Log in

Search

Latest topics

» My latest doodle...by batjac Today at 10:05 pm

» Retail price mark-up.. how much is enough?

by gkamysz Today at 9:29 pm

» Happy 77th birthday Andrew!

by roddie Today at 9:22 pm

» Roger Harris revisited

by rsv1cox Today at 3:38 pm

» My N-1R build log

by GallopingGhostler Today at 3:04 pm

» Tee Dee .020 combat model

by 1/2A Nut Today at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

Cox Engine of The Month

Ball bearings you say? 3D printed BB crankcase.

Page 1 of 2

Page 1 of 2 • 1, 2

Ball bearings you say? 3D printed BB crankcase.

Ball bearings you say? 3D printed BB crankcase.

Chevy Chase said it best in Fletch.

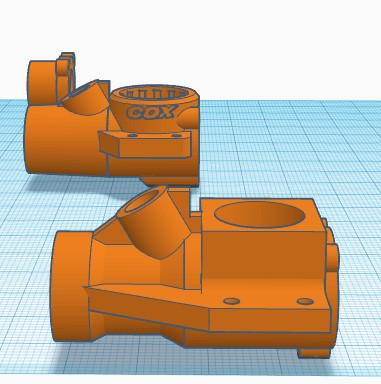

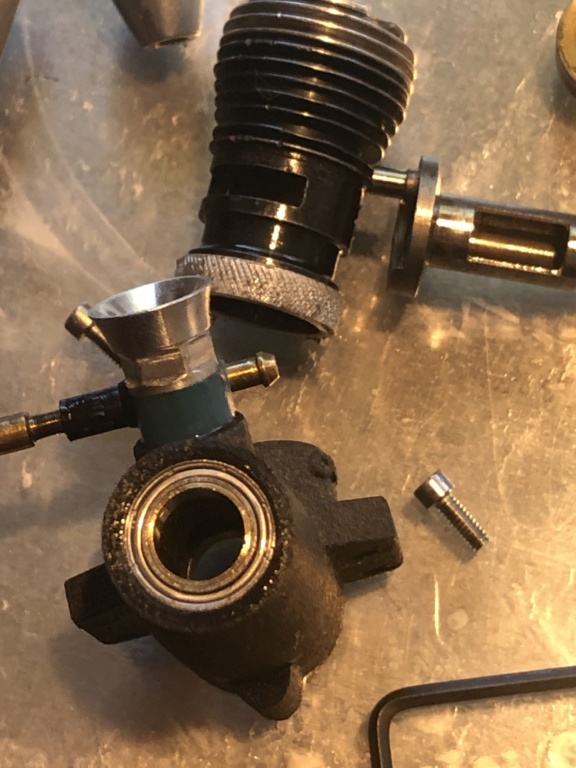

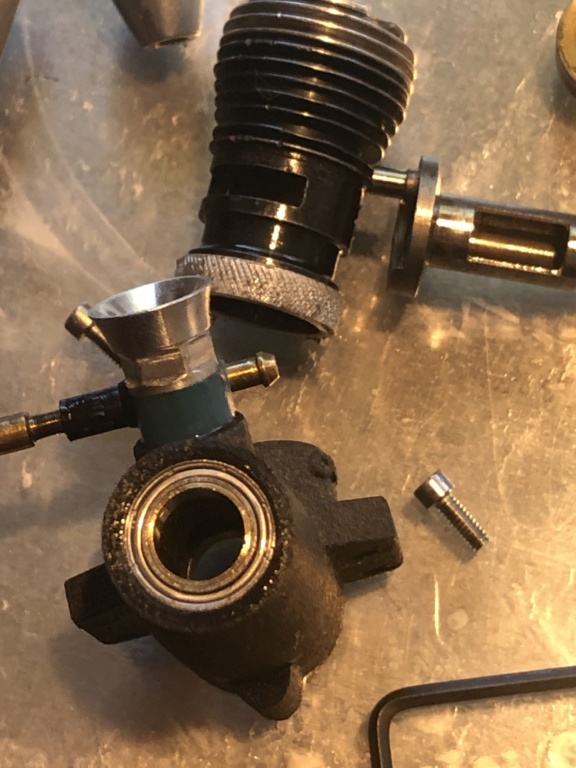

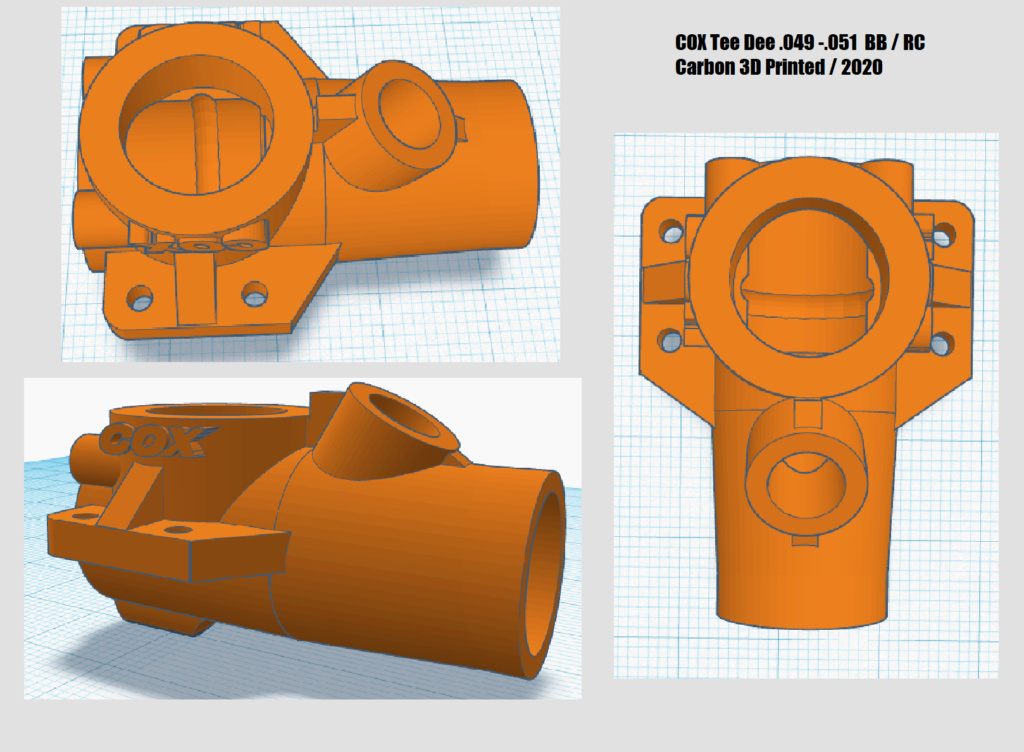

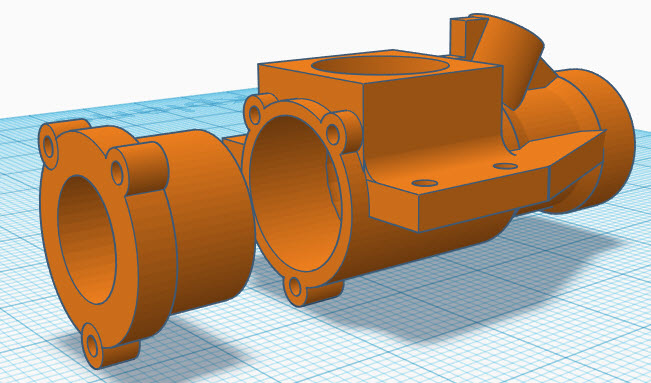

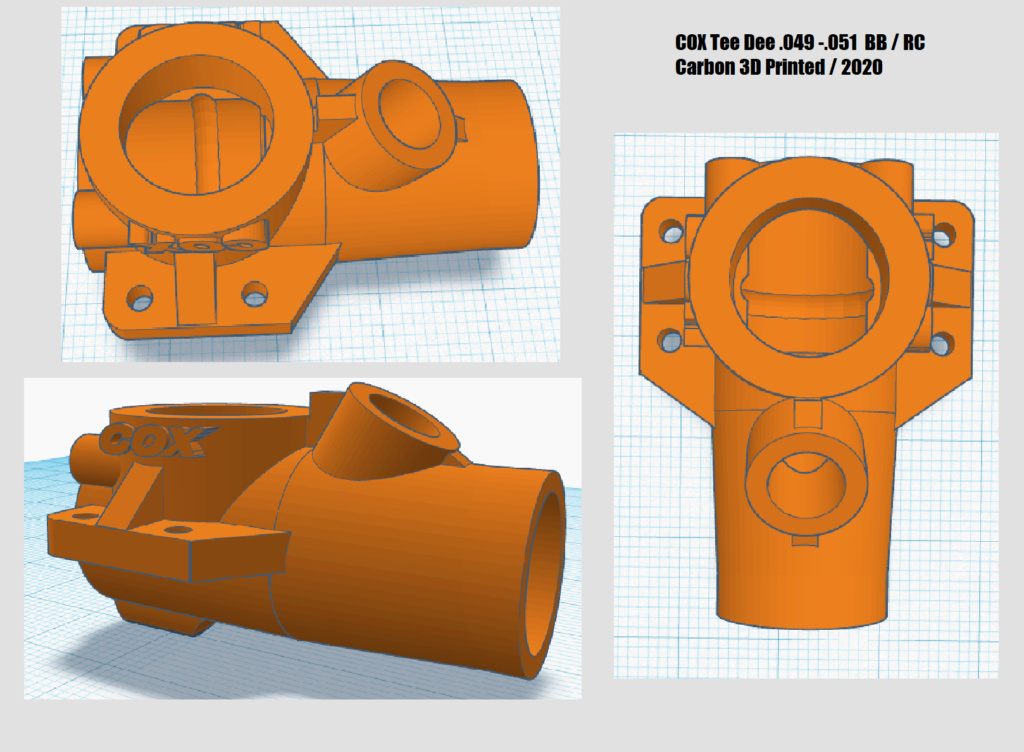

The last few weeks I’ve been working on a 3D printed ball bearing crankcase for the TD 049. I’m using glass fiber Zytel. This is like the 5th revision of the crankcase. Mostly for looks and getting the fit correct.

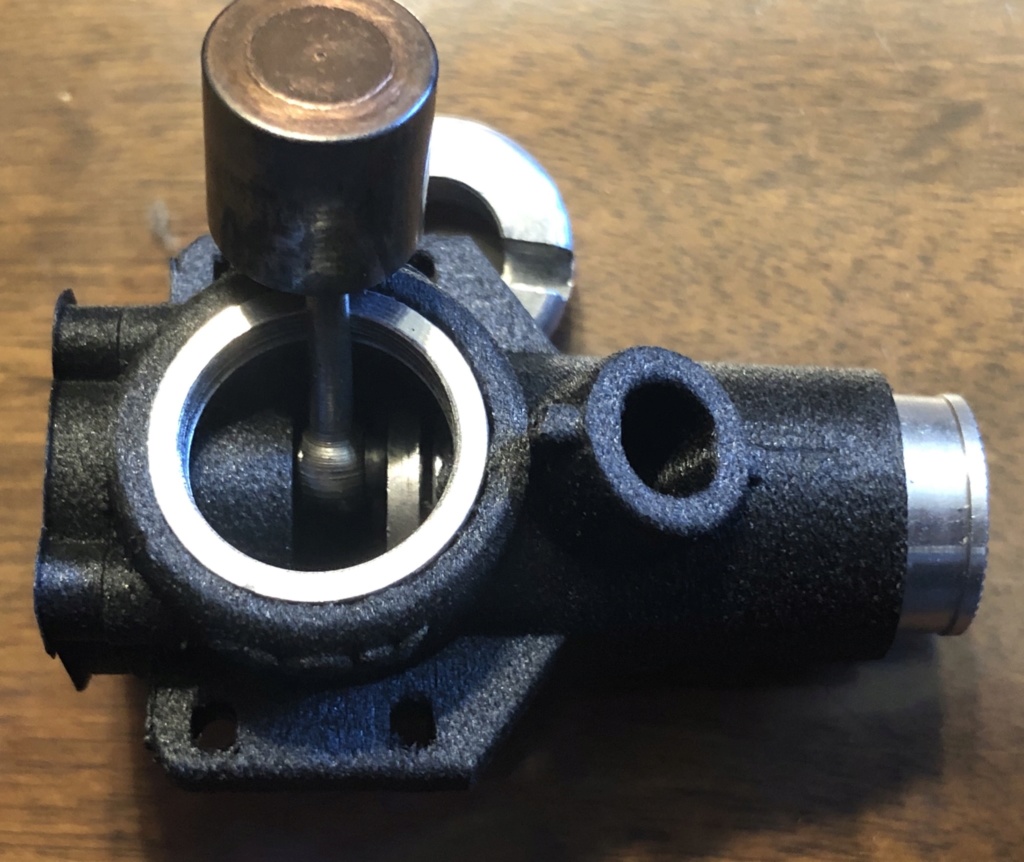

I have to use an aluminum insert for the threads. Kinda like the Testors 8000 plastic crankcase shown here.

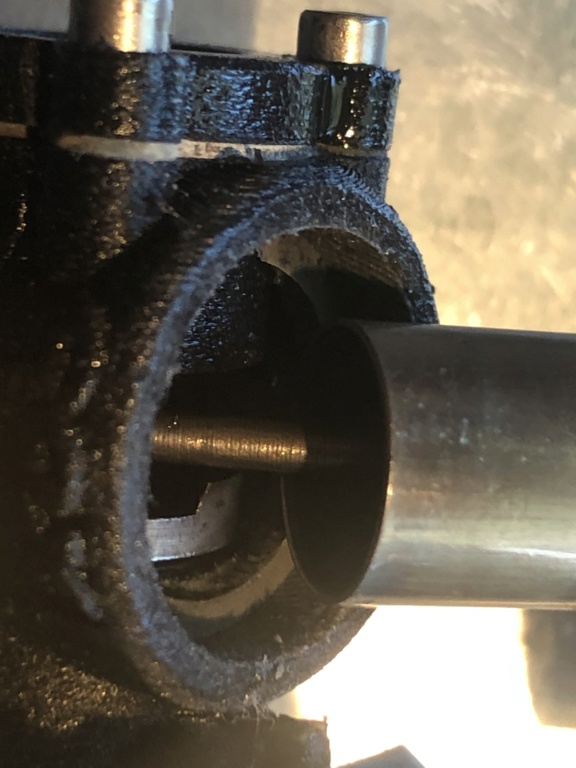

The problem I’m having is JB weld and Belzona 1111 are not holding the insert in most likely due to the heat. I’m knurling the ring for grip and also have pockets in the crankcase for epoxy to hold the insert tight.

This video shows the insert coming out as it runs.

I might use a combination of rings and knurling for the insert. The concentric rings would prevent the insert from coming up. This would only work if the epoxy doesn’t get soft.

I’ve been looking for a different epoxy to use. Need something that bonds plastic and aluminum at high heat. Even looking at furnace cement as an option. It can handle 1200F.

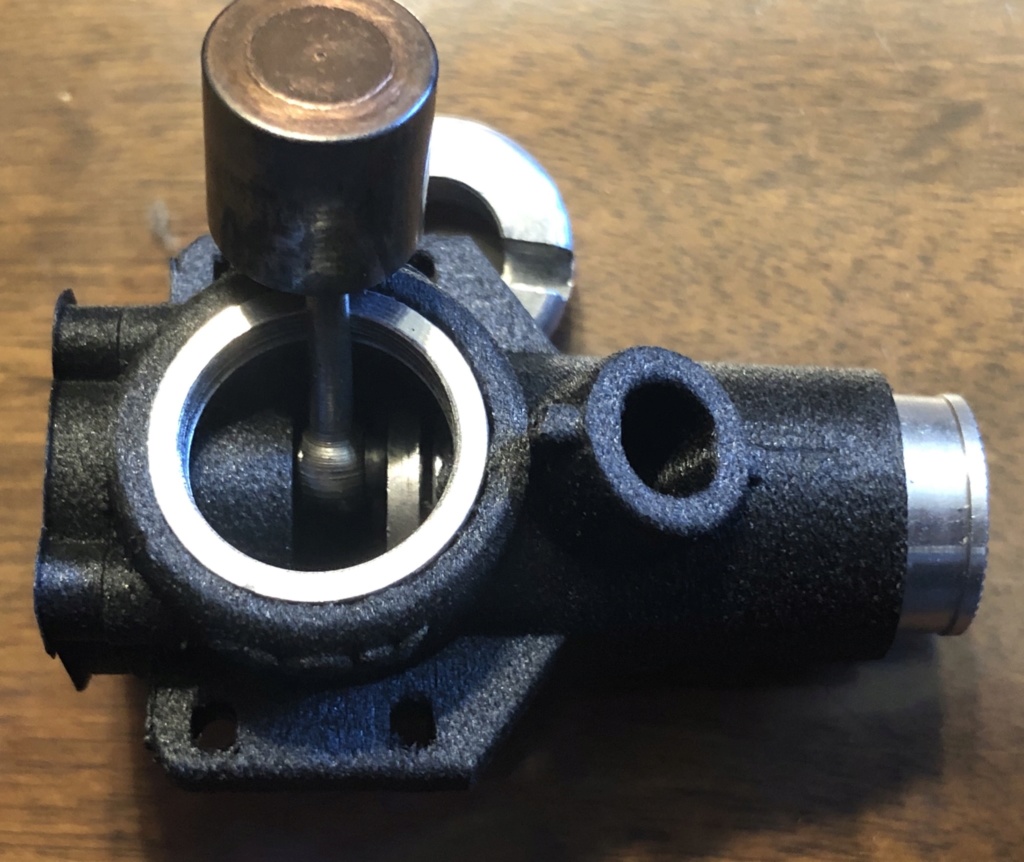

More pics.

The last few weeks I’ve been working on a 3D printed ball bearing crankcase for the TD 049. I’m using glass fiber Zytel. This is like the 5th revision of the crankcase. Mostly for looks and getting the fit correct.

I have to use an aluminum insert for the threads. Kinda like the Testors 8000 plastic crankcase shown here.

The problem I’m having is JB weld and Belzona 1111 are not holding the insert in most likely due to the heat. I’m knurling the ring for grip and also have pockets in the crankcase for epoxy to hold the insert tight.

This video shows the insert coming out as it runs.

I might use a combination of rings and knurling for the insert. The concentric rings would prevent the insert from coming up. This would only work if the epoxy doesn’t get soft.

I’ve been looking for a different epoxy to use. Need something that bonds plastic and aluminum at high heat. Even looking at furnace cement as an option. It can handle 1200F.

More pics.

Last edited by Jason_WI on Thu May 21, 2020 9:32 pm; edited 1 time in total

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: Ball bearings you say? 3D printed BB crankcase.

Re: Ball bearings you say? 3D printed BB crankcase.

Jason how about cutting a thread - deeper and with larger pitch than on the cylinder neck- on the external surface of the aluminum insert, and tapping a thread in the 3D crankcase neck too? Those threads would retain the insert during engine operation..

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Ball bearings you say? 3D printed BB crankcase.

Re: Ball bearings you say? 3D printed BB crankcase.

Man Jason, you have the coolest ideas!

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Ball bearings you say? 3D printed BB crankcase.

Re: Ball bearings you say? 3D printed BB crankcase.

I am sure you are aware of the threaded locking inserts. Might work but it is a really oddball size. https://ca.images.search.yahoo.com/search/images?p=threaded+locking+insert&fr=yfp-t&imgurl=http%3A%2F%2Fwww.threadtoolsupply.com%2Fassets%2Fimages%2Fstainless-steel-key-locking-thread-inserts.jpg#id=0&iurl=http%3A%2F%2Fwww.threadtoolsupply.com%2Fassets%2Fimages%2Fstainless-steel-key-locking-thread-inserts.jpg&action=click

aspeed- Platinum Member

- Posts : 796

Join date : 2013-01-18

Location : Leamington Ont. Can.

Re: Ball bearings you say? 3D printed BB crankcase.

Re: Ball bearings you say? 3D printed BB crankcase.

Without knowing anything about the material you are printing with, as well as the wall thicknesses of both the ring and the printed case, is there a posibility that you can say drill a couple very small holes through the case and insert to 'pin' the ring in place, but not drill completely through the ring the cylinder threads into?

However, it looks great!

However, it looks great!

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: Ball bearings you say? 3D printed BB crankcase.

Re: Ball bearings you say? 3D printed BB crankcase.

Could ceramic work with zytel or any of the other materials available to you? A ceramic coating might be a possibility. You may need to use some type of threaded insert unless you have an adhesive than can bond zytel and aluminum. Your work is very cool!

fit90- Diamond Member

- Posts : 1341

Join date : 2011-08-11

Location : Naples, Florida

Re: Ball bearings you say? 3D printed BB crankcase.

Re: Ball bearings you say? 3D printed BB crankcase.

I was thinking along those lines, using 2 or 3 cup head set screws.NEW222 wrote:Without knowing anything about the material you are printing with, as well as the wall thicknesses of both the ring and the printed case, is there a possibility that you can say drill a couple very small holes through the case and insert to 'pin' the ring in place, but not drill completely through the ring the cylinder threads into?

However, it looks great!

The area around the cylinder base would have to be beefed

up a bit, I guess.

Printing parts has me fascinated. Thanks Jason.

Bob

dckrsn- Diamond Member

- Posts : 2750

Join date : 2010-10-21

Age : 71

Location : Long Island, New York

Re: Ball bearings you say? 3D printed BB crankcase.

Re: Ball bearings you say? 3D printed BB crankcase.

Jason you blow my mind with the things you come up with. That is just too cool! I have no idea how to secure the cylinder, but I have no doubt you'll come up with a solution. Hat's off brother!

Dave P.- Gold Member

- Posts : 477

Join date : 2017-07-31

Age : 67

Location : Durham, NC

Re: Ball bearings you say? 3D printed BB crankcase.

Re: Ball bearings you say? 3D printed BB crankcase.

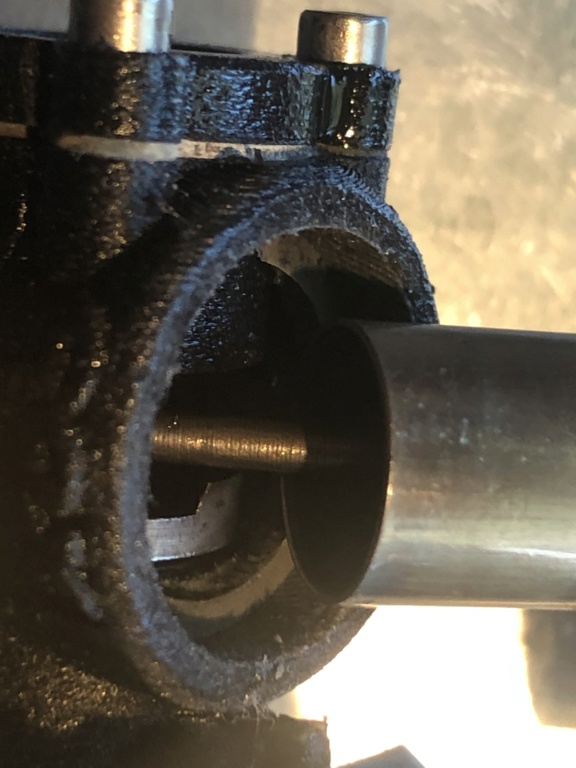

I’m using 5/8” aluminum tubing for the insert. I ream the inside to .500 then tap with the 17/32-40 tap. I was so hoping the epoxy would hold. With a glued in insert I can time the cylinder to the crankcase.

I can try a threaded insert. I have .082” wall on the cylinder mounting of the crankcase. Any bigger and I would need to make cutouts for the mounting screws on the beam mount. I still need to find an epoxy that will lock the insert in place. It could back out when removing the cylinder.

Can throw all these ideas out the window if someone uses an electric starter with it flooded.

Not much material for a set screw unless I add a mounting boss for more threads. Maybe small long dowel pins at the long angle and a groove in the insert that the dowel pin fits tight in.

I did turn a drive plate but didn’t use it. I didn’t like the way the face knurl turned out. It does finish off the look though.

I can try a threaded insert. I have .082” wall on the cylinder mounting of the crankcase. Any bigger and I would need to make cutouts for the mounting screws on the beam mount. I still need to find an epoxy that will lock the insert in place. It could back out when removing the cylinder.

Can throw all these ideas out the window if someone uses an electric starter with it flooded.

Not much material for a set screw unless I add a mounting boss for more threads. Maybe small long dowel pins at the long angle and a groove in the insert that the dowel pin fits tight in.

I did turn a drive plate but didn’t use it. I didn’t like the way the face knurl turned out. It does finish off the look though.

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: Ball bearings you say? 3D printed BB crankcase.

Re: Ball bearings you say? 3D printed BB crankcase.

This might be your best idea yet. More RPM and lighter weight!

I would consider using red loctite instead of epoxy for the threaded insert. It’s pretty tough stuff and used in extreme heat and pressure environments in the auto world.

I would consider using red loctite instead of epoxy for the threaded insert. It’s pretty tough stuff and used in extreme heat and pressure environments in the auto world.

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Ball bearings you say? 3D printed BB crankcase.

Re: Ball bearings you say? 3D printed BB crankcase.

I don’t know about weight savings. It’s 1 gram heavier than a standard TD.

I’ll look into using retaining compound. It’s green loctite. Not sure it will work on Zytel though as I looked at a data sheet of it earlier.

I’ll look into using retaining compound. It’s green loctite. Not sure it will work on Zytel though as I looked at a data sheet of it earlier.

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: Ball bearings you say? 3D printed BB crankcase.

Re: Ball bearings you say? 3D printed BB crankcase.

Jason,

Just amazing programming and printing!

Have you considered JB Weld for the cylinder threads? That stuff is amazingly strong when set, and nearly impervious to crankcase temperatures. Just shim for the desired cylinder depth, press the welded threads into the case, rotate to the desired exhaust port orientation and let it cure. If it works, no need to replace the cylinder/piston until worn out. Replacement is needed at that point anyway.

Might require a guide to hold the cylinder vertical during the cure?

Do you plan on selling these? I doubt I could afford one in any case.

Good luck with the engine!

Bill

Just amazing programming and printing!

Have you considered JB Weld for the cylinder threads? That stuff is amazingly strong when set, and nearly impervious to crankcase temperatures. Just shim for the desired cylinder depth, press the welded threads into the case, rotate to the desired exhaust port orientation and let it cure. If it works, no need to replace the cylinder/piston until worn out. Replacement is needed at that point anyway.

Might require a guide to hold the cylinder vertical during the cure?

Do you plan on selling these? I doubt I could afford one in any case.

Good luck with the engine!

Bill

smooth_bill- Gold Member

- Posts : 229

Join date : 2012-02-19

Age : 87

Location : Beaverton, OR

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: Ball bearings you say? 3D printed BB crankcase.

Re: Ball bearings you say? 3D printed BB crankcase.

Thank you Jason,

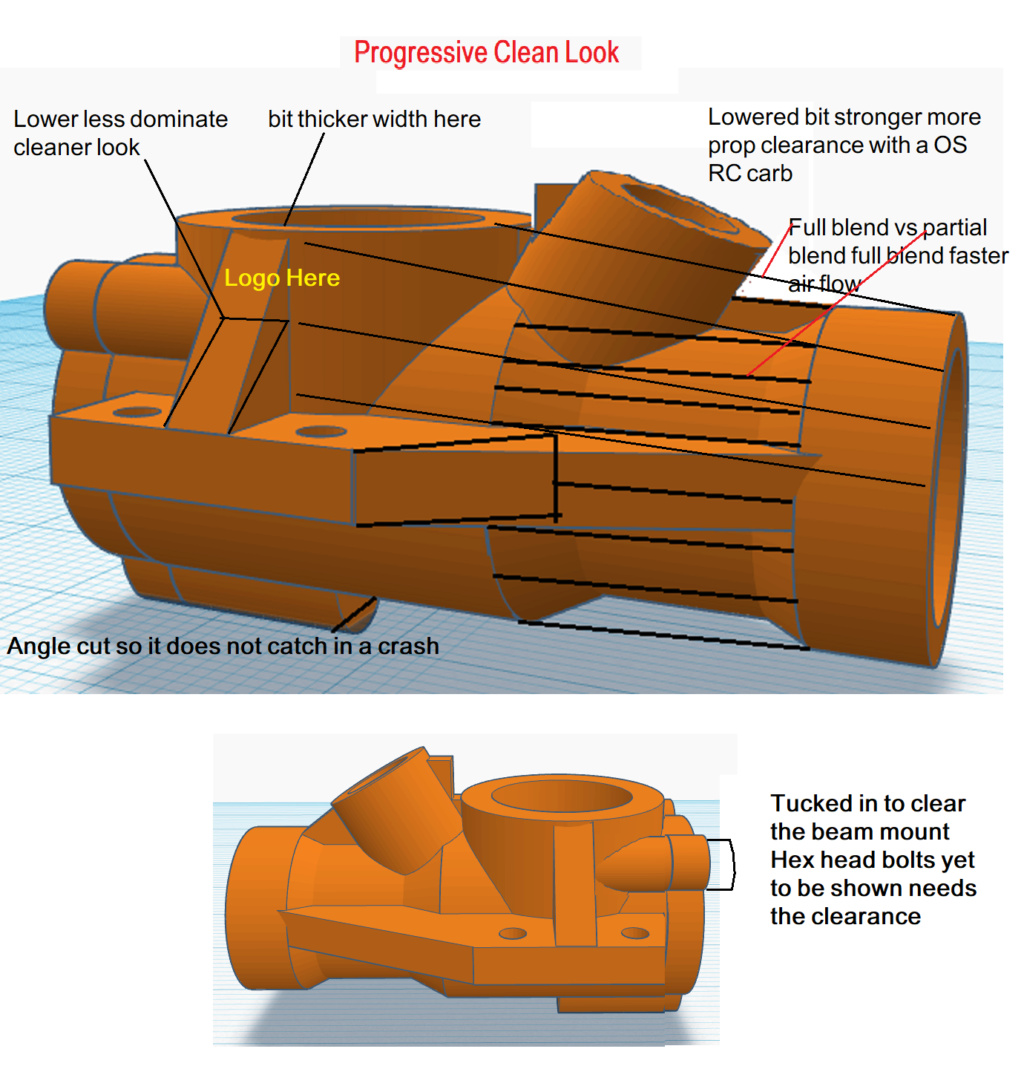

I am always happy to help, aesthetics is a big part of why we love these little engines.

Badging when possible is the icing on the cake after form and function. Jason did a

great job making the mods as the quest continued.

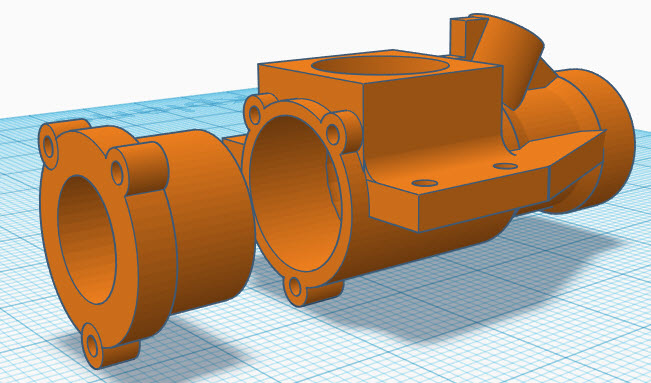

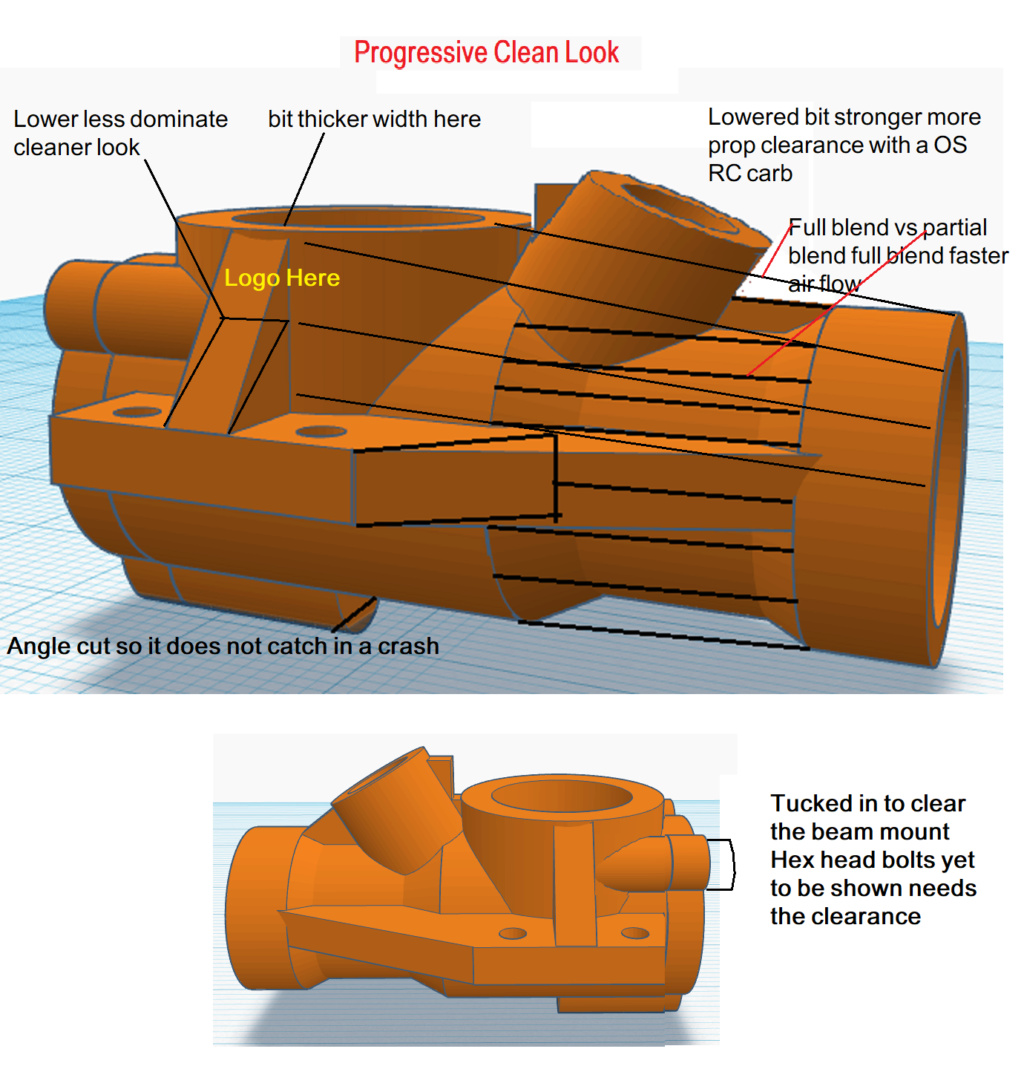

Here was some of the mods that led to where the design is today.

With bearings props will spin with less vibrations this will add power reduce

heat. When the engine is running at it's stabilized thermal state the upswing

will be a leaner mix producing more power. Threaded insert will solve the last

step in getting a running engine. This was realized after the first bench test

a while back. The current insert was modified for a second chance at working.

The vid posted shows it still can't take the pounding. Loctite makes a high temp

thread locker that should bond to the material with suitable results.

I am always happy to help, aesthetics is a big part of why we love these little engines.

Badging when possible is the icing on the cake after form and function. Jason did a

great job making the mods as the quest continued.

Here was some of the mods that led to where the design is today.

With bearings props will spin with less vibrations this will add power reduce

heat. When the engine is running at it's stabilized thermal state the upswing

will be a leaner mix producing more power. Threaded insert will solve the last

step in getting a running engine. This was realized after the first bench test

a while back. The current insert was modified for a second chance at working.

The vid posted shows it still can't take the pounding. Loctite makes a high temp

thread locker that should bond to the material with suitable results.

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Ball bearings you say? 3D printed BB crankcase.

Re: Ball bearings you say? 3D printed BB crankcase.

I like the backplate design, maybe you can make a metal retainer to clamp the cylinder insert down using that design. Just an Idea.

coxaddict- Gold Member

- Posts : 429

Join date : 2013-01-27

Location : north shore oahu, Hawaii

Re: Ball bearings you say? 3D printed BB crankcase.

Re: Ball bearings you say? 3D printed BB crankcase.

Looking really good Jason and Brad , you may want to look into this product only thin is it don't give heat range ? i would contact them if were me .. https://www.henkel-adhesives.com/us/en/products/industrial-adhesives/retaining-compounds.html  Do you know what the heat is coming off the engine at failure ?

Do you know what the heat is coming off the engine at failure ?

Do you know what the heat is coming off the engine at failure ?

Do you know what the heat is coming off the engine at failure ?

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Ball bearings you say? 3D printed BB crankcase.

Re: Ball bearings you say? 3D printed BB crankcase.

On what part / sounds like it would fill the bill1/2A Nut wrote:I have 638 used it up to 50.4k rpm

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

cool nice job jason

cool nice job jason

for insert is it posible to change desing of crank case to aling two top end cap bolt of back plate place on top not on side to alow longer bolt to retain cylinder insert wil look difrent but it wil hold just fine just dril tap after part is insert plus ad materiel on part u save weight alredy programing of part wil have to change no sutch glue wil hold just build case on the insert part insert it self need machining not just tight fit it nead to be part of case it self wit no chance to move bolt wil just ad strenght to insert y saw 2 way posible to work have to change case its not aloy u play wit so copie of engine is no no it wil need biger case insert wit diferent case chape on top case for the two insert retaning bolt hope u chage design for best result keap good work y wil want 1 for my colection price not isue for me

davidll1984- Diamond Member

- Posts : 2327

Join date : 2020-02-12

Age : 39

Location : shawinigan

Re: Ball bearings you say? 3D printed BB crankcase.

Re: Ball bearings you say? 3D printed BB crankcase.

Driveline steel shaft to steel sleeve.

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Ball bearings you say? 3D printed BB crankcase.

Re: Ball bearings you say? 3D printed BB crankcase.

5/8-18 outside and 17/32-40 inside threaded insert. I need to change the crankcase to print a 5/8-18 thread then clean up with a 5/8-18 bottom Tap.

Also need to order some threaded inserts for the 3 backplate screws.

Brass Heat-Set Inserts for Plastic, 2-56 Thread Size, 0.157" Installed Length

https://www.mcmaster.com/94459A240

I’ll need to make changes to the crankcase to use these.

Also need to order some threaded inserts for the 3 backplate screws.

Brass Heat-Set Inserts for Plastic, 2-56 Thread Size, 0.157" Installed Length

https://www.mcmaster.com/94459A240

I’ll need to make changes to the crankcase to use these.

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: Ball bearings you say? 3D printed BB crankcase.

Re: Ball bearings you say? 3D printed BB crankcase.

Looks like a good direction to hold that cylinder down. Inserts for

the backplate will make for a trend. Positive traction ahead.

the backplate will make for a trend. Positive traction ahead.

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Ball bearings you say? 3D printed BB crankcase.

Re: Ball bearings you say? 3D printed BB crankcase.

Jason,

this is an unbelievably elegant upgrade to the TeeDee ..apart from the 3D crankcase, I saw you have produced a new 3D fuel nipple for the RC carb that, with its threaded (?) brass nipple, promises a much better longevity than the stock all-plastic one that is notoriously breaking once you touch it with some determination....

Will you produce such fuel nipples separately for Bernie or Matt to sell, too, or, you plan to package the crankcase with the RC carb components for a combined sell? (Either way, I will be a customer for sure, unless you decide not to sell them, that would be a great sorrow for many in the COX community...

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Ball bearings you say? 3D printed BB crankcase.

Re: Ball bearings you say? 3D printed BB crankcase.

I've never seen those brass 2-56 inserts before. I guess they are a new thing, or I don't get out much. Interesting how a soldering iron locks them into place. The carb nipple could just be a 4-40 standard nipple, or whatever size works. I have done that on LA carbs a few times.

aspeed- Platinum Member

- Posts : 796

Join date : 2013-01-18

Location : Leamington Ont. Can.

Re: Ball bearings you say? 3D printed BB crankcase.

Re: Ball bearings you say? 3D printed BB crankcase.

It is the 3D nipple body with sufficient thickness that, combined with the brass nipple, will last much longer than the stock COX RC nipple. When the fuel stub breaks off - and it will sooner than later- from the stock part, there is no way to replace it with a threaded brass nipple because the plastic sleeve is very thin.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Page 1 of 2 • 1, 2

Similar topics

Similar topics» Cox space hopper ball bearings?

» Olympic .15 crankshaft disassembly?

» O.S. FS 40 Marine

» 3D printed R/C Pee Wee backplate

» WTB Conquest main bearings or source for same

» Olympic .15 crankshaft disassembly?

» O.S. FS 40 Marine

» 3D printed R/C Pee Wee backplate

» WTB Conquest main bearings or source for same

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules