Log in

Search

Latest topics

» Tee Dee .020 combat modelby TD ABUSER Today at 12:38 am

» My latest doodle...

by batjac Yesterday at 9:47 pm

» My N-1R build log

by roddie Yesterday at 8:50 pm

» Free Flight Radio Assist

by rdw777 Yesterday at 4:51 pm

» Purchased the last of any bult engines from Ken Enya

by getback Yesterday at 12:05 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

» My current avatar photo

by roddie Mon Nov 18, 2024 9:05 pm

» Brushless motors?

by rsv1cox Sun Nov 17, 2024 6:40 pm

Cox Engine of The Month

049 Black Widow tuning

Page 1 of 4

Page 1 of 4 • 1, 2, 3, 4

049 Black Widow tuning

049 Black Widow tuning

~25 years ago I was flying U-control 1/2A with 3 up combat with a super simple basically indestructible home brew planes with 049 black widow motors. My third black widow motor I got was a dud, would barely get 14K rpm, where my other two 049's was in the 18K rpm range with 10% nitro thimble drone 5" prop.

Troubleshooting the dud, a friend showed me how to lap sand the case at the carb/tank mount (1500 grit sandpaper put on glass and sprayed with wd40 and sanded in a figure 8 pattern), it knocks off the bulge of the 4 course carb/tank mounting screws (a black sharpie put on before the sanding will show the progress). This did not seem to help the dud motor,,,,but I got an idea.

Why not try it on where the cylinder screws in (effectively changing the timing). I passed my idea by a buddy that road raced the two stroke Yamaha RD400 (and was a auto/diesel mechanic), he said I should raise the exhaust ports (so not remove material, but add to it), so I made a 0.010" base gasket, this made it a super dud motor, lol.

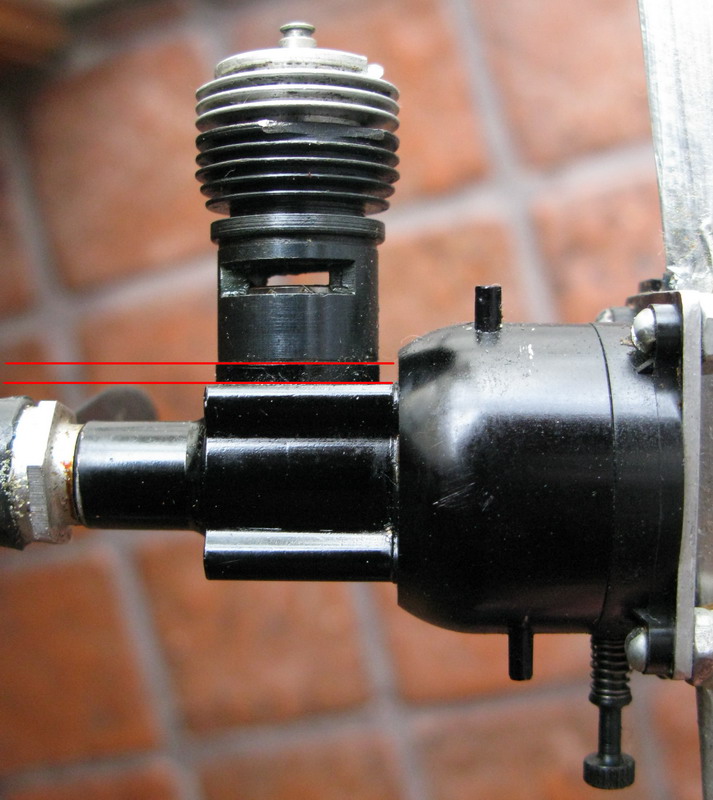

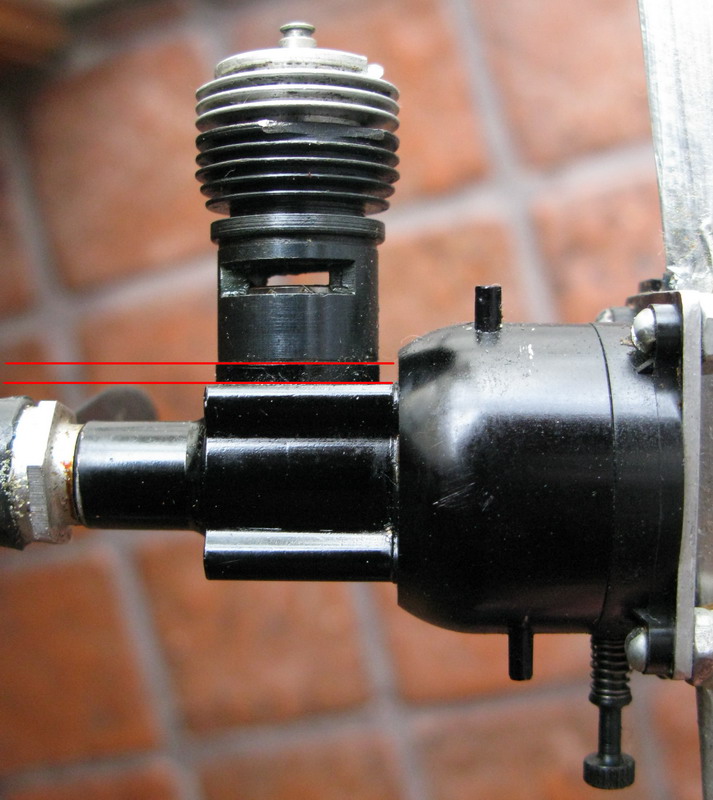

To scientifically gauge what I was about to attempt I measured the height of where the cylinder screws in to the case (see picture of the red lines where I measured - from case to where cylinder screws in), I call this deck height, my normal two good motors was 78 thou (0.078"), the dud was 84 thou, instantly a big grin appeared. With the precision these cox motors are built to, wth was going on with this spec, 0.006" too tall.

I started by taking 5 thou off (glass/sandpaper/wd40, same as I mentioned above) and retesting, result was better, another 5 thou, even better, another 5 thou and was getting hard to start. Then I thought why it was hard to start, hmmm, way to much compression, perfect, the head gaskets were 5 thou, I can compensate with head gaskets, so for every 5 thou I removed from the deck, I added 1 more head gasket.

After continuing this process a few more times (I went down to 53 thou from 84), it turns out, 15 thou off the good motor (was 78 thou, now reduced to ~63 thou with 4 head gaskets (1 original +3)) was the best.

Results are with 10% nitro, Thimble Drone 5x4 balanced prop and plastic reed valve.

Bone stock good motor with 78 thou deck height = 17-18K rpm,

Bone stock dud motor with 84 thou deck height = 14K rpm,

Best was reducing to ~63 thou deck height (on all motors), with a total of 4 head gaskets, 25Krpm and one hit 26Krpm.

I have seen the "timing shims", but these do the opposite, they raise the cylinder, not lower it.

If your motor is older, use the piston reset tool to take the slop out of the connecting rod (do not over do it and make it too tight), have fun with more power.

I have read this great motor tuning guide about 4 years ago (Rusty Knowlton linked it in my rcg thread), he mentioned spi, but never talks about lowering the cylinder to adjust it and compensate with adding head gaskets like I did, or the rpm's I hit (with only 10% nitro)

https://www.coxengineforum.com/t753-t...e-race-program.

If you try this, report back your results.

Troubleshooting the dud, a friend showed me how to lap sand the case at the carb/tank mount (1500 grit sandpaper put on glass and sprayed with wd40 and sanded in a figure 8 pattern), it knocks off the bulge of the 4 course carb/tank mounting screws (a black sharpie put on before the sanding will show the progress). This did not seem to help the dud motor,,,,but I got an idea.

Why not try it on where the cylinder screws in (effectively changing the timing). I passed my idea by a buddy that road raced the two stroke Yamaha RD400 (and was a auto/diesel mechanic), he said I should raise the exhaust ports (so not remove material, but add to it), so I made a 0.010" base gasket, this made it a super dud motor, lol.

To scientifically gauge what I was about to attempt I measured the height of where the cylinder screws in to the case (see picture of the red lines where I measured - from case to where cylinder screws in), I call this deck height, my normal two good motors was 78 thou (0.078"), the dud was 84 thou, instantly a big grin appeared. With the precision these cox motors are built to, wth was going on with this spec, 0.006" too tall.

I started by taking 5 thou off (glass/sandpaper/wd40, same as I mentioned above) and retesting, result was better, another 5 thou, even better, another 5 thou and was getting hard to start. Then I thought why it was hard to start, hmmm, way to much compression, perfect, the head gaskets were 5 thou, I can compensate with head gaskets, so for every 5 thou I removed from the deck, I added 1 more head gasket.

After continuing this process a few more times (I went down to 53 thou from 84), it turns out, 15 thou off the good motor (was 78 thou, now reduced to ~63 thou with 4 head gaskets (1 original +3)) was the best.

Results are with 10% nitro, Thimble Drone 5x4 balanced prop and plastic reed valve.

Bone stock good motor with 78 thou deck height = 17-18K rpm,

Bone stock dud motor with 84 thou deck height = 14K rpm,

Best was reducing to ~63 thou deck height (on all motors), with a total of 4 head gaskets, 25Krpm and one hit 26Krpm.

I have seen the "timing shims", but these do the opposite, they raise the cylinder, not lower it.

If your motor is older, use the piston reset tool to take the slop out of the connecting rod (do not over do it and make it too tight), have fun with more power.

I have read this great motor tuning guide about 4 years ago (Rusty Knowlton linked it in my rcg thread), he mentioned spi, but never talks about lowering the cylinder to adjust it and compensate with adding head gaskets like I did, or the rpm's I hit (with only 10% nitro)

https://www.coxengineforum.com/t753-t...e-race-program.

If you try this, report back your results.

Last edited by --Oz-- on Sun Aug 11, 2019 2:21 pm; edited 1 time in total (Reason for editing : Added prop info 5x4 thimble drone.)

049 black widow tuning

049 black widow tuning

Hi oz good work with your widow mods although you

Have reduce the cylinder height & exhaust duration thus

Allowowing you to pull more pitch you have also increased

Sub piston induction & adjusted head shims to give correct

Piston/ head clearance good job you have gone about this

Mod in the correct way with the obvious results

Rex f.

Have reduce the cylinder height & exhaust duration thus

Allowowing you to pull more pitch you have also increased

Sub piston induction & adjusted head shims to give correct

Piston/ head clearance good job you have gone about this

Mod in the correct way with the obvious results

Rex f.

rex f.- Banned

- Posts : 40

Join date : 2019-07-11

Age : 81

Location : Scone nsw aust 2337

Re: 049 Black Widow tuning

Re: 049 Black Widow tuning

@ Rex f,

Thanks for your comments. I have not been around any cox forums until a week ago, so all my tinkering was 20 to 40 years ago.

I see they make shims to go between the cylinder and case, this of course moves the cylinder up, so seems common knowledge since these parts were for sale. Moving the cylinder up on any of my 3 black widow motors tuned them into duds.

Have you read anything about moving the cylinder down (as I did)? links?

I was fine tuning with a large hammer (0.005" at a time), I would think optimizing the cylinder height and compression on a finer scale could help. 25Krpm on a reed motor with 10% nitro was not bad, but, we always want more.

Thanks for your comments. I have not been around any cox forums until a week ago, so all my tinkering was 20 to 40 years ago.

I see they make shims to go between the cylinder and case, this of course moves the cylinder up, so seems common knowledge since these parts were for sale. Moving the cylinder up on any of my 3 black widow motors tuned them into duds.

Have you read anything about moving the cylinder down (as I did)? links?

I was fine tuning with a large hammer (0.005" at a time), I would think optimizing the cylinder height and compression on a finer scale could help. 25Krpm on a reed motor with 10% nitro was not bad, but, we always want more.

Re: 049 Black Widow tuning

Re: 049 Black Widow tuning

--Oz-- wrote:@ Rex f,

Thanks for your comments. I have not been around any cox forums until a week ago, so all my tinkering was 20 to 40 years ago.

I see they make shims to go between the cylinder and case, this of course moves the cylinder up, so seems common knowledge since these parts were for sale. Moving the cylinder up on any of my 3 black widow motors tuned them into duds.

Have you read anything about moving the cylinder down (as I did)? links?

I was fine tuning with a large hammer (0.005" at a time), I would think optimizing the cylinder height and compression on a finer scale could help. 25Krpm on a reed motor with 10% nitro was not bad, but, we always want more.

Oz. The purpose of the "timing" shims that go under the cylinder is to eliminate the SPI when utilising a muffler. A muffler with an SPI cylinder would cause an engine to ingest its own fumes, potentially deadening the intake charge. Remember when they introduced EGR (Exhaust Gas Recirculation) to vehicles? Breathing spent gasses which no longer contain oxygen kills power. Clearly, the better way to utilise a muffler is with a non-SPI cylinder. Pretty sure the shims were aimed at the Tee Dees which didn't have a non-SPI option.

Finally, would you care to explain "I was fine tuning with a large hammer (0.005" at a time)"? Sounds interesting, if not a little brutal.

Rod.

Oldenginerod- Top Poster

- Posts : 4018

Join date : 2012-06-15

Age : 62

Location : Drouin, Victoria

Re: 049 Black Widow tuning

Re: 049 Black Widow tuning

Timing shims will also raise the ports, and generally raising the port height creates a more "rev-happy" engine, usually at the expense of low end grunt. Not sure how much this affects in the practical world though.

So, if you want to use a muffler, it would be better to use a non-SPI cylinder. A throttle ring works with SPI, it just chokes the exhaust port, but does not feed any exhaust to SPI.

So, if you want to use a muffler, it would be better to use a non-SPI cylinder. A throttle ring works with SPI, it just chokes the exhaust port, but does not feed any exhaust to SPI.

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Re: 049 Black Widow tuning

Re: 049 Black Widow tuning

All I ment was trying in large steps of 0.005" is not really fine tuning, if I did it again, I would try finer steps of say 0.002".Oldenginerod wrote:Oz. The purpose of the "timing" shims that go under the cylinder is to eliminate the SPI when utilising a muffler. A muffler with an SPI cylinder would cause an engine to ingest its own fumes, potentially deadening the intake charge. Remember when they introduced EGR (Exhaust Gas Recirculation) to vehicles? Breathing spent gasses which no longer contain oxygen kills power. Clearly, the better way to utilise a muffler is with a non-SPI cylinder. Pretty sure the shims were aimed at the Tee Dees which didn't have a non-SPI option.

Finally, would you care to explain "I was fine tuning with a large hammer (0.005" at a time)"? Sounds interesting, if not a little brutal.

Rod.

Reading all the tight tolerances these motors are made too, its surprising I got such a dud, maybe it was a monday morning after a holiday motor.

Deck height of +0.006" killed 3~4Krpm!, then reducing it from 78 to 63 (0.015) gained another ~7Krpm (18 to 25Krpm). That is just crazy (~38% more rpm) and on 10% nitro. Knowing this, i would figure they would have a stock deck height of say 55~60 (instead of 78), then add shim(s) down there to tune the motor with 2.5, 5, 10 thou shims. I can see this might confuse the average dad/son (putting the wrong shim in after teardown), but for the performance crowd a win. Maybe its just a well kept secret?

Re: 049 Black Widow tuning

Re: 049 Black Widow tuning

Things would have to be equal. Raising the cylinder would mean dropping the head the same amount to really know if it helps. The deck height, or head space should be equal. 7,000 rpm is quite a difference, I like that. We used to sand a bit off the case, but only to get the exhaust port open face forward for better scavenging. I never had a tach then. The factory machining could be crooked as well as being the wrong dimension too.

aspeed- Platinum Member

- Posts : 796

Join date : 2013-01-18

Location : Leamington Ont. Can.

Re: 049 Black Widow tuning

Re: 049 Black Widow tuning

aspeed wrote:Things would have to be equal. Raising the cylinder would mean dropping the head the same amount to really know if it helps. The deck height, or head space should be equal. 7,000 rpm is quite a difference, I like that. We used to sand a bit off the case, but only to get the exhaust port open face forward for better scavenging. I never had a tach then. The factory machining could be crooked as well as being the wrong dimension too.

One guy mentioned (in my rcg thread 5yrs ago) they did this to make the exhaust port exit 90 degrees from the crank (E.G. not facing forward, and this lines up the internal ports (in line with the crank) for better transfer, I never looked into this or understood how or why this could/would be better. Maybe the whole time they were doing this, they were just lowering the cylinder and getting better preformance regardless of where the ports are facing,,,

You mention "scavenging", I understand 4 stroke exhaust scavenging (negative pressure created by the last exhaust pulse going by the 4n1 section. How does scavenging work on 2 stroke with the exhaust port facing into the wind? tia

Re: 049 Black Widow tuning

Re: 049 Black Widow tuning

aspeed wrote:Things would have to be equal. Raising the cylinder would mean dropping the head the same amount to really know if it helps. The deck height, or head space should be equal. 7,000 rpm is quite a difference, I like that. We used to sand a bit off the case, but only to get the exhaust port open face forward for better scavenging. I never had a tach then. The factory machining could be crooked as well as being the wrong dimension too.

Couple minutes googling 2 stroke scavenging and I now understand it.

By lowering the cylinder (relatively easy to do), and adding head gaskets to compensate (easy to do), this was easy to play with.

Going the other way, raising the cylinder is easy, but lowering the head not so easy (more than 0.005"). How would you go about doing this?

Re: 049 Black Widow tuning

Re: 049 Black Widow tuning

Can you guys measure the deck height of spare 049 cases laying around and report back?

Be interesting how far off from my motors they are.

0.078" 18Krpm

0.078" 18Krpm

0.084" 14Krpm (dud), lowered to 0.063 (with 4 head gaskets) 25Krpm.

TIA for reporting back!

Be interesting how far off from my motors they are.

0.078" 18Krpm

0.078" 18Krpm

0.084" 14Krpm (dud), lowered to 0.063 (with 4 head gaskets) 25Krpm.

TIA for reporting back!

Re: 049 Black Widow tuning

Re: 049 Black Widow tuning

You often see the 50 millionths tolerance quoted, but think this only applies to the pistons and cylinders. Except crank bores, I've found the rest to be quite loose. I assumed the deck height feature you measured was created in one operation, so am a bit surprised that it varies. I have not inspected that particular dimension, but have seen variation in crank center to cylinder seat distance.

This is something I'll have to try. It seems odd that reducing exhaust and transfer duration while increasing SPI would make that much more power. However, there is a lot going on in terms of gas flown even in a simple 2 stroke engine, so it's hard to say what works for this design.

Lowering the cylinder while maintaining compression ratio requires high compression heads.

This is something I'll have to try. It seems odd that reducing exhaust and transfer duration while increasing SPI would make that much more power. However, there is a lot going on in terms of gas flown even in a simple 2 stroke engine, so it's hard to say what works for this design.

Lowering the cylinder while maintaining compression ratio requires high compression heads.

gkamysz- Gold Member

- Posts : 414

Join date : 2018-02-22

Location : Chicagoland

Re: 049 Black Widow tuning

Re: 049 Black Widow tuning

Which prop are you using? A 5x3?

I'm struggling to imagine that an engine will go from 17krpm to 25krpm with just a small "deck height" adjustment...

The tolerance claimed by Cox was likely in the trial and error matching of cylinders and pistons. For the rest the tolerances are far worse. One particular problem is the length of the conrod, you can see large variations of the piston height at TDC (usually referred to as deck height). On the PeeWee this is particularly sever, as there everything else is smaller than on the .049 engines.

I'm struggling to imagine that an engine will go from 17krpm to 25krpm with just a small "deck height" adjustment...

The tolerance claimed by Cox was likely in the trial and error matching of cylinders and pistons. For the rest the tolerances are far worse. One particular problem is the length of the conrod, you can see large variations of the piston height at TDC (usually referred to as deck height). On the PeeWee this is particularly sever, as there everything else is smaller than on the .049 engines.

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

049 black widow tuning

049 black widow tuning

Hi oz have just measured 4 new cases they are

1 .073

2 .073

3 .078

4..084

As you call deck height

To the best of my knowledge .073 is correct for black widow

Giving 132 degrees or exhaust duration and approx 40 degrees

Spi iwould take a further 10 / 15 thou off the piston skirt to achieve 70 degrees

Of spi adjust head clearance using galbreath merlin if you have any

Or cox 1702 head to 15 / 20 thou using 35% nitro ( 1 shim for every 10%)

You wont go wrong with this setup but will still need to play a bit

As all engines vary evev killer bee cranks can vary in stroke by .001

Hope this helps

Rex f.

1 .073

2 .073

3 .078

4..084

As you call deck height

To the best of my knowledge .073 is correct for black widow

Giving 132 degrees or exhaust duration and approx 40 degrees

Spi iwould take a further 10 / 15 thou off the piston skirt to achieve 70 degrees

Of spi adjust head clearance using galbreath merlin if you have any

Or cox 1702 head to 15 / 20 thou using 35% nitro ( 1 shim for every 10%)

You wont go wrong with this setup but will still need to play a bit

As all engines vary evev killer bee cranks can vary in stroke by .001

Hope this helps

Rex f.

rex f.- Banned

- Posts : 40

Join date : 2019-07-11

Age : 81

Location : Scone nsw aust 2337

Re: 049 Black Widow tuning

Re: 049 Black Widow tuning

Surfer_kris wrote:Which prop are you using? A 5x3?

I'm struggling to imagine that an engine will go from 17krpm to 25krpm with just a small "deck height" adjustment...

Thimble Drone 5x4 prop, and it was 18K to 25Krpm, the dud went from 14 to 25Krpm.

rex f. wrote:Hi oz have just measured 4 new cases they are

1 .073

2 .073

3 .078

4..084

As you call deck height

To the best of my knowledge .073 is correct for black widow

Giving 132 degrees or exhaust duration and approx 40 degrees

Spi iwould take a further 10 / 15 thou off the piston skirt to achieve 70 degrees

Of spi adjust head clearance using galbreath merlin if you have any

Or cox 1702 head to 15 / 20 thou using 35% nitro ( 1 shim for every 10%)

You wont go wrong with this setup but will still need to play a bit

As all engines vary evev killer bee cranks can vary in stroke by .001

Hope this helps

Rex f.

Thanks Rex for the measurements and other data. It's good to know the deck height is not accurately controlled and is game for tuning.

With your calculator, going from 0.078 to 063", how does this change exhaust duration (degree wise)?

With my 4 decades of racing experience (Slot cars/rc cars/pc simulation), someone has to know tuning the deck height, I cant be the only one stumbled onto this adjustment (only after buying a dud motor), since it seems its not common knowledge, it must be a secret among some top racers, no?

I would like to see some other pilots try this adjustment and report back what they find. First benchmark the motor, then start lowering the deck height and retest, of course playing with compression with adding head gaskets. Be sure to use a balance prop too.

Re: 049 Black Widow tuning

Re: 049 Black Widow tuning

Those props are very soft and they will not hold their pitch with time, they simply rev higher and higher with usage.

I think that for any type of tuning to be consistent, one need to select an accurate standard prop. The stiffer competition props from Cox or the APC props are more useful.

The adjustment for deck height (or more correctly the piston height at TDC) is a very important tuning parameter. Just take a look at the Bob Mattes tuning advise for the Cox .020 engine, for instance.

I think that for any type of tuning to be consistent, one need to select an accurate standard prop. The stiffer competition props from Cox or the APC props are more useful.

The adjustment for deck height (or more correctly the piston height at TDC) is a very important tuning parameter. Just take a look at the Bob Mattes tuning advise for the Cox .020 engine, for instance.

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: 049 Black Widow tuning

Re: 049 Black Widow tuning

Surfer_kris wrote:Those props are very soft and they will not hold their pitch with time, they simply rev higher and higher with usage.

I think that for any type of tuning to be consistent, one need to select an accurate standard prop. The stiffer competition props from Cox or the APC props are more useful.

The adjustment for deck height (or more correctly the piston height at TDC) is a very important tuning parameter. Just take a look at the Bob Mattes tuning advise for the Cox .020 engine, for instance.

As I mentioned, we were doing combat, these props are good for that as they take a beating, as opposed to acp, just looking at them they break (lol) and the higher cost of them. But its good to know. I also dont think it matters what prop use use, as someone tuning the motor will use the same prop and it will be apples to apples for their data to see if their setup improves.

You mention deck height is important, but it seems it is not common knowledge to lower the cylinder (mod the crankcase) and compensate with head gaskets. Any links to Bob Mattes tuning? tia

Re: 049 Black Widow tuning

Re: 049 Black Widow tuning

Hi, Oz.

Thanks for the test and tune report. That and flying adventures used to be primarily what I posted here at CEF. I was surprised to see you credit my name from an old RCG thread. That was my go-to forum back when I was re-entering the hobby and before I found CEF. This is a great little forum, glad to have you with us.

Rusty

Thanks for the test and tune report. That and flying adventures used to be primarily what I posted here at CEF. I was surprised to see you credit my name from an old RCG thread. That was my go-to forum back when I was re-entering the hobby and before I found CEF. This is a great little forum, glad to have you with us.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

049 black widow tuning

049 black widow tuning

Hi oz to calculate exhaust duration bypass & spi use a simple

Plastic protractor from the newsagents or stationery supplier

Its very easy

Rex f.

Plastic protractor from the newsagents or stationery supplier

Its very easy

Rex f.

rex f.- Banned

- Posts : 40

Join date : 2019-07-11

Age : 81

Location : Scone nsw aust 2337

Re: 049 Black Widow tuning

Re: 049 Black Widow tuning

RknRusty wrote:Hi, Oz.

Thanks for the test and tune report. That and flying adventures used to be primarily what I posted here at CEF. I was surprised to see you credit my name from an old RCG thread. That was my go-to forum back when I was re-entering the hobby and before I found CEF. This is a great little forum, glad to have you with us.

Rusty

Back when I figured out how to increase rpm, this was before internet. Later I found rcg and then later I finally posted what I found. You had posted in that thread the excellent tuning document, thanks, was an excellent read.

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: 049 Black Widow tuning

Re: 049 Black Widow tuning

@ Surfer_kris, thanks for the link (I just finished reading it, awesome work) and the KK info!

Re: 049 Black Widow tuning

Re: 049 Black Widow tuning

I would lower the head by chucking the cylinder in the lathe and removing whatever was desired. Removing the top lip is needed too, or the plug will not bottom out if you go too far. I would think a total of 180 degree s exhaust timing might be something to try if someone wanted to use a pipe.--Oz-- wrote:aspeed wrote:Things would have to be equal. Raising the cylinder would mean dropping the head the same amount to really know if it helps. The deck height, or head space should be equal. 7,000 rpm is quite a difference, I like that. We used to sand a bit off the case, but only to get the exhaust port open face forward for better scavenging. I never had a tach then. The factory machining could be crooked as well as being the wrong dimension too.

Couple minutes googling 2 stroke scavenging and I now understand it.

By lowering the cylinder (relatively easy to do), and adding head gaskets to compensate (easy to do), this was easy to play with.

Going the other way, raising the cylinder is easy, but lowering the head not so easy (more than 0.005"). How would you go about doing this?

The old Cox es are not really ideal for pipes though. I have some Norvel .06s that chew up head gaskets because there is a big radius where the head seats. I have to do those soon with a carbide boring tool. I think the radius is from the plating they do. It is hard to see in the threaded bore without magnification.

aspeed- Platinum Member

- Posts : 796

Join date : 2013-01-18

Location : Leamington Ont. Can.

Re: 049 Black Widow tuning

Re: 049 Black Widow tuning

As a separate thought on manufacturer's tolerances, I have seen, and own pistons where the rod breaks through the top of the piston. I am sure it is from wear, but after running motors with questionable history, this could also be a fudge factor after resetting the rod a few times. Many of these motors are getting to be 60 years old now.

aspeed- Platinum Member

- Posts : 796

Join date : 2013-01-18

Location : Leamington Ont. Can.

Re: 049 Black Widow tuning

Re: 049 Black Widow tuning

My background is electronics. I have many more years playing with electric brush (slot/rc cars) and brushless motors (quads) than fuel motors. Fun fact, my brushless quad motors (RS2206-2400kv $10) can go from idle, zero thrust @ 4% thro to 90% rpm in 0.11sec with 5050x3 prop on 4S.

When talking about timing on these cox motors, is it simply removing the prop, screwing on a simple 360 degree marked timing wheel, and slowly rotating it while watching how long the exhaust port is open?

So 180 degree exhaust timing would be when the crank pin is at 9 o-clock the exhaust port just started to open, travels to 3 0-clock (CCW direction from front of the motor) and just shuts, correct?

On another subject, I took some pics of old model motors (McCoy, testors, G-mark twin) yesterday at the Marconi car museum, is there a thread of random motors where I should post them? link

When talking about timing on these cox motors, is it simply removing the prop, screwing on a simple 360 degree marked timing wheel, and slowly rotating it while watching how long the exhaust port is open?

So 180 degree exhaust timing would be when the crank pin is at 9 o-clock the exhaust port just started to open, travels to 3 0-clock (CCW direction from front of the motor) and just shuts, correct?

On another subject, I took some pics of old model motors (McCoy, testors, G-mark twin) yesterday at the Marconi car museum, is there a thread of random motors where I should post them? link

Re: 049 Black Widow tuning

Re: 049 Black Widow tuning

aspeed wrote:

I have some Norvel .06s that chew up head gaskets because there is a big radius where the head seats. I have to do those soon with a carbide boring tool. I think the radius is from the plating they do. It is hard to see in the threaded bore without magnification.

Yes, NV missed that when they made their diesel head too. It was an easy fix in the lathe though. Rather than changing the cylinder (which is surface hardened) one can change the head. Here's how I changed the diesel head, before the mod:

And after the mod:

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Page 1 of 4 • 1, 2, 3, 4

Similar topics

Similar topics» The Revised 2011 Gibeault Mouse Race Program

» The flying season of 2012 is about to commence!

» First Black Widow

» FS: NIB Black Widow

» *Cox Engine of The Month* Submit your pictures! -November 2016-

» The flying season of 2012 is about to commence!

» First Black Widow

» FS: NIB Black Widow

» *Cox Engine of The Month* Submit your pictures! -November 2016-

Page 1 of 4

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules