Log in

Search

Latest topics

» Roger Harris revisitedby rsv1cox Today at 3:38 pm

» My N-1R build log

by GallopingGhostler Today at 3:04 pm

» Tee Dee .020 combat model

by 1/2A Nut Today at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» My latest doodle...

by batjac Yesterday at 9:47 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

Cox Engine of The Month

My Toy Bow & Arrow Set Hot Wire Cutter

Page 1 of 1

My Toy Bow & Arrow Set Hot Wire Cutter

My Toy Bow & Arrow Set Hot Wire Cutter

Last edited by akjgardner on Tue Oct 03, 2017 7:03 pm; edited 1 time in total

akjgardner- Diamond Member

Posts : 1601

Join date : 2014-12-28

Age : 65

Location : Greensberg Indiana

Re: My Toy Bow & Arrow Set Hot Wire Cutter

Re: My Toy Bow & Arrow Set Hot Wire Cutter

Cool! Let's see some foam wings and bodies! You going to use blue foam or what?

I saw one on UTube awhile back powered by a huge old Lionel train transformer. It was just too far off the path for me, as I have a bunch of balsa kits to get to first.

Let's see what it can do!

I saw one on UTube awhile back powered by a huge old Lionel train transformer. It was just too far off the path for me, as I have a bunch of balsa kits to get to first.

Let's see what it can do!

Marleysky- Top Poster

Posts : 3618

Join date : 2014-09-28

Age : 72

Location : Grand Rapids, MI

Re: My Toy Bow & Arrow Set Hot Wire Cutter

Re: My Toy Bow & Arrow Set Hot Wire Cutter

I'm going to pick up some blue foam this week and start practicing cutting some simple wings I'll let Ya'll know it turns out

akjgardner- Diamond Member

Posts : 1601

Join date : 2014-12-28

Age : 65

Location : Greensberg Indiana

Re: My Toy Bow & Arrow Set Hot Wire Cutter

Re: My Toy Bow & Arrow Set Hot Wire Cutter

Been there done that

Not trying to dash the good idea... but you need a temp control ------12VDC at 6 amps MIGHT be just right for your wire diameter and length ....

BUT ----if it is too hot or too cool it will frustrate your attempts to cut nice shapes

And to frustrate it further you need good virgin foam...re manufacture foam is worthless

and even then---- new virgin foam can have various densities (weight per cubic foot) and each has a good temp setting

Do a bunch of reading here:

http://www.jacobs-online.biz/power_supply_design.htm

If you are not OCD... one method is to use a less than optimal cutter but make templates slightly larger....then block sand out all the imperfections....foam sands very easily with those dry wall screen type pads or even the coarse foam rubber spongy types

I got too frustrated, gave my cutter away, and get the foam cores I need from Phil Cartier (CoreHouse)

Not trying to dash the good idea... but you need a temp control ------12VDC at 6 amps MIGHT be just right for your wire diameter and length ....

BUT ----if it is too hot or too cool it will frustrate your attempts to cut nice shapes

And to frustrate it further you need good virgin foam...re manufacture foam is worthless

and even then---- new virgin foam can have various densities (weight per cubic foot) and each has a good temp setting

Do a bunch of reading here:

http://www.jacobs-online.biz/power_supply_design.htm

If you are not OCD... one method is to use a less than optimal cutter but make templates slightly larger....then block sand out all the imperfections....foam sands very easily with those dry wall screen type pads or even the coarse foam rubber spongy types

I got too frustrated, gave my cutter away, and get the foam cores I need from Phil Cartier (CoreHouse)

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: My Toy Bow & Arrow Set Hot Wire Cutter

Re: My Toy Bow & Arrow Set Hot Wire Cutter

How do you cut shapes, just carefully carve it like it was a big hand plane?

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: My Toy Bow & Arrow Set Hot Wire Cutter

Re: My Toy Bow & Arrow Set Hot Wire Cutter

Rusty when cutting something like an air foil using internal or external templates...if the wire is too hot or too cool the top and bottom of the core will have draggy wavy imperfect finish. When all is good the top and bottom are near finish smooth ready for covering or skins.

Very light block sanding with coarse grit (80) on down to finer grit 150~220 gets you back to the shape and finish needed

Corners / wing tip shapes, are easy to control using the sponge type coarse to medium grit versions....shoe Polish method with 150 grit long strips helps get a nice round profile

Very light block sanding with coarse grit (80) on down to finer grit 150~220 gets you back to the shape and finish needed

Corners / wing tip shapes, are easy to control using the sponge type coarse to medium grit versions....shoe Polish method with 150 grit long strips helps get a nice round profile

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: My Toy Bow & Arrow Set Hot Wire Cutter

Re: My Toy Bow & Arrow Set Hot Wire Cutter

Rusty, I'm goint to use templates tack glued to the inside and outside of the foam. Fred was correct in saying I need to vary the current through my wire to get a clean cut, I used my battery charger as a test bed and it works ok , but I was getting a little of the wavy thing going on that Fred talked aboutRknRusty wrote:How do you cut shapes, just carefully carve it like it was a big hand plane?

akjgardner- Diamond Member

Posts : 1601

Join date : 2014-12-28

Age : 65

Location : Greensberg Indiana

Re: My Toy Bow & Arrow Set Hot Wire Cutter

Re: My Toy Bow & Arrow Set Hot Wire Cutter

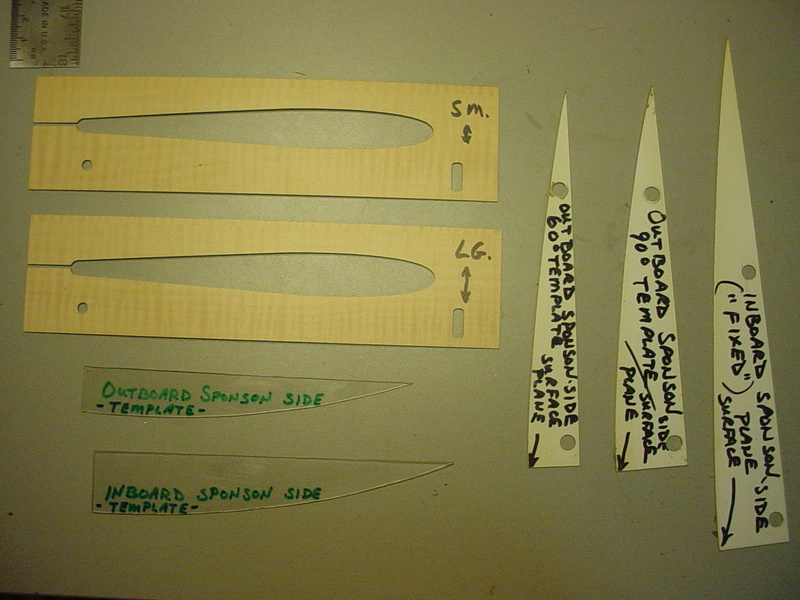

One hint for helping reduce the wavy cut.... make very good templates that have long lead-in and very smooth edges for the wire to slide along

I cut my templates a little large from 1/8th ply, use too holes in the sides to PIN them with Finishing nails into the edge of the blank. I cover the outer edges of the template with Aluminum tape

I make the Trailing edge a bit fat and longer than needed....easy to trim back to width

I mark the center line and drill a hole in the LE front and TE back and force in a 1.5" piece of music wire as my lead in and lead out guides

I never try to hot wire cut out the spar slots...they are done on a router table or long purpose built sanding bar and guides

I cut my templates a little large from 1/8th ply, use too holes in the sides to PIN them with Finishing nails into the edge of the blank. I cover the outer edges of the template with Aluminum tape

I make the Trailing edge a bit fat and longer than needed....easy to trim back to width

I mark the center line and drill a hole in the LE front and TE back and force in a 1.5" piece of music wire as my lead in and lead out guides

I never try to hot wire cut out the spar slots...they are done on a router table or long purpose built sanding bar and guides

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: My Toy Bow & Arrow Set Hot Wire Cutter

Re: My Toy Bow & Arrow Set Hot Wire Cutter

Sorry, guys, I'm just not compiling a picture of this in my little brain. Maybe if you could get a snapshot sometime Thanks.

Rusty

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: My Toy Bow & Arrow Set Hot Wire Cutter

Re: My Toy Bow & Arrow Set Hot Wire Cutter

RknRusty wrote:Sorry, guys, I'm just not compiling a picture of this in my little brain. Maybe if you could get a snapshot sometime Thanks.

Rusty

Rusty, Here's an example of a hot-wire foam-cutting rig. This example uses a single internal-template and one end of the wire has a fixed-location, unlike a conventional bow. It's one way of producing a wing-panel with a varied chord. A conventional bow holds the hot-wire taught and usually there's a template on both-sides of the foam-block.

https://www.youtube.com/watch?v=R0ZCnR_g6ZU

Re: My Toy Bow & Arrow Set Hot Wire Cutter

Re: My Toy Bow & Arrow Set Hot Wire Cutter

Rusty

I got too deep into this with the combat planes once I saw how Jeff Dawson did it

A Lot of variables that are hard to control... especially for OCD folks like you and I

Bob Hunt can supply perfect wing cores...skinned or not ....for most any stunt plane you ever desired

Phil Cartier can deliver near perfect cores for many common stunt planes and a lot of combat planes

But I have to admit... part of modeling is doing it ALL your self... I had fun learning foam cutting, shaping, covering

For Rusty... cutting a full 42"~ 48" twister type wing is technically possible but in reality we make two half's just cuz the Bow is very hard to construct and feed (Volts/amps) to make a good clean long Wing Span cut

A SOLID foam wing in most stunt sizes is too heavy....so we need to Core out voids inside... the hard part... then there is good spars to consider

Balsa sheeting to make it all look pretty adds weight plus a lot of strength

To make a Ring Master Foam wing... because it is NOT a constant Chord requires two panels cut with a lager Root template and a smaller Tip template...

Since you are curious...I want you to just suck it up and Have Phil Cartier send you a Rugged Stunt Trainer

A-- easy and fast build

B- Cheap

C- on this subject the kit will give you a dozen AH Ha moments..

D- Near indestructible and flies as good as most any stunt plane there is

I got too deep into this with the combat planes once I saw how Jeff Dawson did it

A Lot of variables that are hard to control... especially for OCD folks like you and I

Bob Hunt can supply perfect wing cores...skinned or not ....for most any stunt plane you ever desired

Phil Cartier can deliver near perfect cores for many common stunt planes and a lot of combat planes

But I have to admit... part of modeling is doing it ALL your self... I had fun learning foam cutting, shaping, covering

For Rusty... cutting a full 42"~ 48" twister type wing is technically possible but in reality we make two half's just cuz the Bow is very hard to construct and feed (Volts/amps) to make a good clean long Wing Span cut

A SOLID foam wing in most stunt sizes is too heavy....so we need to Core out voids inside... the hard part... then there is good spars to consider

Balsa sheeting to make it all look pretty adds weight plus a lot of strength

To make a Ring Master Foam wing... because it is NOT a constant Chord requires two panels cut with a lager Root template and a smaller Tip template...

Since you are curious...I want you to just suck it up and Have Phil Cartier send you a Rugged Stunt Trainer

A-- easy and fast build

B- Cheap

C- on this subject the kit will give you a dozen AH Ha moments..

D- Near indestructible and flies as good as most any stunt plane there is

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: My Toy Bow & Arrow Set Hot Wire Cutter

Re: My Toy Bow & Arrow Set Hot Wire Cutter

Building the bow and a suspension system can actually be fun. I built one from some plans that I think came from the RCM books. There was a pulley-system with rope.. and a counter-weight. The idea was to suspend the bow and its elec. leads from a swinging-arm mounted above with a pulley hanging from it. The rope would attach to the top/center of the bow and up through the pulley and back down to a counterweight. The counterweight could be anything.. as long as it counter-balances the bow. A piece of 2" PVC pipe a foot or so long, capped on the bottom and filled with sand is an easy way to do it. Drill a cross-hole through the top of the pipe for tying the rope. If your pulley-wheel has a 2" dia.. then the pipe/counter-weight will clear the rope on the "bow-side" of the pulley. This can really be helpful when cutting.. because the weight of the bow isn't working against you.. and the cutting-wire can be guided up or down effortlessly.

The swinging-arm is merely a piece of wood with a pivot or hinge mounted to the wall or an upright post to the side of your work-station. Make it long enough to mount the pulley directly over the center of your workstation. The arm only needs to swing the length of your cut.. and support the weight on the rope. The insulated power-wires can be zip-tied to the bow and also suspended so that they're out of the way.

The swinging-arm is merely a piece of wood with a pivot or hinge mounted to the wall or an upright post to the side of your work-station. Make it long enough to mount the pulley directly over the center of your workstation. The arm only needs to swing the length of your cut.. and support the weight on the rope. The insulated power-wires can be zip-tied to the bow and also suspended so that they're out of the way.

Similar topics

Similar topics» Wire Cutter Idea

» "Cox Gravity Warbirds" F4-U Corsair RC upgrade thread

» Manx Arrow

» My new addition "Red Arrow"

» First tach of my Red Arrow .049

» "Cox Gravity Warbirds" F4-U Corsair RC upgrade thread

» Manx Arrow

» My new addition "Red Arrow"

» First tach of my Red Arrow .049

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules