Log in

Search

Latest topics

» My N-1R build logby roddie Today at 12:32 am

» Happy 77th birthday Andrew!

by akjgardner Today at 12:27 am

» TEE DEE Having issues

by TD ABUSER Yesterday at 9:43 pm

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» Roger Harris revisited

by TD ABUSER Yesterday at 2:13 pm

» Tee Dee .020 combat model

by Ken Cook Yesterday at 1:41 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Yesterday at 1:37 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Fri Nov 22, 2024 11:32 am

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

Cox Engine of The Month

The fever to build..

Page 1 of 1

OhBee- Platinum Member

- Posts : 698

Join date : 2016-03-23

Age : 73

Location : Minnesota

Re: The fever to build..

Re: The fever to build..

But no goggles? Don't you wear goggles?

Levent Suberk- Diamond Member

- Posts : 2265

Join date : 2017-12-24

Location : Türkiye

Re: The fever to build..

Re: The fever to build..

Geez roddie....where do you work? HAZMAT plant? wrote:

Bee Careful out there !!

Bee Careful out there !!

getback- Top Poster

Posts : 10442

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: The fever to build..

Re: The fever to build..

I have the means to try finish-sanding some of my rough-cut balsa sheets using a "time-saver" sanding machine in our shop at work. I went through some of my stock.. and found there to be rough-cut thicknesses of .140"/.150" (nominal) which I would finish-sand to .125" (1/8") thickness.. and another bundle measuring .200"/.220" (nominal) which I would finish-sand to .187" (3/16") thickness.

I've mentioned before; that this stock is all 1.75" wide.. and varies in length from 19"-30".

This was a condition on getting a LARGE amount of it free. I've had it for over ten years, packed in boxes in my shop. It is now time to turn it into usable model-airplane lumber.

The weight/grain-type varies widely.. and will need to be graded/sorted after sanding.

I love to build model airplanes. Having a decent selection of balsa really helps.

I've mentioned before; that this stock is all 1.75" wide.. and varies in length from 19"-30".

This was a condition on getting a LARGE amount of it free. I've had it for over ten years, packed in boxes in my shop. It is now time to turn it into usable model-airplane lumber.

The weight/grain-type varies widely.. and will need to be graded/sorted after sanding.

I love to build model airplanes. Having a decent selection of balsa really helps.

Re: The fever to build..

Re: The fever to build..

Yea Man thats cool that they will let you do the sand down so you can get that stuff made into something useful, i know you had been wanting to do this for some time now

getback- Top Poster

Posts : 10442

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: The fever to build..

Re: The fever to build..

We had a Timesaver at work. It was only used on aluminum sheets. I used it a fair bit. Probably 3-4 ft. wide with a rubber belt to feed it through. I like the trademark symbol with the guy holding onto the giant minute hand of the clock. Always thought that was genius as advertising agencies go. Don't have the building fever, but have to get lots of little details done. New battery packs, hook up controls, exercise batteries, make lines...

aspeed- Platinum Member

- Posts : 796

Join date : 2013-01-18

Location : Leamington Ont. Can.

Re: The fever to build..

Re: The fever to build..

Where do you find Balsa in quantities like that?

OhBee- Platinum Member

- Posts : 698

Join date : 2016-03-23

Age : 73

Location : Minnesota

Re: The fever to build..

Re: The fever to build..

1.75" width would be good for making laminated 1/2A c/l plank wings. (hard up front, soft to the rear)

ticomareado- Account Under Review

- Posts : 1089

Join date : 2013-10-03

Location : NC

Re: The fever to build..

Re: The fever to build..

The "Ironwood" machine can be set to sand within .001" so I'm really looking forward to running some wood through it. The grain-types in my wood are mixed.. because the balsa was originally sourced for graphic-art panels.. without regard for weight or grain-structure. The panels were ordered; 96"L. X 24"W. X 1.75" thick.

A CNC router-program would cut X4 "blanks" in the shape of a rolling-pin and spoon.. (X-oriented) for a customers' bakery dept. sign. The "excess-scrap" was put in refuse. I saved some of the wood.. by running the scrap through a panel-saw. That is why the stock runs thick. I knew that someday I'd be able to finish-sand it.

When I think back........ on the amount of balsa that was thrown away, it makes me wince.

A CNC router-program would cut X4 "blanks" in the shape of a rolling-pin and spoon.. (X-oriented) for a customers' bakery dept. sign. The "excess-scrap" was put in refuse. I saved some of the wood.. by running the scrap through a panel-saw. That is why the stock runs thick. I knew that someday I'd be able to finish-sand it.

When I think back........ on the amount of balsa that was thrown away, it makes me wince.

Re: The fever to build..

Re: The fever to build..

getback wrote:Yea Man thats cool that they will let you do the sand down so you can get that stuff made into something useful, i know you had been wanting to do this for some time now

Yo budd! If you "need sum wud".. let me know..

Yea.. your memory's fine bro. I've been mackin' about getting all this rough-cut balsa finish-sanded since we were young boys..

Re: The fever to build..

Re: The fever to build..

I'm back. A guy that I worked with.. just moved away.. and offered me a box of assorted exotic hardwoods.. that he just couldn't justify making space for in the planned U-Haul trailer. His family had worked in the musical instrument manufacturing business.. and I now have a boxful of interesting hardwoods.

Beautiful wood..

I see all kinds of model aircraft applications for this wood. The dark-tone hardwoods are gorgeous.. "heavy".. yes.. but maybe a heavier pair of engine beams would make the difference on a vintage design.. being built for a more modern/lightweight engine?

Whatever the case.. some of this wood is perfect for ripping into beam-stock.

Beautiful wood..

I see all kinds of model aircraft applications for this wood. The dark-tone hardwoods are gorgeous.. "heavy".. yes.. but maybe a heavier pair of engine beams would make the difference on a vintage design.. being built for a more modern/lightweight engine?

Whatever the case.. some of this wood is perfect for ripping into beam-stock.

Re: The fever to build..

Re: The fever to build..

Nice roddie. Engine beams would be good. I just finished my wing rebuild and I got to use soem of that very nice triangle stock from you for supports in a few areas. They worked awesome. And when I get onto the fuselage repairs, I am sure I will be using a bunch more of them. Thanks!

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: The fever to build..

Re: The fever to build..

NEW222 wrote:Nice roddie. Engine beams would be good. I just finished my wing rebuild and I got to use soem of that very nice triangle stock from you for supports in a few areas. They worked awesome. And when I get onto the fuselage repairs, I am sure I will be using a bunch more of them. Thanks!

Chancey, You're welcome bro. I have a LOT more of that stock. Let me know if you need more.

I'm trying to set some thoughts aside for designing a new Cox engine-powered model...something you could build... if you wanted to.. likely an airplane.

Re: The fever to build..

Re: The fever to build..

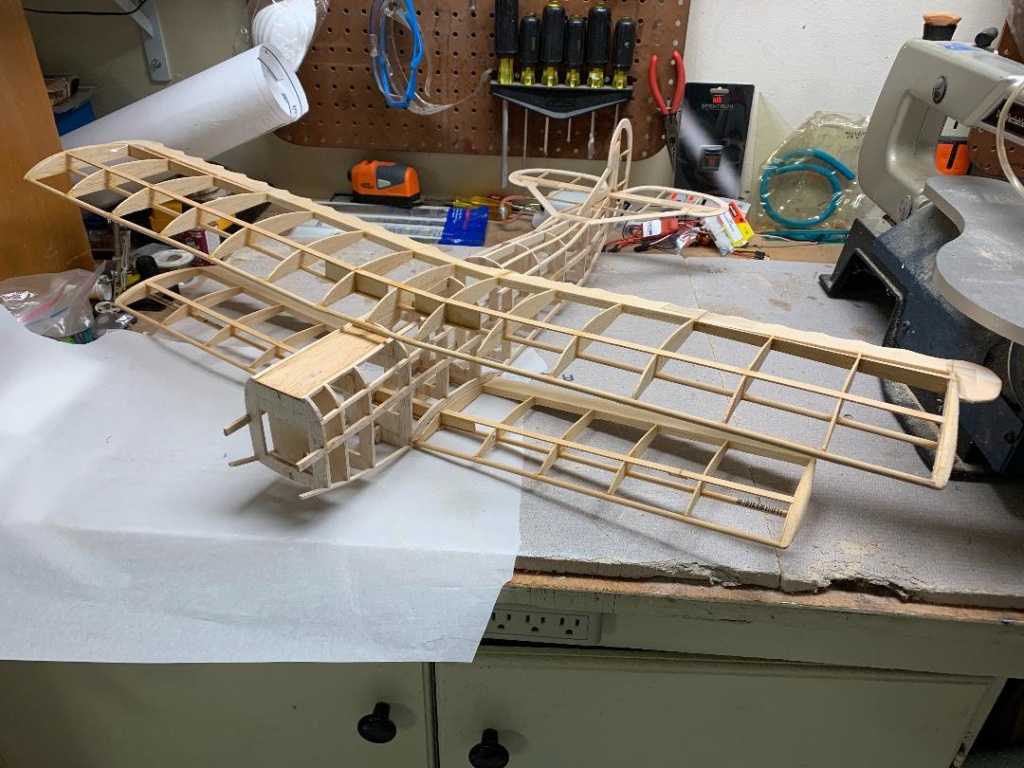

Does one ever have enough things on the go?  But, now bitten by the RC bug again, things are indeed happening!

But, now bitten by the RC bug again, things are indeed happening!

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

daddyo- Gold Member

- Posts : 139

Join date : 2012-11-26

Age : 56

Location : California

Similar topics

Similar topics» The BTC-2 build

» Baby Ringmaster fever

» My Buddy Al and His Fantastic Electrics...Stuka Fever

» Guillows Cessna 150 build circa 1970 (Build Log)

» Help Deciding on Kit

» Baby Ringmaster fever

» My Buddy Al and His Fantastic Electrics...Stuka Fever

» Guillows Cessna 150 build circa 1970 (Build Log)

» Help Deciding on Kit

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules