Log in

Search

Latest topics

» My N-1R build logby roddie Today at 12:32 am

» Happy 77th birthday Andrew!

by akjgardner Today at 12:27 am

» TEE DEE Having issues

by TD ABUSER Yesterday at 9:43 pm

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» Roger Harris revisited

by TD ABUSER Yesterday at 2:13 pm

» Tee Dee .020 combat model

by Ken Cook Yesterday at 1:41 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Yesterday at 1:37 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Fri Nov 22, 2024 11:32 am

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

Cox Engine of The Month

Beam mounts

Page 2 of 2

Page 2 of 2 •  1, 2

1, 2

Re: Beam mounts

Re: Beam mounts

Ya...I knew the big number was tpi...couldn't correlate the 4,6,8 to anything...

OhBee- Platinum Member

- Posts : 698

Join date : 2016-03-23

Age : 73

Location : Minnesota

Re: Beam mounts

Re: Beam mounts

OhBee,

Go here for a chart that shows the specs for each size screw.

https://littlemachineshop.com/reference/tapdrill.php

https://mechanicalc.com/reference/fastener-size-tables#hardware-sizes-inch

Note that #3 isn't listed. #3 was what the smaller Cox engines were built to use. I do have a stash of #3 stuff, but no drill guide for mounting screw holes. If the mounting holes are not laid out just right, then the engine won't match up in your firewall right. #2 hardware, being a bit smaller, allows for a bit of fudge factor.

I seem to remember looking at metric stuff to discover that either M2 (2 mm) or M2.5 (2.5 mm) was pretty close to #3. Blind nuts are pretty hard to find in metric, so it wasn't a path I wanted to investigate more deeply. I think M3 is bigger than #3, but may be the size specified for larger foreign engines, like my Norvels/AP Wasps.

Using #4 hardware will require drilling out the backplate mounting holes. I won't do that to a metal backplate because the mounting ears are already pretty weak. Plastic horseshoe backplates are still pretty common, and have lots of material around the mounting holes, so drill away if you choose. Just like #3 screws, you better be pretty accurate laying out your mounting holes.

And just to make things more confusing, wait until you want to play with prop mounting screws. Those are #5-40! And some 1/2A props have a recessed hub requiring a shorter screw, while some props have a solid/thicker hub requiring a longer screw.

Go here for a chart that shows the specs for each size screw.

https://littlemachineshop.com/reference/tapdrill.php

https://mechanicalc.com/reference/fastener-size-tables#hardware-sizes-inch

Note that #3 isn't listed. #3 was what the smaller Cox engines were built to use. I do have a stash of #3 stuff, but no drill guide for mounting screw holes. If the mounting holes are not laid out just right, then the engine won't match up in your firewall right. #2 hardware, being a bit smaller, allows for a bit of fudge factor.

I seem to remember looking at metric stuff to discover that either M2 (2 mm) or M2.5 (2.5 mm) was pretty close to #3. Blind nuts are pretty hard to find in metric, so it wasn't a path I wanted to investigate more deeply. I think M3 is bigger than #3, but may be the size specified for larger foreign engines, like my Norvels/AP Wasps.

Using #4 hardware will require drilling out the backplate mounting holes. I won't do that to a metal backplate because the mounting ears are already pretty weak. Plastic horseshoe backplates are still pretty common, and have lots of material around the mounting holes, so drill away if you choose. Just like #3 screws, you better be pretty accurate laying out your mounting holes.

And just to make things more confusing, wait until you want to play with prop mounting screws. Those are #5-40! And some 1/2A props have a recessed hub requiring a shorter screw, while some props have a solid/thicker hub requiring a longer screw.

Last edited by 944_Jim on Sat Mar 14, 2020 4:42 am; edited 1 time in total (Reason for editing : Added extra link for drill size by fastener)

944_Jim- Diamond Member

Posts : 2022

Join date : 2017-02-08

Age : 59

Location : NE MS

Re: Beam mounts

Re: Beam mounts

The whole fastener thing can be intimidating.

SAE stuff is spec’d by the thread major diameter and the number of threads inside of one inch.

SI (metric) fasteners are spec’d by major diameter and the thread pitch

Pitch is the distance between each thread peak, or root.

TPI is somewhat of an anachronism.

Pitch is more specific description.

M6-1.0 (6MM) has a major diameter of 6mm and each thread peak is 1mm distant from each other.

1/4-20 is .250” major diameter and has a pitch of .040” between thread peaks.

Metric is nice to deal with because all the info you need to deal with the fastener is in the thread spec.

The tap drill is determined by subtracting the pitch from the major diameter.

6mm - 1mm = 5mm tap drill size.

Same for SAE, but you have to do more math.

1-8 fasteners

1.000 major diameter. 8 TPI.

Pitch is 1/8 which = .125

1.000-.125= .875 or 7/8 tap drill size.

Hope this helps

SAE stuff is spec’d by the thread major diameter and the number of threads inside of one inch.

SI (metric) fasteners are spec’d by major diameter and the thread pitch

Pitch is the distance between each thread peak, or root.

TPI is somewhat of an anachronism.

Pitch is more specific description.

M6-1.0 (6MM) has a major diameter of 6mm and each thread peak is 1mm distant from each other.

1/4-20 is .250” major diameter and has a pitch of .040” between thread peaks.

Metric is nice to deal with because all the info you need to deal with the fastener is in the thread spec.

The tap drill is determined by subtracting the pitch from the major diameter.

6mm - 1mm = 5mm tap drill size.

Same for SAE, but you have to do more math.

1-8 fasteners

1.000 major diameter. 8 TPI.

Pitch is 1/8 which = .125

1.000-.125= .875 or 7/8 tap drill size.

Hope this helps

63expert- Bronze Member

- Posts : 38

Join date : 2014-02-10

Re: Beam mounts

Re: Beam mounts

OhBee, The machine-screws that fit the Cox engines can all be sourced.. but as you know; not at the store down the road.

I sourced some harder-to-find machine-screws from FASTENAL; a hardware specialist. Most of what I needed was only available in quantities/boxes of 100 pieces.. so I chose to order 3-48, 4-40 and 5-40 black-oxide coated cap-screws, in 1" lengths. This way I had the option to custom-cut lengths to suit. The 4-40 size are superior replacement head-screws as well as the backplates on some of your vintage .09 thru .35 American steel-fin 2-stroke model engines. I have some of those.

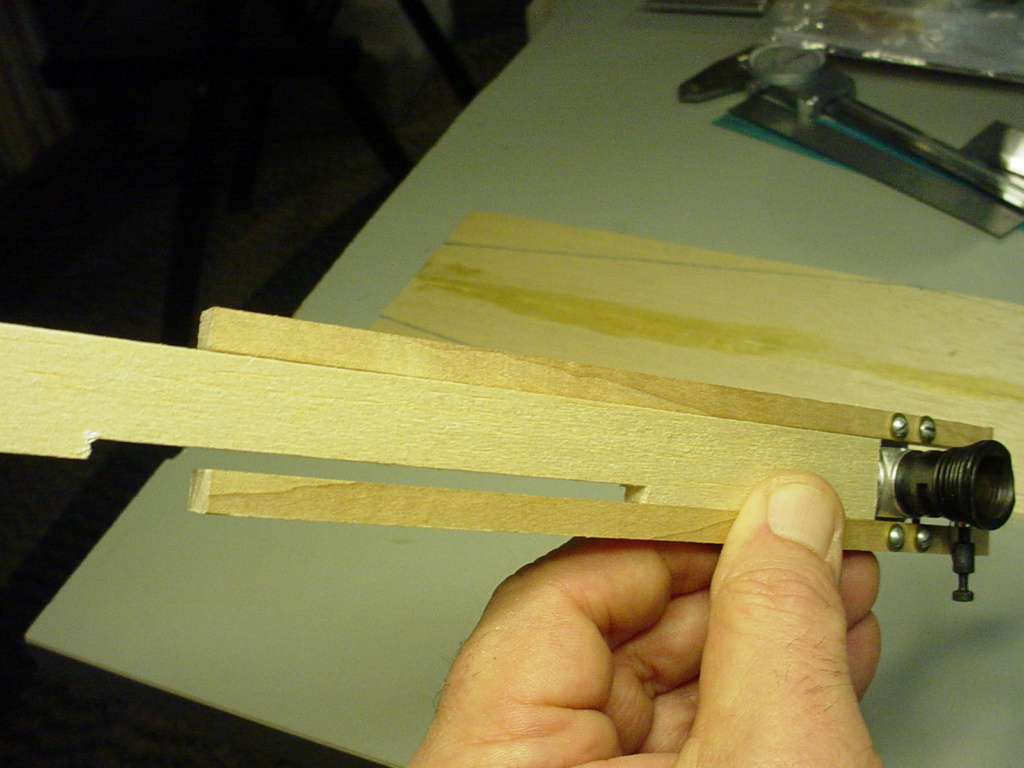

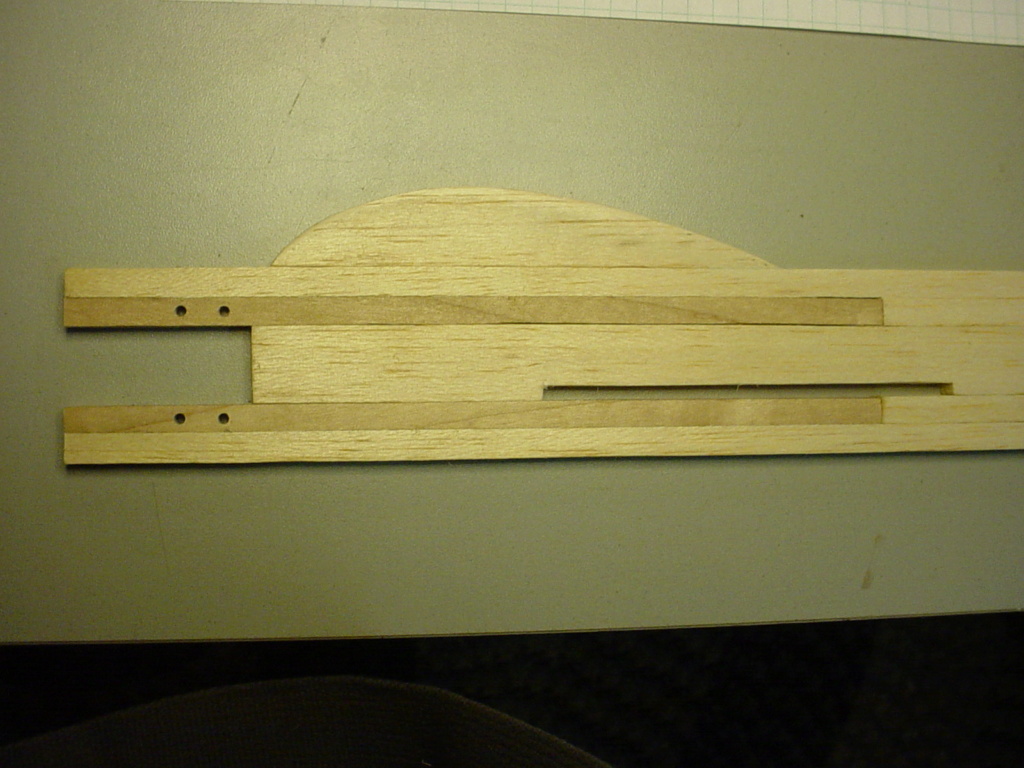

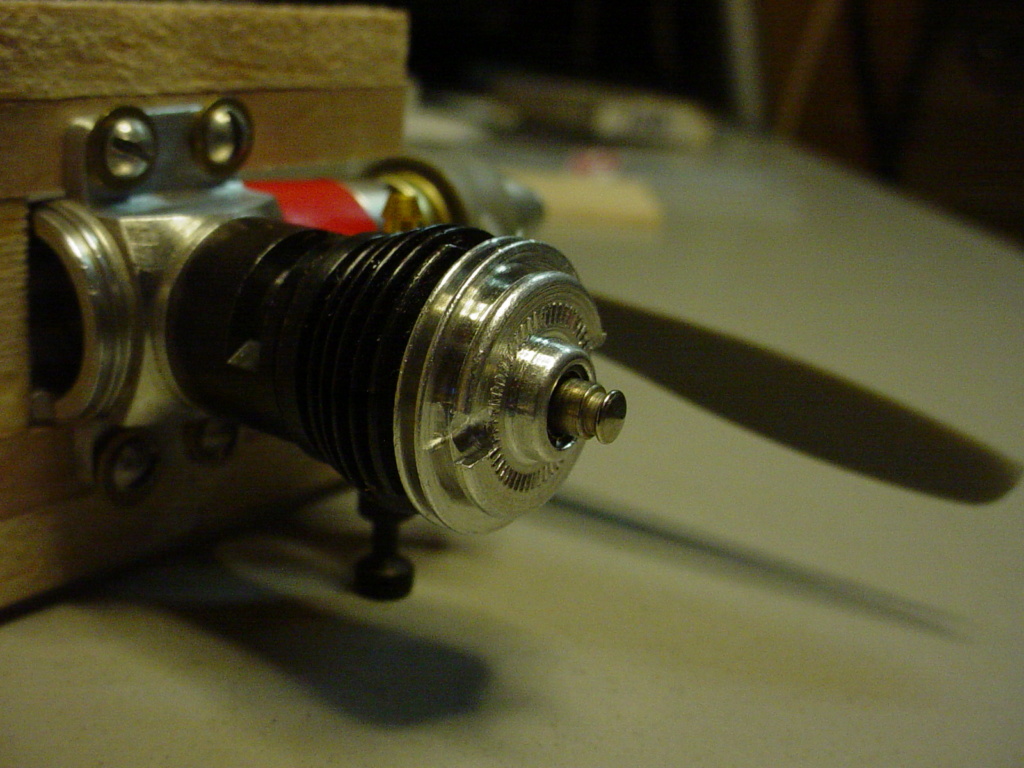

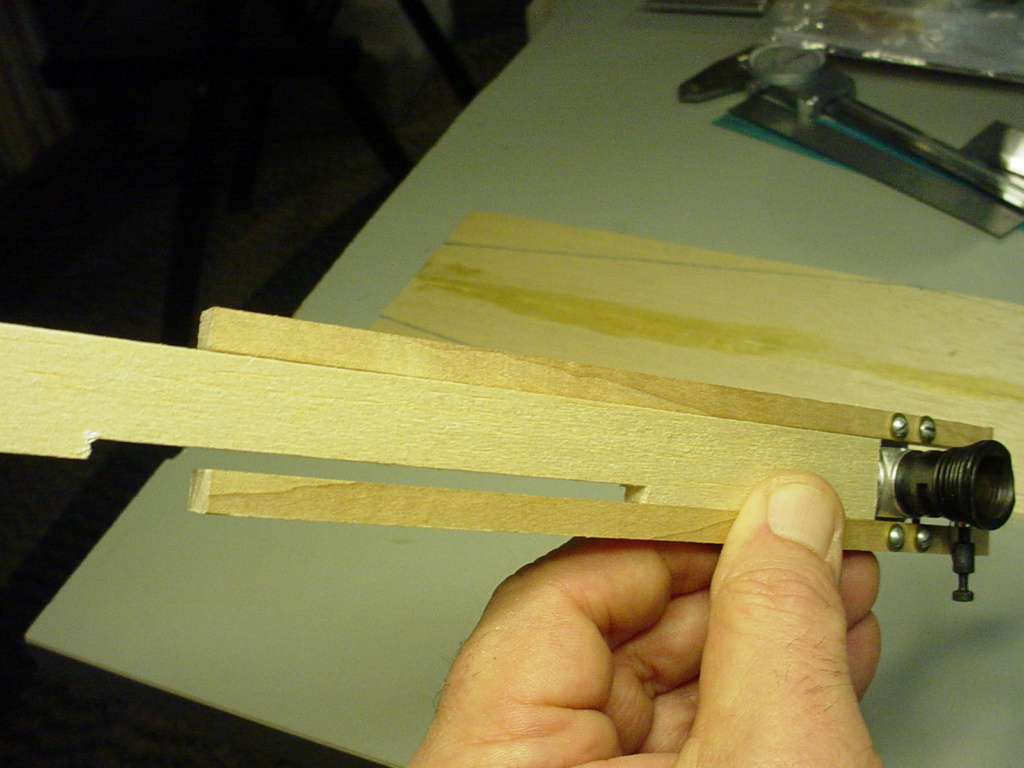

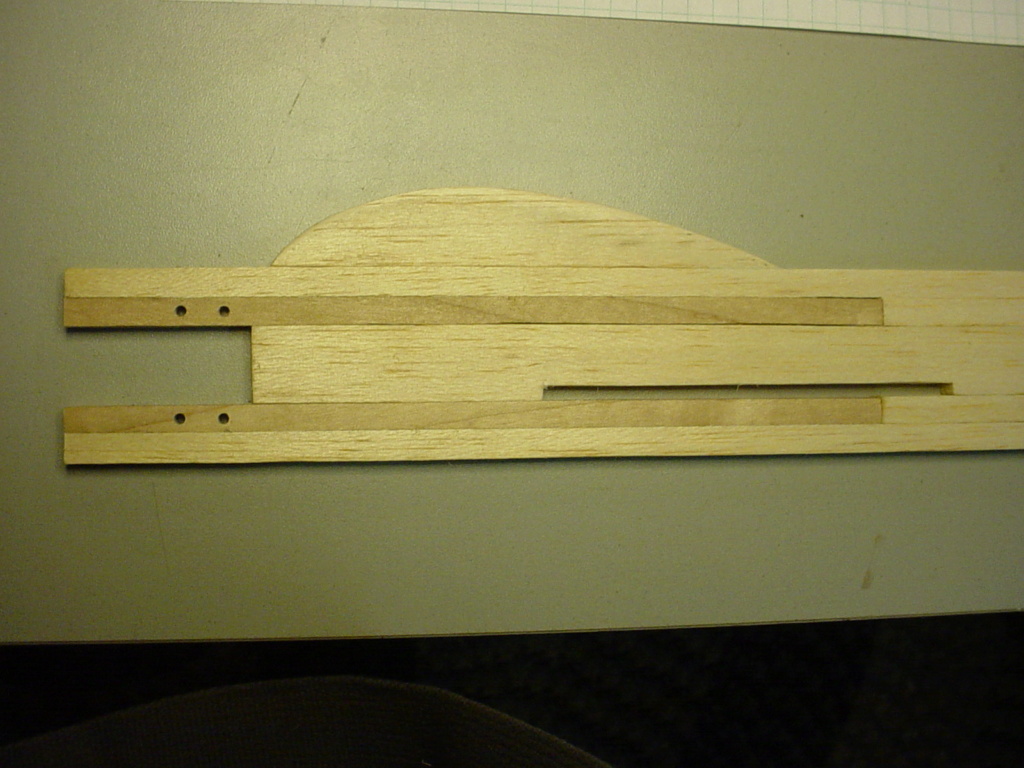

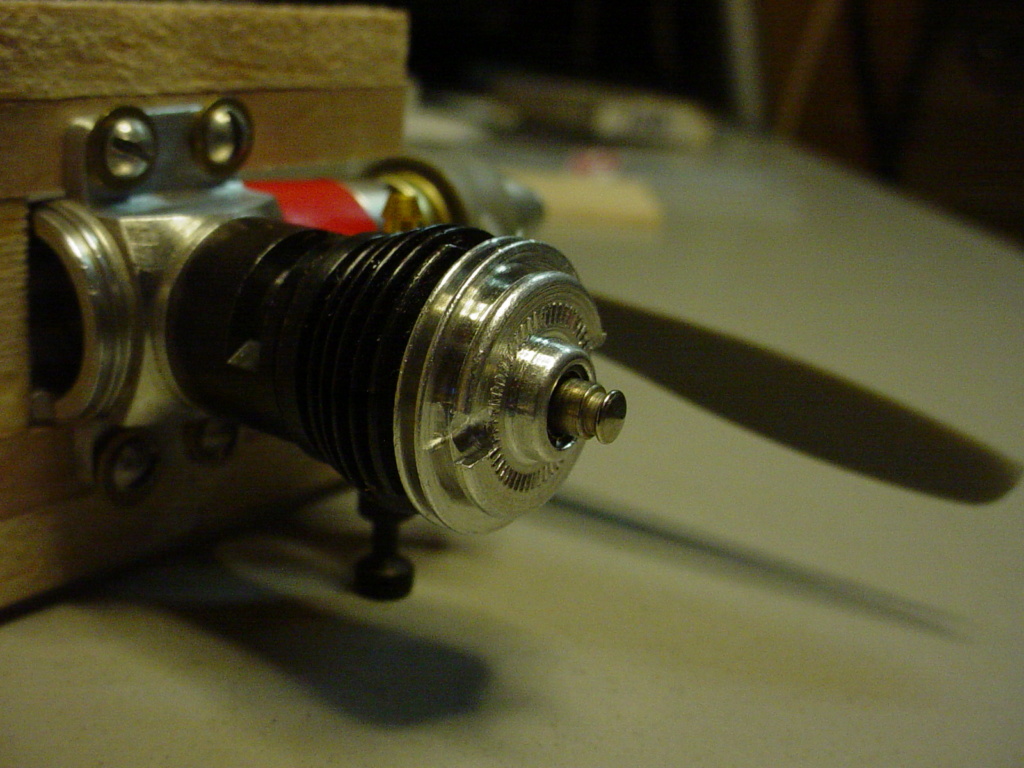

"Beam-mounting" the TeeDee and Medallion (FRV) .049/.051 engines requires a 3-48 size machine-screw. Screw "length" is determined by the thickness of the beam. A typical hardwood beam-size for the aforementioned engines would be between 1/4" (.250") and 5/16" (.312") square-stock. Your machine-screw length needs to be long-enough to pass-through a #3 steel flat-washer, the engine's mounting-ear, the hardwood beam, with enough length remaining to fully accept a 3-48 locknut and washer. Tee-nuts can be used.. but drilling the pilot-holes for them in this small size of a beam, I would not recommend. A #39 drill (.099" dia.) is the proper drill for installing 3-48 size machine-screws.

Here's some photos of the 1/4" square Maple beams in my T33Dee

It's easy to overlook "model-hardware" in your searches.. or even discard packets that were throw-in when sourcing model-supplies 2nd-hand. "Perfect" brand.. for example.

I have and will eventually install 3-48 socket-head/cap-screws and lock-nuts that were sourced from Fastenal.

I sourced some harder-to-find machine-screws from FASTENAL; a hardware specialist. Most of what I needed was only available in quantities/boxes of 100 pieces.. so I chose to order 3-48, 4-40 and 5-40 black-oxide coated cap-screws, in 1" lengths. This way I had the option to custom-cut lengths to suit. The 4-40 size are superior replacement head-screws as well as the backplates on some of your vintage .09 thru .35 American steel-fin 2-stroke model engines. I have some of those.

"Beam-mounting" the TeeDee and Medallion (FRV) .049/.051 engines requires a 3-48 size machine-screw. Screw "length" is determined by the thickness of the beam. A typical hardwood beam-size for the aforementioned engines would be between 1/4" (.250") and 5/16" (.312") square-stock. Your machine-screw length needs to be long-enough to pass-through a #3 steel flat-washer, the engine's mounting-ear, the hardwood beam, with enough length remaining to fully accept a 3-48 locknut and washer. Tee-nuts can be used.. but drilling the pilot-holes for them in this small size of a beam, I would not recommend. A #39 drill (.099" dia.) is the proper drill for installing 3-48 size machine-screws.

Here's some photos of the 1/4" square Maple beams in my T33Dee

It's easy to overlook "model-hardware" in your searches.. or even discard packets that were throw-in when sourcing model-supplies 2nd-hand. "Perfect" brand.. for example.

I have and will eventually install 3-48 socket-head/cap-screws and lock-nuts that were sourced from Fastenal.

Re: Beam mounts

Re: Beam mounts

I think I'll stick to fishing.....A lot to learn and know there too,but after over 60 yrs. of doing it I at least have it all figured out! Non of this was this frustrating or confusing when we were kids. Who messed it all up?

OhBee- Platinum Member

- Posts : 698

Join date : 2016-03-23

Age : 73

Location : Minnesota

Re: Beam mounts

Re: Beam mounts

Well we do have a Fastenal here....but previous attempts at finding stuff hasn't been all that productive there either! Problem with this town is unqualified people unwilling or too lazy to do thier job,!

OhBee- Platinum Member

- Posts : 698

Join date : 2016-03-23

Age : 73

Location : Minnesota

Re: Beam mounts

Re: Beam mounts

The only thing with your Fastenal is that you may still need to order it in if they do not have stock. But they will be able to get you what you need.

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: Beam mounts

Re: Beam mounts

Fortunately Fastenal has an online catalog. Bad part is they want to sell in bulk online. But if you know their part numbers, then they may bust a bag open for a partial sale. I know ours will...if it is in stock.

Also check with Motion Industries. I buy my British Carb o-rings in bulk from them, and GL 4 gear lube for old differentials/gearboxes.

Also check with Motion Industries. I buy my British Carb o-rings in bulk from them, and GL 4 gear lube for old differentials/gearboxes.

_________________

Never enough time to build them all...always enough time to smash them all!

944_Jim- Diamond Member

Posts : 2022

Join date : 2017-02-08

Age : 59

Location : NE MS

Re: Beam mounts

Re: Beam mounts

I realize that people don't want to have to buy 100 screws..  That's a lot of screws. I'd send anybody a "screw or two" for nothin'.. if it meant getting one engine to run.

That's a lot of screws. I'd send anybody a "screw or two" for nothin'.. if it meant getting one engine to run.

Re: Beam mounts

Re: Beam mounts

Here's a link to RTL Fasteners website search for 3-48 hardware. I thought they had 3-48 blind nuts too, but I didn't see them listed. It's worth asking them though. Great folks.

https://www.rtlfasteners.com/Merchant2/merchant.mvc?

Edit - I tried the link and it goes to their home page. Just enter 3-48 in the search.

https://www.rtlfasteners.com/Merchant2/merchant.mvc?

Edit - I tried the link and it goes to their home page. Just enter 3-48 in the search.

Last edited by Dave P. on Sat Mar 14, 2020 7:52 pm; edited 1 time in total (Reason for editing : Incorrect link)

Dave P.- Gold Member

- Posts : 477

Join date : 2017-07-31

Age : 67

Location : Durham, NC

Re: Beam mounts

Re: Beam mounts

I don't know about the shipping, but they're available here.

https://www.gravesrc.com/dubro-3-48-blind-nuts-4.html

Bob

https://www.gravesrc.com/dubro-3-48-blind-nuts-4.html

Bob

dckrsn- Diamond Member

- Posts : 2750

Join date : 2010-10-21

Age : 71

Location : Long Island, New York

Re: Beam mounts

Re: Beam mounts

Just out of curiosity, why use a screw that's been on it's way out for nearly 4 decades? I agree it fits the TD correctly. However, it makes little to no sense to source something difficult to readily obtain when the 2-56 does the job equally as well. Fox used 3-48's for many engines due to being cheap and he obtained them from military surplus. Dubro still offers 3-48 blind nuts but 2-56 is easier buying them in bulk. All modern high performance 1/2A engines use 2-56.

Ken Cook- Top Poster

- Posts : 5640

Join date : 2012-03-27

Location : pennsylvania

Page 2 of 2 •  1, 2

1, 2

Similar topics

Similar topics» Narrowing engine bearers

» TD/Medallion beam mount

» beam mount question

» Brodak 1/2a zero flight video - beam mount converted

» 1/8" balsa I-beam wing spars

» TD/Medallion beam mount

» beam mount question

» Brodak 1/2a zero flight video - beam mount converted

» 1/8" balsa I-beam wing spars

Page 2 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules