Log in

Search

Latest topics

» My latest doodle...by batjac Today at 10:05 pm

» Retail price mark-up.. how much is enough?

by gkamysz Today at 9:29 pm

» Happy 77th birthday Andrew!

by roddie Today at 9:22 pm

» Roger Harris revisited

by rsv1cox Today at 3:38 pm

» My N-1R build log

by GallopingGhostler Today at 3:04 pm

» Tee Dee .020 combat model

by 1/2A Nut Today at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

Cox Engine of The Month

hair-pin needle-clip-DIY

Page 1 of 1

hair-pin needle-clip-DIY

hair-pin needle-clip-DIY

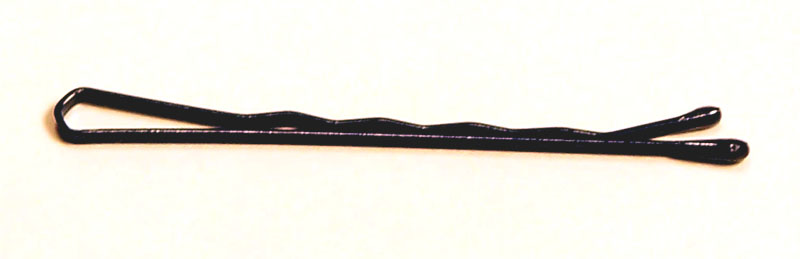

Here's an idea that I thought-up in the last few days. It uses a common hair-pin (Bobby-pin) to make a clip for a needle-valve stem/shaft. It's applicable in this particular example to Cox 1/2A reed-valve engines. Its main purpose is to hold the needle-setting from drifting. Sleeves of silicone fuel-line are used for retainers. The loop on the hair-pin serves as the mount.

This is all it is... I'll show a mount example below.

There are two types of "Bobby-Pins".. We'll call this type the "open-type". The "closed-type" were what I originally perceived for this.. but the clip-arms are too-close together.

A "Closed-type" example..

The above "closed-type" didn't work-out. The hair-pin must be cut shorter if running the cylinder-orientation in the same plane as the needle. I used "vise-grip" locking-pliers having a wire-cutter to shorten my example.

Note the gallon-size freezer-bag. It's plenty-big for inserting cutting-pliers.. and containing small fragments/parts that might otherwise catapult into oblivion when sheared. It's also a second-safety to protect your eyes.

Once shortened.. here's what it looks like on a Cox .049 product-engine with horseshoe-backplate.

Here's the hair-pin mounted to an engine-stand with that same engine.

That could just as well be the nose of a model-airplane. The hair-pin only needs a single anchor-point at its' loop. I used a small screw/washer on my bench-mount.. but the loop affords itself to other methods of attachment. A blob of epoxy.. a small capped dowel-pin... or on new-construction; a point/location that will suit the engine-installation.

a small capped dowel-pin... or on new-construction; a point/location that will suit the engine-installation.

I've had issues with needle-float.. running both; stock and modified needle-springs on horseshoe back-plates. Coiled compression-springs can recoil "radially".. and augment a needle-setting.. especially if the spring "grabs" on something.. It's then "pre-loaded" to recoil radially. Engine-vibration would no-doubt hasten that

Friction-collars for needles are nothing new.. so why not try to adapt them to any engine?

This is all it is... I'll show a mount example below.

There are two types of "Bobby-Pins".. We'll call this type the "open-type". The "closed-type" were what I originally perceived for this.. but the clip-arms are too-close together.

A "Closed-type" example..

The above "closed-type" didn't work-out. The hair-pin must be cut shorter if running the cylinder-orientation in the same plane as the needle. I used "vise-grip" locking-pliers having a wire-cutter to shorten my example.

Note the gallon-size freezer-bag. It's plenty-big for inserting cutting-pliers.. and containing small fragments/parts that might otherwise catapult into oblivion when sheared. It's also a second-safety to protect your eyes.

Once shortened.. here's what it looks like on a Cox .049 product-engine with horseshoe-backplate.

Here's the hair-pin mounted to an engine-stand with that same engine.

That could just as well be the nose of a model-airplane. The hair-pin only needs a single anchor-point at its' loop. I used a small screw/washer on my bench-mount.. but the loop affords itself to other methods of attachment. A blob of epoxy..

I've had issues with needle-float.. running both; stock and modified needle-springs on horseshoe back-plates. Coiled compression-springs can recoil "radially".. and augment a needle-setting.. especially if the spring "grabs" on something.. It's then "pre-loaded" to recoil radially. Engine-vibration would no-doubt hasten that

Friction-collars for needles are nothing new.. so why not try to adapt them to any engine?

Re: hair-pin needle-clip-DIY

Re: hair-pin needle-clip-DIY

Great idea, but is it just me, or does anyone else have any trouble with seeing pictures?

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: hair-pin needle-clip-DIY

Re: hair-pin needle-clip-DIY

NEW222 wrote:Great idea, but is it just me, or does anyone else have any trouble with seeing pictures?

I've seen images rotated the wrong way................... hurts my brain. I pray for the "mods" to fix them!

Re: hair-pin needle-clip-DIY

Re: hair-pin needle-clip-DIY

Its late here now, but I now see the pictures and it looks good. With the better half a hairdresser I may have to try this . Thanks for the great idea.

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

update on clip application.

update on clip application.

NEW222 wrote:Its late here now, but I now see the pictures and it looks good. With the better half a hairdresser I may have to try this . Thanks for the great idea.

Thanks Chancey! I made some discovery that's worth mentioning. The previous open-style clip-example fits the product-engine's needle shaft well because the shaft is 3.18mm diameter. The gap between the clip-arms is approximately 4mm. The silicone tube-sleeves pinch the arms together with good clamping force.

I had abandoned the closed-style clip application.. but now find it works very well to clamp the smaller shaft-diameter of a Cox tanked-engine's needle. See below.. a Cox Babe Bee .049.

There's already sufficient clamping-force without putting a sleeve on the open-end. There's also about 1/4"/7mm more distance between the needle and the engine-cylinder than the product engines' horseshoe back-plate. This distance obviously becomes a non-issue if orienting the cylinder in a different position (IE; 90/180 degrees) from the needle.

Another interesting feature between the closed and open-style bobby/hair-pins, is that the closed-style has 4 detents.. and they're only on one arm of the pin. The other arm is straight. The open-style only has 2 detents.. but has them on both arms.. equidistant.

I figured that this was worth mentioning. If you search Google-images for "hairpins"... you'll see a myriad of shapes/styles.. but these two referenced in this thread, are generally the more common types. I was lucky.. in that my stepdaughter had some of both types.

The closed-type "will work" on smaller-diameter needle-shafts.. and would likely work well on a Cox Pee Wee .020 engine. It takes a good amount of force to spread the arms apart on the closed-style hair-pin. I used a small flat-blade screwdriver to spread the arms.. while installing the "clip" on the .049 tanked-engine's needle.

Take into account.. the hair-pins are spring-steel. Use caution when cutting/shortening them. As I mentioned.. I sheared them with the cutters in the jaws of my Vise-grip locking pliers while inserted into a plastic bag. A better way would be to clamp the hair-pin in a bench-vise.. and cut them abrasively with a dremel/cut-off wheel while wearing safety-glasses.

There is a coating on these hair-pins. It's some type of plastic or resin. This doesn't seem to interfere with the function for these applications.. but if able to be removed.. the hair-pins should accept solder. This would only be required on the loop-end.. where a bracket might be soldered. This could be valuable for fashioning a custom clip stand-off for other engines. Something of an L-bracket with hole to mount under a screw-head on a Cox Medallion, Tee Dee.. or any other beam-mount/front-rotary engine that could use some needle-stabilization.

Last edited by roddie on Mon Jun 05, 2017 3:48 pm; edited 3 times in total (Reason for editing : application)

Re: hair-pin needle-clip-DIY

Re: hair-pin needle-clip-DIY

Good info man , looks like it would work just fine if application needed did'nt know there were so many difft. kinds of Bobbys  But you would sure bee careful cutting them !! Most the time the application of a new seal on horse shoe back plates work IF the threads are not worn too bad or the fuel line for a seal at the needle will keep the needle stable if applied right ..... This is good but if the needle is turning it is loose,, the spring is sprung or the wrong one ?! On these springs they should NOT let the needle move the way they're made being rounded at both ends with the edges turned in ..

But you would sure bee careful cutting them !! Most the time the application of a new seal on horse shoe back plates work IF the threads are not worn too bad or the fuel line for a seal at the needle will keep the needle stable if applied right ..... This is good but if the needle is turning it is loose,, the spring is sprung or the wrong one ?! On these springs they should NOT let the needle move the way they're made being rounded at both ends with the edges turned in ..

Of course i looked through their inventory and some DO look like they would do some digging into the back plate and make a groove == You could file down the edge of the spring end so it would rotate if needed ??

Of course i looked through their inventory and some DO look like they would do some digging into the back plate and make a groove == You could file down the edge of the spring end so it would rotate if needed ??

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: hair-pin needle-clip-DIY

Re: hair-pin needle-clip-DIY

getback wrote:Good info man , looks like it would work just fine if application needed did'nt know there were so many difft. kinds of BobbysBut you would sure bee careful cutting them !! Most the time the application of a new seal on horse shoe back plates work IF the threads are not worn too bad or the fuel line for a seal at the needle will keep the needle stable if applied right ..... This is good but if the needle is turning it is loose,, the spring is sprung or the wrong one ?! On these springs they should NOT let the needle move the way they're made being rounded at both ends with the edges turned in ..

Of course i looked through their inventory and some DO look like they would do some digging into the back plate and make a groove == You could file down the edge of the spring end so it would rotate if needed ??

I'm glad you replied brother. Worn parts should be replaced if possible. This clip design can function as a secondary stabilization for the needle-setting.. worn or new. The weight of the components is negligible. You have to source a hair-pin though...

Re: hair-pin needle-clip-DIY

Re: hair-pin needle-clip-DIY

I'm no stranger to strange harmonics. Today resulted in a problem which ended my flying for that plane for the day. I have a very very good running Sure Start engine, all stock but it stands alone from the several others I own. The main problem is with the engine running, the needle is all over the map due to vibration. I wrap a rubber band around it and then around the fuse of the plane. Today I was prepping for the rubber band wrap around and got everything set in place. The engine was giving me quite a fit and opening the needle wasn't doing anything. I figured I would backflush the system so I removed the needle valve. Well, the needle came out and there was no point on it. Well, that pretty much explains my problem. Vibrations caused the needle to snap off directly on the threads. This actually didn't take very long to do so. While this might not sound like a lot, I have about 30 flights on this plane with this engine. So , in that time this is what happened. Roddie's hair pin clip would remedy this from happening.

Ken Cook- Top Poster

- Posts : 5637

Join date : 2012-03-27

Location : pennsylvania

Re: hair-pin needle-clip-DIY

Re: hair-pin needle-clip-DIY

I'm sure that you'll replace the NVA in short-order. It'll be time well-spent for an otherwise great-running engine. I actually don't use the long-style needles anymore, without some type of support/clip.

Re: hair-pin needle-clip-DIY

Re: hair-pin needle-clip-DIY

I just looked and no stk. i thought i, well i did have several new one but must have sold them .

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

Similar topics

Similar topics» It is not a hair dryer !!

» CEF speed contest Design Discussions (2014)

» Wild Hair JOE (Ken Willard) Pee wee powered

» Balsa Wood got smoky/dusty/maybe dog hair too ;How to clean ?

» CEF speed contest Design Discussions (2014)

» Wild Hair JOE (Ken Willard) Pee wee powered

» Balsa Wood got smoky/dusty/maybe dog hair too ;How to clean ?

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules