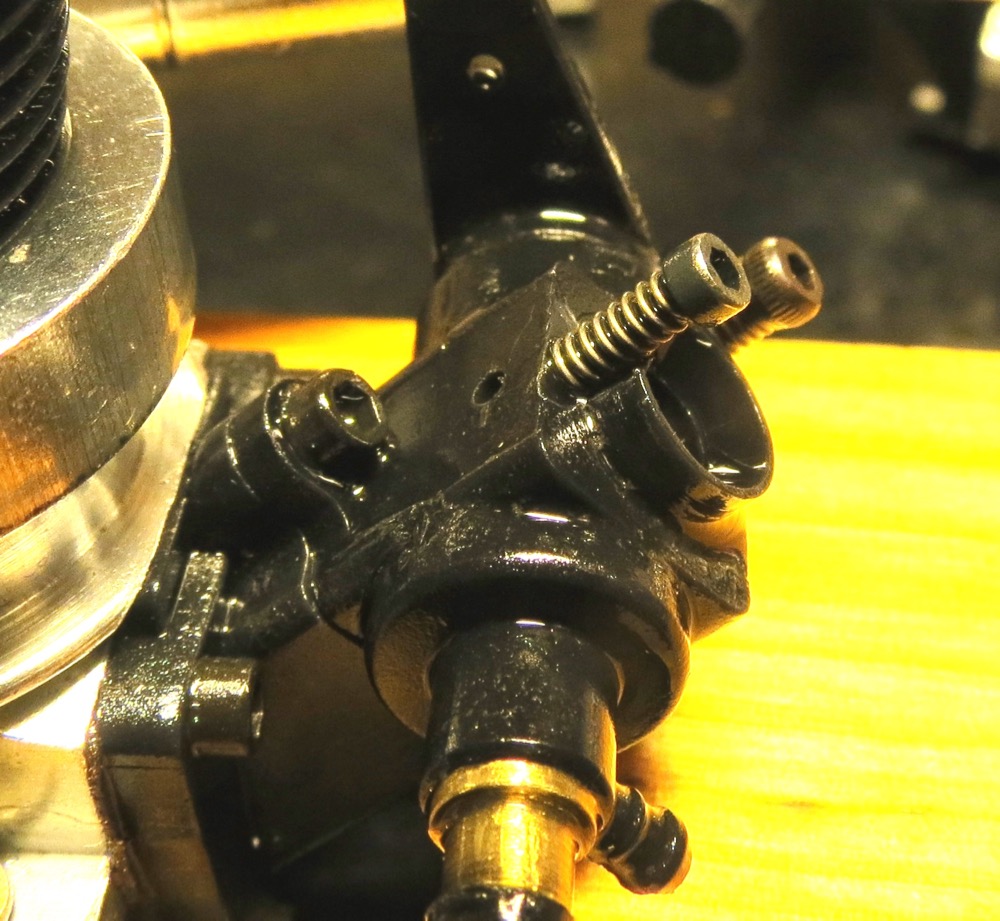

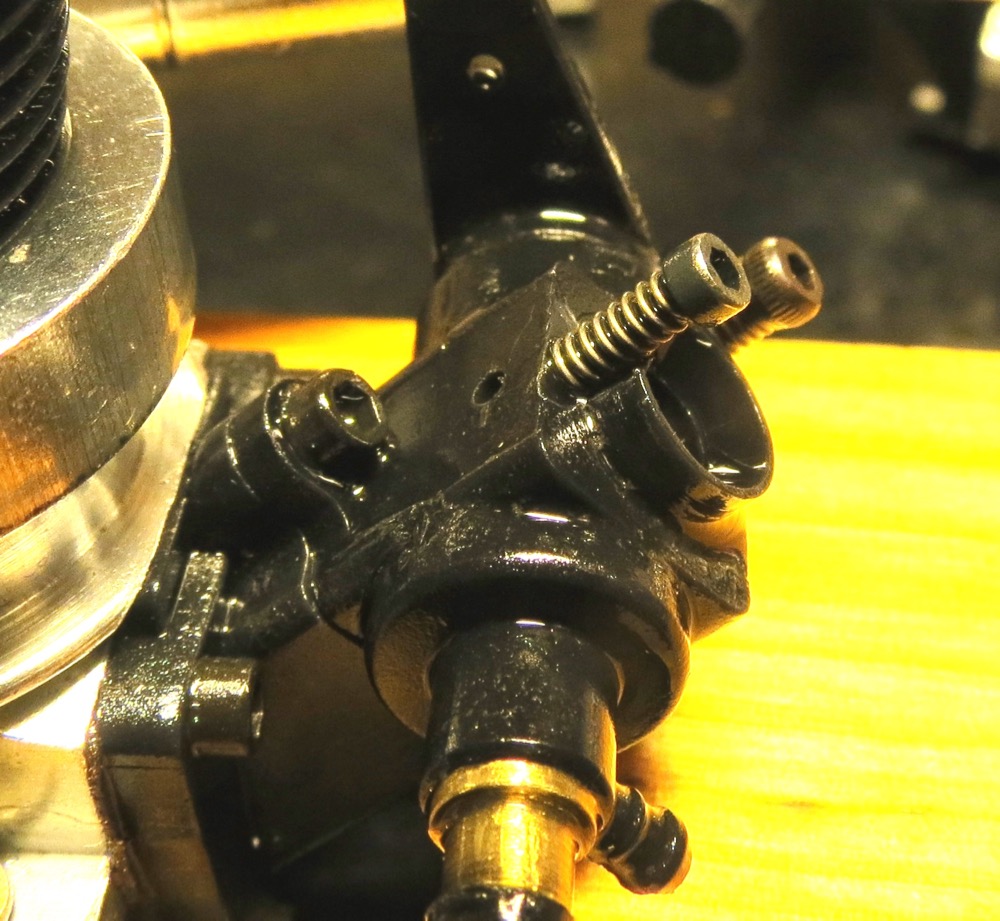

I had not noticed that you guys had posted when I wrote my previous entry. Kriss I followed your sketch and moded the carb as suggested. I see that you added the airbleed screw from the only location available at the top smart move. Nut this engines are built in a way that they can be improved by modifying and get them to produce more power by doing things that might have not being cost effective to cox. I have seen a lot of engines and there is allways something that can be done to get more out of them. I know you have been at it for quite a while and have had a lot of fun. Is too bad that getting parts is a pain. Here are some pics of carb mod.

Juan

I had not noticed that you guys had posted when I wrote my previous entry. Kriss I followed your sketch and moded the carb as suggested. I see that you added the airbleed screw from the only location available at the top smart move. Nut this engines are built in a way that they can be improved by modifying and get them to produce more power by doing things that might have not being cost effective to cox. I have seen a lot of engines and there is allways something that can be done to get more out of them. I know you have been at it for quite a while and have had a lot of fun. Is too bad that getting parts is a pain. Here are some pics of carb mod.

Juan

F4D Phantom II- Gold Member

- Posts : 245

Join date : 2019-04-08

Re: Cox .074 Queen Bee nelson plug

Re: Cox .074 Queen Bee nelson plug

I did the carb mod on mine when I first saw the diagram. Mine idles nicely. I seem to remember having a hard time before. I did not drill .0625". I used a smaller drill in case it was too big, I didn't want a bleed screw. I think I went .040" or whatever # drill I had. Juan, where did you get your Nelson tap? It took me a while to find one reasonably priced.

aspeed- Platinum Member

- Posts : 796

Join date : 2013-01-18

Location : Leamington Ont. Can.

Re: Cox .074 Queen Bee nelson plug

Re: Cox .074 Queen Bee nelson plug

Hello speed

I bought the tap in 2015 to do a head on an OS.40FP and I don`t remember where I got it or how much I paid. The brand is TMX pn# 5-750-5516 11/32-32 GH3 made in Bosnia. I have seen a few on ebay in the 15-18 dollar range.

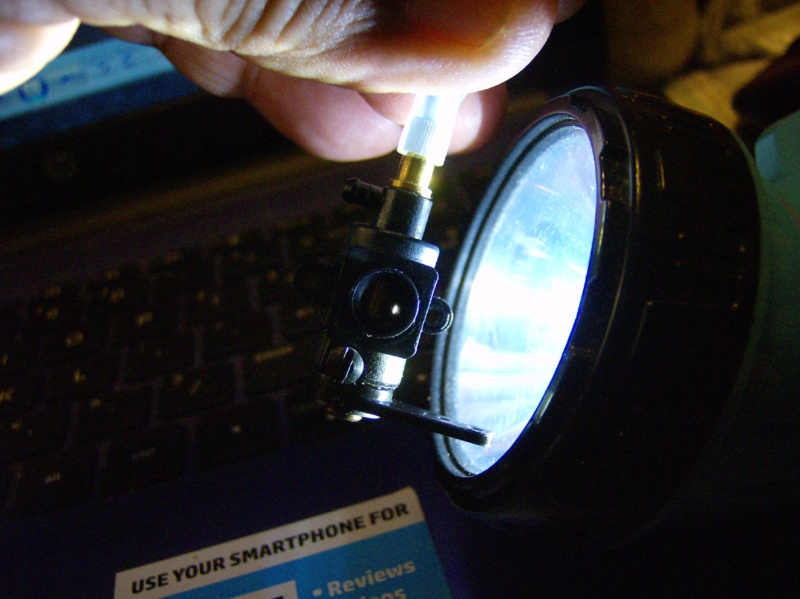

In the idle hole I did as the drawing stated and drilled 1/16 inch 1/8 inch from top and when I drilled the venturi to 3/16 inch I noticed that I could see light coming thru with the barrel fully closed thru the venturi I wish I had gone a little lower with a smaller drill bit. Using a .040 inch bit would have been better. I will try it as is to see how it works. I can alway plug the hole and drill a little lower with a smaller drill. Here is a pic.

Juan

I bought the tap in 2015 to do a head on an OS.40FP and I don`t remember where I got it or how much I paid. The brand is TMX pn# 5-750-5516 11/32-32 GH3 made in Bosnia. I have seen a few on ebay in the 15-18 dollar range.

In the idle hole I did as the drawing stated and drilled 1/16 inch 1/8 inch from top and when I drilled the venturi to 3/16 inch I noticed that I could see light coming thru with the barrel fully closed thru the venturi I wish I had gone a little lower with a smaller drill bit. Using a .040 inch bit would have been better. I will try it as is to see how it works. I can alway plug the hole and drill a little lower with a smaller drill. Here is a pic.

Juan

F4D Phantom II- Gold Member

- Posts : 245

Join date : 2019-04-08

Re: Cox .074 Queen Bee nelson plug

Re: Cox .074 Queen Bee nelson plug

That picture looks correct to me. You should have a connection between the airbleed hole and bore in the barrel around idle and a little higher (up to about 1/4 of throttle advancement roughly). The barrel should also close earlier in the bottom part than in the upper part, this together with the airbleed hole is thus reducing the fuel draw at about 1/4 of throttel and down.

Instead of a light source you can put a thin wire in the airbleed hole that pokes into the barrel opening, then rotate the barrel to check were it stops against the wire.

Instead of a light source you can put a thin wire in the airbleed hole that pokes into the barrel opening, then rotate the barrel to check were it stops against the wire.

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Cox .074 Queen Bee nelson plug

Re: Cox .074 Queen Bee nelson plug

F4D Phantom II wrote:Hello speed

I bought the tap in 2015 to do a head on an OS.40FP and I don`t remember where I got it or how much I paid. The brand is TMX pn# 5-750-5516 11/32-32 GH3 made in Bosnia. I have seen a few on ebay in the 15-18 dollar range.

In the idle hole I did as the drawing stated and drilled 1/16 inch 1/8 inch from top and when I drilled the venturi to 3/16 inch I noticed that I could see light coming thru with the barrel fully closed thru the venturi I wish I had gone a little lower with a smaller drill bit. Using a .040 inch bit would have been better. I will try it as is to see how it works. I can alway plug the hole and drill a little lower with a smaller drill. Here is a pic.

Juan

How do you Machine the head button to fit the Nelson plug? Obviously the threaded part is bored to .312”. What is the angle that the taper seat is cut on?

Thanks!

63expert- Bronze Member

- Posts : 38

Join date : 2014-02-10

Re: Cox .074 Queen Bee nelson plug

Re: Cox .074 Queen Bee nelson plug

I vaguely recall measuring one at 118 degrees. It seems to coincide with a standard drill angle. The turbo plugs are 60 degrees and wear away the aluminum over time.

aspeed- Platinum Member

- Posts : 796

Join date : 2013-01-18

Location : Leamington Ont. Can.

Re: Cox .074 Queen Bee nelson plug

Re: Cox .074 Queen Bee nelson plug

63expert wrote:F4D Phantom II wrote:Hello speed

I bought the tap in 2015 to do a head on an OS.40FP and I don`t remember where I got it or how much I paid. The brand is TMX pn# 5-750-5516 11/32-32 GH3 made in Bosnia. I have seen a few on ebay in the 15-18 dollar range.

In the idle hole I did as the drawing stated and drilled 1/16 inch 1/8 inch from top and when I drilled the venturi to 3/16 inch I noticed that I could see light coming thru with the barrel fully closed thru the venturi I wish I had gone a little lower with a smaller drill bit. Using a .040 inch bit would have been better. I will try it as is to see how it works. I can alway plug the hole and drill a little lower with a smaller drill. Here is a pic.

Juan

How do you Machine the head button to fit the Nelson plug? Obviously the threaded part is bored to .312”. What is the angle that the taper seat is cut on?

Thanks!

Hello 63

Here is the info: NELSON PLUG INFO

-Nelson Plugs are 11/32" X 32 TPI x 110 degree included angle on the nose

87 degree included angle which happens to be what is on a standard jobber drill bit.

Juan

F4D Phantom II- Gold Member

- Posts : 245

Join date : 2019-04-08

Re: Cox .074 Queen Bee nelson plug

Re: Cox .074 Queen Bee nelson plug

What's the advantage of a Nelson plug over a standard "Turbo" plug? Both have the tapered seat. I believe turbo may be a smaller diameter, which could be an advantage in some smaller engine applications.

Oldenginerod- Top Poster

- Posts : 4018

Join date : 2012-06-15

Age : 62

Location : Drouin, Victoria

Re: Cox .074 Queen Bee nelson plug

Re: Cox .074 Queen Bee nelson plug

- element hole is typically smaller than most others attention to this detail is important.

advantage is higher compression with less fuel / air charge going up into the reduced cavity.

- larger dia. plug is an advantage due to increased flat surface area providing increased compression.

- tapper angle and dia. allows better seating tighter bind without blowing out the aluminum head adapter.

- effort made towards the quality of the element, it's dia. and gauge improves burn rate of the fuel charge.

- final effort is the confidence the plug provides to the end user tends to lead folks to tweak the NV for fantastic

power to the prop without frying the plug / able to hold up to higher nitro content.

advantage is higher compression with less fuel / air charge going up into the reduced cavity.

- larger dia. plug is an advantage due to increased flat surface area providing increased compression.

- tapper angle and dia. allows better seating tighter bind without blowing out the aluminum head adapter.

- effort made towards the quality of the element, it's dia. and gauge improves burn rate of the fuel charge.

- final effort is the confidence the plug provides to the end user tends to lead folks to tweak the NV for fantastic

power to the prop without frying the plug / able to hold up to higher nitro content.

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .074 Queen Bee nelson plug

Re: Cox .074 Queen Bee nelson plug

I prefer the turbo plugs to the Nelson because of the diameter and the choice of different brands and heat ranges. The taper of the turbo plugs does wear away the head after a while as was mentioned and the Nelson plug is usually priced better.

aspeed- Platinum Member

- Posts : 796

Join date : 2013-01-18

Location : Leamington Ont. Can.

Re: Cox .074 Queen Bee nelson plug

Re: Cox .074 Queen Bee nelson plug

The Nelson plug with the notches on the sides is best for small engine use, good heat range.

I do like the Gold OS P series plugs as a alternative P3 and 4 seem to work great with sub .07 displacements

that need all the help possible for a steady low idle.

I do like the Gold OS P series plugs as a alternative P3 and 4 seem to work great with sub .07 displacements

that need all the help possible for a steady low idle.

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .074 Queen Bee nelson plug

Re: Cox .074 Queen Bee nelson plug

The one with the notches on is the HD one. The hotter Nelson plug (for 1/2A) is recognised by a larger hole and a smaller diameter wire, if I remember correctly.

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Cox .074 Queen Bee nelson plug

Re: Cox .074 Queen Bee nelson plug

Ok, so from what I can see the Nelson plugs I got from Larry Driskill have a body OD of .299”. So drill a 7/32 hole to clear the nose of the plug, then drill a 5/16 hole to within .005-.010 of the combustion chamber, then tap 11/32-32 ?

Here is a pic of a Tee Dee .09 hi-comp head that Bob Mattes reworked for me to use Nelson plug.

Here is a pic of a Tee Dee .09 hi-comp head that Bob Mattes reworked for me to use Nelson plug.

63expert- Bronze Member

- Posts : 38

Join date : 2014-02-10

Re: Cox .074 Queen Bee nelson plug

Re: Cox .074 Queen Bee nelson plug

Hotter NL05 plug is recommended for RC carb use for improved idle but has less compression with larger element hole.

I have found higher rpm with the HD NL02 plug / smaller element hole - still idles well enough as I use high nitro.

Also have never burned one of these out yet.

http://kittingittogether.com/glow-plugs/nelson-hd-plug-nl02/

Idle example of a Nelson HD NL02:

Published on Jan 12, 2019

HQ carbon blend prop 4 x 4.5 Static Peak 26,086 rpm / 111 mph pitch speed

.147hp / 110w / 7.8oz thrust

I have found higher rpm with the HD NL02 plug / smaller element hole - still idles well enough as I use high nitro.

Also have never burned one of these out yet.

http://kittingittogether.com/glow-plugs/nelson-hd-plug-nl02/

Idle example of a Nelson HD NL02:

Published on Jan 12, 2019

HQ carbon blend prop 4 x 4.5 Static Peak 26,086 rpm / 111 mph pitch speed

.147hp / 110w / 7.8oz thrust

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .074 Queen Bee nelson plug

Re: Cox .074 Queen Bee nelson plug

I was able to run the queen Bee.074 today about 6:00pm. I had a hard time starting the engine and then I realized that my Cox glow clip wires were shorting inside the plastic. the wires would get hot and the glow plug would not. I had crimped new wires on the metal parts and one slid out enough to cause an intermittent short. Fixed the clip and went back to the running table. I filled the tank with 5/22 fuel since that was the fuel I used last time and a 6 x 3 cox grey prop. Engine cranked up and got up to 17,500 Rpm for a gain of 700rpm with the Nelson head. I closed slowly the needle until I could see no gain then I put the muffler on and it reached 16,500 rpm. I still would like to install a few more head gaskets but I would need to buy or make them. Since it was getting dark I called a day.

Juan

Juan

F4D Phantom II- Gold Member

- Posts : 245

Join date : 2019-04-08

Re: Cox .074 Queen Bee nelson plug

Re: Cox .074 Queen Bee nelson plug

Should turn more rpm with the lighter black plastic 6x3

700 rpm gain is not bad at all unloaded will equal to much more.

I think you could use some more compression and hit 1000 rpm

If you make another shim or two then you can also try higher

compression with room to use the shims if it does not increase.

Another trick is put a pressure tap on the muffler may gain more

rpm back. I was able to get more rpm with the TD RC .050 using

a pressure tap.

Note when I hold the plane up to launch where I put the pressure tap

on the Cox muffler, location is important for best pressure.

700 rpm gain is not bad at all unloaded will equal to much more.

I think you could use some more compression and hit 1000 rpm

If you make another shim or two then you can also try higher

compression with room to use the shims if it does not increase.

Another trick is put a pressure tap on the muffler may gain more

rpm back. I was able to get more rpm with the TD RC .050 using

a pressure tap.

Note when I hold the plane up to launch where I put the pressure tap

on the Cox muffler, location is important for best pressure.

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Page 1 of 4 • 1, 2, 3, 4

Similar topics

Similar topics» nelson plug

» Nelson head,plug

» Galbreath head nelson plug

» My Cox .049 reedy with a Galbreath head and Nelson plug

» Queen Bee .074 and .09 Glow Plug Heads

» Nelson head,plug

» Galbreath head nelson plug

» My Cox .049 reedy with a Galbreath head and Nelson plug

» Queen Bee .074 and .09 Glow Plug Heads

Page 1 of 4

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules