Log in

Search

Latest topics

» Cox films/videos...by Coxfledgling Today at 4:46 am

» Purchased the last of any bult engines from Ken Enya

by Coxfledgling Today at 4:18 am

» My N-1R build log

by roddie Today at 12:32 am

» Happy 77th birthday Andrew!

by akjgardner Today at 12:27 am

» TEE DEE Having issues

by TD ABUSER Yesterday at 9:43 pm

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» Roger Harris revisited

by TD ABUSER Yesterday at 2:13 pm

» Tee Dee .020 combat model

by Ken Cook Yesterday at 1:41 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Yesterday at 1:37 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 9:24 am

Cox Engine of The Month

TeeDeeVooDoo- my current project

Page 3 of 4

Page 3 of 4 •  1, 2, 3, 4

1, 2, 3, 4

Re: TeeDeeVooDoo- my current project

Re: TeeDeeVooDoo- my current project

Thanks Mauricio . I really like it and find one of my fastest planes. It flies very straight thanks to the very accurate build of the fiber reinforced fuselage and wings. I had initially problems with the Tarno carburetor but after I have eliminated the air leakages around the needle valve it now works fine. I will try this plane with the COX Black Lynx I won here on CEF. I assume that the unmuffled Lynx will pull it quicker than the muffled TD049.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: TeeDeeVooDoo- my current project

Re: TeeDeeVooDoo- my current project

balogh wrote:Thanks Mauricio . I really like it and find one of my fastest planes. It flies very straight thanks to the very accurate build of the fiber reinforced fuselage and wings. I had initially problems with the Tarno carburetor but after I have eliminated the air leakages around the needle valve it now works fine. I will try this plane with the COX Black Lynx I won here on CEF. I assume that the unmuffled Lynx will pull it quicker than the muffled TD049.

It will be a nice experience to try the Black Lynx I, but before removing the Tee Dee what I would do is remove the exhaust chamber, place an accelerator ring, logically eliminate the carburetor and place the original venturi, an APC 5.7 and a glow High compression plug and your plane will be lightning!

I mention this to you, from my own experience, here a picture, that engine flies!

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-16

Age : 53

Location : ARG

Re: TeeDeeVooDoo- my current project

Re: TeeDeeVooDoo- my current project

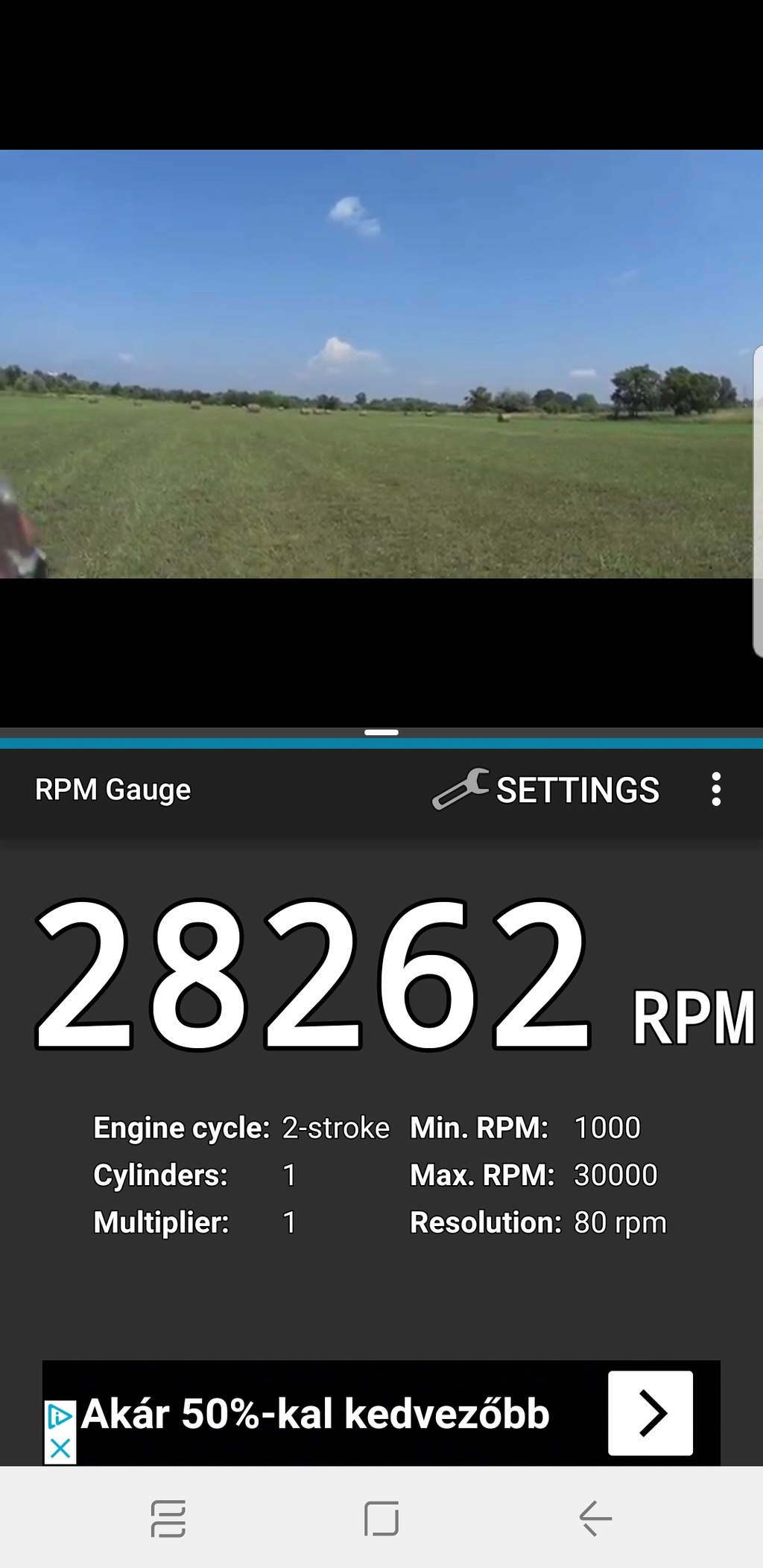

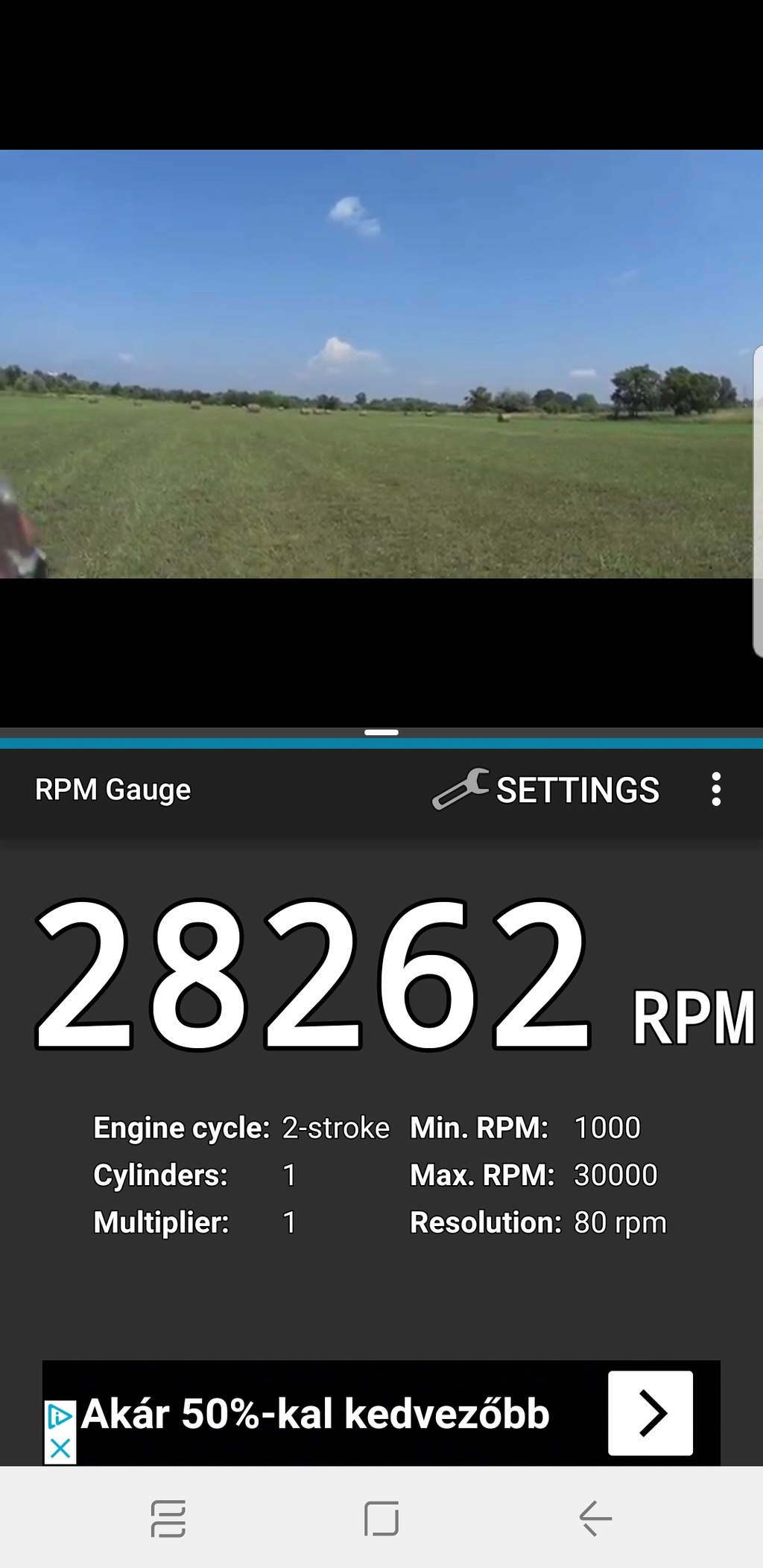

I agree Mauricio and will do. The TD with muffler unloads in air at near 20k. Without muffler it will rev the 5x4 prop unloaded up to 24k. At least this is what I measure on my Toucan RC plane.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: TeeDeeVooDoo- my current project

Re: TeeDeeVooDoo- my current project

balogh wrote:I agree Mauricio and will do. The TD with muffler unloads in air at near 20k. Without muffler it will rev the 5x4 prop unloaded up to 24k. At least this is what I measure on my Toucan RC plane.

You will have one more experience before completely removing the engine, I believe that your Tee Dee will seduce you in many high speed flights, that model of airplane is esquicito in aerodynamic lines added to the Tee Dee with those changes and you will have to put on your seatbelt haha !

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-16

Age : 53

Location : ARG

Re: TeeDeeVooDoo- my current project

Re: TeeDeeVooDoo- my current project

Congratulations on your speedy Voo Doo!!!!

Front induction Cox engines always make more power then the reedie

It makes good power with the Nelson glow plug considering the

exhaust is choked down by that muffler type. I would not run the reedie.

Just try it without the exhaust restriction, see if you can live with the goo.

Do not try a 5.7x3 waste of time no speed there.

Best brief peak pass noted 87 mph

This is the best prop for that engine on that plane without any mods:

https://www.getfpv.com/hqprop-5x4-5-ccw-propeller-2-blade-2-pack-black-carbon-composite.html?utm_source=google&utm_medium=cpc&adpos=2o2&scid=scplp4109&sc_intid=4109&gclid=EAIaIQobChMInorD07eG2gIV07jACh0edQ4hEAYYAiABEgIES_D_BwE

HQ Prop Carbon 5x4.5 must be the carbon speed tip prop will hit 160 kph easy enough down wind passes.

Front induction Cox engines always make more power then the reedie

It makes good power with the Nelson glow plug considering the

exhaust is choked down by that muffler type. I would not run the reedie.

Just try it without the exhaust restriction, see if you can live with the goo.

Do not try a 5.7x3 waste of time no speed there.

Best brief peak pass noted 87 mph

This is the best prop for that engine on that plane without any mods:

https://www.getfpv.com/hqprop-5x4-5-ccw-propeller-2-blade-2-pack-black-carbon-composite.html?utm_source=google&utm_medium=cpc&adpos=2o2&scid=scplp4109&sc_intid=4109&gclid=EAIaIQobChMInorD07eG2gIV07jACh0edQ4hEAYYAiABEgIES_D_BwE

HQ Prop Carbon 5x4.5 must be the carbon speed tip prop will hit 160 kph easy enough down wind passes.

1/2A Nut- Top Poster

- Posts : 3538

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: TeeDeeVooDoo- my current project

Re: TeeDeeVooDoo- my current project

Good friends, I have no experience with the propeller Brad indicates, but if Brad indicates that 5 x 4.5 should not hesitate. Here there is not much to choose from, that APC 5.7, has given me many satisfactions and joys, it was just my shared experience.

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-16

Age : 53

Location : ARG

Re: TeeDeeVooDoo- my current project

Re: TeeDeeVooDoo- my current project

The APC 5.7x3 is a great prop for sport flying

1/2A Nut- Top Poster

- Posts : 3538

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: TeeDeeVooDoo- my current project

Re: TeeDeeVooDoo- my current project

Thanks for the comments Brad and also for the greenie Mauricio. I did not expect it to hit such a speed that Brad indicated and the best flight was not even the one I posted but the last one that was cut short by the micro SD card in the camera getting full mid-air  . Even though I added a silicon tube to seal the NV and prevent "auto-adjustments" due to possible vibrations it is still rather chancy if I can find the sweet spot setting on the ground that will secure an even performance in the air through the last drop of fuel. (The tube not only acts like a lip sitting on the threads of the NV stem and spraybar but also knocks tight against the face of the NV dial knob.)

. Even though I added a silicon tube to seal the NV and prevent "auto-adjustments" due to possible vibrations it is still rather chancy if I can find the sweet spot setting on the ground that will secure an even performance in the air through the last drop of fuel. (The tube not only acts like a lip sitting on the threads of the NV stem and spraybar but also knocks tight against the face of the NV dial knob.)

The TeeDee is surely the strongest COX049 in my fleet but I found the Black Lynx I won also a very powerful engine so out of curiosity I will also give it a try....possibly next weekend because I seem to have caught influenza and the flights in 3-4C weather yesterday just made it worse.

. Even though I added a silicon tube to seal the NV and prevent "auto-adjustments" due to possible vibrations it is still rather chancy if I can find the sweet spot setting on the ground that will secure an even performance in the air through the last drop of fuel. (The tube not only acts like a lip sitting on the threads of the NV stem and spraybar but also knocks tight against the face of the NV dial knob.)

. Even though I added a silicon tube to seal the NV and prevent "auto-adjustments" due to possible vibrations it is still rather chancy if I can find the sweet spot setting on the ground that will secure an even performance in the air through the last drop of fuel. (The tube not only acts like a lip sitting on the threads of the NV stem and spraybar but also knocks tight against the face of the NV dial knob.)

The TeeDee is surely the strongest COX049 in my fleet but I found the Black Lynx I won also a very powerful engine so out of curiosity I will also give it a try....possibly next weekend because I seem to have caught influenza and the flights in 3-4C weather yesterday just made it worse.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: TeeDeeVooDoo- my current project

Re: TeeDeeVooDoo- my current project

Your most welcome the plane is clean so it can build up speed well.

That is a locking NV (drag nut) it can produce drag on the NV threads to help keep it's setting.

I oil the needle valve to help seal from leaks.

The problem is:

Your balloon tank when full it puts pressure on the feed line as the engine runs down

the fuel pressure is less. This requires you to set a bit rich to launch so it does not

run too lean / ( erratic fuel feed) later in the flight this is not a issue with hard tanks.

Hard tanks give you a steady run throughout the flight.

For me I do not like balloon tanks because of that issue. I do not like bladders

even though they can make the engine scream that last portion of the run the

fuel feed is weak and the engine stutters around for a min.+ or so.

If using a muffler a pressure tap is always worth setting up.

Will a 1oz (30cc) round tank fit? How about 3/4th oz (20cc) round tank?

Per this pic it looks like you put a black plastic plug in the refueling line:

That is a locking NV (drag nut) it can produce drag on the NV threads to help keep it's setting.

I oil the needle valve to help seal from leaks.

The problem is:

Your balloon tank when full it puts pressure on the feed line as the engine runs down

the fuel pressure is less. This requires you to set a bit rich to launch so it does not

run too lean / ( erratic fuel feed) later in the flight this is not a issue with hard tanks.

Hard tanks give you a steady run throughout the flight.

For me I do not like balloon tanks because of that issue. I do not like bladders

even though they can make the engine scream that last portion of the run the

fuel feed is weak and the engine stutters around for a min.+ or so.

If using a muffler a pressure tap is always worth setting up.

Will a 1oz (30cc) round tank fit? How about 3/4th oz (20cc) round tank?

Per this pic it looks like you put a black plastic plug in the refueling line:

1/2A Nut- Top Poster

- Posts : 3538

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: TeeDeeVooDoo- my current project

Re: TeeDeeVooDoo- my current project

Yes Brad your observations are correct. I even use a small O ring in that locking nut and oil it when assemble to limit wear and improve sealing.. I try not to overfill the balloon so that when full it still does not force flow of fuel into the carb so in principle it is just engine suction that drives the fuel until the tank is empty.

With a hard cylindric tank I would need a heavy clunk for aerobatics and a vent line. With yhe balloon these complications are saved.. I agree though chances for an even run are higher with a pressurized hard tank. Yes the plug is a black plastic one.

I agree though chances for an even run are higher with a pressurized hard tank. Yes the plug is a black plastic one.

With a hard cylindric tank I would need a heavy clunk for aerobatics and a vent line. With yhe balloon these complications are saved..

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: TeeDeeVooDoo- my current project

Re: TeeDeeVooDoo- my current project

I am happy you have it working your project was a conciderable

investment in regards to the composite plane.

Do you think as the fuel leaves the air tight thick walled rubber

balloon the engine's carb has to work harder to collapse the balloon

in order to draw the last of the fuel?

investment in regards to the composite plane.

Do you think as the fuel leaves the air tight thick walled rubber

balloon the engine's carb has to work harder to collapse the balloon

in order to draw the last of the fuel?

1/2A Nut- Top Poster

- Posts : 3538

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: TeeDeeVooDoo- my current project

Re: TeeDeeVooDoo- my current project

Sure Brad it was not cheap but is worth it plus I do not have the skills and tools for planes built from skratch.

Until the last say 5 seconds when the balloon collapses the fuel feed is even. Then unfortunately a 5 sec lean run ends the flight... (it is not long to cause damage). When I open my planes with balloon tanks right after the flight the tanks are always found collapsed and sucked to almost dry..I use perforations along the syphon inside the tank to make sure fuel should find its way out even if the syphon end slightly sucks in the balloon bottom. And the balloon material is thin...this is a toy party balloon only.

Until the last say 5 seconds when the balloon collapses the fuel feed is even. Then unfortunately a 5 sec lean run ends the flight... (it is not long to cause damage). When I open my planes with balloon tanks right after the flight the tanks are always found collapsed and sucked to almost dry..I use perforations along the syphon inside the tank to make sure fuel should find its way out even if the syphon end slightly sucks in the balloon bottom. And the balloon material is thin...this is a toy party balloon only.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: TeeDeeVooDoo- my current project

Re: TeeDeeVooDoo- my current project

MauricioB wrote:balogh wrote:Thanks Mauricio . I really like it and find one of my fastest planes. It flies very straight thanks to the very accurate build of the fiber reinforced fuselage and wings. I had initially problems with the Tarno carburetor but after I have eliminated the air leakages around the needle valve it now works fine. I will try this plane with the COX Black Lynx I won here on CEF. I assume that the unmuffled Lynx will pull it quicker than the muffled TD049.

It will be a nice experience to try the Black Lynx I, but before removing the Tee Dee what I would do is remove the exhaust chamber, place an accelerator ring, logically eliminate the carburetor and place the original venturi, an APC 5.7 and a glow High compression plug and your plane will be lightning!

I mention this to you, from my own experience, here a picture, that engine flies!

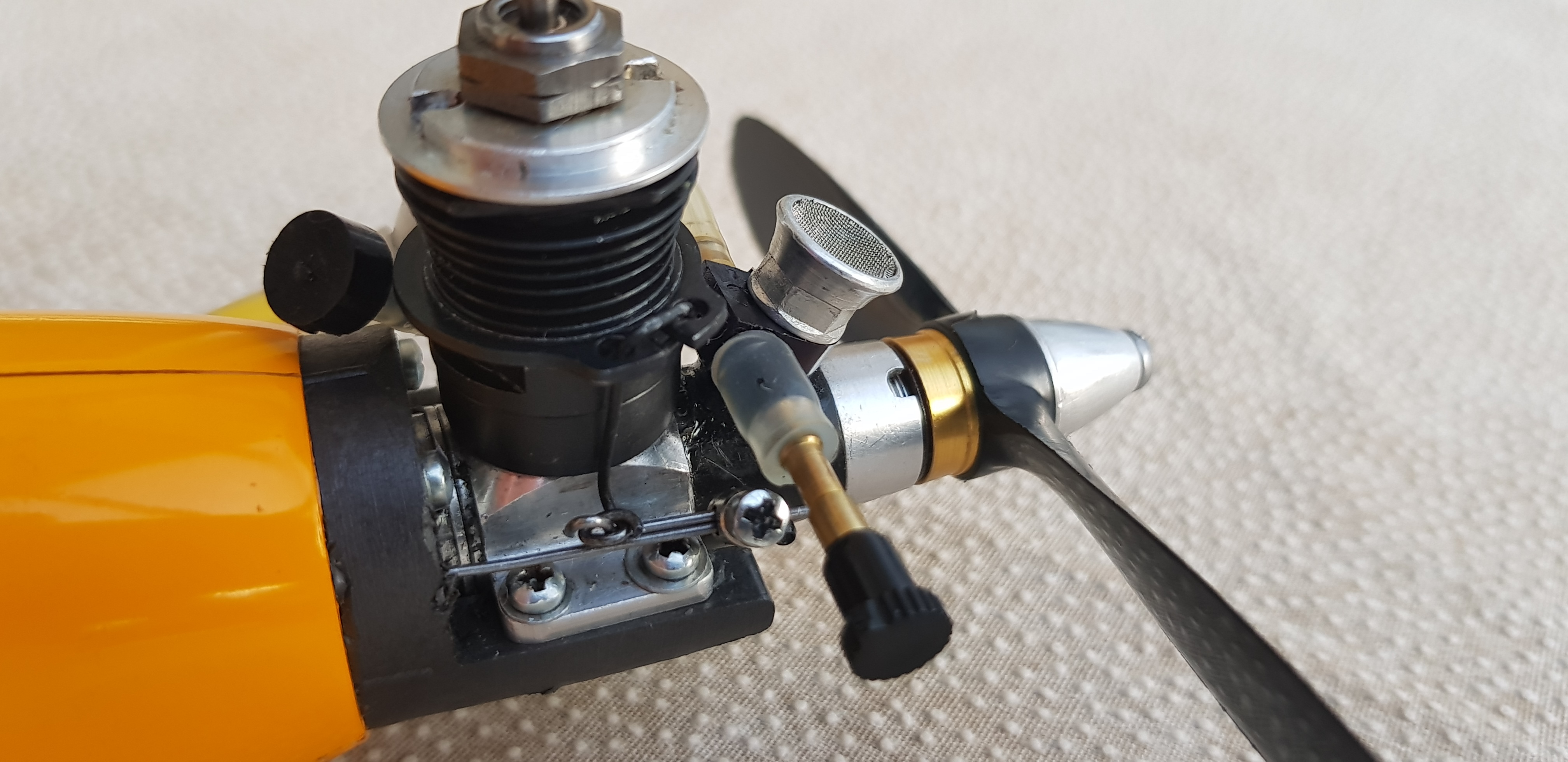

Mauricio with the exhaust muffler and RC carb the performance of the TeeDee being slightly curtailed, I decided to go to a more powerful setup as you also outlined. I will check it out tomorrow in the field weather permitting.

Exhaust throttle activated with unchanged servo linkage from the RC carb setup just an additional hook added to link the pushrod with the exhaust throttle. Fine thread TD needle valve unit ( Kirn Kraft or Kustom Kraftmanship...who knows which one mine is?) added. Nelson turbo plug unit.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: TeeDeeVooDoo- my current project

Re: TeeDeeVooDoo- my current project

Make sure you have a wrench at the field in case the Nelson plug gets loose.

It has happened to me, I had to make do with the wrong type of tool.

Have you bench tested it yet, curious how much static rpm it makes with the

Cox 5x4. Best wishes on the flight test looking forward to the vid!!

It has happened to me, I had to make do with the wrong type of tool.

Have you bench tested it yet, curious how much static rpm it makes with the

Cox 5x4. Best wishes on the flight test looking forward to the vid!!

1/2A Nut- Top Poster

- Posts : 3538

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: TeeDeeVooDoo- my current project

Re: TeeDeeVooDoo- my current project

Thanks Brad. My TD049 and 051 engines typically spin the COX 5x4 prop at around 21k on the bench. The Nelson turbo plug may add a few hundreds more.

When muffled and equipped with the Tarno carb the static was around 18-19k.

I will tach the setup in the field tomorrow.

When muffled and equipped with the Tarno carb the static was around 18-19k.

I will tach the setup in the field tomorrow.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: TeeDeeVooDoo- my current project

Re: TeeDeeVooDoo- my current project

Thank you for the data

Yes looking forward to your flights with the Voo Doo the first vid was a big treat to

see flying with the TD engine!

With stock muffler and pressure tap / Nelson plug.

Cut down props in dia. and with back cut:

- APC 4.22x5.5E static prior to launch 20,428 rpm /80w / pitch speed 106.4 mph

- APC 4.44x5E static prior to launch 20,046 rpm / 95 mph pitch speed.

Stock:

- HQ carbon 4x4.5 static 27,051 / .164hp / 122w / 8.5oz thrust / pitch speed 115 mph

The 3rd prop is too small (thin narrow blades and speed tipped) for a engine with no bearings so was never test flown.

Has been flown with a car engine / tuned pipe with bearings:

Static at launch 27,816 rpm / 119 mph prop speed

Unloaded 37,710 rpm / 161 mph prop speed!

Yes looking forward to your flights with the Voo Doo the first vid was a big treat to

see flying with the TD engine!

With stock muffler and pressure tap / Nelson plug.

Cut down props in dia. and with back cut:

- APC 4.22x5.5E static prior to launch 20,428 rpm /80w / pitch speed 106.4 mph

- APC 4.44x5E static prior to launch 20,046 rpm / 95 mph pitch speed.

Stock:

- HQ carbon 4x4.5 static 27,051 / .164hp / 122w / 8.5oz thrust / pitch speed 115 mph

The 3rd prop is too small (thin narrow blades and speed tipped) for a engine with no bearings so was never test flown.

Has been flown with a car engine / tuned pipe with bearings:

Static at launch 27,816 rpm / 119 mph prop speed

Unloaded 37,710 rpm / 161 mph prop speed!

1/2A Nut- Top Poster

- Posts : 3538

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: TeeDeeVooDoo- my current project

Re: TeeDeeVooDoo- my current project

Did you get some vid of the run?

1/2A Nut- Top Poster

- Posts : 3538

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: TeeDeeVooDoo- my current project

Re: TeeDeeVooDoo- my current project

I did but the quality is poor becaue of a smeared lens that I only recognized when returning home.. I will redo it today and post it. The bird was a ball to fly with the unrestricted TD.that unloaded at 24k+

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: TeeDeeVooDoo- my current project

Re: TeeDeeVooDoo- my current project

That is good news at 24k the prop pitch speed is 91 mph / 147 kph

Look forward to the vid

Look forward to the vid

1/2A Nut- Top Poster

- Posts : 3538

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: TeeDeeVooDoo- my current project

Re: TeeDeeVooDoo- my current project

Here it comes:

The Tee Dee 049 is an ideal powerhouse for this beautiful lil plane, it is a ball to fly. The propeller is a COX 5x4, the fuel is my home blended 20/20/60 mixture of castor, nitro and methanol. The engine revs around 21100 rpm static, but unloads around 27-28k (tried to pick the video section with the incoming plane just passing me in order to minimize Doppler effects...Brad you are more than welcome to correct my measurement with your more sophisticated stuff )

)

I also tested the idle with the exhaust throttle, it is low and stable, thanks also to the hot Nelson turbo plug.

Unfortunately the Sony head cam I used has a moderate resolution plus it was angled a bit low so most of whatever is visible appears mostly on the top of the screen.

I landed just in the right moment because the aileron servos failed mid-air!!! (This is the reason I idled the engine too early before landing) Electrical problems are just too common with Chinese made Graupner servo equipment, yesterday my elevator servo had to be replaced, and the landing was not so smooth!!!...it is definitely not the vibration (which is almost nil) but poor servo quality...will check if a more reliable HiTec product of similar size is available and ditch the Chinese scrap.

The Tee Dee 049 is an ideal powerhouse for this beautiful lil plane, it is a ball to fly. The propeller is a COX 5x4, the fuel is my home blended 20/20/60 mixture of castor, nitro and methanol. The engine revs around 21100 rpm static, but unloads around 27-28k (tried to pick the video section with the incoming plane just passing me in order to minimize Doppler effects...Brad you are more than welcome to correct my measurement with your more sophisticated stuff

I also tested the idle with the exhaust throttle, it is low and stable, thanks also to the hot Nelson turbo plug.

Unfortunately the Sony head cam I used has a moderate resolution plus it was angled a bit low so most of whatever is visible appears mostly on the top of the screen.

I landed just in the right moment because the aileron servos failed mid-air!!! (This is the reason I idled the engine too early before landing) Electrical problems are just too common with Chinese made Graupner servo equipment, yesterday my elevator servo had to be replaced, and the landing was not so smooth!!!...it is definitely not the vibration (which is almost nil) but poor servo quality...will check if a more reliable HiTec product of similar size is available and ditch the Chinese scrap.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: TeeDeeVooDoo- my current project

Re: TeeDeeVooDoo- my current project

Yay András the plane flew great!

Yes saw you messing with aileron servo was shocked it failed, nylon gears?

It is going faster and there are some loads on the servo no doubt. A good

metal gear servo should fix that from happening again. The plane is reasonble

size for the TD .049.

Also need to try to do level passes left to right or right to left in front of the cam.

You kept pulling up and away before it pass by you.

That is the only way to do a Doppler test. It does not need to be as low and close

as I do but does needs to be a bit lower, key is pure incoming pass and out going

to get a solid Doppler shift. Plane needs to be level incoming sound and outgoing sound shift

as it comes at you and passes by. That sound shift I can measure and give you good mph/ kph

speed readings.

The plane is flying great the engine has enough power to enjoy some good flying!!

I did get a noted peak read of 28,167 rpm / 107 mph prop pitch speed / 172 kph.

Most of the rpm was hitting 27k when you flew to generate speed.

Static 21,150 / 12.4oz thrust / .170hp / 126.8w / 80 mph pitch speed.

Good power with the Nelson plug!!!

Notice in my vid I come at the camera and pass the camera this gives solid readings you don't

have to be as close as I do it. Just up higher in front of the camera about 25ft will be fine.

Good level passes that stay level after you pass the camera for a solid Doppler shift and

a honest speed pass of the planes level flying peak. Steady rpm performance the apex

caught in the sweet zone for all to see and hear.

Yes saw you messing with aileron servo was shocked it failed, nylon gears?

It is going faster and there are some loads on the servo no doubt. A good

metal gear servo should fix that from happening again. The plane is reasonble

size for the TD .049.

Also need to try to do level passes left to right or right to left in front of the cam.

You kept pulling up and away before it pass by you.

That is the only way to do a Doppler test. It does not need to be as low and close

as I do but does needs to be a bit lower, key is pure incoming pass and out going

to get a solid Doppler shift. Plane needs to be level incoming sound and outgoing sound shift

as it comes at you and passes by. That sound shift I can measure and give you good mph/ kph

speed readings.

The plane is flying great the engine has enough power to enjoy some good flying!!

I did get a noted peak read of 28,167 rpm / 107 mph prop pitch speed / 172 kph.

Most of the rpm was hitting 27k when you flew to generate speed.

Static 21,150 / 12.4oz thrust / .170hp / 126.8w / 80 mph pitch speed.

Good power with the Nelson plug!!!

Notice in my vid I come at the camera and pass the camera this gives solid readings you don't

have to be as close as I do it. Just up higher in front of the camera about 25ft will be fine.

Good level passes that stay level after you pass the camera for a solid Doppler shift and

a honest speed pass of the planes level flying peak. Steady rpm performance the apex

caught in the sweet zone for all to see and hear.

Last edited by 1/2A Nut on Mon Jun 11, 2018 10:48 am; edited 4 times in total

1/2A Nut- Top Poster

- Posts : 3538

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: TeeDeeVooDoo- my current project

Re: TeeDeeVooDoo- my current project

What are the specs on the aileron servo you used?

One HS-81S Micro Servo with 6-3/4" connector wire.

One 7/8"x7/8" X-shaped servo horn

One 1-1/8" long straight servo horn

Two brass eyelets

Two mounting screws

Two servo grommets

One servo horn screw

SPECS:

Transit Speed: 0.11 sec/60deg at 4.8V

0.09 sec/60 deg at 6.0V

Output Torque: 36.10 oz/in at 4.8V (2.6kg/cm)

41.66 oz/in at 6.0V (3kg/cm)

Length: 1.17" (29.8mm)

Width: 0.47" (12mm)

Height: 1.16" (29.6mm)

Weight: 16.6g (0.58oz)

Mounting holes on-center: 1.31"(33.27mm)

If that is too big to fit then this will bust 30oz at 6v:

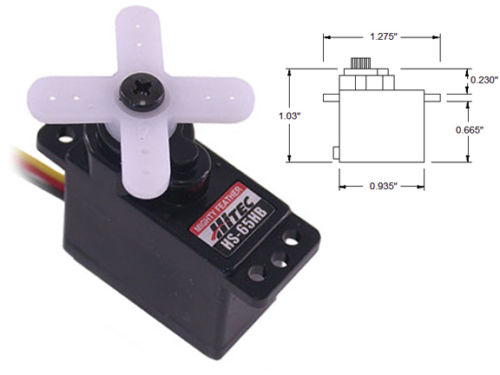

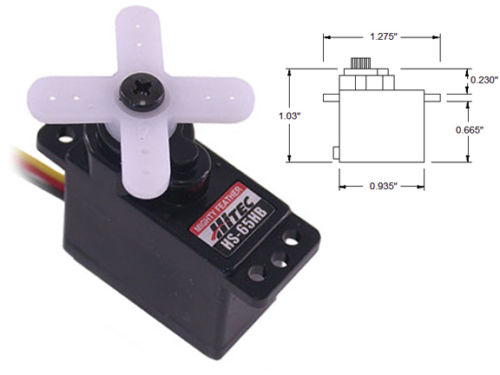

FEATURES: HS-65HB has long lasting and durable Karbonite gears

One of the slimmest micro servos available

Hitec's most powerful servo in the micro class

The HS-65HB was created for higher performance micro helicopters,

electric Park Flyers, & 1/18 scale cars, and features a top ball-

bearing for long life and positive centering

INCLUDES: (1) HS-65HB Micro Servo

(4) M1.7x7 servo mounting screws

(1) Two-sided servo horn

(1) One-sided servo horn

(1) M1.7x3 servo horn screw

(1) Four-sided servo horn

SPECS: Length: 0.92" (23.6mm)

Width: 0.45" (11.6mm)

Height: 0.94" (24mm)

Weigth: 0.38oz (11.2g)

Speed: 0.14/60° @ 4.8V

Output Torque: 24.99 oz-in @ 4.8V

One HS-81S Micro Servo with 6-3/4" connector wire.

One 7/8"x7/8" X-shaped servo horn

One 1-1/8" long straight servo horn

Two brass eyelets

Two mounting screws

Two servo grommets

One servo horn screw

SPECS:

Transit Speed: 0.11 sec/60deg at 4.8V

0.09 sec/60 deg at 6.0V

Output Torque: 36.10 oz/in at 4.8V (2.6kg/cm)

41.66 oz/in at 6.0V (3kg/cm)

Length: 1.17" (29.8mm)

Width: 0.47" (12mm)

Height: 1.16" (29.6mm)

Weight: 16.6g (0.58oz)

Mounting holes on-center: 1.31"(33.27mm)

If that is too big to fit then this will bust 30oz at 6v:

FEATURES: HS-65HB has long lasting and durable Karbonite gears

One of the slimmest micro servos available

Hitec's most powerful servo in the micro class

The HS-65HB was created for higher performance micro helicopters,

electric Park Flyers, & 1/18 scale cars, and features a top ball-

bearing for long life and positive centering

INCLUDES: (1) HS-65HB Micro Servo

(4) M1.7x7 servo mounting screws

(1) Two-sided servo horn

(1) One-sided servo horn

(1) M1.7x3 servo horn screw

(1) Four-sided servo horn

SPECS: Length: 0.92" (23.6mm)

Width: 0.45" (11.6mm)

Height: 0.94" (24mm)

Weigth: 0.38oz (11.2g)

Speed: 0.14/60° @ 4.8V

Output Torque: 24.99 oz-in @ 4.8V

1/2A Nut- Top Poster

- Posts : 3538

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: TeeDeeVooDoo- my current project

Re: TeeDeeVooDoo- my current project

Thank you Brad!

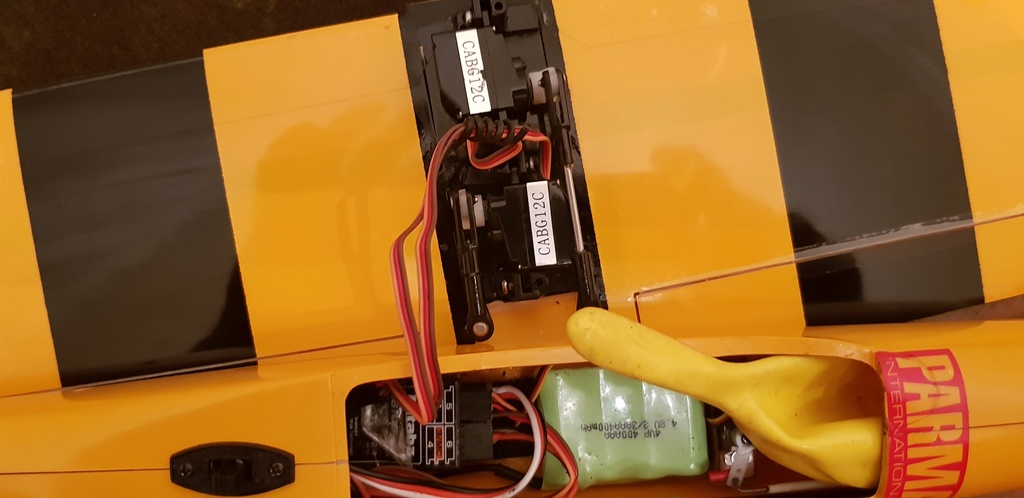

the servo is as follows, this is the genuine specification of the plane's manufacturer. I do not see if any larger servos would fit as they are mounted on the underwing and the fuselage is rather narrow. These servos should mechanically fit in principle even when the plane is powered with a 250W electric motor that will drive it much faster and thus the forces acting on the servos are way higher than with the COX Tee Dee 049 conversion.

https://www.hoelleinshop.com/SONDERAKTIONEN/Sonderangebote-GRAUPNER-RC/Graupner-DES-Servos/Servo-DES-261-BB-Graupner-SJ-7903-LOSE.htm?shop=hoellein&SessionId=&a=article&ProdNr=G7903.LOSE&t=22274&c=68112&p=68112&rdeocl=1&rdetpl=searchpage&rdebox=box2

I have checked 2 of the 3 servos that failed and they all have wiring contact problems inside the servo, probably the wire end soldering is broken. (I made sure when assembling the plane the wires are not spanned or loaded to save the soldering connection, but these are probably inherently poor as made in the factory.)

Yes, I will probably invest in a better camera...in fact the plane flew only maybe 5-8 yards from me when nearest, yet it is hardly visible....added is the wrong vertical angle at which I set the camera on my forehead, that aims the cam too low and the plane leaves the visibility range even if it is not far.

Anyway, the experiment was still worth it as I have never experienced such unloaded max rpm at 28k or so from 049-051 engines (except my TD 010-s), let alone the high flight speed at wich the plane still maneuvers very neatly and easily, with excellent responses from the aileron and elevator....as long as the servos work...

The area I am flying on is not too long so a level flight will take the plane to the boundaries (a road with car traffic, and some groves around) in no time, and I also like the loops and spins and much of the flight time was spent with these crazy aerobatics, also trying to keep the plane in a visible range for the camera...too bad not too much is visible out of that.

The goo control is not much worse than with the exhaust muffler and manifold...maybe a bit more castor is thrown on the fuselage, but at the end it does not really matter if you have to clean the plane after each flight anyway...but the power difference with and without the exhaust muffler is just astounding..

Anyway, like always, thanks for the valuable tips!!!

the servo is as follows, this is the genuine specification of the plane's manufacturer. I do not see if any larger servos would fit as they are mounted on the underwing and the fuselage is rather narrow. These servos should mechanically fit in principle even when the plane is powered with a 250W electric motor that will drive it much faster and thus the forces acting on the servos are way higher than with the COX Tee Dee 049 conversion.

https://www.hoelleinshop.com/SONDERAKTIONEN/Sonderangebote-GRAUPNER-RC/Graupner-DES-Servos/Servo-DES-261-BB-Graupner-SJ-7903-LOSE.htm?shop=hoellein&SessionId=&a=article&ProdNr=G7903.LOSE&t=22274&c=68112&p=68112&rdeocl=1&rdetpl=searchpage&rdebox=box2

I have checked 2 of the 3 servos that failed and they all have wiring contact problems inside the servo, probably the wire end soldering is broken. (I made sure when assembling the plane the wires are not spanned or loaded to save the soldering connection, but these are probably inherently poor as made in the factory.)

Yes, I will probably invest in a better camera...in fact the plane flew only maybe 5-8 yards from me when nearest, yet it is hardly visible....added is the wrong vertical angle at which I set the camera on my forehead, that aims the cam too low and the plane leaves the visibility range even if it is not far.

Anyway, the experiment was still worth it as I have never experienced such unloaded max rpm at 28k or so from 049-051 engines (except my TD 010-s), let alone the high flight speed at wich the plane still maneuvers very neatly and easily, with excellent responses from the aileron and elevator....as long as the servos work...

The area I am flying on is not too long so a level flight will take the plane to the boundaries (a road with car traffic, and some groves around) in no time, and I also like the loops and spins and much of the flight time was spent with these crazy aerobatics, also trying to keep the plane in a visible range for the camera...too bad not too much is visible out of that.

The goo control is not much worse than with the exhaust muffler and manifold...maybe a bit more castor is thrown on the fuselage, but at the end it does not really matter if you have to clean the plane after each flight anyway...but the power difference with and without the exhaust muffler is just astounding..

Anyway, like always, thanks for the valuable tips!!!

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

1/2A Nut- Top Poster

- Posts : 3538

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: TeeDeeVooDoo- my current project

Re: TeeDeeVooDoo- my current project

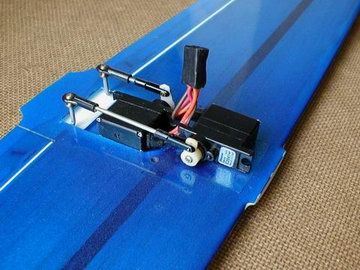

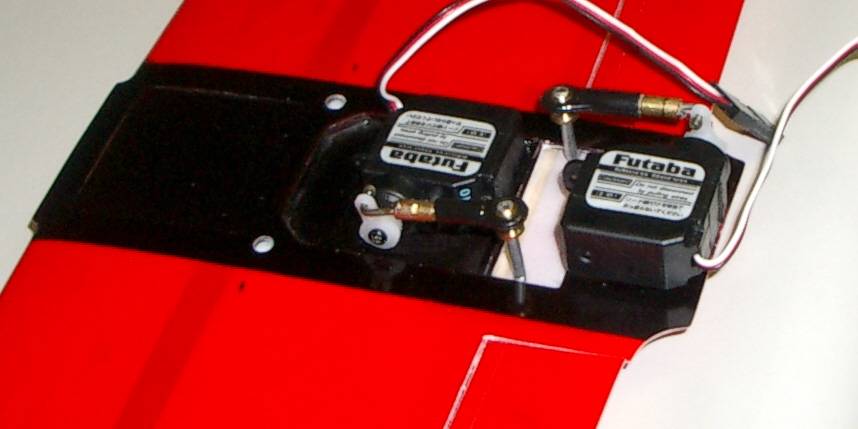

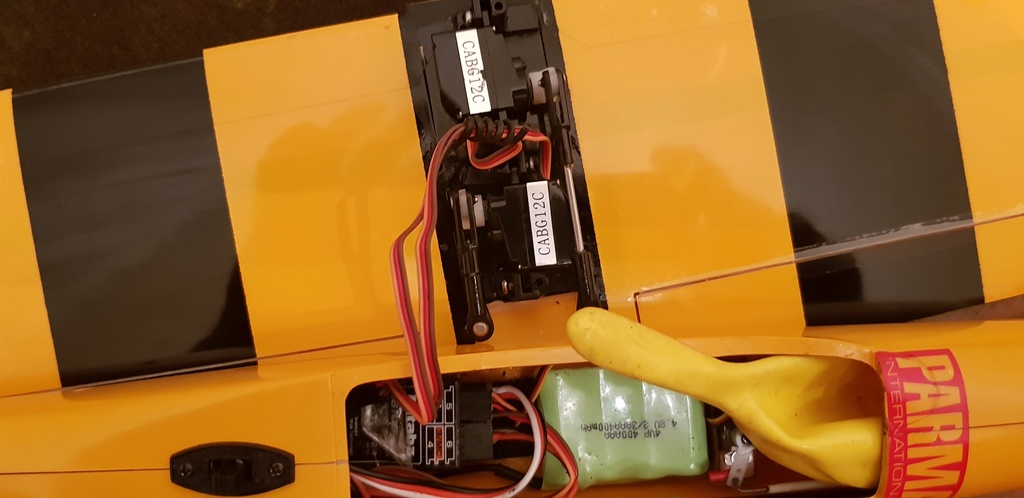

Yes this servo layout is exactly what I have in the VooDoo.. The HiTec HS45 is already too wide but the HS40 is too small .The servos are to be glued to the skin of the wing. I glued 2 fixed servo trays to the underwing and thus made the servos replacable without any destruction needed for the removal :

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Page 3 of 4 •  1, 2, 3, 4

1, 2, 3, 4

Similar topics

Similar topics» what airplanes have you built? post your pics of the models and feel free to talk about your airplanes

» Is this car a good buy? (I won it!!)

» A Traveling Engine plane.

» Watch for my current "build"!

» my old handles and link for current

» Is this car a good buy? (I won it!!)

» A Traveling Engine plane.

» Watch for my current "build"!

» my old handles and link for current

Page 3 of 4

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules