Log in

Search

Latest topics

» My latest doodle...by batjac Today at 10:05 pm

» Retail price mark-up.. how much is enough?

by gkamysz Today at 9:29 pm

» Happy 77th birthday Andrew!

by roddie Today at 9:22 pm

» Roger Harris revisited

by rsv1cox Today at 3:38 pm

» My N-1R build log

by GallopingGhostler Today at 3:04 pm

» Tee Dee .020 combat model

by 1/2A Nut Today at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

Cox Engine of The Month

Ball bearings you say? 3D printed BB crankcase.

Page 2 of 2

Page 2 of 2 •  1, 2

1, 2

Re: Ball bearings you say? 3D printed BB crankcase.

Re: Ball bearings you say? 3D printed BB crankcase.

Oh, OK, I do not have one to be able to comment on it then. There is usually a plan B though if you think hard enough. I have snapped a few plastic nipples off on LAs, and Thunder Tiger .07s just bumping them with starters and being careless, as well as cheap swap meet deals.balogh wrote:It is the 3D nipple body with sufficient thickness that, combined with the brass nipple, will last much longer than the stock COX RC nipple. When the fuel stub breaks off - and it will sooner than later- from the stock part, there is no way to replace it with a threaded brass nipple because the plastic sleeve is very thin.

aspeed- Platinum Member

- Posts : 796

Join date : 2013-01-18

Location : Leamington Ont. Can.

Re: Ball bearings you say? 3D printed BB crankcase.

Re: Ball bearings you say? 3D printed BB crankcase.

The Tarno RC carb had a similar concept for the fuel nipple, with the whole spraybar unit including the nipple body made of brass...

if one wanted to re-purpose it to a COX TeeDee RC carb, the spraybar hole on thr nipple body had to be widened to accommodate the COX spraybar..once I tried it with a used and defunct Tarno carb, but unfortunately cannibalized the all-brass nipple body and have given up...

if one wanted to re-purpose it to a COX TeeDee RC carb, the spraybar hole on thr nipple body had to be widened to accommodate the COX spraybar..once I tried it with a used and defunct Tarno carb, but unfortunately cannibalized the all-brass nipple body and have given up...

Last edited by balogh on Mon May 25, 2020 8:33 am; edited 1 time in total

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Ball bearings you say? 3D printed BB crankcase.

Re: Ball bearings you say? 3D printed BB crankcase.

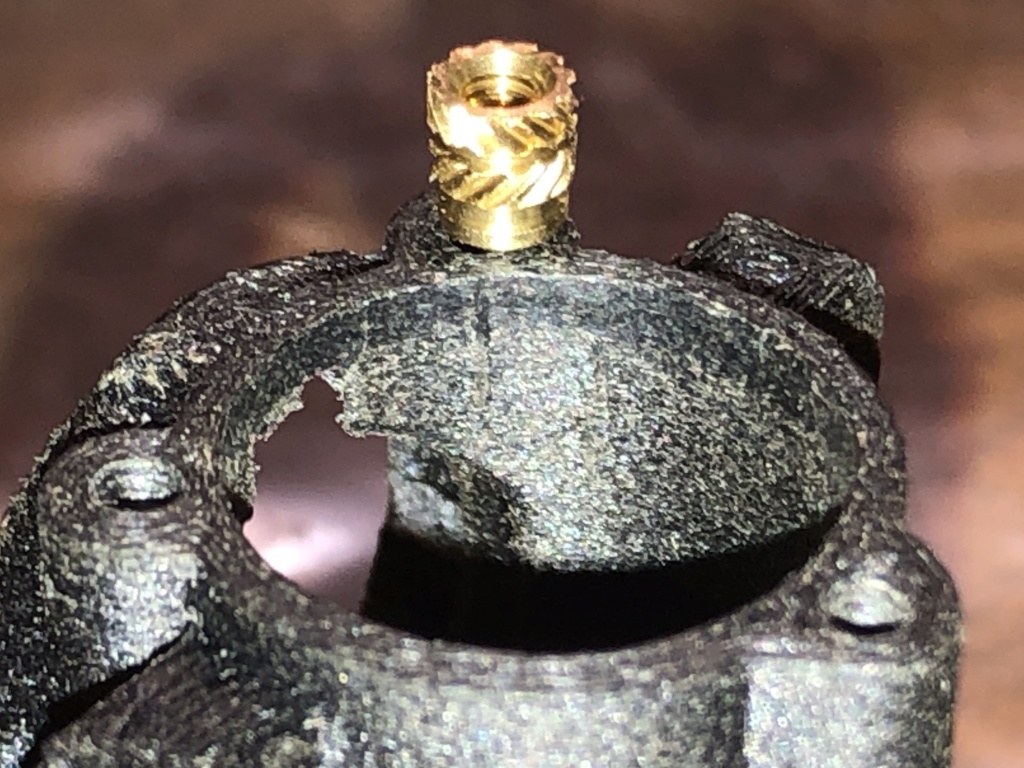

I was wondering how long it was going to take for that new carb fuel inlet to be spotted. I accidentally left it on the carb when it took the picture. I had one crumble when it was installing a carburetor and thought there must be a better solution.

The brass fuel barb is 3-56 threaded one from Clippard. The barb is too small for regular size .049 fuel tubing and only works with the .010/.020 fuel tubing. They are also almost $1 a piece too.

I did approach Matt and he is also working on an alternative solution.

I also tried to do a direct print of the entire part. Being so small I can’t get fine enough detail on the barb fitting. I might be able to change the design of this so the barb comes out round vs oval. This prints as an overhang so I would have to teardrop shape the barb for it to come out round on the 3D print. This would also require a lot of cleanup work where just tapping a hole would be easier with a threaded nipple.

The brass fuel barb is 3-56 threaded one from Clippard. The barb is too small for regular size .049 fuel tubing and only works with the .010/.020 fuel tubing. They are also almost $1 a piece too.

I did approach Matt and he is also working on an alternative solution.

I also tried to do a direct print of the entire part. Being so small I can’t get fine enough detail on the barb fitting. I might be able to change the design of this so the barb comes out round vs oval. This prints as an overhang so I would have to teardrop shape the barb for it to come out round on the 3D print. This would also require a lot of cleanup work where just tapping a hole would be easier with a threaded nipple.

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: Ball bearings you say? 3D printed BB crankcase.

Re: Ball bearings you say? 3D printed BB crankcase.

Jason if the problem is only the size of the fitting fuel tubing, then what I would do is attach an 010 or 020 size, short fuel tube to the nipple so that the barb will hold it, then pull the larger, 049 size fuel tube over the other end of short 010 size tube, and run it up to the 049 engine...I may also pull a small spring - the one used in Babe Bee tanks - into the 010 size tube to prevent it from collapsing under the external pressure by the 049 tube..or would just add a copper or aluminum tube connector in between the 010 and 049 tubes etc...

My garage-tuning solution, not ultimately professional, but would still be working with your small nipple, and be several orders of magnitude better and more reliable than the all-plastic COX fuel nipple...I would still be interested in buying such a hybrid solution...

My garage-tuning solution, not ultimately professional, but would still be working with your small nipple, and be several orders of magnitude better and more reliable than the all-plastic COX fuel nipple...I would still be interested in buying such a hybrid solution...

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Ball bearings you say? 3D printed BB crankcase.

Re: Ball bearings you say? 3D printed BB crankcase.

These fittings would fit the .049 size fuel tubing but have a painfully slow shipping option.

https://m.aliexpress.com/item/32696220692.html?trace=wwwdetail2mobilesitedetail&spm=2114.12057483.0.0.2d50546d9TXC5Y

They are for pneumatic hose but should work fine. They will be larger than the Clippard 3-56 version.

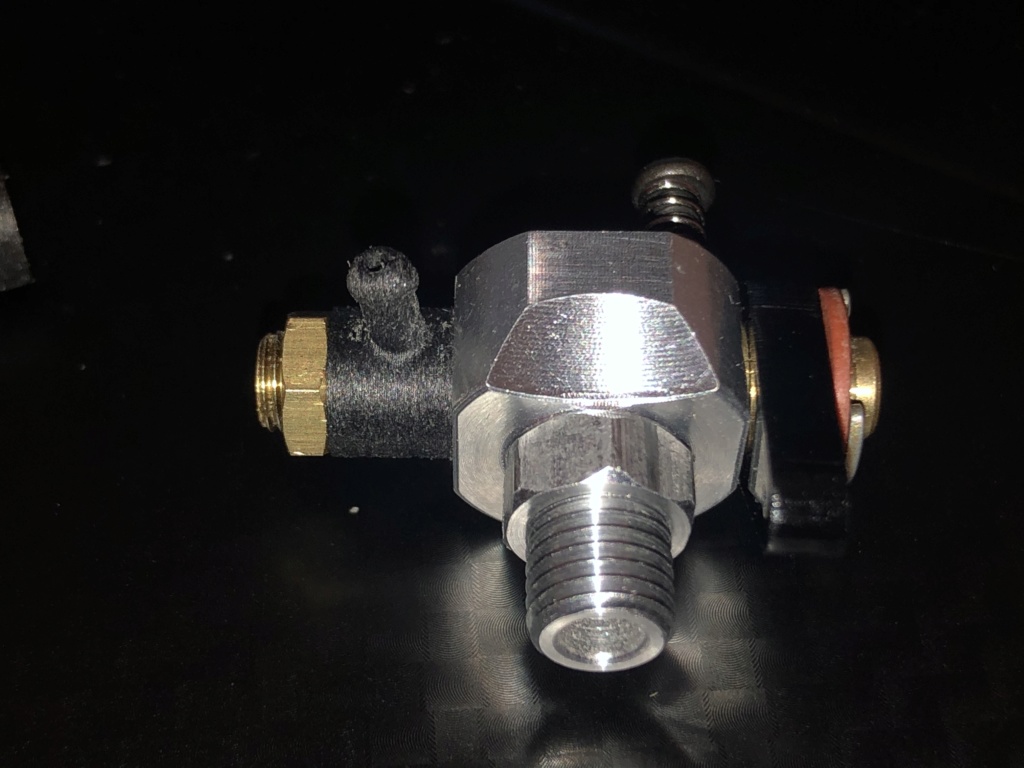

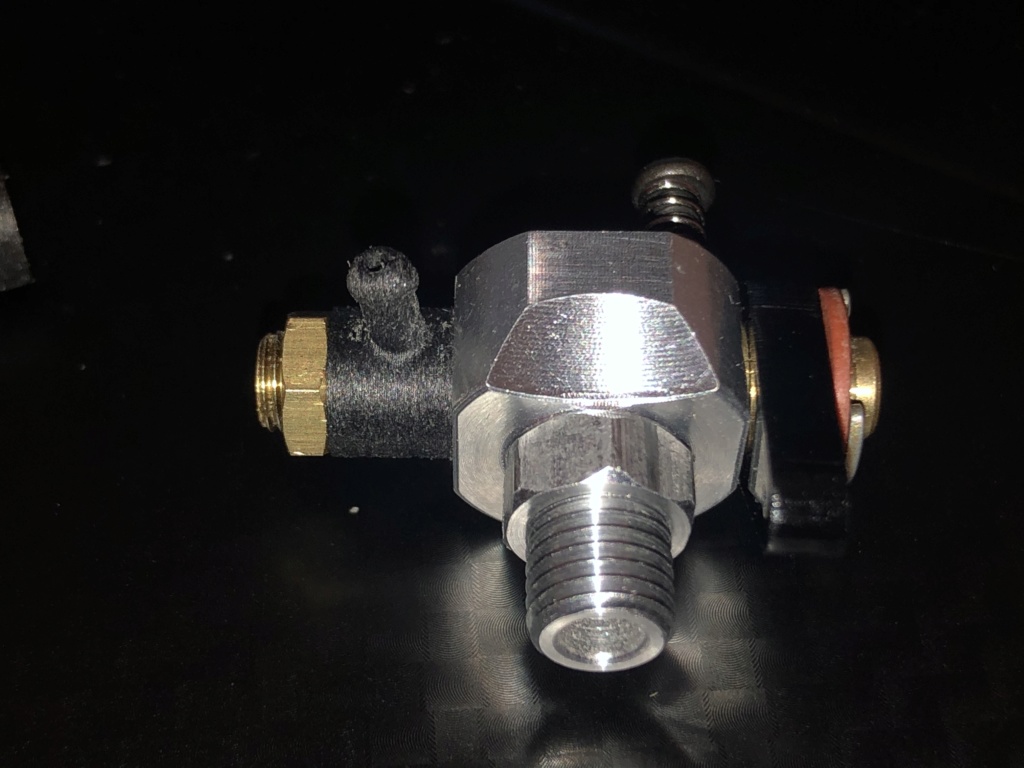

I made the fuel inlet thicker for more strength. I tried to crush a glass filled Zytel Version with my fingers and could not even get it to deform it’s that strong. I need to test it with fuel to make sure there still isn’t an issue with leaks.

https://m.aliexpress.com/item/32696220692.html?trace=wwwdetail2mobilesitedetail&spm=2114.12057483.0.0.2d50546d9TXC5Y

They are for pneumatic hose but should work fine. They will be larger than the Clippard 3-56 version.

I made the fuel inlet thicker for more strength. I tried to crush a glass filled Zytel Version with my fingers and could not even get it to deform it’s that strong. I need to test it with fuel to make sure there still isn’t an issue with leaks.

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: Ball bearings you say? 3D printed BB crankcase.

Re: Ball bearings you say? 3D printed BB crankcase.

Good to see that you will soon find the solution !!! I believe the small nipple size is just cosmetics, if the larger size is difficult to source, I would still happily compromise on the small one...we are modelers anyway and need our part of innovations when completing our fuel systems on our planes..

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Ball bearings you say? 3D printed BB crankcase.

Re: Ball bearings you say? 3D printed BB crankcase.

Any word on the threaded insert?

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Ball bearings you say? 3D printed BB crankcase.

Re: Ball bearings you say? 3D printed BB crankcase.

Well that makes more since , i was thinking it had something to do with the cly. placement But didn't want to sound stupid and say something about the size of the insert >> guess i missed a line . Looks good Brad why is it U use .020 spinners on .049 engines again ( i am having brain farts i guess )

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Ball bearings you say? 3D printed BB crankcase.

Re: Ball bearings you say? 3D printed BB crankcase.

Less mass out at the end of the driveline for less wobble, reduced heat and increase in rpm.

Helps to center the prop / insets a bit and allows the use of a E starter.

Helps to center the prop / insets a bit and allows the use of a E starter.

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Ball bearings you say? 3D printed BB crankcase.

Re: Ball bearings you say? 3D printed BB crankcase.

Thanks Brad , makes since to me

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

SABOO- Moderate Poster

- Posts : 10

Join date : 2019-10-03

Location : HALIFAX NS

Re: Ball bearings you say? 3D printed BB crankcase.

Re: Ball bearings you say? 3D printed BB crankcase.

SABOO. As a new member/poster it would be great to get to know who you are, where you're from and what your interests are. As it is, it just looks like you're on the payroll of a product company.SABOO wrote:Masterbond.com

Oldenginerod- Top Poster

- Posts : 4018

Join date : 2012-06-15

Age : 62

Location : Drouin, Victoria

Re: Ball bearings you say? 3D printed BB crankcase.

Re: Ball bearings you say? 3D printed BB crankcase.

Master Bond One Part Epoxy Compounds

One part, no mix epoxy meets NASA low outgassing specifications.

Serviceable up to 600°F. Tg is 225°C. High shear, tensile and compressive strength properties.

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Ball bearings you say? 3D printed BB crankcase.

Re: Ball bearings you say? 3D printed BB crankcase.

Then you need a mold , right ?

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Ball bearings you say? 3D printed BB crankcase.

Re: Ball bearings you say? 3D printed BB crankcase.

Why do it with epoxy resin if make a mold why not do it with aluminum? Me if I had the chance to have this crankcase I would print with some kind of wax then I would make a mold with I would not waste my time with resin whatever the kind I already have a good result to repair parts of crankcase leaks this kind of thing build parts wit !!!!

Other than to make a beautiful art Decorative display engine

Other than to make a beautiful art Decorative display engine

I will never use this method for Important piece dont waste mony use aluminium If you seriously want to complete this type of engine crankcase This is my humble opinion I must clarify that I find the prototype valid is should just use aluminum rather than losing $$$$% time is money best made of aluminium Not plastiques reson for that is plastiques wil Not hold for long terme use Yes you will say that the cars of our day use different types of plastic in the engine, it is really no good for intensive use the cars are no longer what they are. Now made cheap al this To save mony $$$ Then it's us the poor customers who are fooled its wy That I keep my old nissan gtr for always

made of aluminium Not plastiques reson for that is plastiques wil Not hold for long terme use Yes you will say that the cars of our day use different types of plastic in the engine, it is really no good for intensive use the cars are no longer what they are. Now made cheap al this To save mony $$$ Then it's us the poor customers who are fooled its wy That I keep my old nissan gtr for always

Other than to make a beautiful art Decorative display engine

Other than to make a beautiful art Decorative display engineI will never use this method for Important piece dont waste mony use aluminium If you seriously want to complete this type of engine crankcase This is my humble opinion I must clarify that I find the prototype valid is should just use aluminum rather than losing $$$$% time is money best

made of aluminium Not plastiques reson for that is plastiques wil Not hold for long terme use Yes you will say that the cars of our day use different types of plastic in the engine, it is really no good for intensive use the cars are no longer what they are. Now made cheap al this To save mony $$$ Then it's us the poor customers who are fooled its wy That I keep my old nissan gtr for always

made of aluminium Not plastiques reson for that is plastiques wil Not hold for long terme use Yes you will say that the cars of our day use different types of plastic in the engine, it is really no good for intensive use the cars are no longer what they are. Now made cheap al this To save mony $$$ Then it's us the poor customers who are fooled its wy That I keep my old nissan gtr for always

davidll1984- Diamond Member

- Posts : 2327

Join date : 2020-02-12

Age : 39

Location : shawinigan

Sealant not for Molding

Sealant not for Molding

A low viscosity 1 or 2 part methyl hydrate resistant epoxy could be used to infuse the 3d printed parts. It would prevent leaks and add stiffness. The use of epoxy is not intended to mold or make a mold, but just to seal the porosity of 3d printed parts.

If the part is made of ABS a quick dip in acetone will sometimes achieve the same result. It softens the material and is used to improve the finish of ABS parts.

PETG as a 3d printing filament is resistant to Methyl alcohol.

Has anyone tried using an SLS printer for such fine detail parts? If so what resin was used? SLS is Selective Laser Sintering. A laser scans a layer of powder and cures it or binds it. The bed is lowered and a new layer of powder is spread and the laser process continues. You can have metal parts made this way.

They also have laser cured liquid resin printers. You can buy home ones for less than $1000 with very small build volumes. I am not familiar with the properties of the finished product with respect to chemical resistance etc. In this machine a layer of liquid resin is cured by a scanning laser. Then the print bed is lowered and a film of resin floods the top surface. Then the laser cures the appropriate areas and the process repeats.

A company like Shapeways can make a very high resolution part for evaluation. They have a choice of materials and methodologies of printing to choose from. They are one of many 3D printing service bureaus around the country.

If the part is made of ABS a quick dip in acetone will sometimes achieve the same result. It softens the material and is used to improve the finish of ABS parts.

PETG as a 3d printing filament is resistant to Methyl alcohol.

Has anyone tried using an SLS printer for such fine detail parts? If so what resin was used? SLS is Selective Laser Sintering. A laser scans a layer of powder and cures it or binds it. The bed is lowered and a new layer of powder is spread and the laser process continues. You can have metal parts made this way.

They also have laser cured liquid resin printers. You can buy home ones for less than $1000 with very small build volumes. I am not familiar with the properties of the finished product with respect to chemical resistance etc. In this machine a layer of liquid resin is cured by a scanning laser. Then the print bed is lowered and a film of resin floods the top surface. Then the laser cures the appropriate areas and the process repeats.

A company like Shapeways can make a very high resolution part for evaluation. They have a choice of materials and methodologies of printing to choose from. They are one of many 3D printing service bureaus around the country.

Last edited by SABOO on Thu Apr 22, 2021 3:08 pm; edited 1 time in total (Reason for editing : clarification and adding details)

SABOO- Moderate Poster

- Posts : 10

Join date : 2019-10-03

Location : HALIFAX NS

Page 2 of 2 •  1, 2

1, 2

Similar topics

Similar topics» Cox space hopper ball bearings?

» Olympic .15 crankshaft disassembly?

» O.S. FS 40 Marine

» 3D printed R/C Pee Wee backplate

» WTB Conquest main bearings or source for same

» Olympic .15 crankshaft disassembly?

» O.S. FS 40 Marine

» 3D printed R/C Pee Wee backplate

» WTB Conquest main bearings or source for same

Page 2 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules