Log in

Search

Latest topics

» Purchased the last of any bult engines from Ken Enyaby sosam117 Today at 8:15 am

» TEE DEE Having issues

by balogh Today at 7:42 am

» Retail price mark-up.. how much is enough?

by rsv1cox Today at 7:36 am

» Cox films/videos...

by Coxfledgling Today at 4:46 am

» My N-1R build log

by roddie Today at 12:32 am

» Happy 77th birthday Andrew!

by akjgardner Today at 12:27 am

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» Roger Harris revisited

by TD ABUSER Yesterday at 2:13 pm

» Tee Dee .020 combat model

by Ken Cook Yesterday at 1:41 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 9:24 am

Cox Engine of The Month

Ordered a 1/2A Skyray kit

Page 3 of 6

Page 3 of 6 •  1, 2, 3, 4, 5, 6

1, 2, 3, 4, 5, 6

Re: Ordered a 1/2A Skyray kit

Re: Ordered a 1/2A Skyray kit

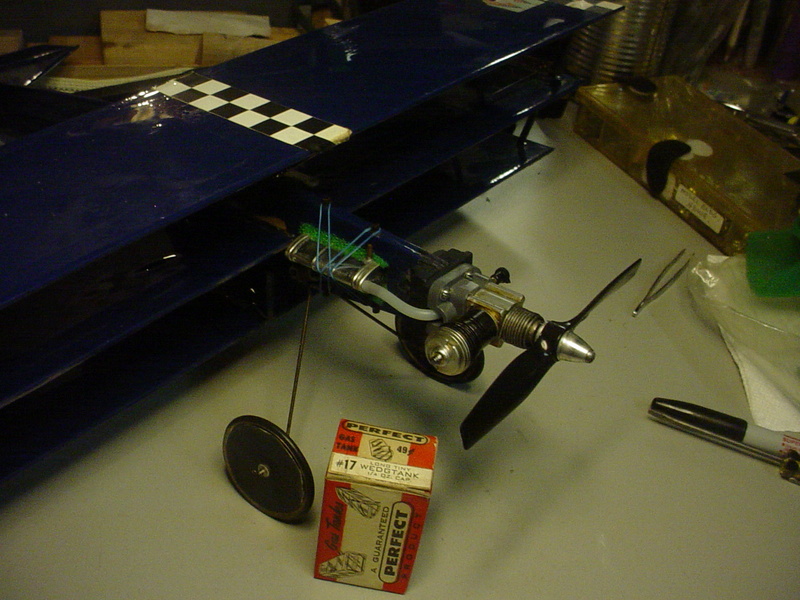

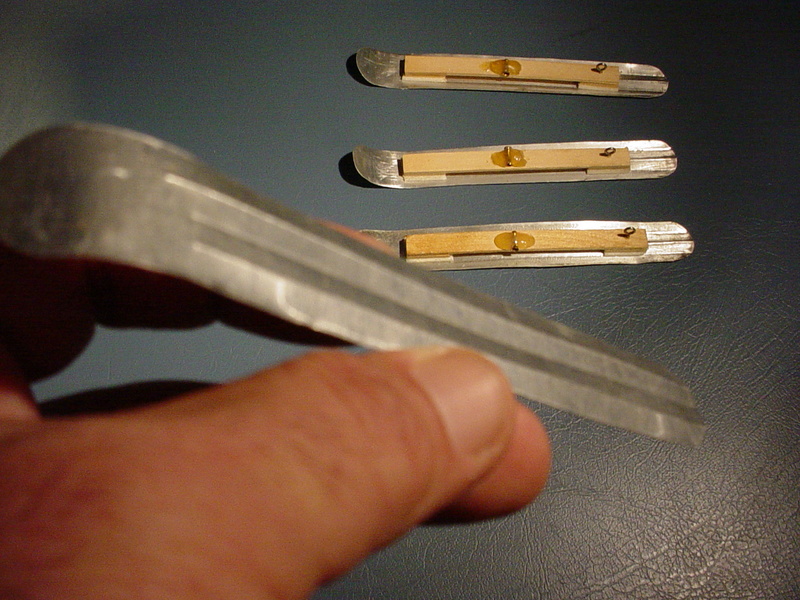

I like that little clunk-tank. It should work for you. I can't understand the issues with the wedge...  I usually (pretty much always..) orient the engines' backplate horizontally on the firewall when running a wedge tank. I realize that you can't do that with your current engine-mount.

I usually (pretty much always..) orient the engines' backplate horizontally on the firewall when running a wedge tank. I realize that you can't do that with your current engine-mount.

Here's a few examples..

It's just a theory.. but your PT's fuel tank feeds straight-down.. and loops back up to its vertically-oriented backplate. Its fuel-line doesn't transition from horizontal to vertical.. and has no trouble using all the fuel. If you experience the same issue with your clunk-tank.. that could be the problem.. and switching to a balloon-tank may not help the situation. I could be wrong... so take that with a grain of salt.

A "pressure-bladder" fuel-feed is another option.. but there's a couple of issues at play. There's a learning-curve associated with their operation.. and they require a "fine-thread" needle-valve to work well. On the positive side; a pressure-bladder will feed the engine in any position. This is why most people use them rather than fussing with tanks. The older Cox .049 product-engines came with the fine-thread needle-valve assemblies. They were know as "postage-stamp" engines.. and had no mounts for use on a balsa model.

Here's what the engine looks like. If you see one.. or just the backplate with needle.. grab it. Its fine-thread NVA can be swapped into the newer style backplate that you have, for running a pressure-bladder.

You may be better-off running an "integrally-tanked" engine like the "Silver Stunter" like you were considering before the build.

Good luck.. I hope you get it figured out.

I usually (pretty much always..) orient the engines' backplate horizontally on the firewall when running a wedge tank. I realize that you can't do that with your current engine-mount.

I usually (pretty much always..) orient the engines' backplate horizontally on the firewall when running a wedge tank. I realize that you can't do that with your current engine-mount. Here's a few examples..

It's just a theory.. but your PT's fuel tank feeds straight-down.. and loops back up to its vertically-oriented backplate. Its fuel-line doesn't transition from horizontal to vertical.. and has no trouble using all the fuel. If you experience the same issue with your clunk-tank.. that could be the problem.. and switching to a balloon-tank may not help the situation. I could be wrong... so take that with a grain of salt.

A "pressure-bladder" fuel-feed is another option.. but there's a couple of issues at play. There's a learning-curve associated with their operation.. and they require a "fine-thread" needle-valve to work well. On the positive side; a pressure-bladder will feed the engine in any position. This is why most people use them rather than fussing with tanks. The older Cox .049 product-engines came with the fine-thread needle-valve assemblies. They were know as "postage-stamp" engines.. and had no mounts for use on a balsa model.

Here's what the engine looks like. If you see one.. or just the backplate with needle.. grab it. Its fine-thread NVA can be swapped into the newer style backplate that you have, for running a pressure-bladder.

You may be better-off running an "integrally-tanked" engine like the "Silver Stunter" like you were considering before the build.

Good luck.. I hope you get it figured out.

TLAnderson- Gold Member

- Posts : 243

Join date : 2016-07-21

Location : Northern Wisconsin

Re: Ordered a 1/2A Skyray kit

Re: Ordered a 1/2A Skyray kit

Hey, the plane looks fine just sitting there. Why mess it up by flying it?

Oldenginerod- Top Poster

- Posts : 4018

Join date : 2012-06-15

Age : 62

Location : Drouin, Victoria

Re: Ordered a 1/2A Skyray kit

Re: Ordered a 1/2A Skyray kit

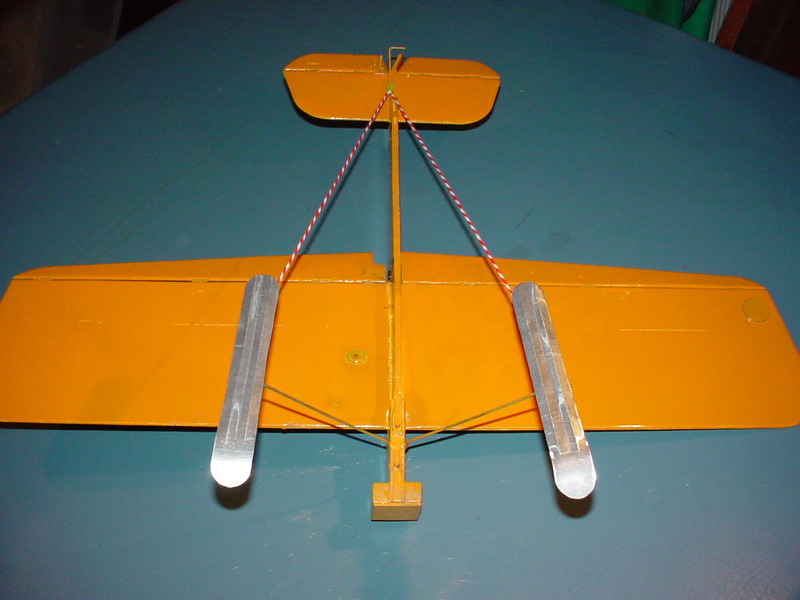

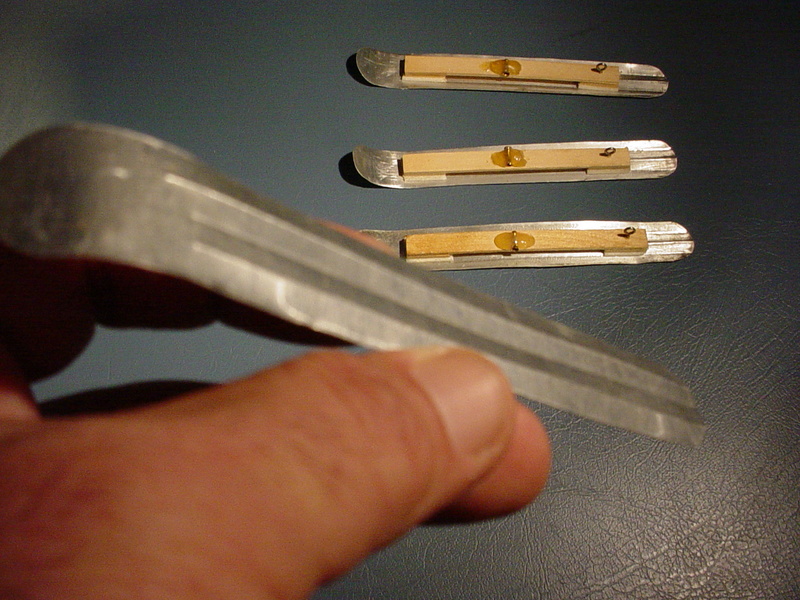

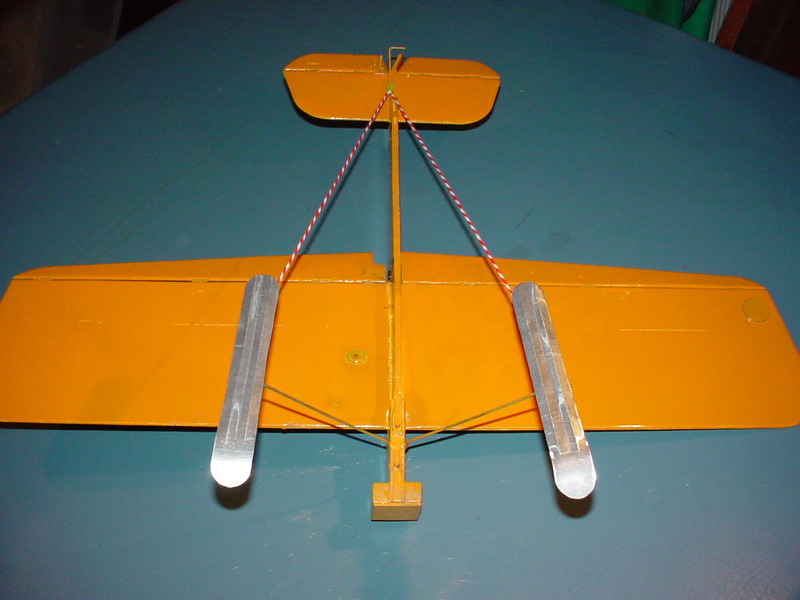

All you need are some skis...  These were very easy to make. Aluminum "flashing" sheet, popsicle-sticks, a tiny pair of eye-screws.. double-sided foam tape, and some tubing for hubs. A piece of string tied to the eye-screws doesn't need to be an exact length. A rubber-band looped-around the string can be stretched over a tail-skid.

These were very easy to make. Aluminum "flashing" sheet, popsicle-sticks, a tiny pair of eye-screws.. double-sided foam tape, and some tubing for hubs. A piece of string tied to the eye-screws doesn't need to be an exact length. A rubber-band looped-around the string can be stretched over a tail-skid.

https://www.coxengineforum.com/t5765-skis-for-winter-flying?highlight=skis

https://www.coxengineforum.com/t5765-skis-for-winter-flying?highlight=skis

Re: Ordered a 1/2A Skyray kit

Re: Ordered a 1/2A Skyray kit

Pretty cool skis, Roddie. Might have to make a set. I remember messing around with my .049s as a kid, when it was cold out. Prop strikes on cold fingers hurt!

TLAnderson- Gold Member

- Posts : 243

Join date : 2016-07-21

Location : Northern Wisconsin

Re: Ordered a 1/2A Skyray kit

Re: Ordered a 1/2A Skyray kit

TLAnderson wrote:Pretty cool skis, Roddie. Might have to make a set. I remember messing around with my .049s as a kid, when it was cold out. Prop strikes on cold fingers hurt!

Thanks for the compliment! Yes.. cold-weather flying is tough on the fingers. There's a few threads here on cold-weather flying. I haven't done a whole lot.. but one trick to getting your engine to start and run.. is to keep its' cylinder-head warm. This can be accomplished with the use of those "hand-warmers" that are sold for Winter activities. One of these placed in to a small zip-seal bag as a "hood" for placing over the cylinder would do the trick. Some modelers claim that "yarn" wrapped-between the cooling-fins of the glow-head helps to keep it "HOT" when flying in cold weather. That makes perfect sense to me.

Why not give it a try? You may find that flying your models through the Winter-months is possible. Often there are beautifully clear and windless days in the Winter.

Re: Ordered a 1/2A Skyray kit

Re: Ordered a 1/2A Skyray kit

I haven't ever flown on snow, but maybe on a sunny day in Massachusetts winter, I don't remember well.

David Ingham- Silver Member

- Posts : 86

Join date : 2017-03-30

Age : 82

Location : Mountsin View, California, USA

Re: Ordered a 1/2A Skyray kit

Re: Ordered a 1/2A Skyray kit

David Ingham wrote:I haven't ever flown on snow, but maybe on a sunny day in Massachusetts winter, I don't remember well.

Did you live in Massachusetts David? I grew-up in Franklin, Mass. It's my hometown.. and I have family there. Franklin is in the South-Eastern part of the state.. roughly 30mi. South of Boston. I now live in Northern Rhode Island.. (N. Smithfield) which borders S.E. Massachusetts.. (Uxbridge/Millville) and is only 30 minutes (back-roads) from Franklin, MA.

Re: Ordered a 1/2A Skyray kit

Re: Ordered a 1/2A Skyray kit

roddie wrote:Often there are beautifully clear and windless days in the Winter.

Only problem with those clear windless winter days around here is that the temperature is usually about 15 degrees below zero

TLAnderson- Gold Member

- Posts : 243

Join date : 2016-07-21

Location : Northern Wisconsin

Re: Ordered a 1/2A Skyray kit

Re: Ordered a 1/2A Skyray kit

Back when I was doing research, I worked for the University of Minnesota for one year and for MIT for bout three years. I lived in Ipswich and few with and joined a stunt control line club in Danvers. I bought my first PT 19 at a yard sale in Ipswich.

If I hadn't spent the year in Minneapolis, I would have thought Massachusetts was cold.

If I hadn't spent the year in Minneapolis, I would have thought Massachusetts was cold.

David Ingham- Silver Member

- Posts : 86

Join date : 2017-03-30

Age : 82

Location : Mountsin View, California, USA

Re: Ordered a 1/2A Skyray kit

Re: Ordered a 1/2A Skyray kit

David Ingham wrote:Back when I was doing research, I worked for the University of Minnesota for one year and for MIT for bout three years. I lived in Ipswich and few with and joined a stunt control line club in Danvers. I bought my first PT 19 at a yard sale in Ipswich.

If I hadn't spent the year in Minneapolis, I would have thought Massachusetts was cold.

-38° f is the coldest I've seen it since I've lived up here. I'm close to Lake Superior. The lake moderates the temperatures somewhat. Not far west of here, in Minnesota, the low hit -60° f one night, a few years ago.

We get a little snow around here also. This is what I push it around with.

It's a 1977 International Harvester Scout II

Last edited by TLAnderson on Fri Jun 15, 2018 10:00 pm; edited 1 time in total

TLAnderson- Gold Member

- Posts : 243

Join date : 2016-07-21

Location : Northern Wisconsin

Re: Ordered a 1/2A Skyray kit

Re: Ordered a 1/2A Skyray kit

That snow is pretty but even prettier that its wee you are LOL . Heck the last few years i have trouble being in the 50 degree outside with my hands getting numb and so cold that it hurts !  Here is 40 at night and around 60 daytime but when the light goes out i go in

Here is 40 at night and around 60 daytime but when the light goes out i go in

Here is 40 at night and around 60 daytime but when the light goes out i go in

Here is 40 at night and around 60 daytime but when the light goes out i go in

getback- Top Poster

Posts : 10442

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Ordered a 1/2A Skyray kit

Re: Ordered a 1/2A Skyray kit

Damn, Dudes, you Northeasterners and Midwesterners are made out of tough stuff. I admire how y'all tough it out through the winter only to be rewarded with a tease of summer. Skis on your planes, plows on your Jeeps, and wearing 20 pounds of clothes.

.............. Nah! I'll opt for my sweat

.............. Nah! I'll opt for my sweat

.............. Nah! I'll opt for my sweat

.............. Nah! I'll opt for my sweat

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Ordered a 1/2A Skyray kit

Re: Ordered a 1/2A Skyray kit

RknRusty wrote:Damn, Dudes, you Northeasterners and Midwesterners are made out of tough stuff. I admire how y'all tough it out through the winter only to be rewarded with a tease of summer. Skis on your planes, plows on your Jeeps, and wearing 20 pounds of clothes.

.............. Nah! I'll opt for my sweat

It's not bad enough "yet" to move down south Rusty! Lynne and I have lived here in the Northeast all our lives. Getting a model-engine roaring when there's frost on the grass is exhilarating.. especially after your finger gets bitten by the propeller a few times.. and your ears start getting numb. I want to try "Phil's" (pkrankow) method of wrapping a few turns of "sewing-yarn" between the cooling-fins of a Cox glow-head.. for when it gets really cold!

Re: Ordered a 1/2A Skyray kit

Re: Ordered a 1/2A Skyray kit

I can promise you I'll never need to try that. While you're playing, I'll be sitting in front of a toasty fireplace in my living room, Lol. But I do pass it on to my cold weather friends when the discussion arises.roddie wrote:RknRusty wrote:Damn, Dudes, you Northeasterners and Midwesterners are made out of tough stuff. I admire how y'all tough it out through the winter only to be rewarded with a tease of summer. Skis on your planes, plows on your Jeeps, and wearing 20 pounds of clothes.

.............. Nah! I'll opt for my sweat

...I want to try "Phil's" (pkrankow) method of wrapping a few turns of "sewing-yarn" between the cooling-fins of a Cox glow-head.. for when it gets really cold!

BrrrRusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Ordered a 1/2A Skyray kit

Re: Ordered a 1/2A Skyray kit

Loud and clear Rusty.RknRusty wrote: I'll be sitting in front of a toasty fireplace in my living room, Lol. But I do pass it on to my cold weather friends when the discussion arises.

BrrrRusty

I don't know how much more Roddy can take, but my dearest

and I are looking south in coming years. I've braved the cold

well, but it's getting old(like me). We're thinking Louisiana, after

several visits.

Bob

edit: I have always loved hitting the beaches in the dead of winter

when the winter is at it's worst, wearing the usual "20lbs" of layers

and layers of clothes. I'm still into that, but having to do the other

day to day stuff in the cold, kinda ........ .

dckrsn- Diamond Member

- Posts : 2750

Join date : 2010-10-21

Age : 71

Location : Long Island, New York

Back to flying after the winter break

Back to flying after the winter break

I was finally able to get some air time in last night. I was hoping that I had eliminated all the bugs by swapping the wedge tank out for the clunk tank. Not quite. A new one showed up.

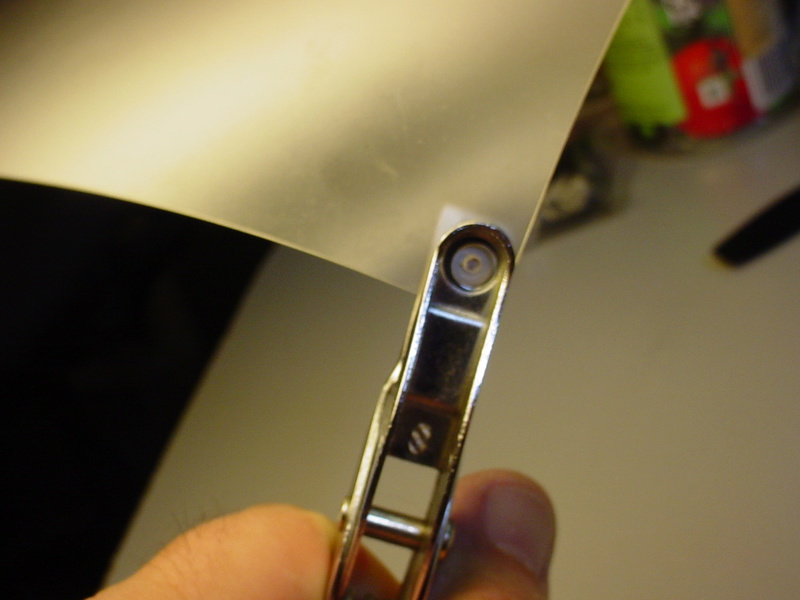

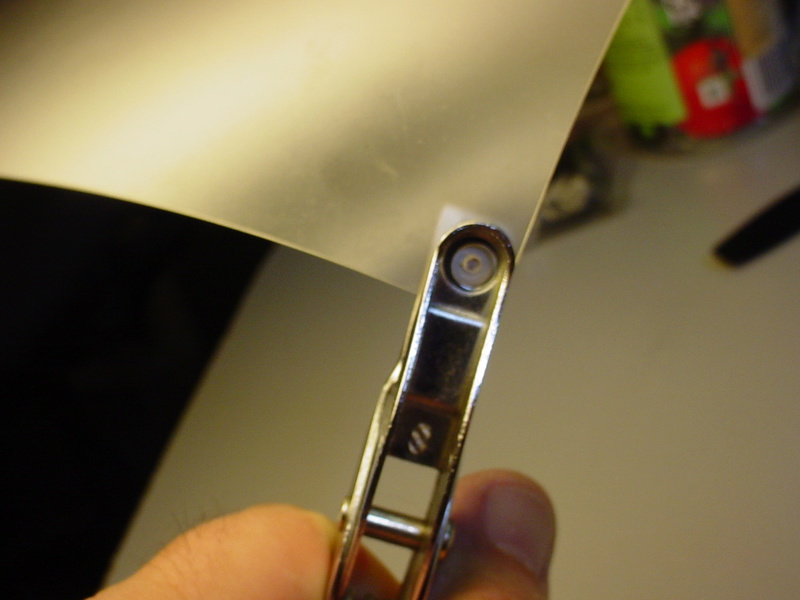

The first couple of flights, I was having an issue where the engine would start and run strong but then start losing rpm until it died. I looked it over while it was running on the ground, and saw that the needle valve was turning from the vibration. I remembered reading about that problem on this forum, and that the fix was to place some fuel tubing over the needle. I tried that, and it seemed to help. I was able to get a few full power flights in after that.

After I got home, I took the engine off the plane, and put a short piece of tubing over the needle seal, and another piece on the needle. I didn't have any washers small enough to fit the needle, so I made the tubing long enough to jam under the cap on the needle. Now we'll see if that works next time.

So here's the current setup.

The first couple of flights, I was having an issue where the engine would start and run strong but then start losing rpm until it died. I looked it over while it was running on the ground, and saw that the needle valve was turning from the vibration. I remembered reading about that problem on this forum, and that the fix was to place some fuel tubing over the needle. I tried that, and it seemed to help. I was able to get a few full power flights in after that.

After I got home, I took the engine off the plane, and put a short piece of tubing over the needle seal, and another piece on the needle. I didn't have any washers small enough to fit the needle, so I made the tubing long enough to jam under the cap on the needle. Now we'll see if that works next time.

So here's the current setup.

TLAnderson- Gold Member

- Posts : 243

Join date : 2016-07-21

Location : Northern Wisconsin

Re: Ordered a 1/2A Skyray kit

Re: Ordered a 1/2A Skyray kit

Looks good. Should work well for you. I still have to replace my tubing over my needle valve as you did.

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: Ordered a 1/2A Skyray kit

Re: Ordered a 1/2A Skyray kit

Hey "TL"...

Good to know that you're getting some flights in! I like your style; with the "stooge" and take-off runway-panels! I'm all about that!

Good to know that you're getting some flights in! I like your style; with the "stooge" and take-off runway-panels! I'm all about that!

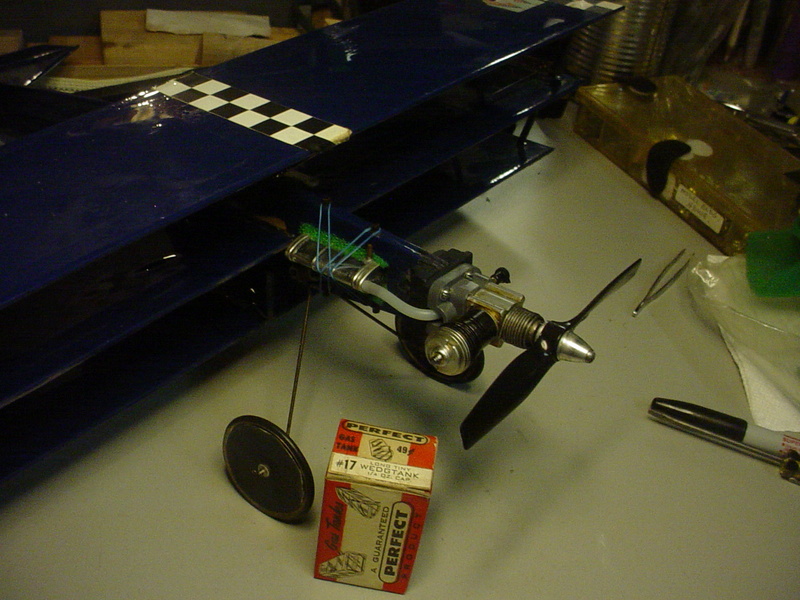

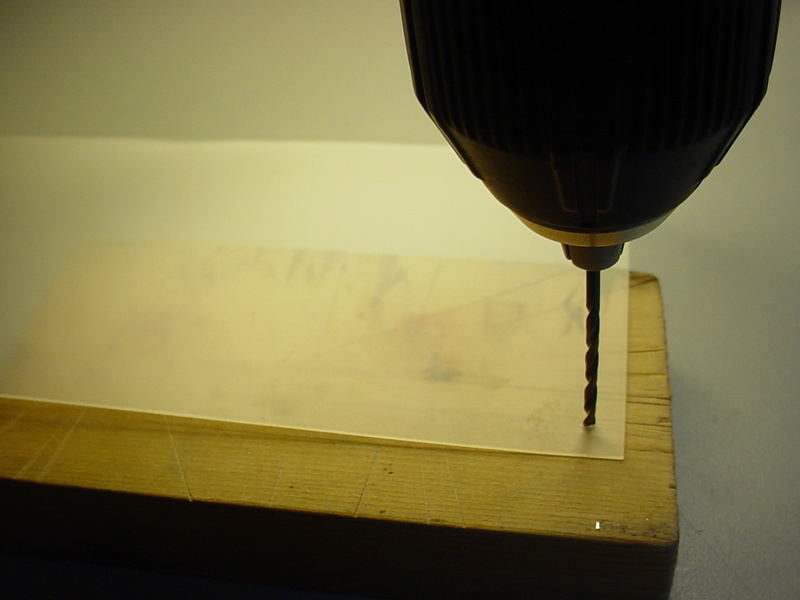

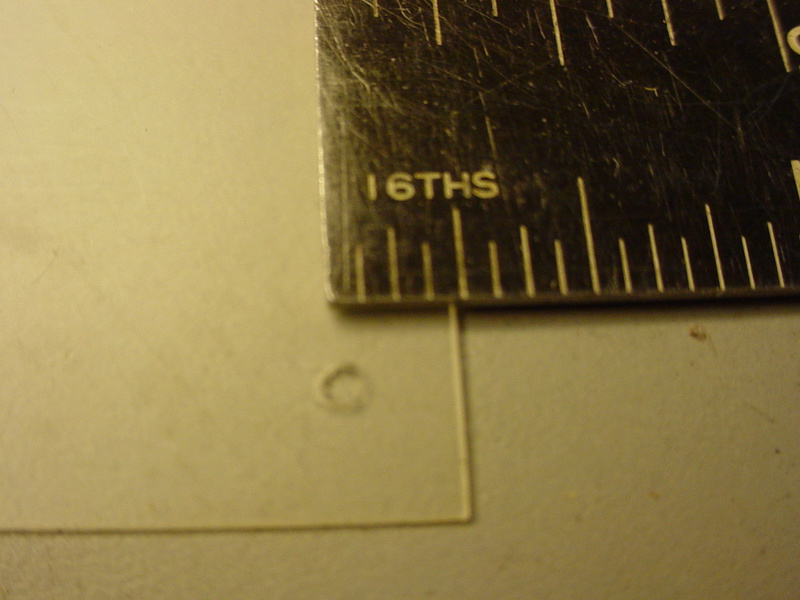

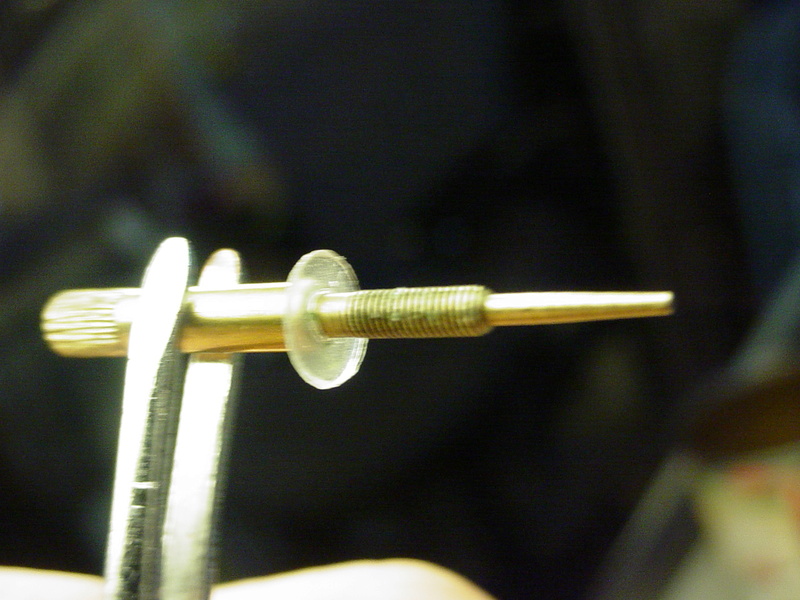

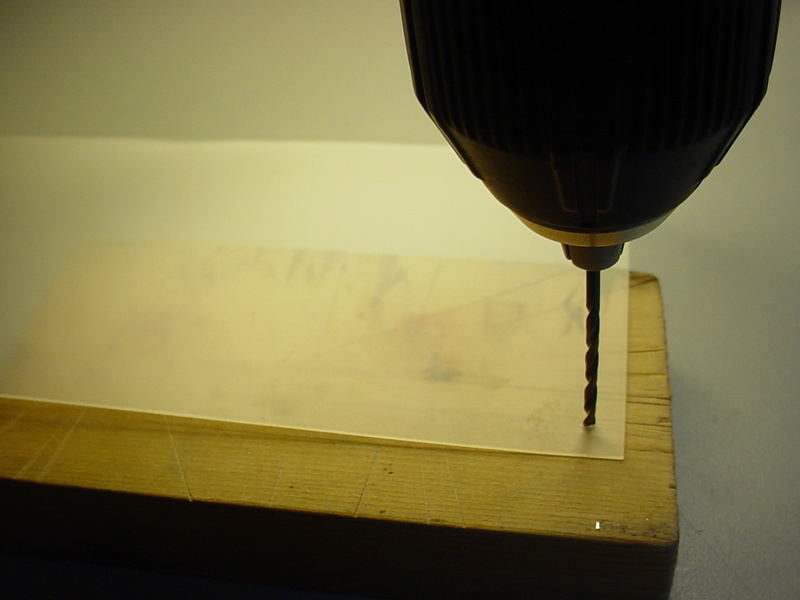

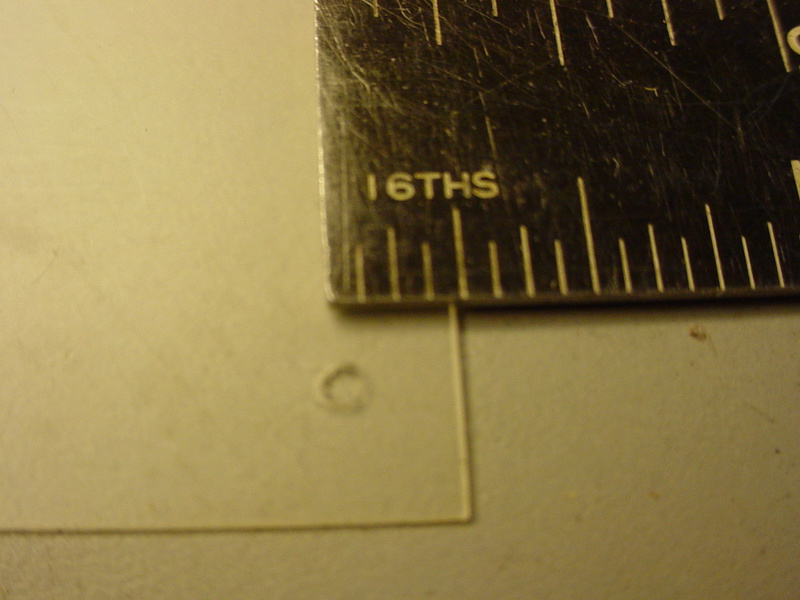

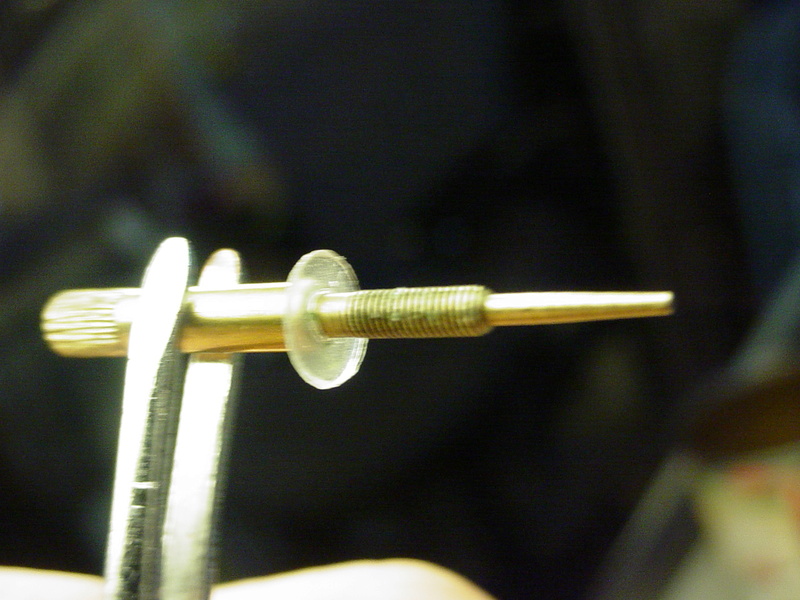

You can make a flat-washer to retain the silicone tubing on your needle-valve.. which will "stop" against the shoulder where the threads end. The diameter below that shoulder is .078". It's better to use a flat-washer here, rather than rely on the needles' plastic-knob to retain the tubing. Those knobs don't "stay-put" for too long. You will need a COMMON fractional-size 5/64" dia. twist-drill/bit (available at any U.S. hardware store) which measures .0781".. and "also" a standard hole-punch (1/4" diameter/plier-type for paper). Try "punching" some plastic-sheet (such as "packaging-material" that would ordinarily be thrown away..) and use the "thickest" material that you can punch.. without too much effort. This will provide the strongest-stock for your flat-washer. It doesn't need to be steel. The washer's 1/4" diameter will "clear" the molded-area of the backplate.. where a larger-diameter (steel..) flat-washer might get stuck.

If the hole-punch has a provision to capture the "punched-pieces".. REMOVE IT; so that you can see-thru the "eye" of the punch to line-up/center the drilled-hole in the eye of the punch. Proceed to punch-out your flat-washer. NOTE: the punched-piece "may" pop-out of the punch and get lost.. so it's a good idea to drill a couple of holes, to make more than one. If none of them get lost.. you'll have spares for your needle-valve parts-bin.

Here's some photos for a reference..

Drill a hole near the edge of your plastic material.. to be punched-out.

sight-thru the eye of the punch.. to line-up/center the hole for punching..

The punched-part.. (it's small.. so be prepared to keep it safe from being lost..)

It fits the needle "snug".. ( you may need to "screw-it" over the needle-threads to get it all the way up to the shoulder where the threads end)

It's as easy as that.. to make your own flat-washers for small-diameter machine-screws. One "plus" is; making them from plastic makes them electrically non-conductive.. and also corrosion-resistant.

Good to know that you're getting some flights in! I like your style; with the "stooge" and take-off runway-panels! I'm all about that!

Good to know that you're getting some flights in! I like your style; with the "stooge" and take-off runway-panels! I'm all about that! You can make a flat-washer to retain the silicone tubing on your needle-valve.. which will "stop" against the shoulder where the threads end. The diameter below that shoulder is .078". It's better to use a flat-washer here, rather than rely on the needles' plastic-knob to retain the tubing. Those knobs don't "stay-put" for too long. You will need a COMMON fractional-size 5/64" dia. twist-drill/bit (available at any U.S. hardware store) which measures .0781".. and "also" a standard hole-punch (1/4" diameter/plier-type for paper). Try "punching" some plastic-sheet (such as "packaging-material" that would ordinarily be thrown away..) and use the "thickest" material that you can punch.. without too much effort. This will provide the strongest-stock for your flat-washer. It doesn't need to be steel. The washer's 1/4" diameter will "clear" the molded-area of the backplate.. where a larger-diameter (steel..) flat-washer might get stuck.

If the hole-punch has a provision to capture the "punched-pieces".. REMOVE IT; so that you can see-thru the "eye" of the punch to line-up/center the drilled-hole in the eye of the punch. Proceed to punch-out your flat-washer. NOTE: the punched-piece "may" pop-out of the punch and get lost.. so it's a good idea to drill a couple of holes, to make more than one. If none of them get lost.. you'll have spares for your needle-valve parts-bin.

Here's some photos for a reference..

Drill a hole near the edge of your plastic material.. to be punched-out.

sight-thru the eye of the punch.. to line-up/center the hole for punching..

The punched-part.. (it's small.. so be prepared to keep it safe from being lost..)

It fits the needle "snug".. ( you may need to "screw-it" over the needle-threads to get it all the way up to the shoulder where the threads end)

It's as easy as that.. to make your own flat-washers for small-diameter machine-screws. One "plus" is; making them from plastic makes them electrically non-conductive.. and also corrosion-resistant.

Re: Ordered a 1/2A Skyray kit

Re: Ordered a 1/2A Skyray kit

roddie wrote:Hey "TL"...

Good to know that you're getting some flights in! I like your style; with the "stooge" and take-off runway-panels! I'm all about that!

Thanks Roddie. The stooge works pretty well. The runway panels are pretty much unnecessary for the skyray. It's off the ground by the second tape joint.

The PT-19 uses the whole thing, and needs more. I'm tempted to strap a couple of model rocket engines to it for a little JATO action.

You can make a flat-washer to retain the silicone tubing on your needle-valve.. which will "stop" against the shoulder where the threads end. The diameter below that shoulder is .078". It's better to use a flat-washer here, rather than rely on the needles' plastic-knob to retain the tubing. Those knobs don't "stay-put" for too long. You will need a COMMON fractional-size 5/64" dia. twist-drill/bit (available at any U.S. hardware store) which measures .0781".. and "also" a standard hole-punch (1/4" diameter/plier-type for paper). Try "punching" some plastic-sheet (such as "packaging-material" that would ordinarily be thrown away..) and use the "thickest" material that you can punch.. without too much effort. This will provide the strongest-stock for your flat-washer. It doesn't need to be steel. The washer's 1/4" diameter will "clear" the molded-area of the backplate.. where a larger-diameter (steel..) flat-washer might get stuck.

If the hole-punch has a provision to capture the "punched-pieces".. REMOVE IT; so that you can see-thru the "eye" of the punch to line-up/center the drilled-hole in the eye of the punch. Proceed to punch-out your flat-washer. NOTE: the punched-piece "may" pop-out of the punch and get lost.. so it's a good idea to drill a couple of holes, to make more than one. If none of them get lost.. you'll have spares for your needle-valve parts-bin.

Here's some photos for a reference..

Drill a hole near the edge of your plastic material.. to be punched-out.

sight-thru the eye of the punch.. to line-up/center the hole for punching..

The punched-part.. (it's small.. so be prepared to keep it safe from being lost..)

It fits the needle "snug".. ( you may need to "screw-it" over the needle-threads to get it all the way up to the shoulder where the threads end)

It's as easy as that.. to make your own flat-washers for small-diameter machine-screws. One "plus" is; making them from plastic makes them electrically non-conductive.. and also corrosion-resistant.

Good info on making the washers. If the tubing solves the problem. I'll give that a try. The season is so short up here, and good flying days so few and far between, that bug fixing, and troubleshooting seem to use up all the flying time. Hopefully, I'll get to the point soon, where I can just set up and fly without a lot of messing around.

TLAnderson- Gold Member

- Posts : 243

Join date : 2016-07-21

Location : Northern Wisconsin

Re: Ordered a 1/2A Skyray kit

Re: Ordered a 1/2A Skyray kit

Hey Roddie, you ought to write a book on 101 things you can make with a hole punch.......LOLroddie wrote:Hey "TL"...

Good to know that you're getting some flights in! I like your style; with the "stooge" and take-off runway-panels! I'm all about that!

You can make a flat-washer to retain the silicone tubing on your needle-valve.. which will "stop" against the shoulder where the threads end. The diameter below that shoulder is .078". It's better to use a flat-washer here, rather than rely on the needles' plastic-knob to retain the tubing. Those knobs don't "stay-put" for too long. You will need a COMMON fractional-size 5/64" dia. twist-drill/bit (available at any U.S. hardware store) which measures .0781".. and "also" a standard hole-punch (1/4" diameter/plier-type for paper). Try "punching" some plastic-sheet (such as "packaging-material" that would ordinarily be thrown away..) and use the "thickest" material that you can punch.. without too much effort. This will provide the strongest-stock for your flat-washer. It doesn't need to be steel. The washer's 1/4" diameter will "clear" the molded-area of the backplate.. where a larger-diameter (steel..) flat-washer might get stuck.

If the hole-punch has a provision to capture the "punched-pieces".. REMOVE IT; so that you can see-thru the "eye" of the punch to line-up/center the drilled-hole in the eye of the punch. Proceed to punch-out your flat-washer. NOTE: the punched-piece "may" pop-out of the punch and get lost.. so it's a good idea to drill a couple of holes, to make more than one. If none of them get lost.. you'll have spares for your needle-valve parts-bin.

Here's some photos for a reference.. Drill a hole near the edge of your plastic material.. to be punched-out.

sight-thru the eye of the punch.. to line-up/center the hole for punching..

The punched-part.. (it's small.. so be prepared to keep it safe from being lost..)

It fits the needle "snug".. ( you may need to "screw-it" over the needle-threads to get it all the way up to the shoulder where the threads end)

It's as easy as that.. to make your own flat-washers for small-diameter machine-screws. One "plus" is; making them from plastic makes them electrically non-conductive.. and also corrosion-resistant.

akjgardner- Diamond Member

Posts : 1602

Join date : 2014-12-28

Age : 65

Location : Greensberg Indiana

Re: Ordered a 1/2A Skyray kit

Re: Ordered a 1/2A Skyray kit

Well, roddie to the rescue again! Darn roddie, you are just full of good ideas. I do agree that you should write a book.  The only thing is now I wish I had screen shot all of your great ideas from the start.

The only thing is now I wish I had screen shot all of your great ideas from the start.

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

TLAnderson- Gold Member

- Posts : 243

Join date : 2016-07-21

Location : Northern Wisconsin

Re: Ordered a 1/2A Skyray kit

Re: Ordered a 1/2A Skyray kit

Good for you! Nice pics. Thanks for sharing.

Did you draft the photographer, or did (s)he volunteer?

Did you draft the photographer, or did (s)he volunteer?

944_Jim- Diamond Member

Posts : 2022

Join date : 2017-02-08

Age : 59

Location : NE MS

Re: Ordered a 1/2A Skyray kit

Re: Ordered a 1/2A Skyray kit

944_Jim wrote:Good for you! Nice pics. Thanks for sharing.

Did you draft the photographer, or did (s)he volunteer?

Thanks

TLAnderson- Gold Member

- Posts : 243

Join date : 2016-07-21

Location : Northern Wisconsin

Page 3 of 6 •  1, 2, 3, 4, 5, 6

1, 2, 3, 4, 5, 6

Similar topics

Similar topics» Great video on building and flying the 1/2A Skyray and Skyray 35

» RARE COX THIMBLE DROME PROTOTYPE "PT-19 COROPLAST BUILD" GAS MODEL AIRPLANE

» I ordered a Baby Flight Streak for a TeeDee!

» RC Japan. Anyone ordered?

» Cox fuel tank

» RARE COX THIMBLE DROME PROTOTYPE "PT-19 COROPLAST BUILD" GAS MODEL AIRPLANE

» I ordered a Baby Flight Streak for a TeeDee!

» RC Japan. Anyone ordered?

» Cox fuel tank

Page 3 of 6

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules