Log in

Search

Latest topics

» Roger Harris revisitedby rsv1cox Today at 3:38 pm

» My N-1R build log

by GallopingGhostler Today at 3:04 pm

» Tee Dee .020 combat model

by 1/2A Nut Today at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» My latest doodle...

by batjac Yesterday at 9:47 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

Cox Engine of The Month

How to dissemble head from cylinder

Page 1 of 1

How to dissemble head from cylinder

How to dissemble head from cylinder

Anybody any idea how to dissemble head from cylinder without harming the cylinder?

I found out that head (aluminium) expansion ratio is higher than cylinder (iron) so heating doesn't work, even make it tighter.

I found out that head (aluminium) expansion ratio is higher than cylinder (iron) so heating doesn't work, even make it tighter.

aungmyatoo- Gold Member

- Posts : 328

Join date : 2012-06-07

Age : 55

Location : Singapore

Re: How to dissemble head from cylinder

Re: How to dissemble head from cylinder

aungmyatoo wrote:Anybody any idea how to dissemble head from cylinder without harming the cylinder?

I found out that head (aluminium) expansion ratio is higher than cylinder (iron) so heating doesn't work, even make it tighter.

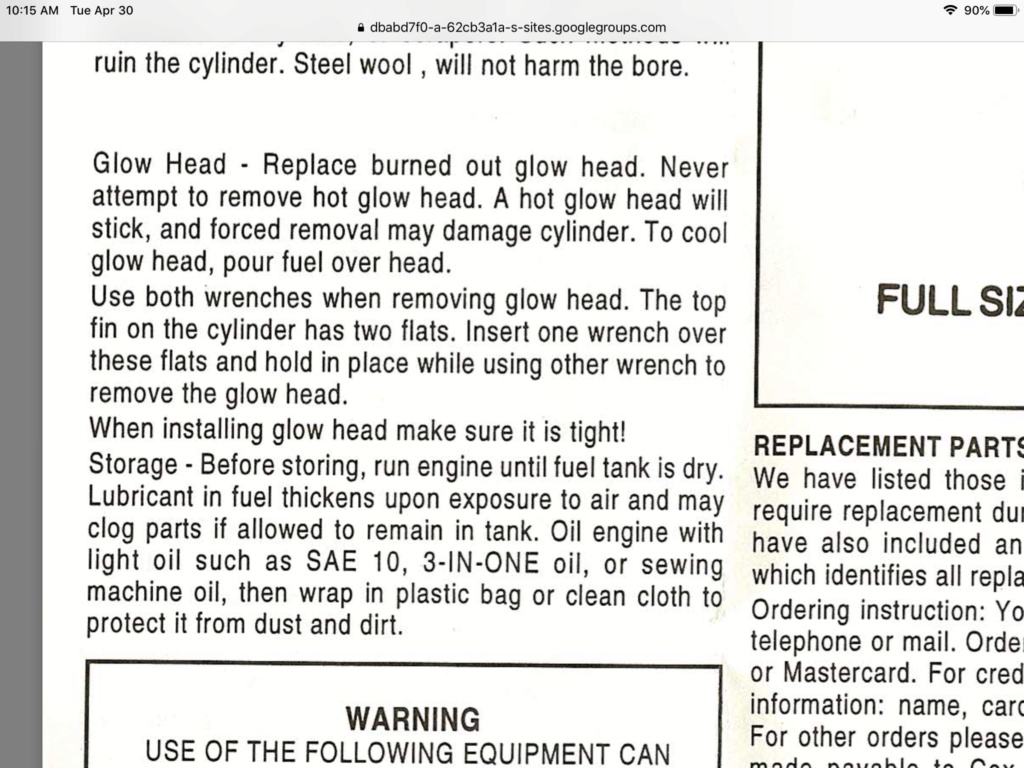

Cox Instructions covered this in some instruction manuals. do not try to remove a glow head while hot! I guess the evaporation of the fuel would help cool the head enough to remove with out damage to the threads. I had success in separating a Testors 049 by leaving it in the freezer overnight. That might help shrink the cylinder enough to let the aluminum head break free. The most success I’ve had was to use a soldering iron and heat the piston and cylinder thru the exhaust slot (heating the bottom of the cylinder) while turning the head with a cox wrench just as the castor oils starts to turn into a liquid, before the aluminum expands and gets to tight.

Marleysky- Top Poster

Posts : 3618

Join date : 2014-09-28

Age : 72

Location : Grand Rapids, MI

Ken Cook- Top Poster

- Posts : 5637

Join date : 2012-03-27

Location : pennsylvania

Re: How to dissemble head from cylinder

Re: How to dissemble head from cylinder

Heat will still help, although you need to then let it cool enough to balance the head and cylinder temperatures. The heat will expand the head, then as it cools it will contract and loosen easier. After warming you could give the head a quick blast of freeze spray. (Loctite Freeze & Release??). This will shrink it quickly, breaking the seal.

Oldenginerod- Top Poster

- Posts : 4018

Join date : 2012-06-15

Age : 62

Location : Drouin, Victoria

Re: How to dissemble head from cylinder

Re: How to dissemble head from cylinder

Hello

I would place it in the freezer until next day. I had a very stubborn Queen Bee head that didn`t want to come out, I placed the cilinder and head in a plastic bag in the freezer and next day it came out. Before that the wrench was starting to deform the slots on the head and the head was not budging. Give it a try before using more forceful methods.

Juan

I would place it in the freezer until next day. I had a very stubborn Queen Bee head that didn`t want to come out, I placed the cilinder and head in a plastic bag in the freezer and next day it came out. Before that the wrench was starting to deform the slots on the head and the head was not budging. Give it a try before using more forceful methods.

Juan

F4D Phantom II- Gold Member

- Posts : 245

Join date : 2019-04-08

Re: How to dissemble head from cylinder

Re: How to dissemble head from cylinder

Definately heed teh above advice. I recently got an engien with a stuck head and did not want to come off. I did teh unthinkable and used pliers only after the Cox wrench damaged the mount on top of the head. Just to note, this was after heating it up using a butane torch. It still did not want to budge. I was upset, so I threw it in some nitro fuel. An hour later I was just windering, so I pulled it out, and it easily came apart..... I put the head in my drill and used a small file and sandpaper to bring it back to looking good. I did know better!

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: How to dissemble head from cylinder

Re: How to dissemble head from cylinder

I heat the cylinder, avoiding heating the head, with a small torch until it's just barely too hot to hold and then hold an ice cube on the top of the head. Ten seconds later the head will loosen up easily. This works well with a stuck cylinder / crankcase too, only I heat the case and ice the cylinder.

Dave P.- Gold Member

- Posts : 477

Join date : 2017-07-31

Age : 67

Location : Durham, NC

Re: How to dissemble head from cylinder

Re: How to dissemble head from cylinder

I have done the same but with hairdryer and run cold water over the part to be removed (( makes it alot easier )) Have used thick rubber hose for cyl. removable put on heat up use channel locks on hose rag and channel locks on case , Crude but effective !!

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

Similar topics

Similar topics» COX glow head filament dropping into the cylinder

» Cylinder Performance Figures

» Need help identifying a cylinder head

» Cox .09 Cylinder Head Adapter

» F/S - Engine with New Tee Dee Cylinder and Head

» Cylinder Performance Figures

» Need help identifying a cylinder head

» Cox .09 Cylinder Head Adapter

» F/S - Engine with New Tee Dee Cylinder and Head

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules