Log in

Search

Latest topics

» Tee Dee .020 combat modelby 1/2A Nut Today at 10:34 am

» Happy 77th birthday Andrew!

by rdw777 Today at 10:04 am

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 8:15 am

» TEE DEE Having issues

by balogh Today at 7:42 am

» Retail price mark-up.. how much is enough?

by rsv1cox Today at 7:36 am

» Cox films/videos...

by Coxfledgling Today at 4:46 am

» My N-1R build log

by roddie Today at 12:32 am

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» Roger Harris revisited

by TD ABUSER Yesterday at 2:13 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 9:24 am

Cox Engine of The Month

P-38 Lightning-Roddie style..

Page 8 of 9

Page 8 of 9 •  1, 2, 3, 4, 5, 6, 7, 8, 9

1, 2, 3, 4, 5, 6, 7, 8, 9

lead-outs.. and guides..

lead-outs.. and guides..

Hey CEF'ers.. I haven't posted much with this build in the last several weeks.. but you know;.... that doesn't mean that I haven't been thinking about the airplane.. and how to apply the finishing-touches to the controls.. with hopes to get the balance close.

To re-cap; this model is my own design, therefore.. the "moment-arms" aren't proven. So far; the U-Control/profile-structure seems to be good.. for a 1/2A model.

I want to fly this airplane.. but I need to be patient.. and get some "air-time" with other models that I have flown before. It's been too long since I've flown; to risk a maiden with an un-proven design.

My "wingtips" continue to be a problem with breaking-off.. I'll definitely need to redesign that part of the wing.

I'll definitely need to redesign that part of the wing.

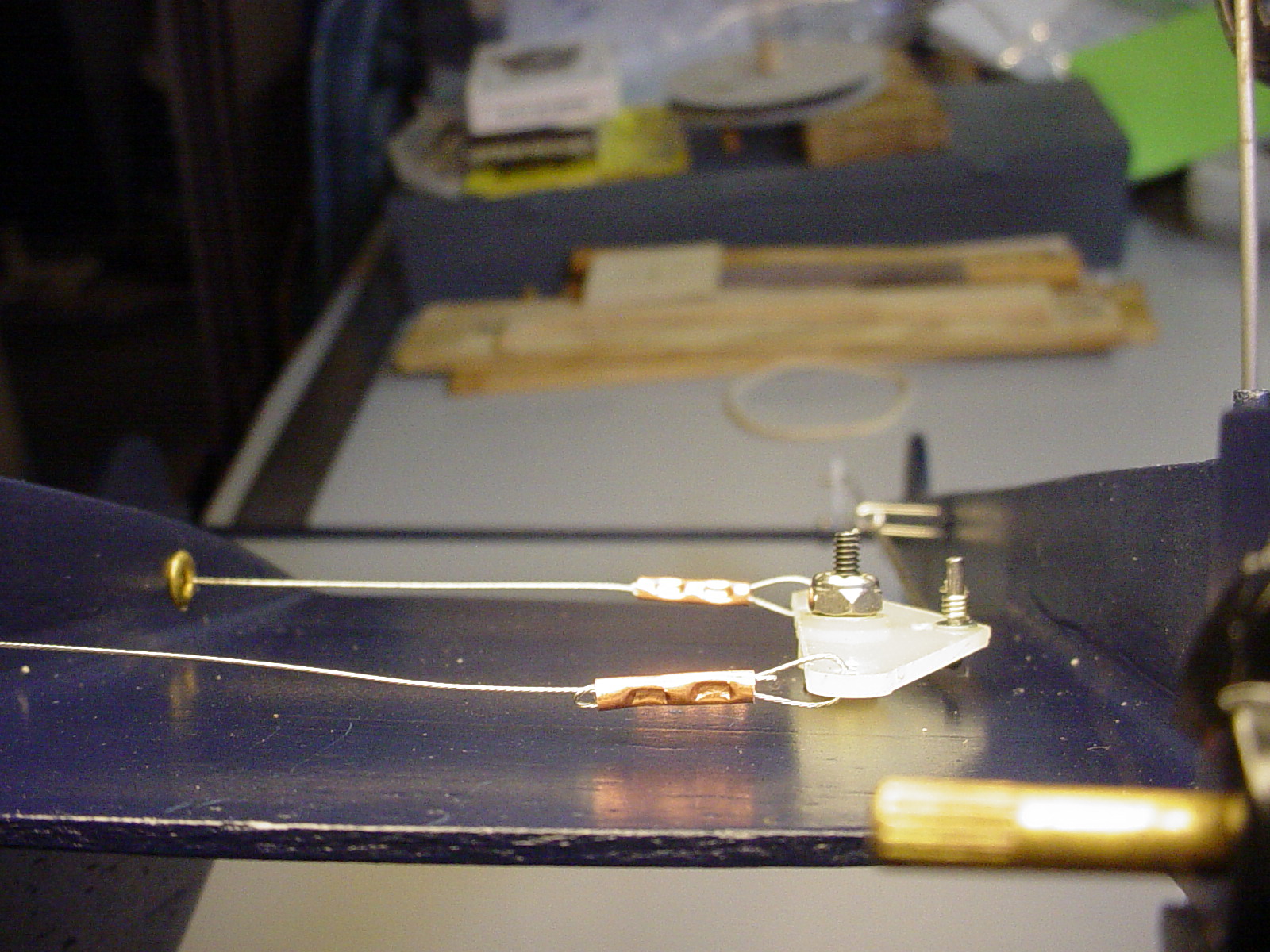

Here's some photos of how I did the lead-outs.. and guides. I'd been wanting to get this done.. but have been very busy working at a new job.

She looks pretty good; hanging from her lead-outs; a slight "nose-out" attitude.

As previously mentioned.. both wing-tips need to be reattached.. They keep breaking-off with discouraging ease..

They keep breaking-off with discouraging ease..

To re-cap; this model is my own design, therefore.. the "moment-arms" aren't proven. So far; the U-Control/profile-structure seems to be good.. for a 1/2A model.

I want to fly this airplane.. but I need to be patient.. and get some "air-time" with other models that I have flown before. It's been too long since I've flown; to risk a maiden with an un-proven design.

My "wingtips" continue to be a problem with breaking-off..

Here's some photos of how I did the lead-outs.. and guides. I'd been wanting to get this done.. but have been very busy working at a new job.

She looks pretty good; hanging from her lead-outs; a slight "nose-out" attitude.

As previously mentioned.. both wing-tips need to be reattached..

Re: P-38 Lightning-Roddie style..

Re: P-38 Lightning-Roddie style..

Roddie the plane is very nice.

As for the wing tips I would reinforce them by gluing a flat carbon strip along the "spar" or 2 along the leading and traveling edges both. Flat enough not to bother the aerodynamics, the carbon strip would definitely make the tips stronger and resist snapping.

As for the wing tips I would reinforce them by gluing a flat carbon strip along the "spar" or 2 along the leading and traveling edges both. Flat enough not to bother the aerodynamics, the carbon strip would definitely make the tips stronger and resist snapping.

balogh- Top Poster

Posts : 4959

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: P-38 Lightning-Roddie style..

Re: P-38 Lightning-Roddie style..

balogh wrote:Roddie the plane is very nice.

As for the wing tips I would reinforce them by gluing a flat carbon strip along the "spar" or 2 along the leading and traveling edges both. Flat enough not to bother the aerodynamics, the carbon strip would definitely make the tips stronger and resist snapping.

Thank You for the "tip" Andras!!! I will reattach the wingtips with some sort of thin over-lapping reinforcement material.. possibly "carbon-veil". So far; cyanoacrylate just keeps breaking-off at the joint.

Re: P-38 Lightning-Roddie style..

Re: P-38 Lightning-Roddie style..

Hobbyshops sell thin glass fibre hinges to be soaked in CA glue. That is also a thin material and provides strong overlap without compromising the airfoil.

balogh- Top Poster

Posts : 4959

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: P-38 Lightning-Roddie style..

Re: P-38 Lightning-Roddie style..

Darn it roddie, I spent countless hours on my scale P-38, measuring, doing the math, cutting, trying, moulding, sheeting, constructing and adding all the little bit's and pieces, then went out and flew the thing. Time for procrastinating is over.

Just fly the thing. It's only balsa.

In the best possible spirit.............

Bob

PS - Same for my MG, many agonizing hours spent. Not for looking. When I'm finished I going to drive the crap out of it.

Just fly the thing. It's only balsa.

In the best possible spirit.............

Bob

PS - Same for my MG, many agonizing hours spent. Not for looking. When I'm finished I going to drive the crap out of it.

rsv1cox- Top Poster

Posts : 11251

Join date : 2014-08-18

Location : West Virginia

Re: P-38 Lightning-Roddie style..

Re: P-38 Lightning-Roddie style..

Butt sand the wings where tips break off.

Make new tips.

Attach with epoxy.

Go fly airplane.

Make new tips.

Attach with epoxy.

Go fly airplane.

JPvelo- Diamond Member

- Posts : 1972

Join date : 2011-12-02

Age : 57

Location : Colorado

Re: P-38 Lightning-Roddie style..

Re: P-38 Lightning-Roddie style..

... or leave the tips off completely. Some racer Warbirds had clipped wings for greater speed:

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Re: P-38 Lightning-Roddie style..

Re: P-38 Lightning-Roddie style..

KariFS wrote:... or leave the tips off completely. Some racer Warbirds had clipped wings for greater speed:

I was going to suggest that as well. Whatever you do get that thing in the air!!!

JPvelo- Diamond Member

- Posts : 1972

Join date : 2011-12-02

Age : 57

Location : Colorado

944_Jim- Diamond Member

Posts : 2022

Join date : 2017-02-08

Age : 59

Location : NE MS

Re: P-38 Lightning-Roddie style..

Re: P-38 Lightning-Roddie style..

Pushy? I'm about ready to climb in that half built MG and head for RI with my flight box and be roddies pit man. Eight pages and still thinking. Enough already! Vintage Triumph on the go. Thumbs up.

Kidding a bit roddie. Different strokes for different folks.

Bob

Kidding a bit roddie. Different strokes for different folks.

Bob

rsv1cox- Top Poster

Posts : 11251

Join date : 2014-08-18

Location : West Virginia

Re: P-38 Lightning-Roddie style..

Re: P-38 Lightning-Roddie style..

wonder were all those greenies are coming from.

getback- Top Poster

Posts : 10442

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: P-38 Lightning-Roddie style..

Re: P-38 Lightning-Roddie style..

I'm going to "redo" the lead-outs. I made the terminations at the wingtip; without the wingtip being glued back on. A dumb mistake.

(Sorry for the blurry image.. it's in tune with the night I did the work. )

)

There's a risk of the crimp-tubes snagging on the wingtip.. once it's glued back on.

I'm keeping the wingtips on the model. I like the contour.. and also want to keep the span at 26" (1/2" scale)

(Sorry for the blurry image.. it's in tune with the night I did the work.

There's a risk of the crimp-tubes snagging on the wingtip.. once it's glued back on.

I'm keeping the wingtips on the model. I like the contour.. and also want to keep the span at 26" (1/2" scale)

Re: P-38 Lightning-Roddie style..

Re: P-38 Lightning-Roddie style..

Good point about the span. If you want to stay traditional, you could use tissue as a reinforcement for the wingtips. If you cover the tip entirely and overlap to the main wing by 1/2” or so, you’ll get a stronger joint and also protection against little dents and dings.

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Re: P-38 Lightning-Roddie style..

Re: P-38 Lightning-Roddie style..

roddie wrote:I'm going to "redo" the lead-outs. I made the terminations...

Hi Roddie,

Are you using brass tubing for your crimps?

I just got back from Hobby Lobby. Their 3-pack of copper tube had two sizes I can use, and one I have no use for.

Their 4-pack of really small diameter brass is the size I wanted for crimping lines...but it is brass.

I saw only one online reference saying brass was useable. All other sites mentioned copper, aluminum, or "soft metal tube."

Thanks in advance!

944_Jim- Diamond Member

Posts : 2022

Join date : 2017-02-08

Age : 59

Location : NE MS

Re: P-38 Lightning-Roddie style..

Re: P-38 Lightning-Roddie style..

3/32" copper tube works perfectly fine for .018" lines which is the correct size wire for 1/2A leadouts. MBS model supply sells crimp tubes as well. I have been experimenting with wrapped line sets vs crimped and purposely breaking them to see where they failed or slip. Here's my latest crimp with ratcheting crimpers.

I pulled this crimp last evening to indicate slippage but the line broke prior.

Not sure why the pic didn't post, I will try again later

This was a experimental test here as I don't leave the frayed wire or the looped tag out of the back of the crimp tube. I found that if I used the brass, I had to anneal it first in order to prevent cracking. These new crimpers support the looped wire on the sides of the tube vs crushing them. This is why crimps are generally not preffered due to the fact the wire is damaged internally.

I pulled this crimp last evening to indicate slippage but the line broke prior.

Not sure why the pic didn't post, I will try again later

This was a experimental test here as I don't leave the frayed wire or the looped tag out of the back of the crimp tube. I found that if I used the brass, I had to anneal it first in order to prevent cracking. These new crimpers support the looped wire on the sides of the tube vs crushing them. This is why crimps are generally not preffered due to the fact the wire is damaged internally.

Last edited by Ken Cook on Sat Jun 09, 2018 7:48 am; edited 2 times in total

Ken Cook- Top Poster

- Posts : 5641

Join date : 2012-03-27

Location : pennsylvania

Re: P-38 Lightning-Roddie style..

Re: P-38 Lightning-Roddie style..

Thanks Ken,

I'm trying to make up a couple of sets of lines.

27, 30, 32, 35, 40, 42, 45, for 1/2A models, and 50. All of them but the 50' will be .008" stranded.

My 50' will be a set of .015"x60' cut down for my BHM Mosquito. I think I'll be wrapping that set.

I'm trying to make up a couple of sets of lines.

27, 30, 32, 35, 40, 42, 45, for 1/2A models, and 50. All of them but the 50' will be .008" stranded.

My 50' will be a set of .015"x60' cut down for my BHM Mosquito. I think I'll be wrapping that set.

Last edited by 944_Jim on Fri Jun 08, 2018 5:29 pm; edited 2 times in total (Reason for editing : Remove a goober)

944_Jim- Diamond Member

Posts : 2022

Join date : 2017-02-08

Age : 59

Location : NE MS

Re: P-38 Lightning-Roddie style..

Re: P-38 Lightning-Roddie style..

Jim, I will just mention this as others can benefit as well. The .008's are good, they're just a pain in the rear to maintain. I've broken them on many occasions just from flying them. Wrapping .008's is a major pain and I avoid doing so. .012" stainless is very beneficial and will endure the rigors we tend to put the lines through. There's little to no difference in weight not to mention drag. Were not going for speed here and .012's are far more durable than .008's. They don't kink like .008's do. Line diameter is based on weight of model and I feel your Mosquito would do far better on .012's than the weight of .015's .

Ken Cook- Top Poster

- Posts : 5641

Join date : 2012-03-27

Location : pennsylvania

lead-out re-do..

lead-out re-do..

I can't seem to upload any images tonight.. but I removed the bellcrank from the P38.. and cut-off the lead-out cables. I'll be able to utilize those long cables on a single-engine 1/2A model in the future.

I found an unopened package of K & S copper-tube 3/32" x 12"L x 3 pieces.. that I didn't realize I had. I cut a pair of 24" length .015" 7-strand stainless cables.. and "re-did" the connections at the bellcrank.. and will post some photos when the image-server is back on-line. Until then; I need to get those wingtips straightened-out..

I found an unopened package of K & S copper-tube 3/32" x 12"L x 3 pieces.. that I didn't realize I had. I cut a pair of 24" length .015" 7-strand stainless cables.. and "re-did" the connections at the bellcrank.. and will post some photos when the image-server is back on-line. Until then; I need to get those wingtips straightened-out..

Re: P-38 Lightning-Roddie style..

Re: P-38 Lightning-Roddie style..

Roddie,

Where did you source the tubing?

$2 for the bundle is too good a deal to pass up. I'm finding it closer to $5 plus S&H...that makes it closer to $5/stick!

That bellcrank/elevator pushrod end keeper, is it Homebrew or commercial?

It looks like an easier method than bending cleanly, or soldering.

Thanks in advance.

Where did you source the tubing?

$2 for the bundle is too good a deal to pass up. I'm finding it closer to $5 plus S&H...that makes it closer to $5/stick!

That bellcrank/elevator pushrod end keeper, is it Homebrew or commercial?

It looks like an easier method than bending cleanly, or soldering.

Thanks in advance.

Last edited by 944_Jim on Sat Jun 09, 2018 3:00 pm; edited 1 time in total

944_Jim- Diamond Member

Posts : 2022

Join date : 2017-02-08

Age : 59

Location : NE MS

Re: P-38 Lightning-Roddie style..

Re: P-38 Lightning-Roddie style..

944_Jim wrote:Roddie,

Where did you source the tubing?

$2 for the bundle is too good a deal to pass up. I'm finding it closer to $5 plus S&H...that makes it closer to $5/stick!

That bellcrank end keeper, is it Homebrew or commercial?

It looks like an easier method than bending cleanly, or soldering.

Thanks in advance.

Hi Jim, The K & S 3/32" copper tubing came from a LHS that closed in 2014. A lot of the prices on items were outdated.

The "keepers" on my pushrod (both ends..) are 1/2A spring-style wheel retainers. Cox International had some NOS packages a while back. Sig used to stock them.. but no more. The thing is; you must use 1/16" (.062") music-wire for the pushrod. The "L-bends" really simplify the whole thing.

Re: P-38 Lightning-Roddie style..

Re: P-38 Lightning-Roddie style..

Roddie seeing how you like those so much, I would give them a call. I know they're still made. I looked this up before and they don't list in a search but they did have them SIG SH121... 1/2A WHEEL RETAINERS 1/16

Send a inquiry to Becky Van Dee becky@sigmfg.com with this part listing I posted.

Send a inquiry to Becky Van Dee becky@sigmfg.com with this part listing I posted.

Ken Cook- Top Poster

- Posts : 5641

Join date : 2012-03-27

Location : pennsylvania

Re: P-38 Lightning-Roddie style..

Re: P-38 Lightning-Roddie style..

Ken Cook wrote: Roddie seeing how you like those so much, I would give them a call. I know they're still made. I looked this up before and they don't list in a search but they did have them SIG SH121... 1/2A WHEEL RETAINERS 1/16

Send a inquiry to Becky Van Dee becky@sigmfg.com with this part listing I posted.

Many thanks Ken! Yes.. I use this simple part for many applications.

wingtip bracing

wingtip bracing

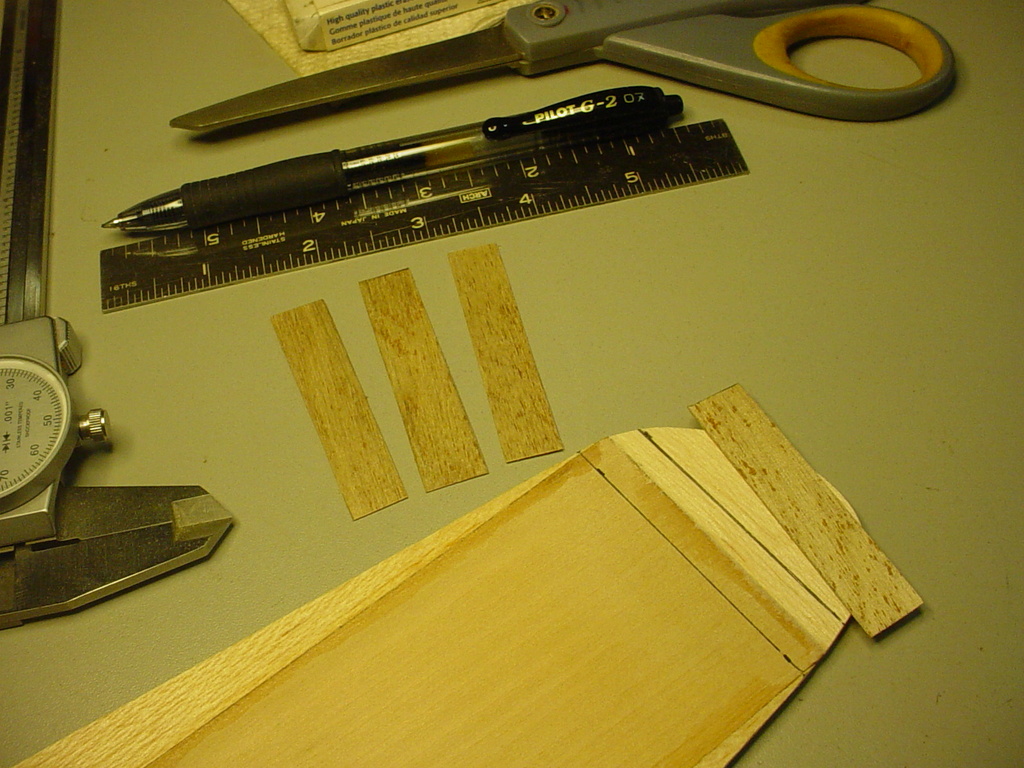

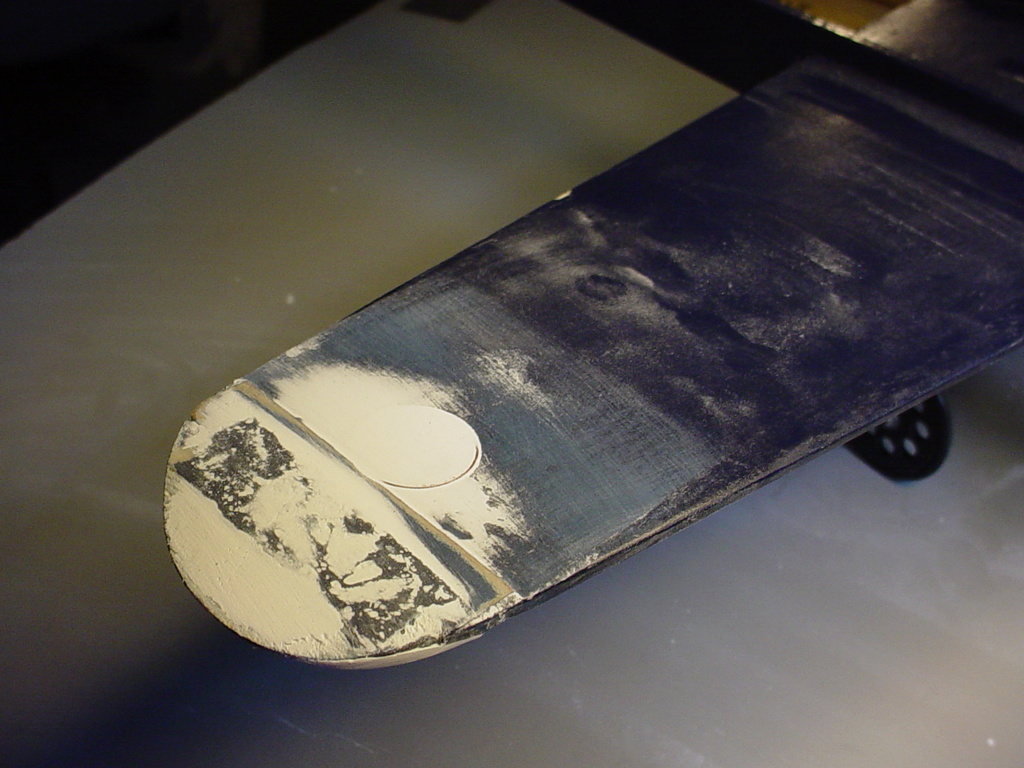

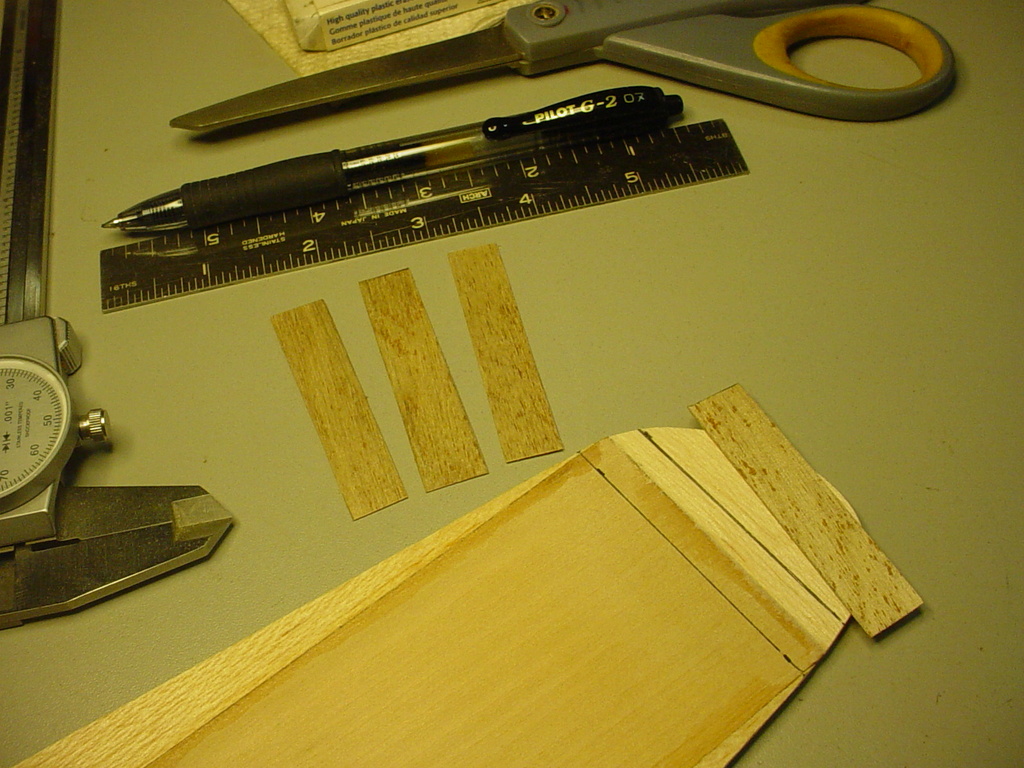

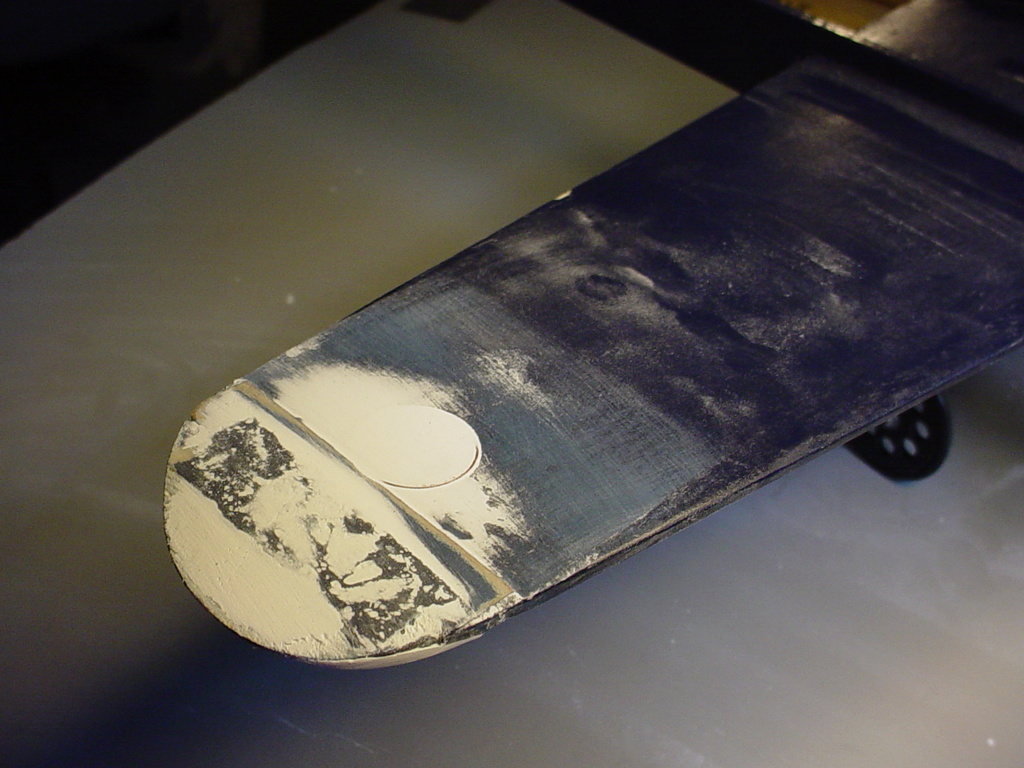

When I designed this model, I made its sheet-wing from dis-similar wood-types. The "core" is 1/8" (3mm) basswood.. with 1/8" balsa leading/trailing-edges.. and wingtips, butt-jointed to the basswood.

The balsa pieces were all edge-glued to the basswood with CA.. but as previously mentioned; the "wingtips" have broken-off during handling (more than once..) with discouraging ease. I'd "braced" the tips (top/bottom) with 1/64" plywood strips in anticipation of a problem.. but should have made the tips with their wood-grain running span-wise.. rather than chord-wise.

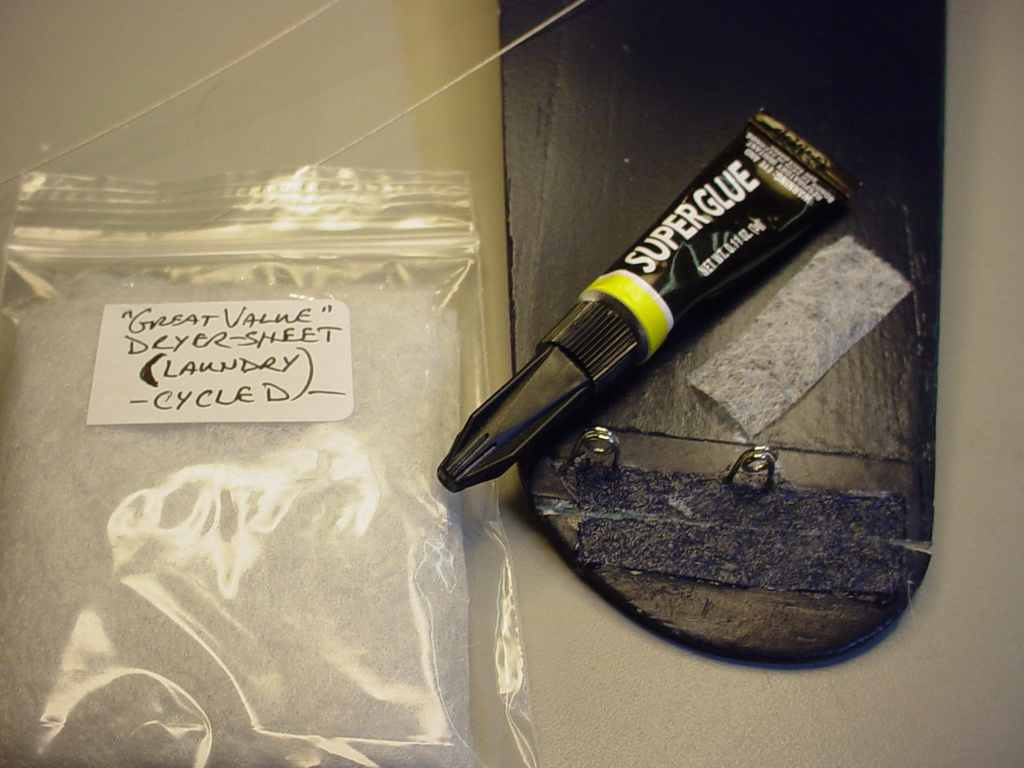

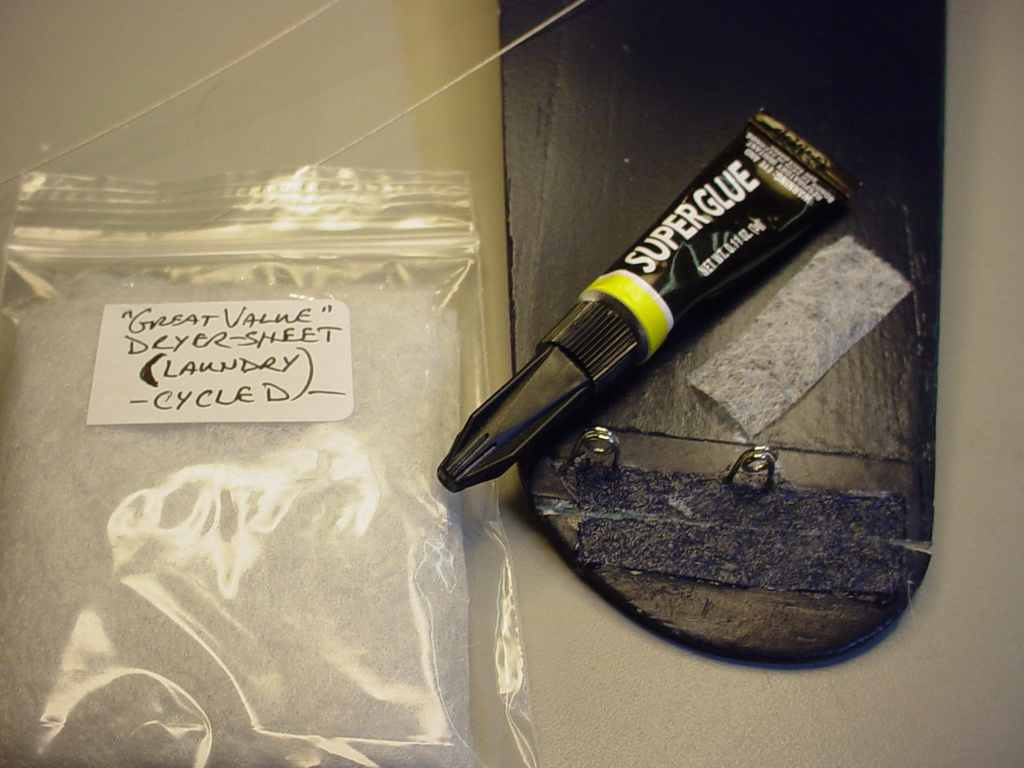

So.. I re-glued the joints once-more.. and decided to try an experimental "skin-graft" using strips of "used" laundry fabric-softener (dryer) sheets.. saturated with thin CA glue.

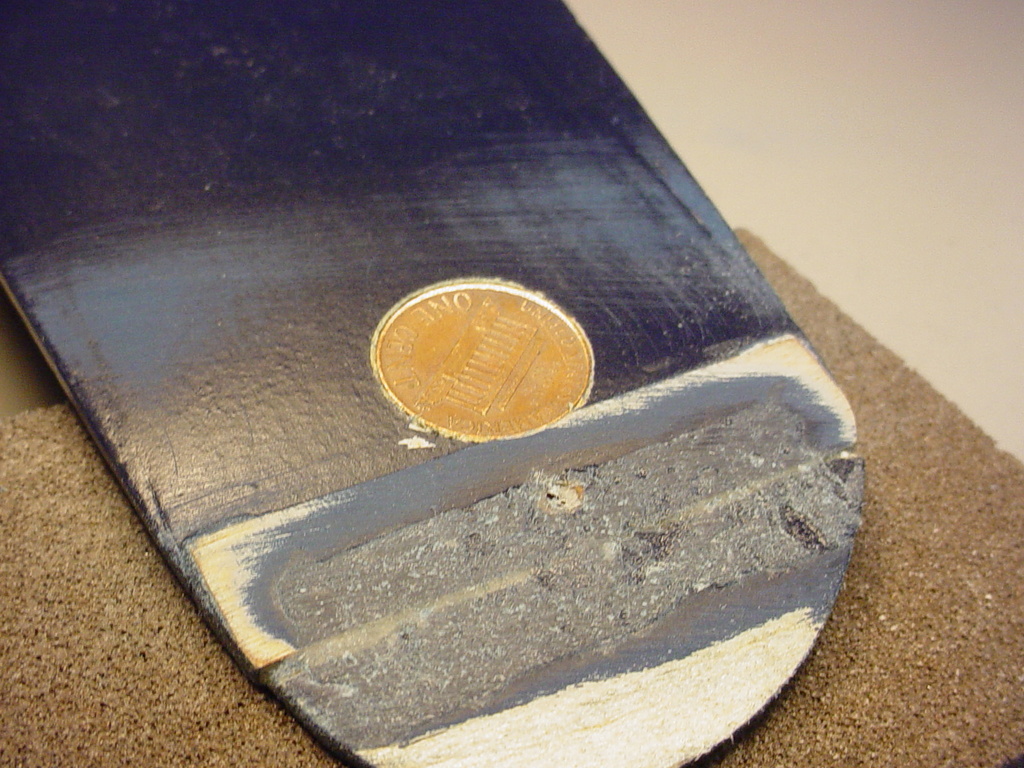

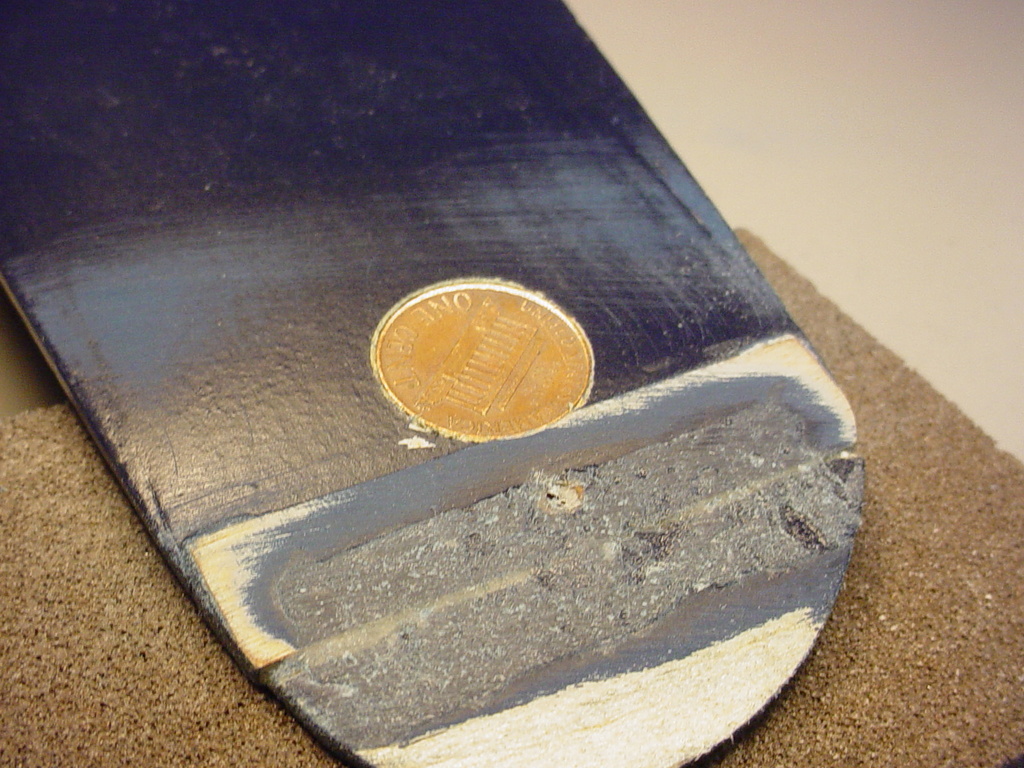

Sanding to a semi-smooth substrate went quick and easy.

I applied vinyl spackling.. and feather-sanded once it had dried.

I won't fuss too much more with imperfections and little surface-dings. The wingtips need to be re-primed/painted, followed by a "misting" of rattle-can clear polyurethane over the entire model.

We're still under 11oz. which isn't too bad for a U-control 1/2A twin.

The balsa pieces were all edge-glued to the basswood with CA.. but as previously mentioned; the "wingtips" have broken-off during handling (more than once..) with discouraging ease. I'd "braced" the tips (top/bottom) with 1/64" plywood strips in anticipation of a problem.. but should have made the tips with their wood-grain running span-wise.. rather than chord-wise.

So.. I re-glued the joints once-more.. and decided to try an experimental "skin-graft" using strips of "used" laundry fabric-softener (dryer) sheets.. saturated with thin CA glue.

Sanding to a semi-smooth substrate went quick and easy.

I applied vinyl spackling.. and feather-sanded once it had dried.

I won't fuss too much more with imperfections and little surface-dings. The wingtips need to be re-primed/painted, followed by a "misting" of rattle-can clear polyurethane over the entire model.

We're still under 11oz. which isn't too bad for a U-control 1/2A twin.

Re: P-38 Lightning-Roddie style..

Re: P-38 Lightning-Roddie style..

Dang! Roddie, that plane looks good enough to FLY! The only thing that should hold you back now is the “Sticker Police “. You gotta have a  or stripes or flags or a Cox sticker on it. Go, go, go for it!

or stripes or flags or a Cox sticker on it. Go, go, go for it!

or stripes or flags or a Cox sticker on it. Go, go, go for it!

or stripes or flags or a Cox sticker on it. Go, go, go for it!

Marleysky- Top Poster

Posts : 3618

Join date : 2014-09-28

Age : 72

Location : Grand Rapids, MI

Page 8 of 9 •  1, 2, 3, 4, 5, 6, 7, 8, 9

1, 2, 3, 4, 5, 6, 7, 8, 9

Similar topics

Similar topics» Wen Mac P-38's

» Red Wen Mac P-38 Lightning

» 1:64 scale Diecast (Hot Wheels)

» The P-38 Lightning Wow factor

» Baby Lightning Streak

» Red Wen Mac P-38 Lightning

» 1:64 scale Diecast (Hot Wheels)

» The P-38 Lightning Wow factor

» Baby Lightning Streak

Page 8 of 9

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules